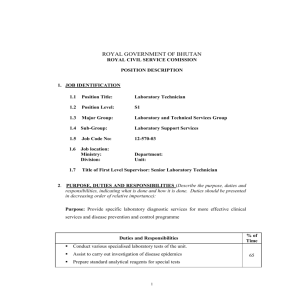

job description position summary position responsibilities/major duties

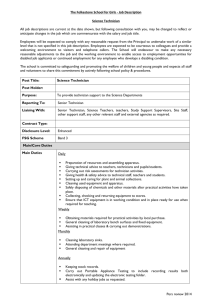

advertisement

__________________________________________________ JOB DESCRIPTION POSITION TITLE…………………………………..PRODUCTION TECHNICIAN MAJOR DEPARMENT…………………………….MANUFACTURING SUB-DEPARTMENT GROUP……………………..PRODUCTION REPORTS TO……………………………………….ROLL PRODUCTION SUPERVISOR POSITION SUMMARY The production technician is capable of contributing to all phases of the production process. Included is the operation of automated production equipment, primary diagnosis of machinery failures, aiding in preventative maintenance, and sanitation of all related equipment. Technicians are expected to be competent to make production decisions concerning the preflight and operation of the equipment. Technicians must be flexible and adaptable as they are required to rotate job assignments throughout production and engineering. In addition, it is the responsibility of the technician to contribute to the maintenance of a safe work environment for themselves and their fellow technicians. Position requires demonstration of competency for all on-the-job activities that may have a direct or indirect affect on product safety, legality and/or quality. POSITION RESPONSIBILITIES/MAJOR DUTIES Checks production work schedule for job assignments and work reporting times. ■ Position may be responsible for operating the facility metal detector(s). For this job responsibility, operator must be fully trained and certified When job assignment is: MIXER / DOUGH DIVIDER OPERATOR Responsibilities include, but are not limited to: ■ Checking production schedules and formulas. ■ Monitoring all sponge making equipment and areas. ■ Operating mixers and divider. ■ Operating dough pump / trough system. ■ Checking and maintaining posted temperatures and scale weights. ■ Operating rounder or rounder beds. ■ Performing start-up / shut-down sanitation and performs limited preventative maintenance. ■ Ensuring that work area is clean and organized at all times. ■ Performing other duties as directed by supervision. When job assignment is: PROOFER / OVEN / PAN OPERATOR Responsibilities include, but are not limited to: ■ Checking and maintaining all standards on related equipment. ■ Adjusting, starting, and operating all necessary equipment. ■ Monitoring seeder / splitter as required. ■ Removing stuck product from pans. ■ Positioning full truck to pan stacker and empty trucks to pan unstacker. ■ Grouping / parking pan trucks according to pan size. ■ Performing start-up / shut-down sanitation and performs limited preventative maintenance. ■ Ensuring that work areas are clean and organized at all times. ■ Performing other duties as directed by supervision. When job assignment is: WRAPPING AREA OPERATOR Responsibilities include, but are not limited to: ■ Checking production schedules for product running order. ■ Checking pan count sheets for product quantity. ■ Checking production wrap count sheet for bag types. ■ Setting and operating slicer, bagger, and tier equipment. ■ Performing quality control inspection of all finished product. ■ Ensuring that all product is loaded into proper containers. ■ Performing start-up / shut down sanitation and performs limited preventative maintenance. ■ Ensuring that work areas are clean and organized at all times. ■ Performing other duties as directed by supervision. Ensures compliance with all company policies and procedures (EEO, Sexual Harassment, Safety, Sarbanes Oxley, etc.) Performance of other duties which are deemed by management to be an integral part of the job, including but not limited to fulfillment of work schedules, adherence to attendance policies, and other applicable operating rules, policies and procedures ESSENTIAL JOB FUNCTIONS/REQUIREMENTS LICENSE- None required. MOBILITY- Ability to move to all production areas of plant. Physical ability to stand a minimum of eight hours to a maximum 16 hours on a daily basis. Ability to climb fixed and portable ladders to a height of ten (10) feet. Ability to stop and bend while lifting weights up to fifty (50) pounds. Ability to climb onto and crawl under machinery as required. SENSORY- Ability to view product at all work stations and determine adherence to quality control standards (size, shape, color, cut, etc.) Ability to distinguish color coded equipment, operating controls, labels, alarms, and signs. Ability to hear and distinguish audible alarms. Hearing, vision, and smell faculties sufficient to detect malfunctions in applicable equipment. COMMUNICATION- Must have ability to read and comprehend production schedules, formula sheets, etc. and record information applicable to position. OTHER- Must meet/maintain CDC food handling requirements and other governmental and/or customer requirements. Ability to read, comprehend and practice necessary safety procedures, signs, etc. Ability to wear and use approved, applicable safety equipment, as needed. Ability to research, ascertain, develop, implement, and monitor required policies and procedures. Ability to work in a 50 degrees F to 120 degrees F environment. DESIRED EXPERIENCE Two (2) or more years of related experience. DESIRED EDUCATION A two year technical degree or military experience. “Other Technical training” may include the completion of the AIB “Science of Baking” course.