10 OM Decisions

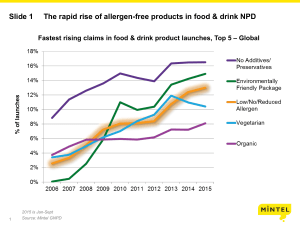

advertisement

10 Operation Management Decisions Goods and services design: Dulcesol is a firm in the sector of food, especially in bakery products. The products offered by Dulcesol are considered goods of convenience: these products are the ones which are mainly consumed, at low price and of which aqcuisition is simple, this means people can buy them everywhere. The firm counts with a large range of bakery products with more than 250: for breakfast, snack, and several lines of fresh bread which have been recently introduced. For the breakfast and afternoon snack we can find, among others, the Pandorino, muffins, napolitanas etc, and for the smallest of the family, we can mention the Briochocos. In the last years, Dulcesol has been introducing in the market a line of sandwich bread (integral, without crust etc.), as well as hot dogs bread, hamburger bread. The firm obtains the raw materials mostly from its own farms. Dulcesol also makes chocolate cream, vanilla, chocolate cover, gelatin, cream filling, liquor and jams. Producing by themselves gives more guarantee of hight quality in their products. New lines of products Dulcesol keeps on increasing year after year its assorment of bakery products. One of the premises of Dulcesol is that every year, without exception, a minimum of one new product has to be introduced in the market. The firm is also expanding the line of fresh bread introducing new kinds of sandwich bread. Star product: Pandorino It is the product which identifies the firm; it is one of the first which began to be produced at Dulcesol. Its sales have always been satisfactory along the years, becoming the first stable product of the firm. The Pandorino is a chocolate and hazelnut filled cake, although in its first years, there also were Pandorinos without filling which are already out of the actual market. It is especially recommended because of its high amount of energy, for breakfast and for young people. Quality: Quality is one of the main goals which Dulcesol adopted since its beginning: "in food, quality is what counts”. In this sense, Dulcesol's Quality Assurance System carries out with the Quality International Standart UNE/EN/ISO 9002, as AENOR certifies. In this way, Dulcesol guarrantees that its products satisfy the quality parameters demanded by the costumers. Furthermore, Dulcesol was the first firm in the bakery sector which got a certificate in quality. Dulcesol wants to show the costumers this quality and wants them to see it clearly. That is why they insit on demonstrating it by means of the publication of manuals in which all the process of elaboration of the products are indicated, and above all the quality controls realized. The firm counts with a Quality Control Department with its own laboratory. The nine technical experts analyze deeply raw materials as well as final products, to make sure thay all are contaminationless, germs, etc., being automatically discarded those which do not carry out the specifications. Process and capacity design With a production about 86000 tons distributed of over 60 different products, over the last four years the company has invested around 75 million Euros in new offices, new manufacture and production premises auxiliary facilities and new production lines, in both the Gandia and Villalonga factories. Currently, there are more than 1800 employees working for the Dulcesol Group. Location selection: The firm was founded in the Comunidad valenciana, but soon its renown and its distribution expands to all Spain, and later to European countries. Dulcesol counts nowadays with factories all around Spain (farms, distribution societies), even in Portugal. Although the two production plants are both located in Gandía and Villalonga, in the Comunidad Valenciana. These two plants supply the 16 distribution firms strategically placed in all Spain. Its international market is increasing year after year, but at the moment Dulcesol does not consider the option of more production plants or other factories outside Spain. Dulcesol is a familiar firm, but it also exports to a large number of European countries like: Portugal, France, United Kingdom, Italy, Benelux, Swiss and Finland. The firm distributes its products everywhere using its own means of transport, although they sometimes use other companies services. Layout design The layout design is the same for all Spain and foreign country, except for the language and other details which appear in the packaging. Dulcesol‘s packaging presents its logo and is mainly blue. At the present the firm adopts new designs for the individual products package, so they are more appealing for children, since they are the main costumers. For the white marks products also produced by Dulcesol, the packaging reminds slightly Dulcesol’s one, even in this case, the firm does not produce the packaging for the white marks, nor do the distribution. For the packaging, Dulcesol counts with its own factory called Duplast. Human ressource and job design One of the wicknesses of the firm: Dulcesol has got a bad reputation regarding the treatment of its employees: hard schedules, individualism, abuses of power etc. Automation does not affect at the moment, since it is still necessary to count whith a big number of workers. Dulcesol tries to improve the situation. In spite of this, the number of employees increases (more than 1800 nowadays) and the firm creates each year new jobs. Dulcesol hires employees by itself and by means of other firms like ETT or CREYF'S. In this last case, these firms are used to hire employees for production chain. Supply chain-management As Dulcesol tries to produce with its own raw materials and services, as well as distribution is provided by its own distribution societies, definitely, Dulcesol uses a vertical integration strategy. Sometimes, when the firm has not other choice, it has to hire services of other firms, for example in foreign countries where Dulcesol can not apply. Inventory Dulcesol starts producing as soon as they receive the order and the products are directly distributed once they have passed the quality test. The production and the quality control last maximum 3 days. Inmediately after, the products are directly distributed to the clients. There is no stock. Scheduling The process of production is really fast and effective, always guarranteeing quality. They can do this using all the resources they have. Maintenance Dulcesol keep on growing in Spain as well as in all Europe, even if the national market is still more important: trying to be leader in the food sector, always with its quality policy in front of it. Mantaining all this infrastructure requires most innovative technology possible, as an example: the camera system on their production plants to quickly find and solve any problem: