Determining Water Saturation from Capillary Pressure in

Liberty Field, Alaska

Jim Lewis and Fred Jenson

Introduction

Capillary pressure is an important characteristic

of rock that helps reservoir engineers determine

where hydrocarbons and water are located in the

subsurface. This characteristic can be measured from

core samples analyzed in a laboratory setting and

compared to other measurements taken in the field.

Capillary pressure analysis can lead to optimized

drilling programs, allowing reservoir engineers to

find the extent of the hydrocarbon accumulations and

avoid drilling into water.

This study combines well information including

logs and capillary pressure from cores to determine

height above free water and create a water saturation

curve that can be compared to log-derived water

saturation. The study also demonstrates that the

capillary pressure model generated for one well can

be applied to other wells in the field as long as there

is no sealing fault to obstruct fluid flow.

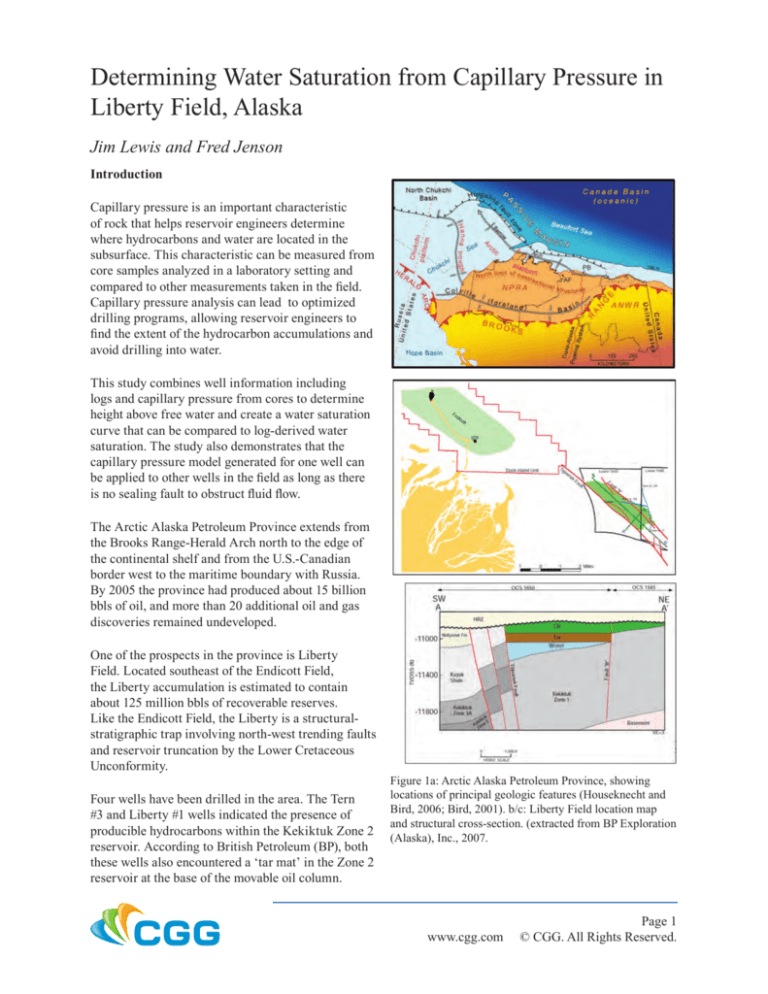

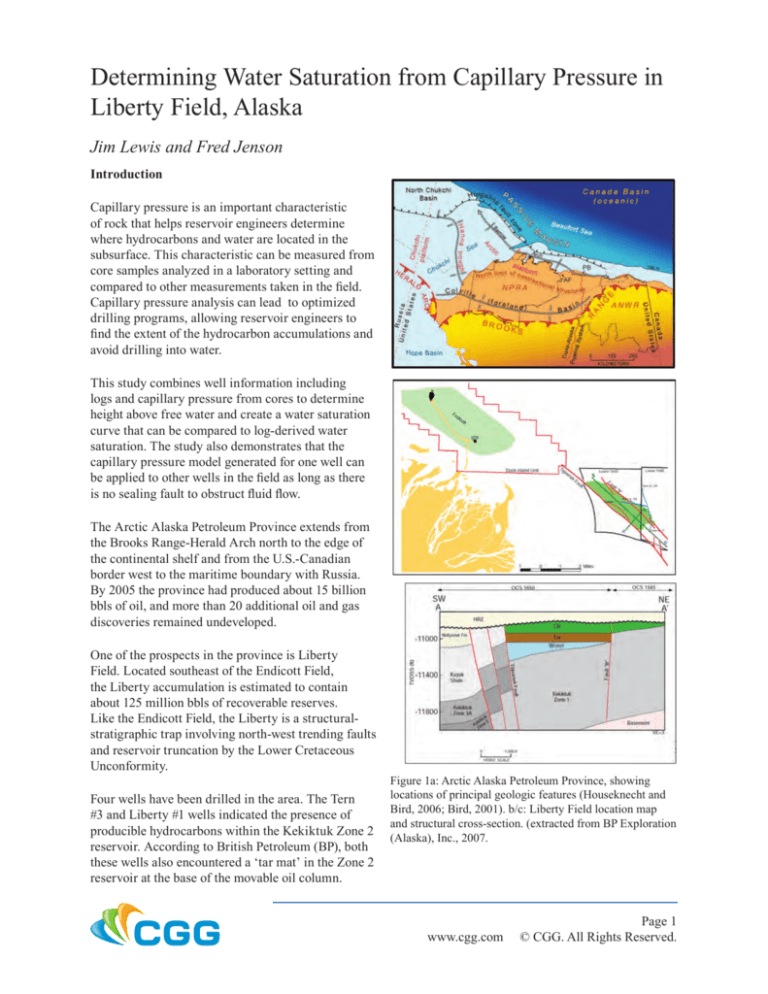

The Arctic Alaska Petroleum Province extends from

the Brooks Range-Herald Arch north to the edge of

the continental shelf and from the U.S.-Canadian

border west to the maritime boundary with Russia.

By 2005 the province had produced about 15 billion

bbls of oil, and more than 20 additional oil and gas

discoveries remained undeveloped.

One of the prospects in the province is Liberty

Field. Located southeast of the Endicott Field,

the Liberty accumulation is estimated to contain

about 125 million bbls of recoverable reserves.

Like the Endicott Field, the Liberty is a structuralstratigraphic trap involving north-west trending faults

and reservoir truncation by the Lower Cretaceous

Unconformity.

Four wells have been drilled in the area. The Tern

#3 and Liberty #1 wells indicated the presence of

producible hydrocarbons within the Kekiktuk Zone 2

reservoir. According to British Petroleum (BP), both

these wells also encountered a ‘tar mat’ in the Zone 2

reservoir at the base of the movable oil column.

Figure 1a: Arctic Alaska Petroleum Province, showing

locations of principal geologic features (Houseknecht and

