LSK - Documents & Reports

advertisement

Public Disclosure Authorized

I~~~~~~~~~Vt

s 4"l

RESTRICTED

LSK

,_

l

ReportNo.

PI-8

Public Disclosure Authorized

This report was prepared for use within the Bank and its affiliated organizations.

They do not accept responsibilityfor its accuracy or completeness,The report may

not be published nor may it be quoted as representing their views.

INTERNATIONAL BANK FOR RECONSTRUCTION AND DEVELOPMENT

Public Disclosure Authorized

INTERNATIONAL DEVELOPMENT ASSOCIATION

APPRAISAL

OF

THE COCHIN II FERTILIZER

THE FERTILISERS

AND CHEMICALS,

Public Disclosure Authorized

INDIA

May 14, 1971

Industrial

Projects

Department

PROJECT

TRAVANCORE

LIMITED

Currency

Equivalents

$0.133

Rs 7.5

1 Rupee (Rs)

1 U.S. Dollar ($)

Rs 1,000,000

'

$133,000

Weights and Measures

All weights

and measures

are

1 metric ton

1 metric ton

1 kilometer

(km)

Principal

GOI, Government

FACT

FEDO

UDL

PCI

UWNDP

TPY

TPD

CIF

expressed

=

-

Abbreviations

in metric

units:

1,000 kilograms

2,205 pounds

0.62 miles

(kg)

and Acronyms Used

The Central Government of India

The Fertilisersand Chemicals,TravancoreLtd.

FACT Engineering

and Design Organisation

Udyogamandal Division of FACT

Fertilizer

Corporation

of India

United Nations DevelopmentProgramme

Metric Tons Per Year

Metric Tons Per Day

Cost, Insurance and Freight

N, P, and K are used throughout

nutrients:

the report

to refer

N = Nitrogen Content

P = P2 05 or PhosphateContent

K = K2 0 or PotashContent

Fiscal Year

April

1 - March 31

to the fertilizer

TABLE OF CONTENTS

Page No.

SUMMARY AND CONCLUSIONS .............................

..............................

I.

INTRODUCTION ..........

II.

FACT'S EXISTING OPERATIONS ..........................

A.

B.

C.

III.

PROPOSED COCHIN II PROJECT ..........................

A.

B.

IV.

V.

2

2

2

3

5

........................... 5

Project Scope .......

............ 5

Project Description and Ecology ....

6

A.

B.

C.

6

7

7

Capital Costs .....................

Working Capital ................................

Financial Plan .................................

PROJECT EXECUTION

.............................

Project Management .............................

Project Schedule and Procurement ...............

Allocation of IDA Credit .......................

MARKET AND MARKETING .......

A.

B.

C.

D.

E.

F.

G.

VII.

1

PROJECT COSTS AND FINANCIAL PLAN ...............

A.

B.

C.

VI.

History and Organization .................

.........................

FACT Management .......

......

Financial Analysis of Existing Operations

i

8

9

10

......................... 11

................ 11

Present Situation in India .....

12

.................

Market Forecast for India .....

........... 13

Fertilizer Market in South India ....

15

....

....

FACT Marketing Area and Handling System

16

............................

NPK Seeding Program

16

...................

Sales Prices and Competition

17

Agricultural Credit ............................

OPERATING COSTS

A.

B.

8

.....................................

Raw Material Costs .............................

Production Costs ...............................

This report has been prepared by Messrs. Donald E. Browni

and Anthony R. Perram of the Industrial Projects Department based on missions to India in December 1970 and

February/March 1971.

18

18

19

Table

of Contents

VIII.

(Continued)

FINANCIAL AND ECONOMIC ANALYSIS OF THE PROJECT

20

A.

B.

C.

20

Financial Analysis and Sensitivity Tests

Economic Analysis .21

Imported Vs. Manufactured Phosphoric Acid

IX.

FUTURE PROFITABILITY AND FINANCIAL POSITION ON FACT .

X.

RECOMMENDATIONS .24

ANNEXES

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

MAP

-

Page No.

Description of FACT's Existing Operations

FACT Historical Income Statements

FACT Historical Balance Sheets

Product Schedule and Sales Price - Cochin II Project

Technical Description - Cochin II Project

Summary of Capital Costs - Cochin II Project

Working Capital Requirements - Cochin II Project

Forecast of Nitrogen Production - India

Forecast of P2 0 5 Production - India

Fertilizer Market - Demand Forecast for South India

Fertilizer Market - Supply Forecast for South India

Annual Cost of Production - Cochin II Project

Forecasted Income Statement - Cochin II Project

Sensitivity Analysis and Major Assumptions

Project Breakeven Analysis

Annual Foreign Exchange Savings

FACT Income Statement Forecasts

FACT Source and Application of Funds Forecast

FACT Long-Term Debt Service Coverage Forecasts

FACT Balance Sheet Forecasts

Present and Proposed Major Fertilizer Plants

in South India.

22

22

SUW4ARYAND CONCLUSIONS

This report appraises a proposed major expansion of the producI.

tion facilities of The Fertilisers and Chemicals, Travancore Ltd., (FACT),

a public sector company in the State of Kerala, India. The Government

of India (GOI) owns 81% of the company. Fertilizer production is a major

part of India's efforts to improve agricultural output. This project,

which will have a design capacity of 485,000 tons per year of granulated

nitrogenous, phosphatic and potash (14PK)fertilizers, would make a significant contribution towards rmeeting India's increasing fertilizer requirements. A small by-product plant for 7,500 tons per year of cryolite which

is used in aluminum manufacture is also included.

Total financing required for the project is estimated at $50.7

ii.

million (Rs 380 million), of which $19.6 million is in foreign exchange.

GOT will provide the financing with at least half in equity and with the

balance in loan. The proposed IDA credit of $20 million (Rs 150 million)

will be relent by the Government as part of its loan. The loan to FACT

will be at 3.5% interest per annum with a maturity schedule that includes

three years of grace and ten equal annual repayments for each wiclhdrawal

from GOI by FACT. Based on expected withdrawals the maximum life of the

loan will be 16 years.

FACT's existing plants are small, in part obsolete and have

iii.

encountered operating difficulties which have adversely affected the

company's financial position. Followin,grecommendations of a 1969 IDA

mission the company prepared a rationalization program which is now being

implemented. The December 1970 appraisal mission reviewed this program

and the Association is satisfied that FACT, with the help of some

experienced consultants, is capable of improving existing operations,

completing and operating a new urea plant (Cochin I) now under construction and of executing the proposed NPK project. To carry out such ambitious investments and to adjust its debt service to realistic expectations

of cash generation, the company's financial position will be improved by

increasing equity and rescheduling existing debt.

The managing contractor for the project will be FACT E.ngineering

iv.

and D)esignf)rganisation (FEDO), a division of FACT, withimajor portions

subcontracted to other engineering firms and local contractors. The

project is based on conventional technology within the experience and

capability of FEDO which has designed and constructed similar plants although not of the same magnitude. To assist with the project, the company

has selected several international engineering firms as process subcontractors who will supply the necessary technical support.

CGovernment-owned fertilizer plants in India have experienced

v.

substantial delays in construction and start-up difficulties and on the

utilizaof capacity

whlole have not yet been able to reach normal levels

-

tion.

Various factors

control of the plants

if

-

have been responsible

for tlhis, niot all within

concerned.

1lowever, GOI has become increasingly

the

aware of the high cost of construction delays and undertutilizedplant.

It has agreed that for the planned project the construction scheduile

should not be more than 33 months. It is therefore expecte(dthat tlle

project will be completed by March 1974.

vi.

Procedures for the procurement of foreign and domestic equipment have been agreed with FACT and GOI. The Government has indicated

that it will reserve about 12% of the value of equipment and materials

for Indian suppliers. These items are expected to be procured within the

requirements of time and quality imposed by the project. All other equipment will be bid competitively by international tender with assurances

given by GOI that all import licenses required will be promptly issued.

Any reserved Indian equipment which is delayed and might endanger timely

completion of the project will be promptly secured from other sources.

The proceeds of the proposed IDA credit would be used for internationally bid equipment, imported materials for equipment on the "reserved

list", costs of foreign process licenses, plant designs and consultant

services as well as a portion of the local costs of FEDO's engineering

and equipment erection costs.

vii.

Projections of Indian fertilizer demand and supply indicate

that, even on optimistic estimates of local production, India will have an

annual production shortfall through this decade of around 900,000 tons

of nitrogen and 800,000 tons of phosphates. The foreign exchange required

to import the tonnages required is substantial and emphasizes the hiigh

priority of the proposed project, which will save India approximately

$16 million per year in foreign exchange.

viii.

In FACT's marketing region in South India, projections of

fertilizer demand and supply show nitrogen in balance in the latter half

of the decade and a continuing shortfall in phosphatic fertilizer supply

of around 150,000 tons per year (in terms of nutrients). Since the

project's output will be NPK fertilizers with a high nutrient content and

ease of application, no sales difficulties are expected. FACT's marketing organization will be strengthened by adding more distribution points

and, on the basis of the company's successful marketing experience in the

past, it should be able to handle the increased volume satisfactorily.

Moreover, FACT will carry out a large seeding program for NPK to assure

the successful introduction of its new products. The effectiveness of

the company's marketing efforts will depend heavily on the availability

of agricultural credit. The Government has assured IDA that FACT will

have a suitable level of working capital to cover normal company operations and to finance required credit to the extent not available from the

banking system.

-

iii

-

ix.

The project provides a suitableeconomicreturn of 13.5%, which

indicates that productioncosts of the project are competitiveinternationally. Profitabilityof the project is satisfactory,with an indicated

financial return of 19.5%. The project is highly sensitive to relative

changes in selling and raw materialprices and to any delay in completion

of the project.

x.

There have been no previous IDA credits or Bank loans to the

Government-ownedfertilizerindustryof India. IFC has participated

in two private sector fertilizerprojects, (IndianExplosives,Ltd., in

Uttar Pradesh and Zuari Agro Chemicals,Ltd., in Goa) and is considering

a third. Indian Explosivesis successfullyin operationand Zuari Agro

is anticipatedto start productionin mid-1972. IDA is also considering

several other fertilizerprojectswith the GOI-ownedFertilizerCorporation of India (FCI), the largest fertilizercompany in India with five

existingplants and three presently under construction. In addition,

the Bank is ExecutingAgency for a UNDP-financedphosphatemining project

study in Rajasthan.

xi.

Based on the assurancesreceived during negotiations,the project

is suitable for an IDA credit of $20 million.

I. INTRODUCTION

The Governmentof India (GOI) has requested financing from the

1.01

InternationalDevelopmentAssociation (IDA) for a major expansion of

fertilizerproduction facilitiesof The Fertilisersand Chemicals,Travancore Limited (FACT),which are located near Cochin port in Southiwest

India. This expansion,designatedas the Cochin II Project, would add

about 115,000metric tons per year (TPY) phosphates (as P2 05); 54,000 TPY

potash (as K20); and 47,000 TPY nitrogen (as N) capacity to FACT's present

capability. The increased productionwill be high nutrient content, granulated NPK 1/ fertilizersto meet the increasingdemand in South India

and will permit FACT to market more balanced and competitivegrades of

fertilizersthan their present products. The plant will produce six different grades with an average NPK analysis of 19-23-11.

FACT has been producing fertilizersin Kerala State since 1948

1.02

and markets its own production,as well as fertilizerfrom the Government

FertilizerPool, in the states of Kerala, Tamil Nadu, Mysore, Andhra Pradesh and the Union Territoriesof Goa and Pondicherry. FACT's existing

factories are in Udyogamandalnear Cochin port (see Map). A major ammoniaurea factory (Cochin I) located about 20 km from Udyogamandalis expected

to begin operations in mid-1971 and the proposed expansion would be adjacent to it. Both factoriesare served by major highway routes and are

located adjacent to commercialwaterways. Cochin has railroad facilities

at its factory and Udyogamandalhas railroad stationsnearby.

The proposednew project was originallyconceivedby FACT as an

1.03

elementalphosphorusproject. An IDA mission studied this proposal in mid1969 and recommendedthat FACT should consider a more economic route for

obtaining phosphoricacid, either by import or manufacturefrom sulfur

and phosphate rock. IDA also recommendedthat FACT review its existing

facilitiesand devise a scheme for increasingperformance. FACT has responded to both recommendationsand submitted a project feasibilityreport

to IDA in October, 1970. An appraisal mission visited FACT in December

1970 to assess the proposed project and a program to rationalize existing

operations.

The Cochin II Project will produce sulfuric acid, phosphoric

1.04

acid, granularNPK fertilizers,as well as cryolitewhich is used in the

productionof aluminum. The design is based on imported sulfur, ammonia,

phosphate rock and potash; plus urea from the Cochin I plant. The!

project includesnecessary port facilities to handle the large quantities

of raw materials and all requiredoffaites.

1/

The nomenclatureused to describe multi-nutrientfertilizersis N-P-K,

referring respectivelyto the % Nitrogen (N), % P2 05 (P), and % K20

(K). Thus 28-28-0 contains 28% nitrogen, 28% P2 05 and no potash;

17-17-17contains 17% of each nutrient. The term phosphate is used in

all cases to refer to the P2 05 content.

-2-

FACT is presently in financial difficulty due to poor operating

1.05

performance at Udyogamandal and a 1-1/2 year delay in completing the

Cochin I ammonia-urea project. Due to losses in recent years, FACT has not

been able to meet portions of its maturing debts to GOT and negotiations

are now being completed between GOT and FACT to restructure the company's

debt.

The appraisal report was prepared by Messrs. Donald E. Brown

1.06

and Anthony R. Perram of the Industrial Projects Department, based on

missions to India in December 1970 and February/March 1971.

II.

A.

FACT's EXISTING OPERATIONS

History and Organization

2.01

FACT was incorporated iln 1943 as a private company with the

Government of the State of Travancore (now part of Kerala) having a substantial holding. The company's management was taken over in 1960 by

the Government of Kerala, by then the major shareholder. GOI, which

subsequently acquired the majority shares, has managed the company since

1963. GOI presently owns about 81% of FACT with the State Governments of

Kerala, Tamil Nadu, PHysoreand Andhra Pradesh holding about 15% of the

shares and the remaining 4% is held by about 5,500 private shareholders.

FACT began operations as a small producer of single super phos2.02

phate and since then has completed several expansion projects. FACT

presently produces and markets ammonium phosphate, ammonium sulfate,

mixed NPK products, and in 1971, will add urea production. The company's

present capacity is about 7% of the total fertilizer capacity in India.

With the Cochin Division the proportion will increase to about 12%.

2.03

FACT has five operating divisions which report to the Managing

Director: (1) Udyogamandal (UDL), which operates the existing plants;

(2) Cochin, which will operate the ammonia/urea plant now under construction and the Cochin II plant when it is completed; (3) FACT Engineering

and Design Organisation (FEDO), the planning and engineering arm of FACT;

(4) FACT Engineering Works (FEW), a small equipment ranufacturer; and (5)

Marketing, which handles all ferti:Lizersales. These divisions are further described in Chapter VI and in Annex 1.

B.

