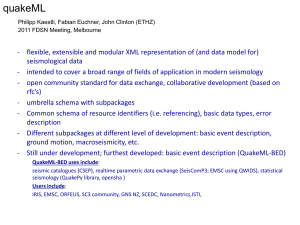

dimensioning and simulation of anisotropic structures

advertisement

DIMENSIONING AND SIMULATION OF ANISOTROPIC STRUCTURES www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 1 INTRODUCTION www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 2 DIMENSIONING OF ANISOTROPIC STRUCTURES • What is a anisotropic material? • Reinforced materials as carbon fiber reinforced polymer (CFRP) or glass reinforced polymer show different physical properties (E mod, Poisson and thermal coefficients…) depending the direction x, y or z. • What does this fact represent for the dimensioning of a beam? • Classical methods for dimensioning structures are not valid because material properties depend on each lay-up, which differ in each case. • For this reason, laminate theory must be used to dimension a composite component. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 3 DIMENSIONING OF STRUCTURES www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 4 DIMENSIONING OF ISOTROPIC PROFILES 1. Find critical section: Section with higher bending moment. 2. Knowing the admissible maximum load, defined by the material properties and security coefficient, 𝑊𝑚𝑖𝑛 can be defined by the relation: 𝜎𝑎𝑑𝑚 = 𝑀𝑧 𝑊𝑚𝑖𝑛 → 𝑊𝑚𝑖𝑛 = 𝑀𝑧 𝜎𝑎𝑑𝑚 where 𝜎𝑎𝑑𝑚 = 𝜎𝑚𝑎𝑥 · 𝐶𝑠 (𝐶𝑠 is security coefficient) 3. Define profile and find in standardized profile’s tables the dimensions of the profile which accomplish that: 𝑊𝑧 𝑡𝑎𝑏𝑙𝑒 > 𝑊𝑚𝑖𝑛 www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 5 DIMENSIONING OF ANISOTROPIC PROFILES Define a lay-up Simplify the beam as a sum of plates Calculate material data of each plate with CAP Apply formulas for strain calculation for each plate 𝑦𝑛𝑎 = (𝐸𝐼)𝑒𝑓𝑓 = 𝜅𝑚𝑎𝑥 = Evaluate solution 𝑦𝑏 𝐸 𝑑𝐴 𝐸 𝑑𝐴 𝜀𝑚𝑎𝑥 ≤ 𝜀𝑎𝑑𝑚 ?? 𝑦 2 𝐸 𝑦 𝑑𝐴 𝐹𝑚𝑎𝑥 (𝜀𝑎𝑑𝑚 ) ≈ 7500 N ?? 𝑀𝑚𝑎𝑥 𝐸𝐼𝑒𝑓𝑓 𝜀𝑚𝑎𝑥 = 𝜅𝑚𝑎𝑥 · 𝑦𝑛𝑎 No Yes Valid solution www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 6 HOW TO CALCULATE THE MATERIAL PROPS WITH CAP 1. Define CAPMAT: New materials at the end of the list. Glass fiber Natural fiber Carbon fiber 2. Define Lay-up of your laminate. IT MUST BE SIMMETRIC, otherwise it won’t work. 3. Define caplam: In each case number of plies, thickness and material number 4. Define in CAPCAP what you want to obtain: Laminate elastic constants, Substitute plate properties and stress distribution. 5. Run CAP executable and press enter 4 times. In CAPOUT you’ll obtain 𝐸11 , 𝐸22 . www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 7 HOW TO COMPUTE THE HAND CALCULATIONS 1. Define a lay-up: Orientation and number of layers. 2. Enter data in CAP and execute solver for every single plate defined in 1. Now you know the material properties of the layup that you defined. Be careful with the reference system!!!! 3 point bending: 4. Calculate the section properties (geometry and material). 4.1. Calculate: geometric parameters depending your profile: 𝑦= 𝑦 𝑑𝐴 𝐼= 𝑑𝐴 𝐸 𝑦 2 𝑑𝐴 𝐸 𝑑𝐴 4.2. Calculate the «EI» of the beam 5. Calculate 𝜅𝑚𝑎𝑥 = 𝑀𝑚𝑎𝑥 𝐸𝐼𝑒𝑓𝑓 Where 𝑀𝑚𝑎𝑥 = (𝐸𝐼)𝑒𝑓𝑓 = 𝑦𝑛𝑎 = 𝑦𝑏 𝐸 𝑑𝐴 𝐸 𝑑𝐴 𝑦 2 𝐸 𝑦 𝑑𝐴 𝐹𝐿 4 6. Calculate 𝜀max 𝑙𝑜𝑎𝑑 = 𝜅𝑚𝑎𝑥 · 𝑦𝑛𝑎 www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 8 7. Calculate the 𝜀max 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 , depending on the material properties in each case. If you only use one type of material then the critical material will be that one, otherwise calculate this parameter for both and choose the more critical one, the one with a higher value. Textile, fiber direction E-Mod “E” [MPa] Flexural strength “𝝈𝒇𝒍𝒆𝒙, ” [MPa] Carbon fiber, fabric, x 70000 540 Carbon fiber, fabric, y 70000 530 Carbon fiber, UD, x 135000 1200 Carbon fiber, UD, y 10000 80 Glass fiber, fabric, x 25000 394 Glass fiber, fabric, y 25000 392 Glass fiber, UD, x 40000 712 Glass fiber, UD, y 8000 31 Natural fiber, fabric, x 18000 383 Natural fiber, fabric, y 18000 22 Natural fiber, UD, x 32000 205 Natural fiber, UD, y 3200 205 www.structures.ethz.ch 𝜀𝑚𝑎𝑡,𝑈𝐷 = 𝜀𝑚𝑎𝑡,𝑓𝑎𝑏𝑟𝑖𝑐 = 𝝈𝑓𝑙𝑒𝑥,𝑈𝐷 𝐸𝑈𝐷 𝝈𝑓𝑙𝑒𝑥,𝑓𝑎𝑏𝑟𝑖𝑐 𝐸𝑓𝑎𝑏𝑟𝑖𝑐 𝜀max 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 =min(𝜀max 𝑈𝐷 , 𝜀max 𝑓𝑎𝑏𝑟𝑖𝑐 ) CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 9 8. Evaluate solution: The solution must accomplish: 𝜀max 𝑙𝑜𝑎𝑑 ≤ 𝜀max 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 There are many solutions that will accomplish these relations. You must try then to reduce the weight (less layers) by a smarter orientation. Once you get the solution, you must simulate it. The simulation considers the following steps: Definition of Geometry CAD Definition of Material parameters of 1 layer Definition of Definition of loads Lay-up & boundary conditions Solution FEM www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 10 FINITE ELEMENT MODELING WITH ANSYS www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 11 WHAT IS THE FINITE ELEMENT METHOD? • For many engineering problems analytical solutions are not suitable because of the complexity of the material properties, the boundary conditions and the structure itself. • The basis of the finite element method is the representation of a body or a structure by an assemblage of subdivisions called finite elements. • The Finite Element Method translates partial differential equation problems into a set of linear algebraic equations. FOR A SIMPLE STATIC ANALYSIS: K q F Nodal vector force Stiffness matrix Nodal displacement vector Reference: Introduction to the finite element method, C. S. Desai and J. F. Abel, Van Nostrand Reinhold Company, New York, 1972. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 12 MODELING WITH ANSYS • The modeling procedure is the following: GEOMETRY ELEMENT TYPE Shell or solid? MATERIAL PROPERTIES Isotropic or anisotropic material? MESH DEFINITION Including the load introduction BOUNDARY CONDITIONS ANALYSIS Static – Buckling analysis POST PROCESSING www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 13 MODELING WITH ANSYS: GEOMETRY AND ELEMENT TYPE • The geometry and the element type have to be considered together. • Shell element are typically used for structure where the thickness is negligible compared to its length and width • Nevertheless, a plate modeled with solid element would provide similar results. The disadvantage lies in the computation time. • Ansys provides a large choices of elements. • Shell181 Shell281 www.structures.ethz.ch Solid186 CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 14 MODELING WITH ANSYS: GEOMETRY AND ELEMENT TYPE • The Ansys command to define the element type is: • The geometry is defined with key points that are connect together to obtain either an area or a volume. 