Paramount - True Fitness

SP

I

NSTALLATION

&

A

SSEMBLY

M

ANUAL

AM-SP

REV. 012813

A M

ESSAGE TO

O

UR

C

USTOMERS

Thank you for purchasing products from the Paramount SP line. Because of the many unique features included in these machines, this manual was created to provide you with information on how to properly install and maintain your equipment. Proper maintenance will ensure that your new equipment will last for years.

For your convenience, product questions can be answered by an Authorized Paramount Dealer or by contacting a Paramount Customer Service Representative at:

1-800-721-2121 or 1-323-721-2121

Office hours are Monday-Friday, 7:30 am - 4:30 pm PST

Or email us at nasales@paramountfitness.com

Thank You for your patronage.

Paramount Fitness Corporation

6450 East Bandini Blvd.

Los Angeles, CA 90040

IMPORTANT

SERIOUS INJURIES TO USERS, BYSTANDERS OR INSTALLERS CAN OCCUR IF THE

INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL ARE NOT FOLLOWED. TO

MINIMIZE THIS RISK, READ THE MANUAL BEFORE BEGINNING THE INSTALLATION TO

FAMILIARIZE YOURSELF WITH ITS CONTENTS AND THEN BE CERTAIN TO FOLLOW EACH

OF THE STEPS AND PRACTICES DESCRIBED. IN ADDITION, REVIEW THE GENERAL

MAINTENANCE MANUAL, FACILITY SAFETY SIGN AND OTHER DOCUMENTS THAT MAY

ACCOMPANY EACH MACHINE, FOR IMPORTANT SAFETY AND MAINTENANCE TIPS. THE

MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER AND CAN ALSO BE

DOWNLOADED FROM OUR WEBSITE AT: http://www.paramountfitness.com

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

2

T

ABLE

O

F

C

ONTENTS

S AFETY ..............................................................................................................

4

G ENERAL C ARE AND M AINTENANCE ......................................................................

7

M ACHINE D IMENSIONS & W EIGHTS .......................................................................

8

L AYOUT & S PACING .............................................................................................

9

I NSTALLATION & A SSEMBLY

R EQUIRED T OOLS ..................................................................................................... 9

U NPACK THE H ARDWARE B AG .................................................................................. 10

F OOT I NSTALLATION .................................................................................................. 10

W EIGHT S TACK I NSTALLATION .................................................................................. 11

O PTIONAL A DDER W EIGHT I NSTALLATION .................................................................. 13

A NCHORING M ACHINES TO THE F LOOR ...................................................................

18

M ACHINE M AINTENANCE

C ABLES ................................................................................................................... 18

W ARNING AND P ROCEDURE L ABLES ......................................................................... 19

H OW TO O BTAIN S ERVICE ......................................................................................... 20

P ARAMOUNT L IMITED W ARRANTY .........................................................................

21

3

S

AFETY

F

ACILITY AND

U

SER

S

AFETY

P

RECAUTIONS

1. Review and understand all of the warning labels affixed to this machine and on the facility safety sign.

2. Be certain that the machine operation is understood before it is used. Refer to the instructional Procedure Label affixed to the machine.

3. Make sure all users are properly trained on how to use this equipment. If this machine is being used in a commercial setting, end users may not have access to this Owners Manual. It is the responsibility of the facility to instruct users as to the proper usage of the equipment as well as making them aware of potential hazards. Maximum user weight is 300 lbs (136 kg).

4. Use each machine only for the intended exercise. Do not allow anyone to invent exercises not included on the Instructional Procedure Label or the Intended Use Label.

5. Do not modify the machine.

6. This equipment meets industry safety standards for stability when used for the intended exercise. Do not allow straps, resistance bands or other means to be attached to the framework of this machine to perform stretching or body weight exercises. This can result in machine instability and lead to serious crushing injuries.

7. Keep children away from this equipment. Adults should closely supervise use by teenagers.

8. It is recommended that users receive a thorough medical exam before commencing an exercise program. All medical issues should be reviewed to ensure that weight training will not aggravate pre-existing medical conditions.

9. If the machine appears damaged or inoperable, contact a facility staff member to place an

“OUT OF ORDER, DO NOT USE” sign on the machine until it is repaired. Only use Paramount supplied replacement components to service this machine.

10. Instruct users not to wear loose or dangling clothes or have headphone wires hanging when using this equipment.

11. Do not attempt to free any jammed assemblies by yourself as this may cause injury.

12. On Plate Loaded and Free Weight machines:

12a. Use of spotter(s). Instruct users to seek the advice of the facility staff as to the appropriate use of spotters when lifting. More then one spotter may be required depending upon the amount of weight being lifted.

12b. Instruct users to load weight plates evenly and carefully (one side and then the other) to avoid tipping equipment and crushing injuries.

12c. If the machine is equipped with safety stops or catches, inspect them and verify their proper operation before use and make sure they are securely in place before using or exiting the machine. Be certain members are instructed on how to operate and adjust all safety mechanisms.

4

S

AFETY

12d. This equipment is designed for standard olympic size weight plates with a 50mm bore

(1.9”).

