Process Costing

advertisement

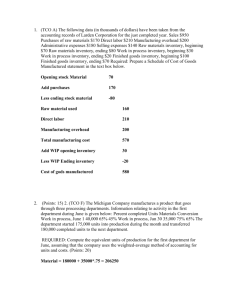

Process Costing When is process costing appropriate? How does it differ from Job Order Costing In some sense, Job Order Costing is focused on output measures and Process Costing is focused on input measures. Homogeneity or similarity of costs across batches To visualize it: think of batches of inseparable products such as petrol, flour, paper. It could be computers, though. Even though they are separately identifiable, for the most part the costs are homogenous (the same). Example 1 Moravia Company process and packages cream cheese. The following data have been compiled for the month of April. Conversion activity occurs uniformly throughout the production process. Work in Process April 1 – 10,000 units Direct material: 100% complete, with a cost of $22,000 Conversion costs: 20% complete, with a cost of $4,500 100,000 units were started during April and 80,000 were completed. Work in Process April 30 – 30,000 units Direct material: 100% complete, with a cost of ?????? Conversion costs: 33% (1/3) complete, with a cost of ?????? Costs incurred during April: Direct materials costs of $198,000 and conversion costs of $158,400 were incurred during April. What is the cost of goods transferred out and the cost of goods in ending inventory (the question marks above)? (Note: there are two approaches, Weighted Average and FIFO – we will only look at weighted average unless we get really bored) First, we look at total units. I like to get a thorough understanding of units. I do this by figuring out what the number of units started and completed this period were: Here is a helpful tool: Every unit that we worked on at all this period was either in beginning inventory or we started it this period. Conversely, every unit that we worked on was either finished or it is in ending inventory. These two must be equal. BI 10,000 EI 30,000 + Units started 100,000 +Units completed 80,000 TOTAL 110,000 TOTAL 110,000 So, there are 100,000 units started, 30,000 of them are not completed. 70,000 units must, therefore have been started and completed this period. In addition, 80,000 units were completed this period, but 10,000 of them were started in the previous period (they were in beginning inventory). Hence there were 70,000 units started and completed this period. This equality follows directly from the previous one above. We now introduce the concept of an equivalent unit. This is why I say we are costing inputs here. We will figure out how much a unit of input (materials or conversion) costs and then use that to allocate costs to Finished Goods Inventory and Work-In-Process. Instead of doing 20% of the conversion work on all 10,000 units that are in beginning inventory, we could have focused our efforts and actually completed 2,000 of the units (and not started the others at all). In that sense, we did work equivalent to 2,000 units worth. For direct materials, we had put 100% of the materials for the 10,000 units into process at the beginning of the process (this is common, you frequently start with all of the materials in process as you start a batch). No materials were added during the period for these 10,000 units. On the other hand, we started 100,000 units this period and we added ALL of the materials that go with those 100,000 units (how do I know that?). In beginning inventory, we had 10,000 units worth of materials inputs, but only 2,000 (equivalent) units worth of conversion inputs. Those will be our equivalent units in beginning inventory. Now that we understand how equivalent units work, lets see how we use them. What we really want is a cost number for an equivalent unit of material and an equivalent unit of conversion. We will be able to use them like we used the cost estimates in the Peterson’s Catering Company problems (2, 3, and 4 from yesterday). We will multiply these unit costs by the number of equivalent units in ending inventory (of materials – and of labor – separately) to get the cost of ending inventory. We will also do the same thing with goods transferred to FGI (Finished Goods Inventory). We are going to average unit costs over both periods (last period and this period). The total costs incurred over the two periods are given below: Beginning Inventory costs Costs incurred THIS period Total Direct Materials Conversion Total $ 22,000 $ 4,500 $ 26,500 198,000 158,400 356,400 $ 220,000 $ 162,900 $ 382,900 These costs correspond to the following equivalent units: Units Completed Equivalent Units in EI Total 1. 2. Direct Materials 80,000 30,000 110,000 Conversion 80,000 10,000 90,000 Why did we add Units Completed to Equivalent Units in EI (Ending Inventory)? Where did the 10,000 Equivalent Units of Conversion come from? Let’s answer the second question first – it’s easiest. There were 30,000 units in EI and they were 100% complete in terms of the materials. In other words, all of the materials had been put into process for those units. But only 1/3 (33%) of the conversion work had been done. So 1/3 of 30,000 total units is 10,000 equivalent units. Now, let us answer the harder question. The costs above are the costs in beginning inventory plus the costs incurred during April. The first thing we did during April was finish the beginning inventory units. Then we started some units – some of which we finished and some we did not. The costs incurred this period went to 3 things: finishing beginning inventory, starting and finishing some units (70,000), and starting the ending inventory units. Add these costs to beginning inventory costs and you have the costs of the units completed (Beginning Inventory + Cost to complete + Cost of units started and completed this period) AND the costs of EI. Did that answer it – or is it still a circle? The cost of an equivalent unit are computed below. This computation is obvious: Costs Equivalent Units Cost per Equiv. Unit Direct Materials $ 220,000 $ 110,000 $ 2.00 Conversion 162,900 90,000 $ 1.81 To compute the cost of goods transferred out, we take the number of units transferred out (notice that they are all COMPLETE) and multiply by the total Cost per Equivalent Unit = $3.81. This gives us 80,000 * $3.81 = $304,800. The cost of goods in Ending Inventory is computed below: Equivalent Units in EI Cost per Equiv. Unit Cost Direct Materials 30,000 $ 2.00 $ Conversion 10,000 1.81 $ 18,100.00 60,000.00 $ Total $ 78,100.00 Notice that if you add the $78,100 to the $304,800, you get the total costs of $382,900. Example 2 Frito-Lay, Inc., manufactures convenience foods, including potato chips and corn chips. Production of corn chips occurs in four departments: cleaning, mixing, cooking, and drying and packaging. Consider the Drying and Packaging Department, where direct materials (packaging) are added at the end of the process. Conversion costs are added evenly during the process. Suppose the accounting records of a Frito-Lay plant provided the following information for corn chips in its Drying and Packaging Department during a weekly period: Beginning work in processa Transferred-in during the week from Cooking Department Completed during the week Ending work in processb Costs added during the week a Physical Units (Cases) 1,250 5,000 Transferred -In Costs $29,000 Direct Materials Conversion Costs $0 $9,060 $25,200 $38,400 5,250 1,000 $96,000 Degree of completion: transferred-in costs, 100%; direct materials, ?%; conversion costs, 80%. b Degree of completion: transferred-in costs, 100%; direct materials, ?%; conversion costs, 40%. Requirements: Compute the cost of goods completed and transferred out using the Weighted-Average method of process costing.