4:(0,0.5,0) • 3:(1,0.5,0) 1:(0,0,0) 2:(1,0,0) www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 15 MODELING WITH ANSYS: MATERIAL PROPERTIES • Isotropic material like aluminum • Fiber reinforced material • 1. Determination of the engineering constants (Using C.A.P.) • 2. Implementation in Ansys • www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 16 MODELING WITH ANSYS: MESH DEFINITION • Before meshing, it is necessary • 1. To select the geometry to mesh • 2. To give a material type • 3. To give an element type • 4. To select the mesh type • • Free or mapped meshing 5. To define the mesh refinement • • www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 17 MODELING WITH ANSYS: BOUNDARY CONDITIONS • Displacements constraints nsel,s,loc,x,50-1,50+1 nsel,r,loc,y,-1,1 cm,support1,node nsel,s,loc,x,550-1,550+1 nsel,r,loc,y,-1,1 cm,support2,node cmsel,s,support1,node cmsel,s,support1,node cmsel,a,support2,node cmsel,a,support2,node D,all, , , , , ,uy, , , , , D,all, , , , , ,uy, , , , , cmsel,s,support1,node nsel,r,loc,z,-1,1 D,all, , , , , ,ux,uy,uz, , , cmsel,s,support1,node nsel,r,loc,z,b-1,b+1 D,all, , , , , ,ux,uy, , , Select „support“ nodes and create components Select components and fix vertical displacement Select other nodes and fix displacements to get a statically determinate structure www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 18 MODELING WITH ANSYS: BOUNDARY CONDITIONS • Loads introduction: • The load is introduced into the structure by a “rigid” cylinder, that contributes to distribute the stresses. How can we model this effect? Simple line load Modeling the cylinder and the contact www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 19 MODELING WITH ANSYS: BOUNDARY CONDITIONS Simple line load Modeling the cylinder and the contact nsel,s,loc,x,l/2-1,l/2+1 nsel,r,loc,y,h-1,h+1 cm,mid,node Select nodes and create component „mid“ cp,next,all,mid Create rigid element between the nodes (Couple DOF) *get,nodes_num,node,0,count F,all,Fy,-10000/nodes_num Apply a force on each node ! Target element type: rigid cylinder ET,11,Targe170 ! Contact element type: deformable elements ET,12,Conta174 ! Setting contact options KEYOPT,12,4,2 KEYOPT,12,5,1 KEYOPT,12,9,1 KEYOPT,12,10,2 KEYOPT,12,11,1 KEYOPT,12,12,0 KEYOPT,12,2,0 KEYOPT,11,1,0 KEYOPT,11,2,1 KEYOPT,11,3,0 KEYOPT,11,5,0 ! Real Constant radius = 15 R,20,radius,radius,1.0,0.1,0, !Real Constants Real,20 RMORE,,,1.0E20,0.0,1.0, RMORE,0.0,0,1.0,,1.0,0.5 RMORE,0,1.0,1.0,0.0,,1.0 ! Contact material, friction coefficient MP,MU,13,0.01 Mat,13 www.structures.ethz.ch ! Mesh deformable contact elements asel,s,area,,4 nsla lsel,s,line,,3,7,4 nsll,a nsel,r,loc,x,l/2-15,l/2+15 Real,20 Type,12 Esurf ! Create rigid target element N,100000,l/2,h+radius+.1,-b/2 N,100001,l/2,h+radius+.1,1.5*b N,100002,l/2,h+radius+.1,b/2 Real,20 Type,11 TSHAP,CYLI E,100000,100001 TSHAP,PILO E,100002 ! Reverse normal vector ESEL,S,TYPE,,12 ESEL,R,REAL,,20 ESURF,,REVERSE !Loads nsel,s,node,,100002 f,all,fy,-10000 CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 20 MODELING WITH ANSYS: BOUNDARY CONDITIONS Simple line load Modeling the cylinder and the contact CPU Time CPU Time 8.3 s 45.4 s „Rigid element“ Displ -1.01 mm „Cylinder“ Displ -1.07 mm Max Von Mises stress 150.1 MPa www.structures.ethz.ch Max Von Mises stress 141.3 MPa CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 21 MODELING WITH ANSYS: Buckling analysis • • Static Analysis Buckling analysis • • • • www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 22 Example: FINITE ELEMENT ANALYSIS WITH SOLIDWORKS www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 23 SIMULATION Definition of geometry (CAD): • Solidworks • ProE • Catia • … Use the program that you want, but be carereful because if the CAD and FEM programs are different, sometimes the importation generates a lot of troubles. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 24 SIMULATION • FEM Simulation: • Definition of material properties: Today, all the simulation tools consider the design of composite materials. This will make much easier the simulation. You’ll define the material properties for 1 layer. Glass fiber Natural fiber www.structures.ethz.ch Carbon fiber CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 25 SIMULATION • Define the lay-up orientation of each layer. • Choose the right element type, (this depends on the FEM used), for ansys it is recommended to use shell elements. (e.g. ET,1,SHELL181). • Define loads: • Fixation of the beam • Load introduction!! • Contact between components www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 26 SIMULATION • Mesh • Solve • Analyze results: • Stress • Displacement • Buckling analysis IMPORTANT: DO NOT SHOW VON MISES IN A COMPOSITE MATERIAL, IS NOT CORRECT • Compare simulation with hand calculation results. Trick: In order to ensure that the simulation is correct, we recommend to simulate an aluminum beam and compare it to the hand calculation www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 27 SIMULATION: Example isotropic beam • • EXAMPLE: ALUMINUM BEAM (Isotropic): Hand calculation results: z= 0.97 mm. • Solid elements. • Thickness of 4 mm in the upper side • Thickness of 2 mm in the lower side • E mod = 69 GPa (isotropic) Hand calculation is much simplified (not buckling, simpler geometry…), but the results mus be at least similar. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 28 SIMULATION: Example isotropic beam • Safety factor: von Mises only in isotropic materials: • The load introduction is critical • If it is improved, the beam will take a much higher load. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 29 SIMULATION: Example CFRP beam • EXAMPLE: CFRP (Anisotropic) in solidworks: • The load is introduced as in the 3 point bending test • Lay-up is defined from SURFACES, not solids. • [+-45, +-45,0, +-45, +-45] • [0]6 www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 30 SIMULATION: Example isotropic beam At each surface, the lay-up is defined, entering the thickness and the orientation of each layer at each surface defined. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 31 Carbon fiber SIMULATION: Example isotropic beam The material properties are then applied www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 32 SIMULATION: Example isotropic beam •The load is applied with a steel load distributor •The beam is fixed at the sides www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 33 SIMULATION: Example isotropic beam Max displacement is 2.14 mm. Hand calculation results: z= 1.59 mm. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 34 SIMULATION: Example isotropic beam Max strain = 0.0165. efasermax = 0.0080 (Material limit) • This beam will delaminate before the maximum load is applied in the region where the load is applied. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 35 SIMULATION: Example isotropic beam Buckling analysis • Load factor 15.4 > 1 www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Mattia Serra & Alberto Sánchez 04.10.2013, page 36