12e. Do not exceed the maximum weight capacity of the machine. Maximum plate size is

45 lbs. (25 kg.).

13. On Selectorized and Cable equipped machines:

13a. Do not allow users to perform any exercise by holding the end of the cable and/or the cable end fitting. Use only appropriate handles or attachments properly connected to the cable end.

13b. Do not high-pin or double-pin the weight stack. Do not allow the machine to be used if the top plate or weight stack is pinned in a raised position. Use an assistant and carefully return the machine to the proper position with the cap plate resting on the top weight. Inspect the entire length of the cable to ensure that it is properly seated in all of the pulley grooves.

13c. Do not allow the use of weight plates or dumbbells to be used as a means to add additional weight to the weight stacks. Use only the Paramount adder weight system specifically designed for the machine.

I NSTALLATION S AFETY P RECAUTIONS

1. Read this Installation Manual entirely before assembling this equipment.

2. Verify that there is adequate space surrounding this piece of equipment for safe access and operation. Installation must meet ADA requirements for accessibility.

3. Install this piece of equipment on a solid level surface that does not deviate more then 1/8” over a 10’ distance (or as defined and required by local building and architectural codes.

4. Paramount strongly recommends that all equipment be anchored to the floor to prevent movement and increase stability.

• Due to the wide variation of flooring on which the unit can be installed, contact a qualified contractor to determine an appropriate fastening system for your floor.

• Use 3/8” diameter hardware (10 mm) to anchor the machine. Anchors should have a minimum pull out force of 220 lbs (110 kgs) for each position.

• When attaching the machine to the floor, if there is a gap between the machine foot and the floor, do not use the anchor to remove the gap as this can cause the machine frame to deform. Instead, place a shim between the bottom of the foot and the floor, then tighten the anchor.

• Anchoring holes are provided on the feet of the frame. All anchoring locations must be used when anchoring the equipment to the floor.

5. DO NOT install any fitness equipment near a pool, hot tub or other damp locations. Corrosion caused by installation in these locations can lead to premature failure of components.

6. Be sure all hardware is tight before using this machine.

5

S

AFETY

M AINTENANCE S AFETY P RECAUTIONS

1. Refer to Maintenance Schedule label on the machine as well as this manual for when to perform maintenance.

2. Check the function of your machine DAILY by verifying the following:

• Inspect cables and end fittings for any signs of wear. Replace if worn, frayed or damaged with original Paramount replacement components.

• Verify that all adjustments are possible and carried out with ease. Make sure that each adjustment pin inserts completely into each position without binding.

• Verify that safety catches and stops are in proper working order and engaged.

• Verify that the exercise is performed smoothly, free of noise and/or binding.

• If equipped with a weight stack, verify that the proper weight selector pin is in place.

3. Check the function of your machine WEEKLY by verifying the following:

• Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become loose, retighten and/or use Loctite ™ Threadlocker 242.

• Frames and Lifting Arms: Inspect weekly for integrity and function. Replace any component at first signs of wear. Use only Paramount supplied components.

4. Replace any warning label at first sign of wear. Labels and the Facility Safety Sign may be obtained from Paramount free of charge.

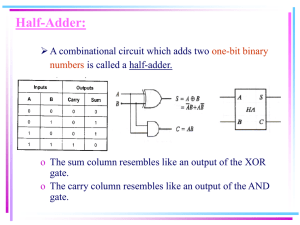

B OLT L ENGTH M EASURING G UIDE

FLAT HEAD SCREW

BUTTON HEAD SCREW

HEX HEAD SCREW

SOCKET HEAD SCREW

1 2

6

3 4 5

G

ENERAL

C

ARE AND

M

AINTENANCE

IMPORTANT

Preventative maintenance is crucial to maintaining the function and safety of this equipment. Your facility must establish written guidelines for preventative maintenance and keep written or online records of the maintenance performed on these products. As a minimum, the items presented in the SAFETY section of this document and the items that follow here, should be included in your maintenance program.

1. Cables: Inspect end fittings daily for wear. Inspect the entire length of the cable weekly.

Replace cables at the first sign of wear and on an annual basis. If the cable tension has been adjusted, be certain that the cable nut is tight.

2. Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become loose, retighten and/or use Loctite TM brand Threadlocker 242. Be sure all hardware is tight before using the machine.

3. Safety Catches: Inspect catches, stop rods and their associated fasteners weekly. Tighten any loose hardware and replace any components at first signs of wear.

4. Frames: Wipe all machines down with a damp cloth and dry completely each day. This includes painted parts, chrome parts and upholstered pads.

5. Painted and chrome plated parts: Use Simple Green or similar cleaner for light dirt and grime. Use Turtle Wax Polishing Compound or a good car polish to remove heavier dirt and grease as well as for polishing. DO NOT use solvents, lacquer thinner, acetone or finger nail polish remover. For scuffs and marks that are not removed by the above methods use a soft scrub cleanser. Make sure all parts are dry upon completion.

6. Weight stack enclosures (shrouds): Wipe down with a damp cloth as needed.

7. Exercise instruction labels: Clean with soap and water as needed.

8. Guide rods: Wipe all dirt and dust from the guide rods before applying a light application of Tri-Flow

TM

or other teflon spray lubricant. Spray the Tri-Flow

TM

on a rag and then wipe the guide rods with the rag. DO NOT use oil lubricants such as WD-40. Caution: Tri-Flow TM will stain carpet and clothing.

9. Bronze bushings: Check monthly for signs of wear and replace as needed.

10. Linear Bearing Shafts: Wipe any accumulation of dust or other contaminants from the shafts on a weekly basis. Apply a thin layer of a Teflon

®

(PTFE) grease on a weekly basis.

Paramount recommends Magnalube

®

brand.

11. When replacing any component, use only Paramount supplied parts.

12. Please refer to the General Maintenance Manual (part number: AM-GMM) for other important safety and maintenance information.

13. Be sure all hardware is tight before using the machine.

Retain these instructions for future reference.

If you have any questions, do not hesitate to contact your Paramount dealer or Paramount Fitness

Corp. at (800)721-2121 or nasales@paramountfitness.com.

7

M

ACHINE

D

IMENSIONS

& W

EIGHTS

A T R EST

M ODEL D ESCRIPTION

SP5000 Leg Extension

SP5100 Seated Leg Curl

SP5200 Leg Press

SP5300 Inner Thigh

SP5400 Outer Thigh

SP5500 Biceps Curl

SP5600 Triceps Extension

SP5700 Pec Fly/Rear Delt

SP5800 Rotary Chest

Press

SP5900 Seated Row

SP6000 Lower Back

SP6100 Lat Pulldown

SP6200 Rotary Shoulder

Press

SP6300 Abdominal

SP6400 Rotary Torso

SP6500 Calf Raise

SP6600 Glute

L

IN / CM

42 /

107

58 /

147

72.5 /

184

68 /

173

68 /

173

38 /

96.5

48 /

122

66 /

167

W

IN / CM

46 /

117

49/

124.5

44 /

112

H

IN / CM

56.5/

143.5

56.5/

143.5

71 /

180

26 / 66 56.5/

143.5

26 / 66 56.5/

143.5

60 /

152.4

56.5/

143.5

51 /

129.5

56 /

143

56.5/

143.5

74.5 /

189

41.5 /

105

69 /

175

45 /

114

52 /

132

54 /

137

56 /

142

44 /

112

50.5 /

128

49 /

124.5

57 /

145

42/107 47/119 56.5/

143.5

37 / 94 50 /

127

56.5/

143.5

60/152 38/97 56.5/

143.5

40/102 39/99 56.5/

143.5

71 /

180

56.5/

143.5

56.5/

143.5

93 /

236

56.5/

143.5

D URING E XERCISE M AX M ACHINE M AX F LOOR

L W H LB kg

LB ./ FT

L OAD

2

KG / M

2

IN / CM IN / CM IN / CM

60/

152

46 /

117

56.5/

143.5

501 228 59 288

570 259 67 327

41.5 /

105

69 /

175

60 /

152

62 /

157.5

54 /

137

58 /

147

87 /

221

68/

173

68/

173

38 /

96.5

48 /

122

72.5 /

184

49 /

124.5

44 /

112

65 /

173

65 /

173

60 /

152.4

51 /

129.5

61 /

155

56 /

142

44 /

112

50.5 /

128

49 /

124.5

59 /

150

42/107 47/119 56.5/

143.5

38 /

96.5

52 /

132

56.5/

143.5

60/152 38/97 56.5/

143.5

60/152 39/99 56.5/

143.5

56.5/

143.5

71 /

180

56.5/

143.5

56.5/

143.5

56.5/

143.5

56.5/

143.5

74.5 /

189

71 /

180

56.5/

143.5

56.5/

143.5

93 /

236

71 /

180

714

521

534

522

568

646

623

502

517

538

594

486

521

467

474

325

236

242

237

258

294

271

228

235

245

270

220

236

212

215

51

57

59

61

61

81.3

61

41.5

77

53

49.5

64

63

50

142

250

278

288

300

300

397

300

203

378

259

242

312

305

243

693

The width measurement (W) is in the direction across the chest of the user as positioned in the machine performing the exercise.

Max machine weight and floor loading is figured with the heavy weight stack option for each machine.

8

L

AYOUT AND

S

PACING

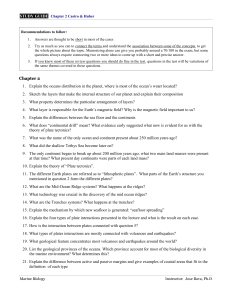

Per ADA guidelines, there must be a 30” wide x 48” long area of open space at the entrance to the machine to allow wheelchair access.

Maximum user weight is 300 lbs (136 kg)

30” (76 cm.) or more

30”

(76 cm.) or more

WALL

30” (76 cm.) or more

DO NOT install any fitness equipment near a pool, hot tub or other damp locations. Corrosion caused by installation in these locations can lead to premature failure of components.

I

NSTALLATION AND

A

SSEMBLY

REQUIRED TOOLS

Phillips Head Screw Driver

Open end and socket wrenches (9/16”, 3/4”, 7/8” and

15/16” or an adjustable crescent wrench). Used for guide rod bracket, cable bolt, and cable nut.

Rubber mallet - may be needed for foot installation

9

I

NSTALLATION AND

A

SSEMBLY

!

U NPACK THE H ARDWARE B AG

FOR SAFETY REASONS, THE INSTALLATION OF THE MOLDED RUBBER FEET

REQUIRES MORE THAN ONE PERSON. BE CERTAIN THAT THE MACHINE OR

MACHINES ARE PLACED IN THE FINAL LOCATION BEFORE INSTALLING THE

RUBBER FEET.

THE HARDWARE BAG WILL CONTAIN:

S 550 - Rubber Foot - qty varies.

B 470 - Magnetic Selector Pin.

F OOT I NSTALLATION

1. Position the machine in the facility in its desired location. Tilt / lift the machine to one side, remove the shipping foot. You may find it helpful to support the frame on wood blocks.

2. Place one of the rubber feet onto the plates as shown.

3. Lower the machine then tilt the machine towards another side. Install another foot .

Repeat until all of the feet have been installed.

10

W

EIGHT

S

TACK

I

NSTALLATION

1. Weight plates are packaged (4) per box and are marked with the quantity and weight of the plates. The various configurations are shown below.

10 LB. Weight Plate Box

Part Number: B1602

Comprised of

(4) x 10 lb. Weight Plates

15 LB. Weight Plate Box

Part Number: B1603

Comprised of

(4) x 15 lb. Weight Plates

Standard

170 LB.

(16) x 10lb. plates

4 boxes of B1602

Standard

210 LB.

(20) x 10lb. plates

5 boxes of B1602

Optional

210 LB.

(8) x 10lb. plates

(8) x 15lb. plates

2 boxes of B1602

2 boxes of B1603

Optional

310 LB.

(20) x 15lb. plates

5 boxes of B1603

Heavy Optional

250 LB.

(16) x 15lb. plates

4 boxes of B1603

2. Review the equipment order and the front panel of the machine to determine the correct weight stack configuration for each machine. Use the following table to assist you in noting your configuration .

M

ACHINE

D

ESCRIPTION

SP5000 Leg Extension

SP5100 Seated Leg Curl

SP5200 Leg Press

SP5300 Inner Thigh

SP5400 Outer Thigh

SP5500 Biceps Curl

SP5600 Triceps

SP5700 Pec Fly/Rear Delt

SP5800 Chest Press

SP5900 Seated Row

SP6000 Lower Back

SP6100 Lat Pulldown

SP6200 Shoulder Press

SP6300 Abdominal

SP6400 Rotary Torso

SP6500 Calf Raise

SP6600 Glute

S

TANDARD

170 lb. (77) kg.)

170 lb. (77) kg.)

210 lb. (95) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77) kg.)

170 lb. (77 kg.)

170 lb. (77 kg.)

O

PTIONAL

210lb (95 kg)

210lb (95 kg)

310 lb (141 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95 kg)

210lb (95kg)

210lb (95kg)

210lb(95kg)

H EAVY

250 lb. (114) kg.)

250 lb. (114 kg.)

N/A

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

250 lb. (114 kg.)

11

W

EIGHT

S

TACK

I

NSTALLATION

THUMB SCREW

Phillips Screws reach up and through

3. Reach under the top cover and unscrew the single attachment screw. This can be done by hand. Lift the cap straight up and off of the machine.

4. Use a phillips screw driver and remove the 2 screws holding the rear panel in place. Lift the rear panel up and out of the machine.

5. Disconnect the cable from the cap plate/selector bar; remove the upper pulley and lay the cable out of the way; remove the bolts holding the guide rod bracket and tilt the guide rods outward as shown on the following page.

GUIDE ROD BRACKET

REMOVAL - NOTE

ORIENTATION

6. Slide the guide rod bracket and the cap plate/selector bar upward and off the guide rods.

7. Slide each weight plate onto the guide rods.

8. After installing all of the weights, slide the cap plate/selector bar back onto the guide rods and reinstall the guide rod bracket, cable & upper pulley. Note that the open portion of the bracket should be facing away from the user side of the machine.

9. If you have purchased the optional adder weight kit, continue with STEP 10.

Otherwise skip to STEP 11.

12

SP O

PTIONAL

I

NCREMENTAL

A

DDER

W

EIGHT

10. If you purchased the optional incremental adder weight system, these instructions will show you how to assemble it to your machine. Use the chart below to determine the required parts for each machine and weight stack configuration:

MACHINE

WEIGHT

STACK

(

LBS

.)

SP-5000 (Leg Extension)

SP-5100 (Leg Curl, seated)

SP-5200 (Leg Press)

SP-5300 (Inner Thigh)

SP-5400 (Outer Thigh)

SP-5500 (Biceps Curl)

SP-5600 (Triceps Extension)

SP-5700 (Pec Fly/Rear Delt)

SP-5800 (Rotary Chest Press)

SP-5900 (Seated Row)

SP-6000 (Low Back)

SP-6100 (Lat Pulldown)

SP-6200 (Rotary Shoulder Press) 170

250

SP-6300 (Abdominal) 170

250

SP-6400 (Rotary Torso)

SP-6500 (Calf)

170

250

170

250

170

250

170

250

170

250

170

250

130

190

170

250

170

250

170

250

170

250

170

250

210

310

170

250

W

A

DDER

EIGHT

K

IT

#

SPADR10A

X

X

X

X

X

X

X

X

X

X

X

X

X

X

A

DDER

W

EIGHT

K

IT

#

SPADR15A

X

X

X

X

X

X

X

X

X

X

X

X

X

X

W

A

DDER

EIGHT

K

IT

#

SPADR10AT

X

X

W

A

DDER

EIGHT

X

X

K

IT

#

SPADR15AT

13

SP O

PTIONAL

I

NCREMENTAL

A

DDER

W

EIGHT

The following diagram shows the parts included in the adder weight kits. Please refer to the previous table to determine the correct kit required for your machine & weight stack configuration.

PART

9007ADR048

DESCRIPTION

GUIDE ROD, ADDER WEIGHT 2

QTY

9007ADR045*

C 610

C 730

9007ADR049

GUIDE ROD, ADDER WEIGHT

*Taller guide rod used only on

SP5200 & SP6100.

2

1/4-20 X 1 1/4 SOC HD SCREW 2

1/4 HEX NUT

COLLAR (Height Adjust)

2

2

D 721

9007ADR060X*

9007ADR065X*

RUBBER WASHER 8

ADDER WEIGHT SLIDERS

*For use on weight stacks with

10 lb . plates. (170 & 210) shown on left.

1 EA.

9007ADR070X*

9007ADR075X*

ADDER WEIGHT SLIDERS

*For use on weight stacks with

15 lb . plates. (250 & 310) shown on right.

1 EA.

FOR 10 LB.

PLATES

FOR 15 LB.

PLATES

S 572 GUIDE ROD RETAINER 2

D 913 SPRING

9005TWT004XB ADDER SELECTION PLATE,

+3.3 lb./+6.6 lb.

*For use on weight stacks with

10 lb . plates. (170 & 210)

2

1

9005TWT004XA ADDER SELECTION PLATE,

+5 lb./+10 lb.

*For use on weight stacks with

15 lb . plates. (250 & 310)

1

D 588 1’’ BRONZE THRUST WASHER 2

9005ADR030X SELECTOR ASSY 1

D 160

C 702

9005ADR035

WAVE WASHER 1

5/16-18 x 3/8 LONG SET SCREW 2

CAP 1

14

TOOLS REQUIRED

SP O

PTIONAL

I

NCREMENTAL

A

DDER

W

EIGHT

Phillips Screw Driver (Shroud Removal)

Hex Wrenches:

- 5/32” (Selector Cap and height adjust collar)

- 3/16” (1/4 x 1-1/4” long socket head screws)

7/16” Wrench (for 1/4” nut)

INSTALLATION

10a. Place the adder weight guide rods through the square holes in the base retainer tubes.

NOTE: There is a hole at one end of the guide rod. Orient the guide rod so that the hole is toward the top of the machine (see the diagram for step 8).

ADDER WEIGHT

GUIDE RODS

BASE RETAINER

TUBES

10b. Install the 1/4 x 1-1/4” long socket head screws and hex nuts into the base retainer tubes. DO NOT TIGHTEN at this time.

10c. Slide a COLLAR and a RUBBER

WASHER onto each guide rod as shown.

10d. Install the ADDER WEIGHT SLIDERS.

Refer to the diagram and position the slider with the catch on the right side of the machine (when looking at the rear).

Be sure to use the correct sliders for your particular weight stack. The diagram to the right shows the

“smaller” sliders used with 10 lb. weight plates (170 & 210 lb. weight stacks).

STEP

5

RUBBER

WASHER

COLLAR

ADDER WEIGHT

SLIDERS

CATCH

15

SP O

PTIONAL

I

NCREMENTAL

A

DDER

W

EIGHT

10e. Tilt the guide rods up and into the frame. Install a spring and the GUIDE

ROD RETAINER as shown.

10f. Tighten the socket head screws in the

BASE RETAINER TUBES to secure the guide rods. Tighten the nuts against the

BASE RETAINER TUBES to lock the screws.

GUIDE ROD RETAINER

10g. If the cable is attached to the TOP

PLATE/SELECTOR BAR assembly, disconnect it.

10h. Remove the two stainless steel screws at the front of the TOP PLATE and install the appropriate ADDER SELECTION

PLATE for the weight stack used on the machine.

TIP: For weight stacks comprised of 10 lb. plates (170 lb. & 210 lb.), the label on the ADDER SELECTION PLATE should read +3.3 lbs. and +6.6 lbs.

For weight stacks comprised of 15 lb. plates (250 lb. & 310 lb.), the label on the ADDER SELECTION PLATE should read +5 lbs. and +10 lbs.

CAP

WAVY WASHER

BRONZE THRUST

WASHER

,

D588

SELECTOR ASSY

.

BRONZE THRUST

WASHER

,

D588

ADDER SELECTION

PLATE

C702

10i. Slide one bronze thrust washer (D 588) over the selector bar followed by the

SELECTOR ASSEMBLY.

TOP PLATE

10j. Place another bronze thrust washer on top of the SELECTOR ASSEMBLY followed by the WAVY

SPRING WASHER (D 160).

10k. Install the set screws into the CAP and place the CAP on the selector bar. Press the CAP down firmly and tighten the two set screws.

10l. Verify the function of the SELECTOR ASSEMBLY by moving it through its range to the left and to the right. At the center point you should feel it “click” into position. If it doesn’t click, loosen the set screws in the CAP and press down harder while retightening the screws.

16

SP O

PTIONAL

I

NCREMENTAL

A

DDER

W

EIGHT

10m. Verify that the ADDER SELECTION PIN is vertically centered in the ADDER WEIGHT

SLIDER slot as shown. If needed, add rubber washers under the ADDER WEIGHT SLIDER to raise it. NOTE: On the SP5200 Leg Press, there are 20 weight plates. Adjust the collars up 4” to center the selection pin in the adder weight slider slot. Verify that the back side of the slider plates are flush. Tighten the set screws on the collars.

10n. Raise the top plate. Verify that when the selection pin, when set to the 3.3 lb (or 5 lb.) position, lifts one adder weight slider. Move the selection pin to the 6.6 lb (or 10 lb.) position. Raise the top plate and verify that both adder weight sliders lift up.

SELECTION PIN must be centered in slot

Catch plate must be on this side. Plates should be flush.

Adjust up 4” for SP5200

Leg Press.

17

11. Attach the lanyard to the adder weight label plate (if installed) or around the cable bolt (if adder weight not installed. Re-attach the cable to the

SELECTOR BAR.

12. With the weight stack selector pin in the TOP

PLATE, tighten the cable so that the TOP PLATE just barely starts to lift off of the first weight plate. Verify that you can insert the weight stack selector pin into the bottom weight plate. If not, loosen the cable tension slightly.

IMPORTANT: Verify that the cable bolt does not protrude more than 1-3/8” from the selector bar as shown. Tighten the locking nut.

1-3/8’’

[35mm] maximum

INSTALL LANYARD

ANCHORING THE MACHINES TO THE FLOOR

Paramount strongly recommends that the machines in the SP line can be anchored into position.

Holes in the base frame have been provided for bolts to be used to fasten the machines to the floor.

Due to the wide variation of flooring on which the machines can be installed, contact a qualified contractor to determine the appropriate fastening method.

FINAL CHECKS

• Lubricate the guide rods with a teflon spray lubricant such as Tri-Flow

TM

.

• Inspect the machine. Check and tighten ALL fasteners and cable fittings as required.

• Make sure that the machine and all adjustments function correctly and smoothly. Be certain to cycle the machine with and without weight to be certain that the cable is tracking in all of the pulleys.

• Reinstall rear shroud and top cap.

Cable Replacement

Paramount recommends that the cable ends be inspected daily and that the area that passes over the pulleys be inspected weekly. Inspect the cable while someone cycles the machine.

Replace the cable at the first sign of wear or on an annual basis .

If a machine must be disassembled, disconnect the cable at the machine side, leaving the section of cable that is routed through the upright, intact. When replacing a cable, disconnect it at the machine side first, remove the rear panel and top cover as described earlier in this manual and then disconnect it at the weight stack. Loosen and lift pulleys as needed to remove the cable from the machine. To install, pass the ball end of the cable through the frame, seating each pulley as you go and secure the cable to the machine. Reinstall the upright pulleys, lift the cap plate selector bar and secure it to the weight stack. If the cap plate is raised significantly above the weight stack, the cable is not routed properly around a pulley. Carefully check all pulleys and reseat as needed. After installation, make sure that the machine functions smoothly and that the cable tracks through the pulleys and that all pulleys rotate.

18

W

ARNING AND

P

ROCEDURE

L

ABELS

BE ALERT!

THE FITNESS EQUIPMENT IN THIS FACI

PRESENTS HAZARDS WHICH, IF NOT AV

COULD CAUSE SERIOUS INJURY OR DE

PRIOR TO USING THE EQUIPMENT, READ THE WARNING

AND INSTRUCTION PLACARDS AFFIXED TO EACH MACHI

IF YOU ARE UNSURE ON HOW TO USE A MACHINE, SEEK

ASSISTANCE OF OUR FLOOR PERSONNEL. WE WILL BE H

TO INSTRUCT YOU ON HOW TO USE THE EQUIPMENT PR

IMMEDIATELY REPORT ANY PIECE OF EQUIPMENT THAT

FUNCTIONING PROPERLY TO OUR FLOOR PERSONNEL S

IT MAY BE EVALUATED AND SERVICED PROMPTLY.

DO NOT ATTEMPT TO USE OR FIX ANY PIECE OF EQUIPM

THAT IS NOT FUNCTIONING PROPERLY.

P/N FAC. SIGN ASTM F1749

FACILITY SAFETY SIGN

!

WARNING

SERIOUS INJURY CAN OCCUR

ON THIS EQUIPMENT IF THE

CABLES AND THEIR ATTACH-

MENT COMPONENTS ARE NOT

INSPECTED OFTEN. REPLACE

AT FIRST SIGNS OF WEAR.

P/N B2051

ASTM F1749

B2051

SERIOUS INJURY CAN OCCUR ON

THIS EQUIPMENT. FOLLOW THESE

PRECAUTIONS TO HELP AVOID INJURY.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

BEFORE USING: Read and understand all of the warnings and obtain instruction on the use of this machine. DO NOT modify the machine.

Get a medical exam before beginning an exercise program.

Keep body and clothing clear of all moving parts. DO

NOT wear anything loose or dangling.

Inspect the machine before use. DO NOT use if it appears damaged. DO NOT try to fix any machine.

Notify staff immediately.

INSPECT MACHINE DAILY for loose, worn or damaged parts. Replace any part or label at first signs of wear. Inspect all cables and their connections closely. If you are in doubt about any part, DO NOT use the machine until the part is replaced.

Inspect all cables and connections before using the machine. DO NOT use this machine if any part appears worn or damaged.

Be certain that weight pin is completely inserted. Use only the pin provided by Paramount. If unsure, seek assistance.

NEVER pin weights or top plate into an elevated position. DO NOT use the machine if found in this condition. DO NOT try to fix. Seek assistance.

Use only the incremental weights supplied by

Paramount. DO NOT use dumbbells or other means to add resistance to machine.

NEVER allow children near this machine. Supervise teenagers.

DO NOT REMOVE THIS LABEL. REPLACE IF

DAMAGED.

MAINTENANCE SCHEDULE

Check the integrity and function of the following items. Replace all worn components immediately.

Cables:

Upholstery:

Frame:

Chrome:

• Check tension, end fittings, and coating. x

• Check weight stack locking nut.

• Replace cables annually.

• Wipe down and dry.

• Clean and condition.

• Wipe down and with damp cloth and dry. x x

• DO NOT leave parts damp. Polish/Wax

• Wipe down with damp cloth and dry.

• DO NOT leave parts damp. Polish/Wax

Nuts/Bolts/Fasteners:

• Check Tightness. x

Guide Rods: • Clean and lubricate.

Adjustments/Locking Pins/Knobs

Weight Stack Pin

Warning/Instruction Labels x

Springs

Anti-Skid

Hand Grips x x x x x x x x x x x

For recommended maintenance products refer to the owner’s manual or Paramount’s Web site www.paramountfitness.com

1-800-721-2121 S630 6/06

S 630

!

WARNING

SERIOUS INJURY CAN OCCUR ON THIS EQUIPMENT IF

THE PIN IS NOT COMPLETELY INSERTED BEFORE USE.

P/N B2065

ASTM F1749

B2065

!

WARNING

MOVING PARTS

STAY CLEAR!

P/N B2064

ASTM F1749

B2064

SAMPLE

PROCEDURE

LABEL

19

S

ERVICE

H OW TO O BTAIN S ERVICE

For warranty service, contact an Authorized Paramount Dealer or Paramount Customer

Service at 1-800-721-2121. Before you call, please have the following information ready:

• Model Number

• Serial Number

• Date of installation

• A brief description of the problem

The space below is provided for you to record the model and serial numbers of the equipment that you purchased. Serial numbers are located near the bottom of the upright.

Installation Date _____________________ Serial Number

M

ACHINE

D

ESCRIPTION

SP5000

SP5100

SP5200

SP5300

SP5400

SP5500

SP5600

SP5700

SP5800

SP5900

SP6000

SP6100

SP6200

SP6300

SP6400

SP6500

SP6600

Leg Extension

Seated Leg Curl

Leg Press

Inner Thigh

Outer Thigh

Biceps Curl

Triceps Extension

Pec Fly/Rear Delt

Chest Press

Seated Row

Lower Back

Lat Pulldown

Shoulder Press

Abdominal

Rotary Torso

Calf Raise

Glute

R

ECORD

S

ERIAL

N

UMBERS

H

ERE

20

P

ARAMOUNT

L

IMITED

W

ARRANTY

READ PARAMOUNT’S WARRANTY SET FORTH BELOW PRIOR TO USING PARAMOUNT PRODUCTS. BY INITIAL USE OF PARAMOUNT

PRODUCT YOU ARE CONSENTING TO BE BOUND BY THE FOLLOWING WARRANTY TERMS AND CONDITIONS. THE WARRANTY

PERIODS COMMENCE ON THE INVOICE DATE OF THE ORIGINAL PURCHASE. LABOR COVERED DURING WARRANTY PERIODS

REQUIRES PRIOR AUTHORIZATION OF PARAMOUNT. PARAMOUNT WARRANTS TO THE ORIGINAL BUYER OF ALL NEW EQUIPMENT

PURCHASED FROM A PARAMOUNT AUTHORIZED DEALER OR FROM A PARAMOUNT AUTHORIZED MANUFACTURING CONTRACTOR

THAT THESE PRODUCTS WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USE AND SERVICE FOR

THE FOLLOWING PERIODS AND IN THE FOLLOWING RESPECTS:

STRENGTH PRODUCTS

• TEN YEAR WARRANTY COMMERCIAL PRODUCTS – Frame Components and Welds excluding coatings

• FIVE YEAR WARRANTY - Bronze Bushings, Sealed Rotating Bearings, Pulleys, Weight plates and Guide Rods excluding coatings

• ONE YEAR WARRANTY - Cables, Linear Bearings and Shafts and all other components not mentioned elsewhere in this warranty

• 90-DAY WARRANTY - Normal wear parts including but not limited to labels, upholstered pads and grips

• ONE YEAR WARRANTY – Labor

THE SHIPPING MODE OF PARTS REPLACED UNDER WARRANTY TO BE DETERMINED BY PARAMOUNT. PARTS REPLACED UNDER

WARRANTY CARRY THE REMAINING ORIGINAL WARRANTY PERIOD OR 90 DAYS, WHICHEVER IS LONGER.

THIS LIMITED WARRANTY DOES NOT COVER AND NO WARRANTY IS GIVEN WITH RESPECT TO:

• Products not manufactured by Paramount or by an Authorized Paramount Manufacturing Contractor.

• Products which are altered without the express written consent of Paramount.

• Products purchased other than directly from Paramount or through a Paramount Authorized Dealer.

• Defective paint, chrome and other coatings caused by environmental conditions including but not limited to climate conditions, cleaning materials and moisture or humidity coming from HVAC systems.

• All parts including but not limited to frames with cosmetic damage. Such damage includes but is not limited to scratches and dents caused after the initial installation.

• Products not maintained in compliance with Paramount’s specifications as shown in the owners’ manual and on product labels.

• Products with a missing, unreadable or altered serial tag.

• Labor for components beyond their warranty coverage.

• On site service calls to solve installation errors or to provide technical training on the proper use and servicing of the equipment.

THIS WARRANTY APPLIES UNDER THE FOLLOWING CONDITIONS.

• These products have not been subjected to misuse, abuse, modifications not authorized by Paramount or any damage caused by improper handling, natural disasters, acts of God or servicing by non-Authorized Dealers. This includes but is not limited to the relocation of the product and the application of cleaning materials or lubricants not specified by Paramount.

• These products remain in possession of the original purchaser.

• Warranty claims are made within the warranty periods previously shown and that such claims occur within 30-days after the date of discovery.

• Labor coverage applies only within the United States and Canada.

• Warranties for parts and labor may vary outside the United States. Contact the Paramount Dealer within your geographic area for warranty terms.

THE OBLIGATION OF PARAMOUNT UNDER THIS WARRANTY IS LIMITED TO REPAIRING OR REPLACING WARRANTED DEFECTIVE

PARTS, AS PARAMOUNT MAY ELECT, AT PARAMOUNT'S PLANT IN LOS ANGELES, CALIFORNIA. PURCHASER IS RESPONSIBLE FOR

ALL TRANSPORTATION AND INSURANCE COSTS ON RETURNED OR REPLACED EQUIPMENT TO AND FROM PARAMOUNT'S PLANT IN

LOS ANGELES. ANY IMPLIED WARRANTY, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE AND THE IMPLIED WARRANTY OF MERCHANTABILITY, IS LIMITED TO ONE-YEAR DURATION FROM THE DATE

OF DELIVERY TO THE ORIGINAL PURCHASER. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. THE REMEDY OF REPAIR AND REPLACEMENT IS THE EXCLUSIVE AND

SOLE REMEDY OF THE PURCHASER.

PARAMOUNT SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, CONTINGENT OR CONSEQUENTIAL DAMAGES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, DAMAGE OF LOSS OF PROPERTY OR EQUIPMENT AND LOST PROFITS AND REVENUE. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. NO ACTION FOR BREACH OF THIS WRITTEN LIMITED WARRANTY OR AN

IMPLIED WARRANTY SHALL BE COMMENCED MORE THAN ONE YEAR AFTER THE ACCRUAL OF THE CAUSE OF ACTION. THIS

WRITTEN LIMITED WARRANTY IS THE COMPLETE, FINAL AND EXCLUSIVE AGREEMENT OF THE PARTIES WITH RESPECT TO THE

QUALITY OR PERFORMANCE OF THE GOODS AND ANY AND ALL WARRANTIES AND REPRESENTATIONS. NO MODIFICATIONS OF

THIS LIMITED WARRANTY OR WAIVER OF ITS TERMS SHALL BE BINDING ON EITHER PARTY UNLESS APPROVED IN WRITING BY AN

AUTHORIZED CORPORATE OFFICER OF PARAMOUNT. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY

ALSO HAVE OTHER RIGHTS, WHICH MAY VARY, FROM STATE TO STATE. CONTACT PARAMOUNT FITNESS CORP., 6450 E. BANDINI

BLVD., LOS ANGELES, CALIFORNIA 90040-3185, FOR A LIST OF AUTHORIZED DEALERS OR BEFORE RETURNING ANY DEFECTIVE

EQUIPMENT. PARAMOUNT FITNESS CORP. ©FEBRUARY 1, 2013.

27

N