synthesis of aspirin

advertisement

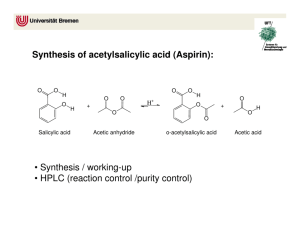

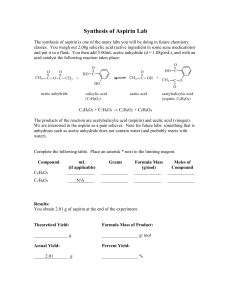

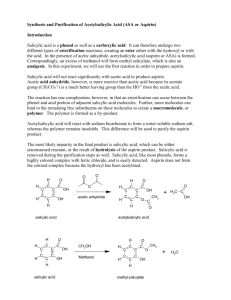

EXPERIMENT 29 SYNTHESIS OF ASPIRIN INTRODUCTION Aspirin is one of the most widely used medications in the world. It is employed as an analgesic (pain relief), an anti-pyretic (fever control) and an anti inflammatory. More recently, studies have indicated that daily intake of small doses of aspirin can lower the risk of heart attack and stroke in high-risk patients. The history of aspirin and its precursor dates back to ancient times. Documents attributed to Hippocrates, the father of modern medicine, from the 4th century B.C. refer to the alleviation of pain by chewing on the bark of a willow tree or ingesting a powder made from the bark and leaves of the willow. This remedy was passed on from generation to generation. Fast forward now to the 19th century, where the field of organic chemistry began to experience tremendous growth. By 1838, chemists had managed to isolate, purify and identify the component of willow bark that provided the analgesic benefit. The compound was named salicylic acid, which was based on the genus name of the willow. Efforts to market salicylic acid met with failure, due to an unfortunate side effect--prolonged ingestion of salicylic acid led to stomach pain, and in some cases, ulcers. Inspection of the structure of salicylic acid molecule (Figure 29-1) sheds some light on the cause of this problem. Salicylic acid contains two functional groups, a carboxylic acid (-COOH) and an alcohol (-OH). The carboxylic acid group, as the name implies, has a tendency to generate H3O+ in aqueous solution. In addition, since the alcohol group is bound to a benzene ring, it belongs to a special class of alcohols known as phenols. Phenols have many unique properties, one of which being that they are substantially more acidic than other types of alcohols. As a result, the two acidic functional groups serve to lower the pH of the stomach, leading to the gastric distress described above. Figure 29-1. Structures of aspirin and salicylic acid Chemists sought to modify the salicylic acid molecule, reasoning that modification of one of the functional groups could lower the acidity of the compound without affecting the medical benefits. This was achieved by taking advantage of some fundamental organic chemistry. When an alcohol is allowed to react with a carboxylic acid in the presence of an acid catalyst, the functional groups combine in a condensation reaction to form an ester and water: (29-1) By reacting the phenol group of salicylic acid with acetic acid, an ester group (which is not acidic) is formed and the resulting compound was named acetylsalicylic acid. (29-2) Although this reaction was first achieved in the 1850's, it wasn't until 1899 that scientists at the Bayer company in Germany identified acetylsalicylic acid as a commercially viable compound. They gave it the brand name aspirin (derived from the arcane genus name of meadowsweet, another natural source of salicylic acid). The drug was in high demand almost immediately, and Bayer was soon on its way to becoming a pharmaceutical giant. Synthesis In this experiment, aspirin will be produced by reacting salicylic acid with acetic anhydride, a derivative of acetic acid that has similar chemicals properties to acetic acid, but reacts more rapidly and efficiently. to form acetylsalicylic acid (aspirin). Note in Equation (29-3) that the byproduct of the reaction is now acetic acid rather than water . (29-3) Recrystallization A chemical reaction seldom occurs in such a manner that the desired product is obtained in an absolutely pure state. The synthetic reaction in this experiment will be no exception. The acetic anhydride will be added in excess, so unreacted acetic anhydride will be present at the end of the reaction. In addition, sulfuric acid (added as a catalyst) and acetic acid product will also contaminate the product. Failure to remove these acidic impurites would defeat the purpose of the reaction, which is to lower the acidity of the product compared to the salicylic acid starting material! Consequently, a purification procedure must be carried out to separate the aspirin from such impurities as unused starting materials and the acetic acid by-product. Recrystallization is an extremely useful technique for purifying crystalline solids. The impure product is dissolved in a minimum volume of hot solvent. The solvent is carefully selected so that the product is much less soluble in cold solvent than hot, so that the product will recrystallize when the solvent is cooled, leaving the soluble impurities behind in the solvent. The pure product is then isolated by vacuum filtration. Iron (III) Chloride Test for Phenols A convenient test can be carried out to identify the change in functional group from reactant to product. A comparison of the structural formulas of aspirin and salicylic acid shows that the salicylic acid has a phenolic group while aspirin has none. A specific test for a phenolic group will illustrate this change in functionality. If a drop of iron (Ill) chloride (FeCl3) solution is added to an aqueous solution containing traces of a phenolic group, a color change occurs. The color varies from reds to blues to greens depending on the particular phenol molecule present. Percentage Yield of Product The amount of product obtained in a chemical reaction (experimental mass) is almost always less than what was expected (theoretical mass). This difference occurs because of incomplete reaction of the reactants, side reactions (in which different products are formed), and/or loss of product from careless experimental technique. The smaller the difference is between the experimental and theoretical masses, the more successful is the synthesis. The success is measured in terms of percentage yield, which is calculated using the formula: experimental mass percent yield 100% theoretical mass EQUIPMENT NEEDED 50mL beaker 150mL beaker 600mL beaker (2) 125mL Erlenmeyer flasks 50 or 100 mL graduated cylinder 10mL graduated cylinder (2) medium test tubes disposable pipets microspatula watch glass Büchner funnel with sidearm flask Filter paper (7cm) hot plate glass stirring rod balance CHEMICALS NEEDED distilled water ice salicylic acid concentrated H2SO4, sulfuric acid acetic anhydride ethanol 0.2M FeCl2 solution, iron(II) chloride II. PROCEDURE A. Equipment Set-Up: Ice Bath 1. Partially fill a 600 mL beaker with ice. Add about 50 mL of distilled water to an Erlenmeyer flask and place it into the ice bath to cool. B. Aspirin Synthesis 1. Measure out ~3 g of salicylic acid on an analytical balance, recording its mass to the nearest 0.001 g. Transfer the salicylic acid into a 125-mL Erlenmeyer flask, and record the mass of the salicylic acid on your report sheet. 2. Add about 6 mL of acetic anhydride and ~1/4 mL of concentrated (18 M) sulfuric acid (using the mark on the barrel of the disposable plastic pipet) to the flask. Caution: acetic anhydride and sulfuric acid are corrosive materials. Swirl the flask until the salicylic acid has dissolved. Allow the mixture to sit at room temperature for 15 minutes with occasional swirling. During this time, assemble the vacuum filtration apparatus. C. Separation of Product from the Reaction Mixture 1. Cool the reaction flask by placing it in the ice bath. Stir constantly; the mixture should thicken to a semi-solid sludge. 2. Add slowly, with stirring, 35 mL of the cooled water. Continue stirring until the mixture is a watery sludge. (Place the remaining cooled water back into the ice bath. It will be used during the vacuum filtration.) Allow the mixture to continue cooling in the ice bath for 10 to 15 minutes. During this time, determine and record the mass of your watchglass. Also, warm ~50 mL of distilled water to 5070 ºC on a hot plate. 3. Vacuum filter the mixture. Use small portions of the cooled water to assist in rinsing the last of the crystals from the flask. 4. When filtration is complete, disconnect the vacuum tubing from the flask. Discard the solution in the filter flask. If all of the cooled water has been used, place another 20 mL of distilled water into the flask and return the flask to the ice bath. This water will be needed for the second vacuum filtration. D. Recrystallization of the Product 1. Transfer the impure aspirin from the Büchner funnel to a 150-mL beaker. Add 10 mL of 95% ethanol. 2. Add about 25 mL of warm (50-70 °C) distilled water and stir to dissolve the impure aspirin. The mixture can be heated gently until the solid completely dissolves, but do not allow the mixture to boil. If some product will not dissolve, add ethanol a few drops at a time until all the solid has dissolve. Do not add too much ethanol, or you will have trouble getting the aspirin to recrystallize. 3. Place the beaker in the ice bath to cool. Stir the mixture constantly for the first five minutes as crystals begin forming. Stir frequently after that, until the beaker has been in the ice bath for a total of about 15 minutes. 4. Set up the vacuum filtration apparatus with a new piece of filter paper and vacuum filter the purified aspirin. Use small amounts of the cooled water to help rinse the last of the aspirin crystals from the beaker. Keep the aspirator on and allow air to be drawn through the product to help dry it as you perform Part E. Spreading the product out over the filter paper in the funnel will aid in the drying process. E. Iron (III) Chloride Test for Phenols 1. Place a match head-sized quantity of the pure aspirin into a medium test tube. Into a second medium test tube place a match head-sized quantity of salicylic acid. 2. Add 5 mL of distilled water to the tubes containing the aspirin and the salicylic acid, and to an empty tube. This third tube will be used as a control for color comparison. Agitate the tubes to dissolve the solids as completely as possible. Add 2 to 3 drops of 0.2 M FeCl3 solution to each tube and shake. An orange to purple color is indicative of the presence of the phenol group of salicylic acid. Record your observations. F. Yield of Purified Aspirin 1 Once your aspirin appears to be dry, transfer it to the watchglass. Determine and record the mass of the watchglass and dried aspirin. After you have obtained the mass of the aspirin, it should be discarded in a wastebasket. Report Sheet: Synthesis of Aspirin Name Date Partner's Name Aspirin Synthesis Mass of salicylic acid Recrystallization of product Mass of watchglass Mass of watchglass and dried aspirin Mass of dried aspirin Results Mass of aspirin expected Calculation: Percent yield of aspirin Calculation: Instructor's Initials Iron (III) Chloride Test for Phenols Salicylic Acid Observation: Conclusion: Purified Aspirin Observation: Conclusion: Blank Observation: Conclusion: