48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition

4 - 7 January 2010, Orlando, Florida

AIAA 2010-1401

Dual-pump CARS Measurements in a Gas Turbine Combustor Facility using the

NASA 9-Point Lean Direct Injector

Mathew P. Thariyan1, Aizaz H. Bhuiyan2, Sameer V. Naik3,

Jay P. Gore4, and Robert P. Lucht5

Maurice J. Zucrow Laboratories, Purdue University, West Lafayette, IN 47906

ABSTRACT

Lean direct injection (LDI) has been among the several combustion strategies

being studied by NASA Glenn Research Center (GRC) to reduce oxides of nitrogen

(NOx) emissions while maintaining high combustion efficiency [1]. The NASA 9-point

top-hat LDI assembly is a multiplex fuel injector containing nine fuel injection tips and

multiple burning zones that replace one conventional fuel injector. The nine injectors are

placed in a 3 × 3 square matrix arrangement. We have developed a gas turbine

combustor facility (GTCF) at the High Pressure Laboratory in Purdue’s Zucrow

Laboratory complex. The GTCF has been modified for optical access and dual-pump

coherent anti-Stokes Raman scattering (DP-CARS) measurements have been performed

at supersonic cruise conditions.

A window assembly has been designed, fabricated, and assembled in the GTCF at

Purdue University for advanced laser diagnostic studies. The window assembly allows

optical access from three mutually perpendicular directions using a pair of thin and thick

fused silica windows on each side. The assembly is cooled using water while filmcooling air is provided for the inside of the thin windows. The thin windows are

designed for thermal load while the thick windows are designed for pressure loading.

Combusting flows are studied using the central injector of the aforementioned 9-point

lean direct injection (LDI) device. The combustor has been operated using Jet-A fuel at

inlet air temperatures up to 725 K and combustor pressures up to 10.2 atm. DP-CARS

temperature and major species concentration measurements have been performed in the

GTCF at various operating conditions. An injection-seeded optical parametric oscillator

(OPO) is used as a narrowband pump laser source so as to improve the accuracy and

precision of the CARS measurements. Spatial maps of temperature and major species

concentrations have been obtained in high-pressure LDI flames by translating the CARS

probe volume in axial and radial directions inside the combustor rig without loss of

optical alignment.

1

Graduate Research Assistant, Member AIAA

Graduate Research Assistant, Member AIAA

3

Senior Research Associate/Visiting Assistant Professor, Senior Member AIAA

4

Reilly Professor of Engineering, Fellow AIAA

5

Ralph and Bettye Bailey Professor of Combustion, Associate Fellow AIAA

2

1

Copyright © 2010 by the American Institute of Aeronautics and Astronautics, Inc. All rights reserved.

I. Introduction

A gas turbine combustion facility (GTCF) has been developed at the HighPressure Laboratory (HPL) in Purdue’s Zucrow Laboratory complex. The development

of the facility began under a collaborative project with Rolls Royce Corporation in

Indianapolis, Indiana, funded by the State of Indiana’s 21st Century program. In the

current work, we have performed dual-pump coherent anti-Stokes Raman scattering

(CARS) measurements in the GTCF at pressure up to 10.2 atm at inlet air temperature up

to 725 K. These recent activities are funded under a cooperative agreement with NASA

Glenn Research Center in Cleveland, Ohio.

A new laser system has been developed to measure temperature and species

concentrations using dual-pump N2-CO2 CARS [2]. An injection-seeded optical

parametric oscillator (OPO) is used as a narrowband pump laser source to improve the

accuracy and precision of dual-pump CARS measurements. For the CO2 molecule,

Raman transitions near 1300 cm-1 are excited by 532-nm pump beam and 607-nm Stokes

beam; while the probe beam at 560 nm is scattered from the induced polarization to

generate the CARS signal near 496 nm. For the N2 molecule, the pump and probe beams

are reversed with the CARS signal produced at the same wavelength. The second

harmonic output (~532 nm) from an injection-seeded Nd:YAG laser is used as one of the

narrowband pump beams. An OPO consisting of two nonlinear β-BBO crystals is

pumped using the third harmonic output (~355 nm) of the same Nd:YAG laser and

injection-seeded using an external cavity diode laser at an idler wavelength near 970 nm

to generate signal near 560 nm [3]. Output from a broadband dye laser (BBDL), pumped

using the second harmonic output of an unseeded Nd:YAG laser to generate radiation

centered near 607 nm (FWHM ~ 250 cm-1), is employed as the Stokes beam. This

system has been used for an extensive set of measurements of temperature and major

species concentrations at various axial and radial locations within the flame zone in the

GTCF.

II. Experimental Systems

Gas Turbine Combustion Facility (GTCF)

The gas turbine combustor facility (GTCF) at Purdue University, shown in Fig. 1,

has been built for conducting combustion tests at pressures higher than atmospheric

pressure using commercial and research injectors at various flight operating conditions.

A compressor system produces 137 atm air at a flow rate of 0.45 kg/sec. There are 56.6

actual cubic meters of air storage for 137 atm pressure. Heated high-pressure air is

introduced into the facility using remotely-actuated valves and regulators. A natural gasfired air heater with a maximum discharge temperature up to 750 K at 4 kg/sec and 48

atm is utilized for heating the inlet air. The inlet air mass flow rates are precisely

controlled and measured using dome-loaded pressure regulators and sonic orifices. After

flow straightening, inlet air enters the NASA top-hat LDI assembly where the flow

passage transitions from circular to square cross-section measuring 76.2 mm on each

side. The combustor window assembly (CWA) is installed downstream of the NASA

top-hat LDI assembly and has an internal square flow passage of side 76.2 mm each. The

LDI assembly protrudes into the CWA such that the injector exit aligns with the upstream

2

end of the UV fused silica windows used in the window assembly, thereby allowing

optical access to the entire combustion zone. The optical access is 63.5 mm (2.5 in.) in

the axial direction and 38.1 mm (1.5 in.) in the transverse direction with location of the

middle line fuel injectors coinciding with the center of the facility. This allows

visualization of the combustion process in the middle line of injectors and study of the

interaction between swirling streams from two sides. An annular effusion-cooled liner,

which utilizes a small percent of the relatively lower temperature upstream inlet air, is

installed downstream of the CWA. A water-quench section is installed downstream of

the liner, where the sampling of gases can be performed if necessary. A high-pressure

pump with a maximum capacity of 75 liters per minute at 31 atm is used to pump highpressure cooling water into the combustor. The water circulates through the quench

section and mixes with combustion exhaust products. A butterfly valve is used to control

the pressure inside the combustion chamber. The cooling water helps maintain the

temperature of the butterfly valve in its operating range.

Air is pre-heated to the burner inlet temperature (BIT) prescribed for a particular

operating conditions; the maximum value of BIT is 725 K. Two pressurizable fuel tanks

filled with Jet-A fuel are used to independently control the fuel flow rate into the

injectors. Control valves and flow meters are used to control and to record the fuel flow

in each fuel line to the combustor. An igniter system is installed on one of the faces of

the CWA using metal windows. The CWA is cooled using de-ionized water. During the

operation of GTCF, important parameters involved in the combustion process are

monitored real time. These include the air flow rate, fuel-air ratio, normalized pressure

drop across the injector, fuel injector face temperature, cooling water flow rate and

temperature, combustion exhaust temperature at the quench section, and temperature at

back-pressure control valve.

Combustor Window Assembly (CWA)

The CWA consists of six separate sub-sections: retainer section, upstream flange,

downstream flange, clamp section 1, clamp section 2, and thick window clamp. An

exploded view of the assembly is shown in Fig. 2. The window assembly is designed to

withstand pressures up to 14 atm (200 psia). The retainer section and the upstream and

downstream flange sections have an internal opening of 76.2 mm × 76.2 mm (3 in. × 3

in.) to match the flow passage of the 9-point injector. These three sections constitute a

sub-assembly termed hereafter as the “retainer sub-assembly”. The upstream and

downstream flanges are brazed onto the retainer section using AMS4777 Nickel braze

alloy. A combination of one thin window (6.4 mm thick) and one thick window (12.7

mm thick) is used on each face of the CWA so as to withstand the elevated pressure and

temperature conditions inside the combustor rig. The thin windows are placed on

grooves in the retainer section such that flow of gases inside the combustor rig is not

disturbed. Two pairs of clamping sections, namely clamp section 1 and clamp section 2,

attached onto the retainer section secure the thin windows while maintaining optical

access. The clamp sections contain grooves for placement of the thick windows. Thin

strips of Fiberfrax ceramic fiber papers (Thermal Products Company, Inc.) are used as a

shield between the thin window and the retainer section as well as the clamp sections.

The Fiberfrax paper contains aluminosilicate fibers and it does not seal against pressure.

3

The chamber between the thin and the thick window on each face is pressurized to the

combustor pressure by using a small fraction of the heated inlet air. As a result, there is

negligible pressure difference across the thin windows. This ensures that only the thick

windows withstand the entire pressure loading. On the other hand, most of the combustor

thermal loading is withstood by the thin windows owing to their proximity to the flame

zone. The thick windows experience a relatively smaller but constant thermal load

because the chamber between the thin and the thick windows is pressurized using

constant temperature heated inlet air.

Water cooling passages are machined internally to cool the retainer section using

de-ionized water. Water cooling manifolds are machined on the faces of the upstream

and downstream flanges. The upstream flange has another manifold for cooling air. The

retainer section has corresponding passages for cooling air. These three sections, viz., the

upstream flange, the retainer section, and the downstream flange are brazed together

ensuring that air and water cooling lines are independent of each other. Cooling air lines

are designed to use a small quantity of the inlet air to film-cool the inside faces of the thin

windows. The air passage slots are at an angle of 15º with respect to the bulk air flow

direction, as seen in Fig. 3, which shows axial and radial cut-outs of the CWA. Thin

windows are 6.25 mm (0.25 in.) thick and made out of fused silica. The edges of the thin

windows are chamfered at 45º with a total viewing area 63.5 mm (2.5 in.) long and 38.1

mm (1.5 in.) high. The retainer section has complementary grooves for the windows.

Three thin windows are installed on three faces of the retainer section while the fourth

face consists of a metal window machined to incorporate an igniter. Four clamping

sections are assembled outside the retainer sub-assembly. The four outer faces of the

retainer section have grooves machined on the surface to incorporate metal O-rings to

ensure sealing when in contact with the clamping sections. The clamping sections also

have internal passages machined for water cooling. Each clamping section has one

groove for a thicker window. The thick windows are 12.7 mm (0.5 in.) thick and also

made out of fused silica. The thicker windows are constrained using four small outer

clamps. Graphite gaskets are used on both sides of the thick windows to ensure sealing.

De-ionized water at 5 atm (75 psia) inlet pressure is used to cool both the retainer subassembly and the four clamping sections.

NASA 9-point Top Hat LDI Assembly

Lean-direct injection (LDI) is one of the several combustion concepts being

studied by NASA Glenn Research Center (GRC) to reduce NOx emissions while

maintaining high combustion efficiency. LDI assemblies have been utilized to develop a

broad measurement database for characterizing phenomena such as fuel vaporization and

turbulent mixing during combustion. The 9-point top-hat LDI assembly is a multiplex

fuel injector containing nine fuel injection tips and multiple lean burning zones to replace

one conventional fuel-injector. The nine injectors are placed in a 3 × 3 square matrix

arrangement as shown in Fig. 4. The square flow passage, 76.2 mm long on each side,

has three injectors on each side. Each LDI element contains axial swirlers with helical

vanes at 60º which generate swirling air that passes through a converging- diverging

venturi section. A set of nine simplex fuel injectors, assembled in a 3 × 3 square

configuration, is inserted through the center of the swirlers so that fuel injection tips are

4

at the throats of venturi sections. Fuel mixes rapidly with the heated inlet air; thereby,

shortening the distance required for complete combustion. Flame stabilization process is

aided by the formation of a central toroidal recirculation zone for each injector in the

axial direction, as validated by computations for this geometry [4]. The “top-hat” prefix

refers to the injector exit face protruding out as a 76.2 mm × 76.2 mm square section as

compared to older versions of the assembly where the injector exit plane was coincident

with the rest of the injector housing. The LDI assembly allows for various fuel-staging

possibilities. In this study, only the central fuel injector was operated for swirler vane

angles of 60°.

Dual-Pump CARS System

A laser system, comprised of two narrowband pump beams and a broadband Stokes

beam, was developed to measure temperature and species concentrations using dualpump coherent anti-Stokes Raman scattering. A diagram showing the generation of the

three laser beams required for the dual-pump CARS process is shown in Fig. 5. An

injection-seeded, Q-switched Nd:YAG laser (SpectraPhysics Model Pro 290-10) having a

repetition rate of 10 Hz and a pulse width of approximately 8 ns (FWHM) was used to

produce one of the pump beams in the CARS process and to pump the optical parametric

process. The Nd:YAG laser is equipped with active feedback control systems to obtain

excellent pointing stability (BeamLok) and minimum divergence (D-Lok) of the output

laser beams. The second harmonic output of the Nd:YAG laser at 532 nm was passed

through the combination of a half-wave plate and a Glan polarizer to provide variable

power attenuation of the output beam during alignment and measurements. The 532-nm

pump beam was directed through a delay line so that it arrived at the probe volume

coincident in time with the remaining two beams. Approximately 175 mJ of the 532-nm

output from the same Nd:YAG laser is used to pump a broadband dye laser.

An optical parametric oscillator (OPO) was employed to produce the second

pump beam [5]. The OPO consisted of a pair of co-rotating beta barium borate (β-BBO)

crystals, with two flat mirrors on either side of the crystals to form a feedback cavity.

The β-BBO crystals were cut at 30° to the optical axis and were supplied by Fujian

Casix. The face of each crystal has cross sectional dimensions of 8 mm × 10 mm. The

crystals were 12 mm long and were coated with MgF2 protective coating. These crystals

were pumped using the 100 mJ/pulse of the third harmonic output at 355 nm from the

above-mentioned injection-seeded Nd:YAG laser.

One of the flat mirrors had nearly 100% reflectivity at the signal wavelength, but

low reflectivity at the pump and idler (seed) wavelengths. The other flat mirror with a

reflectivity of 70% was used as the output coupler. The optical parametric process was

initiated using a continuous wave (cw) external cavity diode laser (ECDL) (Toptica DL100) at the idler wavelength of 970 nm. The ECDL produced 100 mW of singlelongitudinal-mode output and its wavelength was adjusted by manually rotating the

diffraction grating to achieve coarse tuning or by varying both the diode temperature and

current using a diode laser controller (TuiOptics Series DC 100). The angles of the βBBO crystals were adjusted to obtain the signal. Type 1 phase matching was for the

optical parametric process, with the pump beam horizontally polarized and the idler and

5

signal beams vertically polarized. 100 mJ/pulse of 355 nm pump radiation and 20.5 mW

of ECDL radiation at 970 nm were incident on the first β-BBO crystal. The OPO signal

intensity can increase by a factor of at least 50 times when it is injection-seeded [2]. Two

Faraday isolators, with a total attenuation of 60-dB, were used to prevent any back

reflection into the ECDL that could cause instability in the diode laser. The 560-nm

output signal beam was separated from the residual 355 nm pump beam using a dichroic

mirror and a polarizer. The output signal from the OPO was amplified using a pulsed dye

amplifier (PDA) consisting of a dye cell filled with 25 mg Rhodamine 590 in 750 ml of

methanol. The dye cell was pumped by the second harmonic output (~532 nm) of an

unseeded Nd:YAG laser (Quanta-Ray GCR4). A lens-aperture combination was used to

reduce the undesirable amplified stimulated emission (ASE) produced in the PDA. The

560-nm signal beam from the OPO was directed through the dye cell and the temporal

overlap of the 532-nm pump and signal beam in the dye cell was maintained using a

delay generator (Berkeley Nucleonic Corporation Model 55) which adjusted the Q-switch

delay between the OPO pump and PDA pump lasers. The dye cell was tilted at

Brewster’s angle to allow maximum transmission of the signal beam. The optical details

regarding the OPO are shown in Figure 6.

A broadband dye laser (BBDL) was pumped using 175 mJ/pulse of the second

harmonic output (~532 nm) of the aforementioned injection-seeded Nd:YAG laser so as

to produce the Stokes beam required in the CARS process. 25 mg of Rhodamine 640 dye

in 750 ml of methanol was used to produce laser radiation with a center wavelength near

607 nm (ωs = 16474 cm-1) and linewidth of approximately 250 cm-1 FWHM. Two flat

mirrors, coated at 600 nm, with 100% and 30% reflectivity were used at the front and

back of the oscillator cavity, respectively. The 30% reflectivity mirror with a wedged,

uncoated glass flat acted as the output coupler. The Stokes beam was directed through a

delay line so that it arrived at the probe volume coincident in time with the two pump

beams. All laser beams were generated in an air-conditioned laboratory adjacent to the

GTCF. The three CARS beams were directed towards the GTCF through long tubes.

The two pump beams and the Stokes beam, arranged in a folded BOXCARS

configuration, were passed through prisms fixed to high-precision mounts so as to allow

fine tuning of their spatial overlap in the probe volume inside the windowed-combustor.

The beams were passed through 2 in. prisms mounted on horizontal and vertical

translation stages in order to facilitate traversing of the probe volume inside the

combustor. The timing of the three beams at the probe volume was checked in a

“reference leg” (described later) using a fast photodiode and an oscilloscope to ensure

that all beams arrived within 1 ns of each other. The three beams were focused inside the

combustor using a plano-convex lens having a focal length of 180 mm. The energies of

the 532-nm, 560-nm, and the Stokes beam were nominally 20 mJ/pulse. The three beams

and the CARS signal were re-collimated using another 180 mm plano-convex lens. The

input beams were separated using prisms and beam dumps. The CARS signal was

focused onto an adjustable entrance slit of a 0.5-meter spectrometer using a spherical

convex lens having 200 mm focal length. The entrance slit was typically adjusted to a

width of 400 µm, eliminating most of the residual scatter due to the pump and Stokes

lasers. The re-collimating lens and the mirrors for guiding the signal beam into the

spectrometer were mounted on another pair of translation stages to keep the signal beam

focused on the spectrometer slit when translating the probe volume inside the combustor.

6

A Macor aperture was placed after the re-collimating lens to reduce flame emission. A

mechanical shutter (Uniblitz LS-6, Vincent Associates) and an interference filter having

50% transmission near the CARS signal wavelength were incorporated in the beam path

to minimize the interference from flame emission and to block any scattered light.

A “reference leg” of optics was assembled close to the main chain of optics leg in

the dual-pump CARS system. This leg could be activated, when needed, by moving a 2

in. prism mounted on a translation stage in or out of the path of CARS beams after the

beams pass through prisms mounted on the high-resolution mounts, as seen in Figure 7.

In the “reference leg”, the three beams were first focused using a plano-convex lens

having a focal length of 200 mm and then through a combination of thin and thick

windows arranged so as to replicate the actual probe volume inside of the combustor.

This was necessary in order to ascertain the maximum beam energies that the thin

window could endure without cracking. The distance traveled by the three beams up to

the probe volume in both legs was kept approximately the same. The three beams and

the CARS signal generated in the reference leg were re-collimated using another 200 mm

focal length plano-convex lens. The CARS input beams were separated using prisms and

beam dumps. The CARS signal was passed through an adjustable mirror mounted on a

translation stage to focus onto the entrance slit of the aforementioned spectrometer using

a spherical convex lens having 200 mm focal length. The CARS beams were passed

through either one of the legs by translating the 2 in. prism in the path of the CARS input

beams side and by moving the adjustable mirror in the path of the CARS collection

optics. This arrangement ensured that changes in the relative beam positioning in the

reference leg affected that in the main leg directly because the relative positioning of the

CARS beams in the main optics leg could not be optimized once they passed the high

resolution prisms.

The biggest advantage of setting up the reference leg of optics was the ability to

measure non-resonant signal to account for the spectral intensity variation of the BBDL.

The non-resonant signal was recorded by flowing pure argon gas through a tube placed

such that it surrounded the three CARS beams in the probe volume of the reference leg.

This eliminated the need for any special arrangement to measure the non-resonant signal

inside the combustor rig. Furthermore, the CARS signal could be optimized in the

reference leg before acquiring data in the main leg. In case of any misalignment during

combustion tests, the CARS signal could be re-optimized easily using the reference leg.

A pin-hole aperture is usually positioned at the CARS probe volume to ensure that all

beams are focused onto a spot. Such a pin-hole aperture cannot be implemented inside

the windowed-combustor; however, doing so in the reference leg was relatively

straightforward for the initial alignment to acquire CARS signal.

The optical grating of the spectrometer had 1200 grooves/mm. Two camera

lenses were used at the exit slit of the spectrometer so as to image the CARS signal onto

an unintensified CCD camera. A 28-mm focal length, f/2.8 Nikon camera lens and a 70210 mm adjustable focal length, f/4.5-f/5.6 Nikon telephoto lens were used to increase

the system dispersion. An Andor back-illuminated, unintensified CCD camera (Andor

MCD DU-440) with a 2048 × 512 pixel array was used to detect the CARS signals. The

spectral dispersion of the CARS signal was 0.25 cm−1/pixel and the resolution of the

CARS detection system was approximately 0.8 cm−1. The frequency separation of the

7

two CARS signals was adjusted so that the spectral features for N2 and CO2 molecules

did not overlap, allowing the CARS spectra to be imaged onto the CCD camera with the

highest possible resolution. The CARS signal from the reference optics leg was at a

slightly different location on the CCD detector as compared to signal from the main

optics leg signal. As a result, the non-resonant CARS signal from reference leg was

shifted so that its spectral peak matched that of the N2 spectra recorded in the combustor.

III. Data Analysis and Experimental Results

Combustion tests were conducted on the GTCF in a single-point injection mode,

with fuel supplied only to the central injector. For ignition, inlet air temperature was

maintained between 645-670 K (700-750ºF) at a combustor pressure of 4 atm (60 psia)

and a normalized pressure drop of 3 % across the LDI injector. The air flow rate was

approximately 0.21 kg/s (0.46 lbm/s) and the equivalence ratio was approximately 3.5 for

the central injector (0.39 overall). Flames were stabilized at combustor pressures of 5.4,

6.8, 8.5, and 10.2 atm (80, 100, 125, and 150 psia) at equivalence ratios ranging from 0.4

to 1.2, while maintaining normalized pressure drop across the injector at a value of 4 %.

Table 1 indicates flow conditions for operation of the GTCF, at which dual-pump CARS

measurements were performed.

High quality optical mounts were used for stable operation of the optical

arrangement near the combustor during the operation of the GTCF. In order to minimize

misalignment of the optics around the combustor while operating for long test durations,

metal plates were placed on both sides of the combustor. This helped in shielding the

optics from the radiation heat load of the combustor, especially under fuel-rich operating

conditions. The CARS probe volume was traversed inside the combustor in order to

perform measurements at different axial and radial locations within the swirl-stabilized

flame. The CARS probe volume measured approximately 500 µm along the beam

propagation direction and approximately 50 µm in the perpendicular direction.

Measurements were performed from 10 mm to 50 mm downstream of the injector in the

axial direction in steps of 5 mm. In the radial direction, measurements were performed

along the injector centerline and at 3, 6, 9, and 11 mm off the centerline on both sides.

All measurements were obtained in the central plane perpendicular to the beam

propagation direction. In this way, a complete map of temperature and species

concentrations downstream of the injector could be obtained.

Figure 8 shows a typical dual-pump CARS spectrum obtained at 6 mm away from

the injector centerline, 50 mm downstream of the injector for a combustor pressure of 6.8

atm (100 psia), local equivalence ratio of 0.8, and burner inlet temperature of 725 K

(850ºF). It shows the N2 and the CO2 spectral features. A set of 1000 to 2000 such

spectra were acquired at a frequency of 5 Hz at various measurement locations.

Background-corrected CARS spectra were normalized using non-resonant spectrum

obtained by flowing pure argon gas in the reference leg to account for the spectral

variations in the broadband dye laser. For all measurements, the raw spectral data was

filtered to reject either the spectra having low signal levels or those having spectral

interferences from liquid fuel droplets. CARS signals displaying spectral interferences

from liquid droplets showed a markedly different structure compared to normal CARS

signals. Such spectra could be identified by comparing the average background signal

8

count on each side of the N2 CARS signal. In order to reject spectra with low signal

level, average signal count over an 80 cm-1 spectral range that included the nitrogen part

of dual-pump CARS signal was compared to the average background signal level. Only

those spectra with high enough average CARS signal counts were further analyzed. The

square-root of the background corrected dual-pump CARS signal normalized by the nonresonant argon signal was compared with theoretical CARS spectra calculated using the

Sandia-CARSFT code [6]. The CARSFT code was used in the batch mode so as to

determine temperature and CO2/N2 concentration ratio for each spectrum. The N2 part of

the spectrum was analyzed first to obtain temperature for each spectrum. The CO2

concentration was then determined by fixing the temperature at the value obtained by

analyzing the N2 part of the spectrum.

Figure 9 shows the probability density function (PDF) of temperature distribution

at the injector centerline at 10 mm downstream of the injector for a combustor pressure of

7.04 atm (104 psia), and burner inlet temperature of 725 K (850ºF) and local equivalence

ratio of 0.4. The temperature PDF shows a mean of 2020 K and standard deviation of

370 K at the measurement location. A complete map of the temperature field can help

ascertain location of high temperature zones and of recirculation zones which influence

the NOX formation. Probability density functions for CO2/N2 concentration ratios are

being evaluated by analyzing the CO2 part of the dual-pump CARS spectra and fixing the

temperature for each spectrum. Figure 10 displays the radial variation of mean

temperature and temperature standard deviation at different axial locations downstream

of the injector for combustor pressure of 7.04 atm (104 psia), burner inlet temperature of

725 K (850ºF), and equivalence ratio of 0.4. At 10 mm downstream of the injector (Z =

10 mm), the mean temperature decreases by 250 K from R = 9 mm to R = 11 mm, while

the standard deviation in temperature distribution increases by more than 100 K. This

indicates increased mixing of the flame with relatively low temperature inlet air at R = 11

mm as compared to R = 9 mm. The average flame location and perturbation can be

estimated from studying the temperature field and its standard deviation. At Z = 20 mm,

the radial decrease in temperature is lower than that at 10 mm while moving away from

the injector centerline, while the temperature profile is almost flat at 45 mm. The higher

value of centerline temperature standard deviation at Z = 10 mm indicates potential

recirculation zones along the injector centerline close to that axial location. The

temperature standard deviation decreases further downstream from the injector. The

radial temperature standard deviation profiles are flatter for Z = 20 and Z = 45 mm as

compared to Z = 10 mm indicating a constant level of temperature fluctuations from the

mean values for the downstream locations.

Figure 11 compares the variation of axial mean centerline temperature and radial

mean temperature with respect to pressure at 20 mm downstream from the injector. The

combustor was operated for pressures of 7.0 atm (104 psia), 8.5 atm (125 psia), and 10.2

atm (150 psia) and an inlet air temperature of 725 K (850ºF) for an equivalence ratio of

0.4. The axial temperature profile indicates a consistently higher centerline temperature

for combustor pressure of 104 psia as compared to 125 psia and 150 psia. This would

manifest directly in an increased NOx potential at the lower combustor pressure. The

radial temperature profile at Z = 20 mm for combustor pressure of 150 psia indicates a

lower centerline temperature as compared to that at R = 3mm. However, similar profiles

for 100 and 125 psia indicate continuously decreasing temperature profiles in the radial

9

direction. This suggests different characteristics of the central torroidal recirculation

zone at different pressures. By comparing radial temperature profiles at Z = 10 mm for

combustor pressure of 104 psia (Fig. 10 (a)) and that at Z = 20 mm for a combustor

pressure 125 psia (Fig. 11 (b)), it can be argued that the flame cone angle reduces when

the combustor pressure increases from 104 psia to 125 psia. The overall spatial

temperature maps can thus be extremely helpful in understanding the complete flame

structure for various combustor pressures and equivalence ratios.

IV. Conclusions and Future Work

Temperature and species concentrations have been measured by performing dualpump N2-CO2 coherent anti-Stokes Raman scattering in combusting flows using the

center injector of a 9-point lean direct injection (LDI) device developed at NASA Glenn

Research Center. In order to facilitate these measurements, a windowed-gas turbine

combustor facility (GTCF) has been built and successfully operated at inlet air

temperatures up to 725 K (850ºF) and combustor pressure up to 10.2 atm. (150 psia).

The facility includes a stainless steel window assembly that allows optical access from

three sides with a pair of thin and thick windows on each side. For the DP-CARS

measurements, an injection-seeded optical parametric oscillator (OPO) was used as a

narrowband pump laser source so as to improve the accuracy and precision of the CARS

measurements. In order to obtain the spatial maps of temperature and CO2/N2

concentration ratio, the CARS probe volume has been successfully traversed in axial and

radial directions inside the combustor rig while maintaining the optical alignment at such

harsh conditions. A “reference leg” of optics that could split off from the path of the

CARS beams was employed to enable straight-forward measurement of non-resonant

signal away from the combustor and to allow relatively easy alignment of the CARS

system. Temperature probability density functions have been obtained for measurement

locations inside the flamezone by analyzing the single-shot CARS spectra. Such

measurements will be helpful for validation of CFD code development activities at

NASA Glenn along with providing an insight into the flame structure at various

combustor pressures and equivalence ratios.

Acknowledgements

Funding for this work was provided by NASA Glenn Research Center under

Cooperative Agreement Number NNX07AC90A. The technical monitor of the project is

Dr. Yolanda Hicks. We wish to thank Dr. Hicks and Drs. Clarence Chang and Randy

Locke at NASA Glenn for numerous helpful suggestions concerning the design and

fabrication of the GTCF, and for the loan of the 9-point LDI device and other equipment.

We thank Vijaykumar Ananthanarayanan for his help with the design of the window

assembly, and Dr. Ning Chai with the help while conducting experiments. We thank Dr.

Ju Chin at Rolls Royce Corporation in Indianapolis, Indiana for helpful technical

discussions during the window assembly design. We would like to sincerely thank Toby

Lamb at the Purdue University Central Machine Shop for valuable discussions during the

design of the window assembly and for fabricating the window assembly.

10

References

1) Tacina, K. M., Lee, C. M., and Wey, C., “NASA Glenn High-Pressure Low-NOx

Emissions Research,” NASA Technical Memorandum, 2008-214974, 2008.

2) Lucht, R. P., Velur, V. N., Carter, C. D., Grinstead, Jr., K. D., Gord, J. R.,

Danehy, P. M., Fiechtner, G. J., and Farrow, R. L., “Measurements of

Temperature and CO2 Concentration by Dual-Pump Coherent Anti-Stokes Raman

Scattering,” AIAA Journal, Vol.41, No.4, 2003, pp. 679-686.

3) Kulatilaka, W.D., Anderson, T.N., Bougher, T.L., Lucht, R.P., “Development of

Injection-Seeded, Pulsed Optical Parametric Generator/Oscillator Systems for

High-Resolution Spectroscopy,” Applied Physics B, Vol. 80, No. 6, 2005, pp.

669-680.

4) Davoudzadeh F, Liu N-S, Moder J P 2006 Investigation of swirling air flows

generated by axial swirlers in a flame tube ASME Turbo Expo 2006: Power for

Land, Sea, and Air, Barcelona, Spain GT-2006-91300.

5) Thariyan M. P., Ananthanarayanan V., Bhuiyan A. H., Naik S. V., Gore J. P.,

Lucht R. P., “Dual-pump CARS Temperature and Major Species Concentration

Measurements in Counter-Flow Methane Flames Using Narrowband Pump and

Broadband Stokes Lasers,” Combust. Flame In review.

6) R. E. Palmer, “The CARSFT Computer Code for Calculating Coherent AntiStokes Raman Spectra: User and Programmer Information,” Sandia National

Laboratories, Report No. SAND89-8206, Livermore, CA, 1989.

11

Table 1: Operating conditions for the Purdue GTCF at burner inlet temperature of

725 K (850ºF).

Combustor

Pressure

(atm)

Normalized

Injector

Pressure Drop

(%)

Air Flow

Rate

(kg/s)

Fuel Flow Rate

(kg/hr)

Central Injector

Equivalence Ratio

5.5

6.8

6.8

6.8

7.0

7.0

8.5

10.2

3

3

4

4

4

4

4

4

0.34

0.36

0.40

0.40

0.42

0.42

0.52

0.61

9.4

10.0

13.3

8.8

6.7

4.5

5.6

6.6

1.00

1.00

1.20

0.80

0.59

0.40

0.40

0.40

12

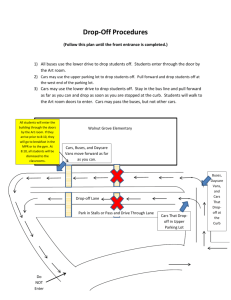

Figure 1: A photograph of the Purdue gas turbine combustor facility (GTCF).

I

C

G

H

B

D

J

A

F

E

Figure 2: Exploded view of the combustor window assembly (CWA) showing (A)

retainer section, (B) downstream flange, (C) upstream flange, (D) clamping section

1, (E) clamping section 2, (F) outer clamp, (G) cooling water manifold, (H) filmcooling air manifold, (I) thick window groove, and (J) thin window groove.

13

Figure 3: Schematic of the axial and radial cut-outs of the combustor window

assembly.

Figure 4: NASA 9-point top-hat LDI assembly.

14

To Purdue GTCF

607 nm

BBDL

PDA 2

0° Mirror

355 nm

970 nm

BS

PDA 1

0° Mirror

ECDL

BS

BS

532 nm

Seeded Nd:YAG

560 nm

OPO

Figure 5: Schematic diagram showing the generation of laser beams required in the

dual-pump CARS process using an injection-seeded Nd:YAG laser and an injectionseeded OPO for the two pump beams, and a BBDL for the Stokes beam.

BD: Beam Dump

CM: Curved Mirror

ECDL: External Cavity Diode Laser

λ/2: Half-wave-plate

M: Mirror

MA: Makor Aperture

OC: Output Coupler

OPO: Optical Parametric Oscillator

PDA: Pulsed Dye Amplifier

Pol: Polarizer

T: Telescope

CC: Concave lens

Pol. λ/2

355nm

M

To PDA

MA

OC

970 nm

T

560 nm

ECDL

BD

Seeded Nd:YAG

Faraday

Isolator

M

CC

β-BBO Crystals

CM

BD

OPO Cavity

Figure 6: Experimental system to produce single-longitudinal-mode laser radiation

near 560 nm using an optical parametric oscillator.

15

A: Aperture

BD: Beam Dump

CL: Camera Lens

IF: Interference

Filter

L: Lens

λ /2: Half-waveplate

Pol: Polarizer

S: Shutter

TS: Translation

Stage

ZL: Zoom Lens

Window

608 nm

Assembly

Entrance

Translation

Stages

Exit

Translation

Stages

L4

BD

BD

BD

L5

Flow

L3

Probe

Volume

561 nm 532 nm

λ/2

Pol.

Main Leg

S

A

Pol.

Reference Leg

λ/2

S

SPEX

CL

λ/2

Pol.

IF

TS

S

ZL

TS

496 nm

BD

A

BD

BD

L2

Probe

Volume

L1

Figure 7: Optical arrangement near the GTCF for performing the dual-pump

CARS measurements.

16

(CARS Intensity)1/2 (arb. units)

65

55

45

N2

Data

Theory

Residual

T = 1535 K

CO2/N2 = 0.0742

35

25

15

CO2

CO2

5

-5

-15

1300

1320

1340

1360

1380

1400

1420

-1

Raman Shift (cm )

Figure 8: Comparison between experimental and theoretical dual-pump CARS

spectra measured 6 mm away from centerline, 50 mm downstream of the injector.

The combustor was operated at a pressure of 6.8 atm (100 psia), an inlet air

temperature of 725 K (850ºF) for an equivalence ratio of 0.8.

Temperature PDF: Z = 10 mm, R = 0 mm

100

Mean Temp. = 2020 K

Std. Dev. = 370 K

Counts

80

60

40

20

0

1000

1500

2000

2500

3000

Temperature (K)

Figure 9: Temperature histogram determined from dual-pump CARS

measurements at the injector centerline, 10 mm downstream of the injector. The

combustor was operated at a pressure of 7.0 atm (104 psia), an inlet air temperature

of 725 K (850ºF) for an equivalence ratio of 0.4.

17

2200

(a)

Z = 10 mm

Z = 20 mm

Z = 45 mm

Temperature (K)

2000

1800

1600

1400

1200

0

2

4

6

8

10

12

Radial Distance (mm)

700

Temperature (K)

Z =10 mm

Z = 20 mm

Z = 45 mm

(b)

600

500

400

300

200

100

0

0

2

4

6

8

10

12

Radial Distance (mm)

Figure 10: Radial variation of (a) mean temperature and (b) standard deviation in

temperature for various axial locations downstream of the injector. The combustor

was operated at pressure of 7.0 atm (104 psia), and an inlet air temperature of 725 K

(850ºF) for an equivalence ratio of 0.4.

18

(a)

Temperature (K)

2000

104 psi

125 psi

150 psi

1800

1600

1400

1200

0

10

20

30

40

50

Axial Distance, R (mm)

1700

(b)

104 psi

125 psi

150 psi

Temperature (K)

1600

1500

1400

1300

1200

0

2

4

6

8

10

12

Radial Distance, R (mm)

Figure 11: Variation of (a) axial centerline mean temperature, and (b) radial mean

temperature at 20 mm downstream of the injector. The combustor was operated at

pressure of 7.0 atm (104 psia), 8.5 atm (125 psia), and 10.2 atm (150 psia) and an

inlet air temperature of 725 K (850 ºF) for an equivalence ratio of 0.4.

19