FACT Management

FACT has a 12-member Board of Directors of which eight are chosen

2.04

by GOI, two by Kerala, and two by private shareholders. The Board meets

about seven times a year to review operations and decide on major investments, budget and policy issues. The Board has delegated considerable authority to the Managing Director, who is a Board member chosen by GOI. He

acts as principal liaison with the shareholders and directs day to day

operations assisted by the Finance Manager, who functions as his deputy.

-32.05

FACT's overall managementcapabilitywas assessedby IDA in July

and August 1969, includinga report by P. A. ManagementConsultants,Limited, of London. The major problems found then were: (1) managementinformation, such as production,marketing,and financial reportswere not complete nor prepared on time; (2) the UDL division had excessivestaff, with

poorly defined lob specifications;and (3) maintenancewas not properly

scheduled. Some improvementhas occurredbut the basic problems still

exist.

2.06

The Managing Directorhas recentlybeen transferredand a new Managing Directorhas been appointedwho appears to be capable and is satisfactory to the Association.

The Cochin II Project

Manager has had production

and engineering

experience

and appears to be capable.

The appointment

of

highly competent people to the senior managementpositions (three key personnel have been lost recentlyby death or transfer)and continuityof management are particularlyimportant to the company and the execution of the

project since the company is not deep in managementpersonnel.

2.07

The company recognizesthat cost accountingand reportingneed improvement. Reasons given for the unsatisfactoryreportingwere union problems within the accountingdepartment,installationof a new computer system, and concentrationon improving productionrates. However, the speed

with which informationrequestedwas produced,was impressiveas was the

amount of detail provided. The company intends to introducemonthly production cost data for each individualproductionunit, improve quarterly fi-.

nancial statementsand budget goals for future operations,using realistic

production targets to stimulate improvementsin operations. FACT has given

assurances to IDA that its cost accountingand managementinformationsystem will be satisfactoryby January 1972.

C.

Financial Analysis of Existing Operations

2.08

Historicalincome statementsfor the fiscal years (FY) 1966

through 1971 are contained in Annex 2 and are summarizedbelow.

Summary Income Statements

(millionof Rs)

Total

1966-

Fiscal Years

FY66

FY67

Net Sales (from operations)

Operating Costs

25

31

Operating Profit (Loss)

Non-OperatingIncome

Gross Profit (Loss)

Interest

Taxes

FY68

FY69

57

51

77

73

119

116

(6)

2

6

5

4

2

3

7

(16)

3

(3) (12)

2

21

(4)

3

11

7

6

6

10

7

(13)

6

(1)

9

_

Net Income (Loss)

*Preliminaryfigures

__

(7)

4

FY70

118

134

___

-__

3

FY71* 1971

133

136

529

541

9

38

-__

(19)

(10

(9)

-4FACT's earnings

record has been unsatisfactory

over the past years.

Increasing sales and stable selling

prices since 1968 have been offset

by low

operating

performance and higher operating

costs, particularly

labor.

These

problems were quite evident in 1970. Net losses over the six-yea?r period

total Rs 29 million or about 5.5% of net sales from operations.

The corn-pany expects that fiscal

1971 will show a loss although the exact result

will depend upon decisions

to *bemade regarding

deferred

expenses for rmarket

development.

Historical

2.09

below.

balance

sheets

are shown in Annex 3 and are summarIzed

Summary Balance Sheets

(millionof Rs)

Fiscal

Years

Assets

Current Assets

Net Fixed Assets

Other Assets

Total Assets

Liabilities

and Capital

Current Liabilities

Long-Term Debt

Equity:

Share Capital

Reserves & Surplus

Total

Total

Equity

Liabilities

Current Assets/Current

Long Term Debt/Equity

*Preliminary

& Capital

Liabilities

FY66

FY67

FY68

FY69

FY70

54

172

4

98

207

4

177

257

4

232

499

10

216

598

12

189

684

16

230

309

438

741

826

889

59

100

75

(4)

109

124

75

1

166

197

75

-

205

392

141

3

277

391

174

(16)

318

371

226

(26)

71

76

75

144

158

200

230

309

438

741

826

889

.9:1

58/42

.9:1

62/38

1.1:1

72/28

1.1:1

73/27

.8:1

71/29

.6:1

65/35

FY71*

figures

2.10

Recent losses and delays in the completion

of the Cochin I Project

have prevented

FACT from paying its maturing debt to GOI. By March 31,

1971 this unpaid debt had accrued to Rs 81 million including

Rs 21 million

interest

which is now being renegotiated.

Payments on outstanding

loans

to the Industrial

Finance Corporation

of India and on the Italian

credits

for Cochin I have been paid on schedule.

GOI has been supplying

funds to

FACT, particularly

for the Cochin I project,

in the form of two-thirds

debt and one-third

equity.

The combination

of high debt and losses has

made the company financially

weak and has required increased

short-term

borrowings which have been difficult

to obtain.

The company now has a

negative working capital

position

and high debt service requirements

which

will be eased by the rescheduling

of the GOI loans and the provision

of

additional

funds by GOI if required

(para. 4.08).

III.

A.

PROPOSED COCHIN II PROJECT

Project Scope

3.01

The proposed expansion (Cochin II) has a design capacity of

435,000 TPY of granulated, high analysis NPK fertilizers and 7,500 TPY

cryolite. The grades, production schedule and ex-factory sales prices

for the NPK products and cryolite are shown in Annex 4. NPK production

is based on imported phosphate rock, potash, sulfur and ammonia and

includes manufacture of sulfuric and phosphoric acid as intermediate

products. Urea will be obtained from Cochin I. The major plants will

be based on licensed designs from contractors that have been selected by

FACT. The project also includes the necessary facilities at Cochin port,

about 15 km away.

B.

Project Description and Ecology

3.02

The phosphoric acid plant will have a design capacity of 115,000

TPY P205. FACT has a licensing agreement with The Engineering and Industrial Corporation of Luxembourg (Prayon) for phosphoric acid design knowhow. The process represents conventional and commercial technology, and

Prayon and FACT both have considerable experience in design and operation

of these plants.

3.03

The sulfuric acid (H2SO4 ) plant is a 330,000 TPY unit based

on elemental sulfur. The process and size represent commercial and conventional technology and FACT's licensor, Chemiebau, Dr. A. Zieren GmbH

& Company KG (Chemiebau), of Germany has adequate experience, including

designs of up to 264,000 TPY sulfuric acid.

3.04

The NPK plant will have a design capacity of 485,000 TPY NPK

based on technology from Wellman-Power Gas Inc., of the U.S. Their

granulation experience includes about 20 commercial plants including

Coromandel in India.

3.05

The cryolite plant will produce 7,500 TPY and is based on a

similar plant that FACT now has under construction.

3.06

Port facilities and other offsites represent a major portion of

the project. The Cochin Port Trust has agreed to provide a wharf and a

mooring berth exclusively for FACT. GOI and FACT have agreed to provide

the necessary assurances from the Cochin Port Trust as a condition of

effectiveness of the IDA credit. FEDO's design of the port, transportation and site facilities was reviewed with FEDO's engineering staff and

is considered adequate.

3.07

A phosphate fertilizer complex such as the Cochin II project

discharges several streams that are potential pollution hazards. The

effluents are fluorine and sulfur compounds that may be discharged to

- 6the atmosphere, fluorine compounds that may be discharged in liquid

wastes, and a solid material (gypsum) that is stored. FEDO has designed

the project to control these effluents within normal practice in the

industry. The cryolite plant offers the advantage of recovering fluorine

from phosphoric acid manufacture and decreases a potential pollution

problem.

A more complete technical description of the project, including

3.08

pollution control is given in Annex 5.

IV.

A.

