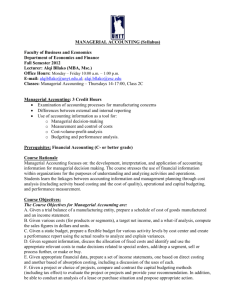

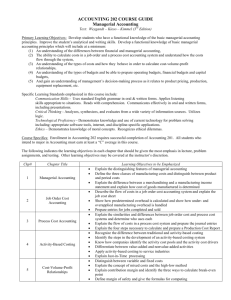

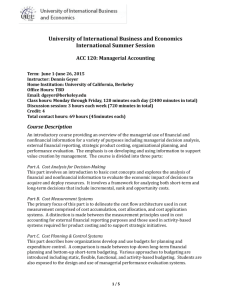

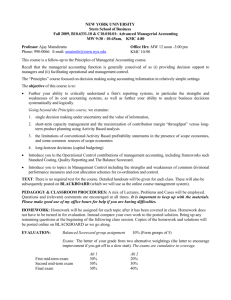

Conceptual Framework for Managerial Costing

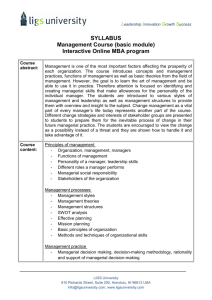

advertisement