Bird, 2006; Bird, 2001). b/c: Liberty Field location map

and structural cross-section. (extracted from BP Exploration

(Alaska), Inc., 2007.

www.cgg.com

Page 1

© CGG. All Rights Reserved.

Figure 2a: Slabbed Conventional Core, Interval 12976.6 to 12991.1 feet (red arrow & text added to show Plug #3).

Figure 2b: Core Slab with Cap Pressure Plug location for Plug #3, 12,989.30 feet.

Figure 2c: Core Slab with Cap Pressure Plug location for Plug #9, 13,216.55 feet.

Source a: Alaska Department of Natural Resources, Alaska Geological Materials Center Data Report No.336.

Source b/c: Alaska Department of Natural Resources, Alaska Geological Materials Center Data Report No.338.

In Liberty #1, the tar mat lies near the base of Zone 2

at 10,932 ft TVDSS; above it, the oil column extends

to the top of the reservoir at 10,707 feet. No gas cap

was encountered in this well.

In Tern #3, the tar mat extends from 10,922 to 11,045

ft TVDSS. Above it, the first eight feet in the Zone

2 reservoir (10,914 to 10,922 feet) appear to have

movable hydrocarbons. Below the tar mat, a water leg

occurs in the lower portion of the reservoir.

Laboratory data for Tern #3 was evaluated,

conditioned and converted to the reservoir fluid

system. Liberty #1 was used as the control well, to

demonstrate that the model from Tern #3 could be

extended to the field.

Background

Each rock and fluid type has unique features that

can be determined by laboratory measurements.

These physical features can be matched to field data

collected through well logs, cores, borehole images

and other well data. This matching process enables

the reservoir engineer to classify the rocks and

fluids in the field of study. Reservoir engineers are

particularly interested in identifying the gas/brine,

gas/oil and oil/brine interfaces.

The pore spaces inside of rocks are microscopic,

giving capillary forces a significant effect. Their

densities, surface tension and the curvature due to

the spaces between pores make different fluids have

different pressure and as relative saturations change,

pressure difference also changes. Typically, capillary

pressure is measured using mercury injection, porous

plates or centrifuge.

From capillary pressure, reservoir engineers can

discover:

•

Hydrocarbon/water contacts, even if they are

below the total well depth

•

Rock types in the zone(s) of interest

Figure 3a: SEM image, 70x, for Plug #3, 12,989.30 feet.

Figure 3b: SEM image, 700x, for Plug #3, 12,989.30 feet.

Figure 3c: Thin-Section image for Plug #3, 12,989.30 feet.

Source: Alaska Department of Natural Resources, Alaska Geological Materials Center Data Report No.338.

www.cgg.com

Page 2

© CGG. All Rights Reserved.

•

Heights of transition zones

•

Connectivity across the field

Measurements from the field are often

compared to laboratory analysis both as

a quality control step and to broaden the

analysis. For example, the water saturation

and height above free water can be calculated

from resistivity and other wireline logs

and then compared to the depth converted

laboratory core measurement of capillary

pressure. The combination of these methods

provides confirmation of the reliability of the

analysis.

Data Acquisition

Capillary pressure plug data from

conventional core was obtained from the

Alaska Department of Natural Resources for

the Tern #3 well. A total of 422 feet of core

was recovered, but only ten plug samples

comprised this capillary pressure data set.

Figure 4: MICP (mercury-injection capillary pressure)

measurements for Plug #3, 12,989.30 feet. Source: Alaska

Department of Natural Resources, Alaska Geological Materials

Center Data Report No.338.

A set of core slab photographs (indicating the

plug locations), thin sections images, and scanning

electron microscope (SEM) photographs indicated

that there was a grain size, therefore pore size,

difference between the three shallowest plugs and the

deeper plugs. All ten plugs were treated as a set.

The remainder of the standard porosity and

permeability measurements (191 samples) over the

complete core were obtained from the Bureau of

Ocean Energy Management (BOEM) through a

Freedom of Information Act (FOIA) request.

A comprehensive logging package (circa 1987) for

the Tern #3 consisted of conventional wireline log

data (gamma ray, spontaneous potential, caliper;

spherically focused, medium induction, and deep

induction resistivities; sonic travel time, bulk density,

and neutron and density sandstone porosities) were

also obtained from the Alaska Department of Natural

Resources. Other data gathered included geological

tops, TOC (total organic carbon), rock-eval pyrolysis,

whole oil gas chromatograms, directional surveys

and surface location maps.

Comparable data for the other three wells—the

OCS-Y-0195 1, Tern #1; the OCS-Y-0196 1, Tern

#2; and the OCS-Y-1650 1, Liberty #1—were also

obtained from the Alaska Department of Natural

Resources. Capillary pressure data was available only

for the OCS-Y-0197 1, Tern #3 well.

No seismic data was obtained or used in this analysis.

Data Loading

All well data—including logs and cores—were

loaded into PowerLog® for analysis. Quick analysis

showed that the Tern #3 well had an apparent 232

foot hydrocarbon bearing section, overlaying a welldefined waterleg. Three of the cap pressure plugs

were found to be located at the top of the interval,

with the remaining seven located in the waterleg. The

information released by British Petroleum (BP) stated

that a tar mat existed between near the top of the

interval and water zone. No mid-zone cap pressure

plug samples were available, likely because of the

presence of the tar mat.

The conventional core measurements of porosity,

permeability, and grain density from the 191

plugs, which were taken from the 422 feet of core,

www.cgg.com

Page 3

© CGG. All Rights Reserved.

Inc. (SWEPI), who drilled the Tern #3 well. Initial

impressions of the logs were that the Liberty #1 well

looked normal and did not penetrate water.

The high log-measured resistivities in the Tern #3

were suspect, as the logging program only included

the induction curves, which typically are unable to

resolve resistivities when they exceed 200 Ohm-m.

Considerable separations between values were

present for the three resistivity measurements over

the Kekiktuk Zone 2 reservoir. If an impermeable tar

mat were present, no mud filtrate invasion would be

possible and the resistivity logs should have had near

identical values for the shallow, medium and deep

resistivities.

Data Conditioning

Before modeling and analysis, the data was reviewed

for any needed corrections. Capillary pressure data

corrections were applied to correct laboratory data

for borehole conditions. Any extraneous or suspect

data—including individual points, an entire series

or complete collection—could have been excluded at

this time as well.

Figure 5: Tern #3 Log Plot. Source: Data from Alaska

Department of Natural Resources.

indicated that the core depths were approximately

13.25 feet deep to the log measurements. Within the

cored interval of 12,915.0 to 13,361.5 feet, the core

slab photographs indicated oil stained sandstones,

several coal sections, and a brecciated interval from

12,930 to 12,976 feet.

The log resistivities in the Tern #3 were unusually

high, sometimes exceeding 2000 ohm-m, and

therefore suspect. The logging program included

only induction-based resistivity curves which

are often unable to accurately measure formation

resistivities when their values exceed 200 Ohm-m.

Two successful wireline-conveyed Repeat Formation

Tester (RFT) fluid samples (unidentified types) were

reported to the state of Alaska, one of these was

taken over the interval indicated as permeable by

the microlog and the other was taken very near the

water. No mention of a tar mat was found in any

of the available state filings by Shell Western E&P,

Saturation data was converted from percentages

to decimal values and the rock quality index was

calculated. Although the PowerLog Capillary

Pressure module provides an opportunity to apply

stress and clay corrections, these corrections were not

required for this reservoir.

Moving to the Reservoir Fluid System

Option Value Description

σ Res

25

interfacial tension in reservoir (oil-water)

θ Res

30

contact angle in reservoir (oil-water)

σ Lab

485

interfacial tension in the lab (mercury-air)

θ Lab

140

contact angle in lab (mercury-air)

Table 1: MICP interfacial tension and contact angle

constants for laboratory measurements and reservoir

conditions. Source: OMNI Laboratory, Alaska Department

of Natural Resources, Alaska Geological Materials Center

Data Report No.338.

Following data correction, the fluid system used

in the laboratory was converted to the fluid system

found in the reservoir. Capillary pressure is a

www.cgg.com

Page 4

© CGG. All Rights Reserved.

function of the interfacial tension between two

immiscible fluids and the contact angle between the

wetting phase and the rock surface. Consequently,

to convert data from one fluid system to the other,

interfacial tensions (σ) and contact angles (θ) are

needed.

The Leverett J-function was used to normalize

capillary pressure data to take into account variations

in porosity and permeability. This method is useful

for averaging capillary pressure data derived from a

given rock type and reservoir and, with caution, can

sometimes be extended to different reservoirs with

the same lithology.

A quality control check of the oil/water height values

recorded in the lab showed that they were consistent

with the values calculated in PowerLog. Similarly the

plug J-Function values obtained from the lab agreed

with those calculated by PowerLog.

Modeling Capillary Pressure Data

Model input data were normalized for porosity

and permeability using the Rock Quality Index

function. A regression was then performed to fit

the normalized data using a single equation for all

curves.

Figure 6: Liberty #1 Log Plot. Source: Data from

Alaska Department of Natural Resources.

Capillary pressure models can be built using one of

three different approaches.

•

•

Separate Equation for Each Curve—The

model is the regression equation that provides

the best fit to the input plug data. Several types

of regressions can be run, including Thomeer

(G-function) and Skelt Harrison. A separate

regression equation is generated for each plug.

The method for how coefficients developed

for each plug are combined to yield the

coefficients in the final model is then specified.

Methods include taking the average, taking the

median, or doing a linear regression of plug

coefficients versus some specified attribute.

One Equation for All Curves—The model is

the regression equation that provides the best

fit to the input plug data. All the input plug

data are taken together to develop a single,

combined equation. A variety of methods for

normalizing the input data including Leverett

J-function, Cuddy, Rock Quality Index,

and Johnson are available. The algorithm

for normalizing the data (for variations in

porosity, permeability, or both) was used as an

input in the regression equation.

•

Spatial Averaging—The model is a collection

of array attributes and single-value attributes

from input plugs. For example, for a saturation

versus pressure model, the model might

consist of saturation and pressure arrays and

porosity and permeability values. Attributes

are specified and the input data, in essence,

becomes the model. No equation is generated.

When a spatial averaging model is applied,

the water saturation (Sw) for each sample

in the target well is computed based on its

proximity to the corresponding plug data

attribute values. A sequence of linear and

inverse distance weighting interpolations is

performed.

www.cgg.com

Page 5

© CGG. All Rights Reserved.

In addition to the model, all three approaches

output a new saturation attribute. This attribute

was compared to the original to evaluate the model.

Because the “one equation” approach was used, a

J-function attribute was also output and compared to

original data.

Crossplot QC

Quality control is a critical aspect of any subsurface

analysis. Following the regression, several crossplots

were generated to verify the results. These compared

the modeled water saturation to:

•

Pressure

•

Height

•

J-function pressures

•

Rock Quality Index height

These crossplots showed the related fit of the

regression to the input data as well as the match

between the corrected laboratory-based water

saturation and the modeled capillary pressure-based

water saturation. Small adjustments were made to

saturation, pressure and height cutoffs. Although

individual data points or entire plugs could have been

marked as invalid, none were marked in this case.