Capital

PROJECT COSTS AND FINANCIAL PLAN

Costs

is Rs 380

for the project

required

financing

estimated

The total

4.01

during

construction.

which includes

interest

million

(US$50.7 million)

These costs

are summarized below and further details are given in Annex 6.

Summary of Project Costs

(in millions)

Indian Rupees

Total

Lcocal Foreign

Local

U.S. Dollars

Foreign

Total

510.3

20.2

39.4

68.3

8.8

-

79.7

9.9

0.5

3.9

130.0

20.2

49.3

68.3

9.3

3.9

6.7

2.7

5.3

9.1

1.2

-

10.6

1.3

0.1

0.5

17.3

2.7

6.6

9.1

1.3

0.5

Sub-Total

Working Capital

Contingency

187.0

12.0

13.0

94.0

38.0

15.0

281.0

50.0

28.0

25.0

1.6

1.7

12.5

5.1

2.0

37.5

6.7

3.7

Total Project Costs

Interest during Construction

212.0

21.0

147.0

-

359.0

21.0

28.3

2.8

19.6

-

47.9

2.8

Total Financing Required

233.0

147.0

380.0

31.1

19.6

50.7

Freight

Equipment,

Materials,

Duty, Sales Tax

Design, Erection

Civil Works, Land, Offices

Pre-Operating Expenses

Technical Assistance

The foreign exchange portion of capital costs, including working

4.02

capital, is estimated at $19.6 million. The foreign exchange costs are

based on 12% of total equipment beLng reserved for Indian procurement and

the expectation

that approximately 40% of the internationally bid equipmnent will be won by Indian suppliers.

4.03

The above costs represent:preliminary estimates based on the

escalation.

project beginning in mid-1971 and iincludeadequate price

Costs have been conservativelystated and the contingency,representing

10% of the direct project costs, should be sufficient.

B.

Working Capital

4.04

Total working capital requirementsfor the project at an annual

productionrate of 436,500 tons (90% of capacity)are estimatedat Rs 209

million ($28 million) as shown in Annex 7. The above figure is based on

four months accounts receivable,three months raw material storage (except

urea and ammonia) and two months product storage. The initialworking

capital is assumed at Rs 50 million ($6.7 million) of which the foreign

exchange componentis $5.1 million.

C.

Financial Plan

4.05

The Rs 380 million financingneeded for the project will be

providedby the Government,with at least half (Rs 190 million) in the

form of equity and the balance as loan. The proceedsof the proposed

IDA credit of Rs 150 million ($20 million)would be relent by the

Governmentas part of its loan under a subsidiaryloan agreement.

4.06

The interestrate for the subsidiaryloan agreed to in negotiations is 8.5% per annum. GOI's normal policy is to approve the funds

for the entire project and then disbursethem to the recipient in quarterly

installments,each of which constitutesa separate loan. Each disbursement has a three-yeargrace and a ten-yearrepaymentperiod. Since the

final disbursementis expected to be made in the fourth year after start

of constructionthe last maturitywould be in the sixteenth year of the

project. The financialforecasts in the annexes correspondto this

maturity schedule. Since the loan from GOI to FACT is wholly a rupee

loan, the exchangerisk remains with the Government.

4.07

The followingtable gives a summary of the total estimated

sources and applicationof funds for FACT as a whole during implementation of the project (Refer to Chapter IX).

Summary of Source and Applicationof Funds

during Project Implementation1971/1974

(millionsof rupees)

Sources

Long-TermDebt

Equity

Cash Generation- UDL/CochinI

Short-TermFunds

Total

Application

190

213*

380

60

843

*IncludingRs 23 million for Cochin I.

Cochin II Project

UDL and Cochin I

Debt Service

Total

380

199

264

843

- 8 -

4.08

The forecastedcash generationis based on UDL operating at

improved levels and Cochin I achieving its expected production. GOI and

FACT are currently renegotiatingthe company's debt. It is expected that

the actual amount of reschedulingwill be Rs 85 million with repayment beginning in FY 1972 and ending five years thereafter. Completionof the

arrangementsfor the debt reschedulingwill be a conditionof effectiveness

of the proposed credit. Although IDA anticipates that further rescheduling

may be necessary for some arnounts;

due towards the end of FY 1972, the Association has agreed to this scheme because (a) negotiationsfor the rescheduling are virtually completedand (b) the Governmenthas agreed to keep

the company in a liquid position during constructionwith a current ratio

of at least 1.5:1 being obtained at the start of commercialproduction.

4.09

To protect against an overrun in project costs (includingCochin

I) or shortfall in cash generation,GOI has agreed to provide funds necessary to complete the project and put FACT in a sound financial position

including adequateworking capital. To this end the Governmentwill put a

minimum of 50% of the funds representingCochin I and Cochin II investments

in the form of equity by completionof Cochin II. GOI also agreed to set

a goal of a long-term debt/equityratio of not greater than 55/45 for the

company after Cochin II begins commercialoperation. The Association's

projectionsshow that at the time Cochin II starts up, FACT should be in

a sound financialposition (a long-term debt/equityratio of about 50/50

and a current ratio of about 1.5:1).

V.

A.

PROJECT EXECUTION

Project Management

5.01

FEDO will act as managing contractorfor the Cochin II project.

IDA's evaluationof FEDO as an engineeringcompany, is given in Annex 1.

In view of the overall size and complexityof Cochin II, FACT has agreed

to employ an experiencedAssistant Project Manager plus one experienced

Engineer to assist FEDO in budget and schedule control and in general engineering,procurement,and constructionduties. The Assistant Project

Manager will remain until completionof the project and the Engineer is

expected to stay 2-3 years.

5.02

Tn addition, FACT will use selectedprocess licensors in design,

equipment selection,constructionand start-up. The extent of such assistance by the licensors (beyond their initial process package) is expected to

be as follows:

-9-

Man Months

Sulfuric Acid (Chemiebau)

PhosphoricAcid (Prayon)

NPK (Wellman-Power Gas)

8-12

12-18

60-80

The assistanceis primarily aimed at adding depth and experienceto the

FEDO organizationto ensure the success of Cochin II. FEDO has already

establishedcontinuingassociationswith Chemiebau and Prayon for sulfuric

and phosphoricacid designs, respectively,and has recently concluded a

contractwith Wellman-PowerGas for the NPK plant. FACT is now completing

final agreementswith Chemiebau and Prayon and arranging for the engineering personnel described above. IDA has reviewed these agreementsin draft

form and found them acceptable. Their satisfactoryconclusionis a condition of effectivenessof the proposed credit.

To avoid FEDO's overextendingits management and engineering

5.03

staff capacity during project execution,FEDO will not accept any engineering contractsin excess of Rs 1,500,000 ($200,000)each without first

consultingwith IDA until engineering for Cochin II is substantially

completed. FACT has agreed not to undertake any other major capital investment program in excess of Rs 7,500,000 ($1,000,000)per year without IDA's

consent.

B.

Project Schedule and Procurement

on

for the project

path schedule

FEDO has updated its critical

5.04

the basis of a completiontime of 33 months. For appraisal purposes, project constructionhas been assumed as 36 months, but a concerted effort will

be made to realize the 33-monthschedule. The shorter schedule is largely

dependent on efficient implementationof procurement. GOI has expressed

a strong desire to minimize project execution time and has agreed to the

33-monthschedule as the governing criterion to which all its and the company's actions will be geared and has modified its procurementpolicy with

this objective in mind.

The Governmentagreed that the equipment and materials reserved

5.05

for procurement from Indian supplierswill be limited to about 12% of the

total estimated equipment value. IDA is satisfied that the "reserved list"

includes only those items that do not have critical delivery time and can be

supplied from Indian firms in adequate quality. If it should become evident

affect

that delivery of any equipment on the reserved list would adversely

the project's criticalpath schedule, then the Governmentwill permit such

items to be shifted promptly to internationalor other procurementsources.

-

10

-

All other equipmentwill be bid by internationalcompetitive

5.06

tender, including India. Indian suppliers will be given a 15% cost preference in bid evaluationscompared against the CIF India price of competitive equipmentbids. GOI has given assurance that after FEDO has completed

its bid analysis and decided the procurementsource, any required import

licenseswill be issued promptly.

In collaborationwith the process licensors,FEDO will prepare

5.07

suitablebid packageswhich will permit qualified Indian suppliers to compete on the smaller of the packages but still maintain project schedule

and equipmentstandardizationrequirements.

The proposed IDA credit will include an estimated $0.5 million

5.08

of foreign exchangecosts for the import of materials and componentsto

be used by Indian suppliers for items on the "reserved list". While to

the extent practical these imports will be subjected to international

shopping, their speed of procurementwill be the governing factors. FEDO

will coordinatethe import of such materials and components.

C.

Allocationof IDA Credit

The proceeds

5.09

(see Annex 6):

of the proposed

IDA credit

would be used as follows

Use of IDA Credit

$ Million

1.

2.

3.

4.

5.

Equipment

Equipment (for foreign components

of "reserved list")

and Equipment Erection

Engineering

Licensors

(a)

(b) FEDO

TechnicalAssistance

Unallocated

Total

15.2

0.5

1.3

0.5

0.5

2.0

20.0

The allocationof IDA funds to the above categoriesis approximateat this

time and may have to be revised somewhatwhen FEDO has completedits detailed

engineeringwork. The credit will cover the CIF cost of imported equipment

and the ex-factoryprice (excludingtaxes) of locally procuredequipment

that is internationallybid. As mentioned before, the credit will also

include the CIF cost of imported foreign componentsof locally procured

equipmenton the "reservedlist", and the foreign exchange costs of process

licensesand consultants'services. A portion of FEDO's local costs for

engineeringand equipment erectionis also included. The estimated foreign

-

11

-

exchange content of the proposed credit is about $15 million, which assumes

that 30% of the internationally bid equipment is won by Indian suppliers

(para. 4.02). The projected disbursement schedule for the IDA credit is

contained in Annex 6.

VI.

A.

MARKET AND MARKETING

Present Situation in India

6.01

A major goal of Indian economic development is self-sufficiency

in agriculture, including fertilizer production. However, India currently

imports about half of the required fertilizer nutrients as finished products and as intermediate raw materials. Nitrogen, the major fertilizer

nutrient, is produced in India primarily as ammonia and urea with most

manufacture based on naphtha from imported petroleum feedstocks. Current

plans propose increasing reliance on fuel oil and indigenous coal as raw

materials to produce nitrogen fertilizer. India permits some ammonia

imports, but imposes a 60 percent duty on the CIF price. Use of imported

ammonia may increase as a result of recent trade agreements between India

and Iran.

6.02

Virtually no phosphate material is produced in India. While

feasibility studies are about to start (financed by UNDP with the Bank

as Executing Agency) to develop promising phosphate rock deposits in

Rajasthan these deposits are not likely in the near future to produce

enough rock to make India self-sufficient. India imports large amounts

of phosphate rock and, in recent years, the Government has granted permission for three companies 1/ to also import phosphoric acid. Potash,

or potassium chloride, is not produced locally; so all requirements are

imported, either as potash or in a finished NPK product.

Fertilizer consumption and production for the period 1964-1970

6.03

are shown below based on data from the Fertilizer Association of India,

the Ministry of Food and Agriculture and IDA.

1/

Madras, Zuari Agro, and Indian Farmers Fertilizer Cooperative

(IFFCO).

- 12

-

FertilizerConsumptionand Productionin India

(thousandsof tons)

Nitrogen (N)

Phosphate (P205)

Apparent

Apparent

ConsumptionProductionImports ConsumptionProduction Imports

FY

FY

FY

FY

FY

FY

65

66

67

68

69

70

580

530

660

920

1,200

1,450

240

240

310

400

560

720

340

290

350

520

640

730

160

160

200

290

410

560

130

120

150

210

210

220

30

40

50

80

200

340

6.04

Consumptionof nitrogen increasedduring the six-year period at

an average annual rate of about 20%. Local productionrose even more

quickly (about 28% per year) but was not able to catch up with demand.

Phosphate consumption increased

at about 28% annually and here too production was unable to meet demand. Low production levels (about 60% of

capacity) in existing plants have contributedto these deficits. Furthermore, while a more normal ratio between nitrogen and phosphate should be

approximately2:1, the actual ratio in India in 1969/70was about 3.3:1.

Consumptionof phosphate fertilizerthereforehas lagged substantially

behind that of nitrogenous fertilizer.Foreign exchange expendituresfor

imports of nitrogen and phosphate have averaged in excess of $150 million

annually during recent years.

6.05

Annexes 8 and 9 give lists of the fertilizerplants now in operation, under construction,or planned in India; recent production;and

major sources of finance.

B.

Market Forecast for India

6.06

Estimates for supply and demand of nitrogen and phosphate fertilizer nutrients for all of India for the current Fourth Five-Year Plan (ending March 31, 1974) and the Fifth Five-YearPlan (endingMarch 31, 1979)

are shown below. These projectionsare based on a previous Bank study

(September30, 1970) and a projectionrecently preparedby the GOI (Ministry

of Petroleum and Chemicals). The demand projectionsthrough 1973/74 are

taken from the Bank study mentionecd

above and are based on a projection

model that included historical

data plus growth rates in area irrigated

and in fertilizer

consuming crops.

The figures for the Fifth Five-Year

Plan (1974/79) are based on IDA's extrapolation

of these data and its

estimate of completiondates for individualplants (Annexes 8 and 9).

- 13 Market in India

Fertilizer

of tons)

(thousands

Demand

FY

FY

FY

FY

FY

FY

FY

FY

FY

1,760

2,110

2,500

2,910

3,300

3,700

4,100

4,600

5,200

71

72

73

74

75

76

77

78

79

Nitrogen

Supply

850

1,470

1,830

2,050

2,260

2,590

3,390

3,860

4,230

(N)

Deficit

910

640

670

860

1,040

1,110

710

740

970

Demand

750

970

1,220

1,510

1,700

1,900

2,100

2,300

2,600

Phosphate

Supply

(P 2 05 )

Deficit

230

380

430

530

750

940

1,310

1,540

1,730

520

590

790

980

950

960

790

760

870

The table indicates a substantialnitrogen deficit through the

6.07

period. The deficit decreases slightly in the early years as new Fertilizer

Corporationof India (FCI) and FACT urea units come on stream but widens

again thereafter. The phosphatedeficit grows from about 500,000 tons per

year to 800-900,000. The supply forecastsare based on a realizablebut

optimisticschedule for new projects and on all plants achieving a 90%

capacityutilization. The assumptionsused in the forecasts are explained

in Annex 8. Therefore, the supply figures representIDA's best estimate

of the maximum fertilizerproduction India can reasonablybe expected to

achieve. If the assumptionson capacityutilizationand schedule of projects are not fulfilled,then the estimated supply could be 10-20% below

the above forecasts.

C.

FertilizerMarket in South India

Estimated consumptionof nitrogen and phosphate from 1969/70

6.08

(actual) to 1978/79 for the four southern states (FACT's marketing area)

is given in Annex 10. Average annual growth rates anticipatedby FACT

through 1973/74 are about 10% for nitrogen and 20% for phosphate and

thereafterare assumed for both nutrients at about 13%. It has been

assumed that phosphate consumptionwould increase at a faster rate than

nitrogen until the ratio reaches 2:1. FACT assumed fertilizergrowth

rates below those for the rest of India because of the already higher

fertilizerapplicationin South India. The FACT estimates are the most

conservativeand are used in this evaluation. They are based on extensive market surveys and the requirementsof N, P and K for the area's

main crops (rice, wheat, tea, fruits, nuts, spices, sugar, cotton, vegetables, and tobacco).

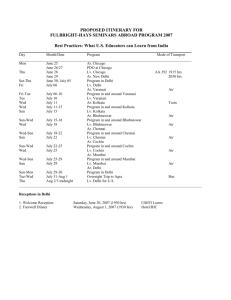

The projected supply and demand of fertilizerfor South India

6.09

are shown below. The supply data are taken from Annex 11.

- 14 -

FertilizerMarket in South India

(thousandsof tons)

Demand

FY

FY

FY

FY

FY

FY

FY

FY

FY

71

72

73

74

75

76

77

78

79

6.10

600

670

730

810

910

1,030

1,180

1,330

1,500

Nitrogen (N)

Deficit

Supply

140

340

550

670

720

810

1,180

1,330

1,530

460

330

180

140

190

220

0

0

-30

Demand

Phosphates(P2 05)

Supply

Deficit

230

280

330

400

470

550

620

700

790

The locations of the fertilizer producers

110

180

230

260

330

380

490

530

630

in

120

100

100

140

140

170

130

170

160

South India are

shown in the map along with major broad gauge rail lines to illustratethe

market area served by FACT. The principal competitorsto FACT will be Zuari

Agro (Goa), Madras (Tamil Nadu), and Coromandel(Andhra Pradesh). IDA's

assessmentof supply assumes that the above three producerswill operate

at 90% capacity from 1974/75onward. Superphosphateproductionis projected

at 40,000 TPY P2 05 based on FACT's estimate. Other proposed projectsin

South India are CoromandelExpansion (II and III), Mangalore,Tuticorin

(SouthernPetrochemicalIndustriesCorporation),Ramagundam,and Occidental

at Vizag. These are assumed to come into productionover the period 19751979; however, the probabilityof all five of these projectsmaintaining

the schedule given is consideredunlikely. These productionforecastsare

more optimisticthan the all-India forecast in Annexes 8 and 9 to show the

maximum competitionthat FACT would have to contendwithin its marketing

area.

6.11

In spite of the optimisticsupply forecast, a phosphateproduction deficitwill still exist in South India and FACT should have no sales

difficultyas far as total market demand is concerned. The phosphatedeficit ranges from 130-170,000TPY over 1974-1979and would be met by a net

inflow from North Indian plants (such as FCI Trombay) or imports. The supply deficitwill remain high unless a number of the other projectsproceed

at a considerablyfaster rate than now appears likely.

6.12

The nitrogensupply could be essentiallyin balance in South

India by 1976/77based on FACT's conservativeestimateof consumptionand

the optimistic forecastof supply. Nevertheless,even if such balance could

be achieved the nitrogen from Cochin II will be sold as NPK fertilizerand,

with the large deficit of P2 05 expected, the company'sNPK fertilizersshould

be marketed with no difficultyeven if competitiondevelopsin straight nitrogen. The company's competitiveposition is further discussedin paras.

6.21 to 6.23 below.

- 15 -

D.

FACT Marketing Area and Handling System

6.13

The marketing area of FACT in South India includes the four states

of Kerala, Tamil Nadu, Andhra Pradesh, and Mysore. Within this area, FACT

has establishedan extensive distributionnetwork of godowns,wholesale and

retail dealers, and a marketing staff to service the more than 6,000 final

distributionpoints. At present the company markets about 460,000 TPY fertilizers of which 250,000 TPY are purchased. Tonnagesmay increase to

about 700,000 TPY with Cochin I and about 1,000,000TPY with Cochin II,

excluding amounts for seeding programs or other outside purchases. To

handle this expanded tonnage, FACT expects to utilize its existing distribution network more efficientlyand also to establish additionaldistribution

points.

6.14

The market share that the company expects to obtain in each of

the four southern states is shown below:

FACT Market Share by Area

Market

Kerala

Tamil Nadu

SouthernMysore

Northern Mysore

Andhra Pradesh

% of Market

N P205 K20

70

25

25

12

12

70

25

25

7

7

70

25

25

7

7

Rail Freight

Avg. Cost

Rs/ton

12

35

35

45

45

Sales

Headquarters

Trivandrum

Madras

Bangalore

Bangalore

Hyderabad

Selling

Points

Dec. 1970

3,000

2,100

210

(inc. above)

500

6.15

Kerala forms the principalmarketing area. At present FACT markets about 70% of the total supply to the state and its forecasts are based

on maintaining this percentage. No other producer can effectively compete

with FACT in Kerala due to the company's location advantage and its wellestablishedname. FACT has a large sales network in Tamil Nadu and Southern

Mysore and estimates that it will supply 25% of the total market demand.

The lower share is due to the longer freight distanceinvolved and the competition from Madras Fertilizerand Zuari Agro, both of which will be marketing similar products.

6.16

The other marketing areas contain northern Mysore and Andhra

Pradesh. These are much farther from FACT and substantial competitionmay

be expected from Zuari Agro and from Coromandel. Therefore,FACT has estimated that it will obtain only 12% of the nitrogen market and 7% of the

phosphate and potash market. The market penetration projectedseems reasonable for all areas.

FACT reports an average Rs 138/ton ($18.40/ton)distributioncost,

6.17

which includescharges for freight,storage, marketing overhead, credit and

dealer comnission. These costs compare favorablywith marketing costs in

- 16 other countries. Distributioncosts, plus sales and excise taxes, are

passed on to the farmer. About 70% of the fertilizeris sold under some

credit arrangement. Fertilizercredit is discussed further in paras. 6.24

and 6.25.

E.

6.18

NPK Seeding Program

Presently FACT sells the followingtonnagesof fertilizerannually:

110,000

20,000

60,000

100,000

170,000

NPK Mixtures

Superphosphate

Ammonium Phosphate

Ammonium Sulfate

Urea

460,000

Total

While sales of the above provide FACT witlhvaluablemarketing experience,

they provide little help in developingmarkets for the NPK's to be produced

in Cochin II. The analysisof the above NP and NPK mixtures varies but they

are generallymuch lower in nutrient content than those expected from the

project.

6.19

It will be necessary for FACT to develop a comprehensiveseeding

program for Cochin II based on the import of grades conformingas closely as

possible to those to be produced. This is particularlyimportantsince most

grades are not now available to the farmers. The specific grades are listed

in Annex 4 along with detailed commentson the fertilizerrequirementsof the

area and the basis for the selectionof the grades to be producedby the

project. To be successfulthis program should provideNPK fertilizersin

suitablegrades in at least the followingamounts (in tons per year):

FY 72

FY 73

FY 74

25,000 - 50,000 NPK

100,000 - 150,000 NPK

200,000 - 250,000 NPK

FY 75

As necessary to supplementproduction

During negotiationsit was agreed that FACT will implementa suitable seeding program and that the Governmentwill import fertilizersfor that purpose

as necessary.

F.

6.20

Sales Prices and Competition

Typical current retail fertilizerprices in India are:

Source

GovernmentPool

GovernmentPool

Coromandel

Grade

14-14-14

15-15-15

28-28-0

Ex-plant prices

Rs/ton

US$/ton

757

832

1,270

101

111

170

-

17

-

Witlhthe exceptionof 28-28-0,the grades proposedby FACT (Annex 4) are

not now marketed in India. Therefore,FACT calculatedthe current prices

for its NPK productsbased on the above prices of the Governmentpool and

Coromandel (Annex 4). The average grade of 19-23-11would thus have an

ex-factorysales price of Rs 928/ton ($124/ton).

6.21

Fertilizersales prices have been constant for about two years

during which time raw material prices on the whole have increased slightly.

Currently, only Coromandel is producing and marketing high analysis, ureabased NPK fertilizers in India. When Madras and Zuari Agro come on strces

in 1971 and 1972 respectively with new NPK capacity, the price could rea-

sonably be expected to drop due to increasedcompetitionbut this tendency

will probably be offset by the continuingshortfall in supply. IDA concludes, therefore, that prices are likely to remain at about existing levels

and represent a reasonable basis for evaluating the project.

6.22

FACT will face major competition in its market area from Coromandel

and Madras but other producers will be less competitive. Zuari Agro will

market a bulk blend based on urea and ammonium phosphate. Although the

grades can be the same, bulk blends are not generally as acceptable as the

granular product that FACT will manufacture. Also, Goa and the nearby area

of Mysore are serviced only by narrow gauge rails so transportation becomes

a major problem for Zuari Agro.

6.23

Manufacturers in north India will not be able to compete very

well in South India due to higher freight costs and product disadvantages.

Thus, competition from Northern producers should have limited impact and

FACT should be able to sell its output within its marketing area at projected prices.

G.

Agricultural Credit

6.24

The importance of credit to fertilizer consumption is well recognized in India. At present credit is provided by the commercial banking

system and by the GOI to cover purchases from the Government Pool. The

Fertilizer Association of India (FAI) has estimated total fertilizer credit

for India of Its2,970 million ($400 million) in 1970/71. Based on consumption forecasts, the requirements in 1974/75 will be approximateLy Rs 5,000

million ($670 million). While availability of credit has thus far not

seriously restricted growth in fertilizer demand, continuing efforts will

be necessary if future consumptionforecastsare to be met. To fulfill

this need FAI recommended comprehensive changes in the agricultural credit

policy of India including establishment of a Fertilizer Credit Guarantee

Corporation by the GOI. This corporation has not yet been established.

Other programs to improve fertilizer credit are being studied by GOI, the

State Governments, and the Reserve Bank of India.

6.25

FACT estimates its total fertilizer credit needs in the latter

1970's at about Rs 800 million annually, of which it expects to provide

- 118 -

about Rs 120 million from its own resources. The company's financialprojections indicate that FACT can readily provide this amount. Total credit

will be supplied as follows (in Rs million):

Dealers

CommercialBanks

Cooperatives

FACT

200

400

80

120

Total

800

The above distributionof credit sources has been proposed by FACT to reduce

the amount of credit to be suppliedby FACT and its dealers through increased

relianceon commercialbanks. The company has been successful in involving

local banks in selected areas in extending fertilizercredit but this system

is not in wide use at present. FACI's marketing efforts depend on the availability of such credit, and the Governmenthas agreed to provide adequate

working capital if funds are not available from commercialbanking sources.

VII. OPERATING COSTS

A.

Raw Material Costs

7.01

Raw material costs representabout 70% of total production costs

and their impact on the company's profitabilitytherefore is significant.

As noted before, the project is based on urea from Cochin I plus imported

phosphate rock, sulfur, potash and ammonia. At full production,annually

recurring foreign exchange expendituresfor the importedraw materials alone

are approximately$21 million at present prices. Prices of raw materials

have fluctuatedwidely over the past two to three years which makes accurate

forecasts of raw material costs difficult. The following table shows the

present prices (actually paid by FACT and used in the financial forecasts)

for these materials and the price trend (used in the economic return calculations) expectedby IDA.

Comparisonof Present and Future CIF Prices

Present Prices

Delivered

CIF

Plant Site

$/ton

Phosphate Rock

Sulfur

Potash

Ammonia (plus 60%

duty)

Urea (from Cochin I)

Rs/ton

Assumed Future

Prices

Rs/ton

$/ton

30

36

53

227

270

400

245

290

423

24

30

40

37

278

318

37

620 ($82.70)

60

-

-

There are no import duties on phosphate rock, sulfur and potash. Other raw

materials,such as filler and coating agent, are available in India.

-

7.02

All imports

now channeled

of sulfur,

through

19

-

phosphate

the Minerals

rock and potash

and Metals

Trading

into

India

Corporation

are

(MMTC),

a government-ownedcorporationwhich contracts for supplies from international sources,usually under bilateral trade agreements. MMTC suplies

the materials to the users such as FACT at its import price plus a fee.

Present raw material prices are generallyhigher than current international

prices due to such bilateral arrangements. Ammonia will be supplied for

Cochin II through a long-term contractrecently concludedbetween Iran and

GOI.

GOI has

bagging

agreed

supplies

to permit

to the extent

import

of all

not available

raw materials

needed

including

in India.

7.03

Present

raw material

prices are higher than those expected by

IDA in the longer run.

IDA's assumptionsare based on internationalprices

and assume that freight rates, which have greatly escalatedover the past

two years, will decline to more normal levels. Present prices have been

used in financialprojectionsto allow an accurate comparisonwith present

NPK prices. The effect of raw material and fertilizerprice changes on

the company'sprofitabilityis discussedin Chapter VIII.

7.04

The project analysis does not include the possibilityof supply

of phosphate rock from the mining project now being consideredin Rajasthan

(para. 6.02). It is too early to predict the quantity and price of any

indigenousrock supply, and it is not anticipatedthat Rajasthan phosphate

rock will be supplied to FACT in the near future. Cochin II will, however,

be designed to permit use of Rajasthan rock when it does become available.

B.

ProductionCosts

7.05

Productioncosts were calculated for the average NPK grade to be

produced (19-23-11)and include costs for sulfuric acid and phosphoricacid.

Details of these costs are given in Annex 12 for various levels of plant

utilizationand are summarizedbelow for the normal operating level assumed

at 90% of design capacity.

Annual ProductionCosts- at 90% of Design Capacity

(Rs million)

NPK

Variable Costs

Fixed Costs

Total ProductionCosts

/1

Cryol:Lte

258.2

46.9

8.3

1.1

305.1

9.4

Includes depreciation,but no intereston long-term debt.

7.06

The high proportionof variablecosts reflects the large raw material component. Since the raw material costs used in the projectionsare

higher than the estimated trend, they should not increase further unless

- 20

-

affectedby bilateral arrangements. Overall productioncosts are therefore

consideredconservative. A direct comparisonof Cochin II's projected operating costs with FACT's existing cost of productionis not possible since

the grades produced differ markedly in nutrient content and composition.

However, a comparisonon a cost per ton nutrient basis indicatesmuch lower

productioncosts at Cochin II than FACT can obtain at UDL Division. While

cryolite representsonly about 3% of the project's output and will hardly

influence the company'sprofitability,it is neverthelessan importantproduct in that it is crucial in the productionof aluminum and would help to

replace current imports.

7.06

The project will provide direct employment for about 500 skilled

and semi-skilledpersonnel. The lprojectis capital intensive and labor costs

representonly a small fractionof operating costs. No attempt was made to

project employment created as an Lndirectresult of the project in ancillary

industries.

VIII. FINANCIALAND ECONOMICANALYSIS OF THE PROJECT

A.