Figure 8: Tern #3 CPI (computer-processed interpretation)

with saturation comparison.

The regression was rerun several times until the data

was in agreement.

Applying the Model

Once the water saturation model was built, it was

applied to the well and compared to water saturation

calculated from resistivity. There was a good

agreement between the two models.

After verifying the veracity of the Tern #3 analysis,

the model was applied to the Liberty #1 well. In

general, capillary pressure models are applicable

to wells in the same field and with similar porosity

regimes and lithologies.

The water saturation-versus-pressure model was

converted to a water saturation-versus-height model

by replacing the pressure attribute with height above

free water level (in true vertical depth), reservoir

porosity and permeability. The output was a water

saturation curve which had no dependency on a

resistivity log measurement.

Figure 7: A Comparison of Capillary Pressure Based

Saturations vs Height above FWL (Swcorrected from data

conversion from laboratory to reservoir and SwModeled

from Rock Quality Index Method Regression).

Using a structure map, the water saturation model

derived from capillary pressure can be applied

across the field to determine hydrocarbons present.

This approach assumes that the rock is the same

everywhere within the study area—deposited

www.cgg.com

Page 6

© CGG. All Rights Reserved.

well within the same connected reservoir even when

there is no water contact. Understanding where the

fluid contacts are leads directly to improved decisionmaking in the drilling program.

Managing all well data in a single database

provides great value for iterative analysis and

future modification. It also enables geoscientists to

review how the data was used in the model, what

assumptions were made and what calculations were

applied. It makes it easy to add more data as it is

acquired, enhancing the model. This practice ensures

consistency across the field lifecycle.

References

Figure 9: Liberty #1 CPI with saturation comparison.

under the same conditions from the same source

and with the same porosity and permeability. As

long as there are no sealing faults, water level

can be safely assumed to be the same, because

water seeks the same level. If there are multiple

zones with the same free water levels, then the

zones are in communication. This helps determine

compartmentalization.

Conclusions

The capillary pressure model developed from one

well successfully predicted the water saturation data

in another well within the same field. By applying

the two separate saturation models, one based on

the fine-grained samples and the other based on the

coarse-grained samples, a prediction might have been

possible for an expected range of water saturations

for the two rock types for comparison to the actual

log based water saturation.

The capillary pressure analysis of Tern #3 provided

a more consistent indication of water saturation than

using the traditional resistivity-based computed

saturation. The water saturation curve proved

consistent with Liberty #1, for which there were no

capillary pressure measures available and water had

not been contacted. The analysis demonstrated the

ability to use capillary pressure data from one well

to calculate height above free water for any other

Alaska Department of Natural Resources, Division

of Oil and Gas, 2011, Point Thompson Area.Available

online at: dog.dnr.alaska.gov.

Bird, K.J., 2001. Alaska; a twenty-first-century

petroleum province, in Downey, M.W., Threet, J.C., and

Morgan, W.A., eds., Petroleum provinces of the twentyfirst century: American Association of Petroleum

Geologists Memoir 74, p. 137–165.

BP Exploration (Alaska) Inc., 2007. Liberty

Development Project Development and Production

Plan. Submitted to U.S. Minerals Management Service.

Anchorage, Alaska.

Holmes, Michael. “Capillary Pressure & Relative

Permeability Petrophysical Reservoir Models.” Digital

Formation, 2002.

Houseknecht, D.W., and Bird, K.J., 2006. Oil and gas

resources of the Arctic Alaska petroleum province:

U.S. Geological Survey Professional Paper 1732-A, 11

p., available online at: http://pubs.usgs.gov/pp/pp1732/

pp1732a/index.html.

Omni Laboratories, Inc., 2007, Core analyses of the

Shell Oil Company OCS Y-0197-1 (Tern Island #3) well

(12977.25’-13221.35’); which includes permeability and

porosity data, mercury injection capillary pressure data,

X-ray diffraction dat, sample photographs, petrographic

thin-section photographs, and SEM photographs:

Alaska Division of Geological & Geophysical Surveys

Geologic Materials Center Data Report 338, 41 p.

Shell Oil Company and Alaska Geological Materials

Center, 2006, Core Photographs (12915’-13361.5’) dated

June 2003 of the Shell Oil Company OCS Y-0197-1

(Tern Island #3) at the Alaska GMC: Alaska Division of

Geological & Geophysical Surveys Geologic Materials

Center Data Report 336, 3 p.

www.cgg.com

Page 7

© CGG. All Rights Reserved.