FinancialAnalysis and SensitivityTests

8.01

Detailed income statements for the project are containedin Annex

13. Summary statementsof these forecastsare shown below:

Summary Income Statements- Cochin II

(in millions of rupees)

FY75 FY76 FY77 FY78 FY79 FY80 FY81 FY82 FY83 FY84 FY85 FY86 FY87

CapacityUtilization (%)

50

80

90 90

90 90

90

90

90

90

90

90

90

Sales

195 353 413 422 422 422 422 422 422 422 422 422 422

Operating

Costs

162 269 308 315 315 315 315 315 315 315 315 315 289

Gross Profit

Interest

Profit before

Taxes

Taxes

Net Profit

33

14

84

15

105 107 107 107 107

14 13

11

10

8

19

69

91

94

96

97

99 101

-

-

-

-

-

53

54

56

56

57

58

19

69

91

94

96

44

45

45

46

47

47

107

6

107

5

107

3

107

2

107

1

133

-

102 104 105

106

133

58

73

48

60

8.02

The project shows a small profit in the first year of production

in the next two years as

are expected to rise rapidly

(FY 1975).

Profits

production increases to 90%, and remain at a level above Rs 90 million

- 21 -

per year until FY 1980, when - after a tax holiday of five years - the

impact of taxes (about 55%) forces net profit down to approximatelyRs 45

million per year.

8.03

Due to the relativelyhigh selling prices of fertilizer:LnIndia,

the project is very profitable and, after taxes become applicable,net profit equals 11% of sales and 24% of share capital. If Cochin II were carried

out in a separate corporation,it would have a quite satisfactorydebt service coverage of around 4.0 times in the early years when no taxes are paid,

and about 2.9 times thereafter.

8.04

The internal financial return (IFR) for the project has been calculated at 19.5%. The assumptionsused in this analysis,as well as for the

sensitivity tests, are shown in Annex 14.

8.05

The project has been tested for various factors and is very sensitive to changes in raw material and product selling prices. If raw material

prices are reduced to the level of the expected long-rangetrend, selling

prices could be decreased 7% without reducing the financial return. With

current raw material prices and a 10% reduction in selling price, the IFR

decreases to 9.3%.

The project is not appreciablyaffectedby changes in production

8.06

levels. The IFR for a maximum of 80% productionbeginning in the second

year and 100% beginning in the fourth year are 16% and 21% respectively.

A project delay, however, is critical. A one-year delay with a resulting

15% cost overrun would decrease the IFR to 9.2%. If this delay were followed by other adverse circumstances,such as a 10% decline in selling prices,

the project would show a negative return.

8.07

As shown in Annex 15, the profit break-even point for the project

at the assumed selling prices is 37% of capacity. At normal production the

project would break-even profitwiseif NPK prices were reduced as much as

22%. The cash break-evenpoint on the same basis including the service of

long-termdebt would require sales at 32% capacityor an NPK selling price

of Rs 710/ton (22% reduction).

B.

EconomicAnalysis

The internal economic return (IER) for the project is 13.5% as

8.08

shown in detail in Annex 14 and is based on the followingmajor assumptions:

(1) Raw material costs are the long range trend prices shown

in para. 7.01.

(2) The average selling price is equivalentto expected CIF

import prices of N (as urea); P2 05 (as phosphoricacid),

and K20 (as potash) in the proportions required for the

--

22

-

project's average NPK formulation£A2 notional manufacturing costs and profits if produced in a modern and efficient plant in one of the industrializedcountries.

8.09

Although the above analysis has its shortcomings,it still offers

the best comparisonwith importedNPK products, since the grades to be manufactured at Cochin II are not avaLilable

internationally.

This evaluation

indicates that when using internaLtional

input prices, the project would be

competitivewith imported NPK fertilizerswhile earning at the same time

an acceptableeconomic return.

8.10

Sensitivityanalyses of the economic return show the same trends

as the financialreturn with the project being very sensitive to relative

changes in raw material costs and selling prices. Again, a delay in project

completion reduces the return substantiallyto 6.0% and a delay coupled with

a relative selling price reductionof 10% results in a negative return.

Details of the sensitivity tests are contained in Annex 14.

8.11

As shown in Annex 16 the project would realize net annual foreign

exchange savings of $15.6 million at normal 90% production. The local currency expenditurerequired to achieve this savings is Rs 92 million ($12.2

million) per year.

C.

ImportedVs. ManufacturedPhosphoricAcid

8.12

In consideringCochin II, an analysishas been made to see if a

more optimum solutionwould be to use imported phosphoricacid rather than

to produce acid from imported raw materials (phosphaterock and sulfur).

Essentially the decision to import phosphoricacid would save about $18 million in capital costs, of which $4-6 million would be foreign exchange. However, local productionof acid would save annually about $3.7 million in

foreign exchange operating costs, albeit at an increasein local costs of

about $3 million equivalentper year. Details of this evaluation are contained in Annex 16.

8.13

As shown more fully in Annex 14, an economic return has been calculated on a separate project to produce phosphoricacid. The return has

been based on two alternativeassumptionsof delivered cost of imported

P205 - $160 per ton and $150. The return at the higher cost is 13.7% and

at the lower 9.0%. The foreign exchange savings (para. 8.12), plus the

possible use of phosphate rock from Rajasthan support the decision to

produce rather than import phosphoricacid.

IX.

FUTIUREPROFITABILITYAND FINANCIAL POSITION ON FACT

9.01

Forecastedincome and cash flow statements for the company as a

whole through FY87 are containedin Annexes 17 and 18. Consolidatedincomes

statement forecasts through FY79 are summarizedbelow:

-

23 -

Summary Income Statements-- FACT

(millionof rupees)

FY72 FY73 FY74 FY75 FY76 FY77 FY78 FY79

Net Sales

251

379

14

31

72

29

Profit before Taxes

Tax Provision

(17)

-

Net Profit

Operating Profit

Interest

Debt Service Coverage

421

586

721

774

783

783

86

24

115

34

173

30

193

26

195

21

195

17

43

-

62

-

81

-

143

-

167

-

174

50

178

85

(17)

43

62

81

143

167

124

93

.9

1.6

1.8

2.1

2.5

3.5

:3.0 2.8

9.02

FACT is expected to show an operatingprofit in FY72, Cochin I's

first year of operation;however, this will be more than offset by interest

expense and a net loss for the year of Rs 17 million results. A net profit

of Rs 43 million is expected in FY73 which will increase in succeedingyears

as Cochin I output increases and Cochin II comes on stream. Profit reaches

a peak in FY77 at a level of Rs 167 million when Cochin II reaches 90% capacity. Net profit is reduced in FY78 when income taxes are first applicable

and again the next year when the full tax impact is felt. In that year net

profit reaches a plateau of about Rs 90 million, or 11% of net sales. This

profit level is consideredsatisfactory.

9.03

The likelihoodof FACT profitabilitybeing in line with estimates

rests primarily on its ability to completeCochin II within the time and cost

now forecast,and to reach expected productionlevels at Cochin I and II.

UDL's contributionto profits is marginal and, after completionof Cochin II,

will amount to only about 7% of profit before interest and taxes, while those

from Cochin I and II are 38% and 55% respectively.

9.04

As the company'searnings improve,its cash buildup should enable

FACT to begin paying dividendson share capital. It has been assumed that

Rs 44 million, or 10% on share capital,will be paid each year beginning in

FY76. This will representonly about one-half of net profit after full

taxes are reached in FY79 and furtherpaymentsmay be possible.

9.05

After FY72 when some debt may have to be postponed (para. 4.08),

debt service coverage,Annex 19, is adequateat 1.6 to 1.8 times in FY73

and FY74 and above 2 times in each year thereafter. Since GOI has assured

IDA that FACT will have adequate liquidityduring project execution,protection against the lower coveragein the first three years is provided.

9.06

Forecastedbalance sheets for 1972-1987are containedin Annex 20.

Pertinent data from these for FY72 through FY79 are as follows:

- 24 Selected Balance Sheet Items - FACT

(in millions of rupees)

FY72 FY73 FY74 FY75 FY76 FY77 FY78 FY79

Current assets

Current liabilities

229

309

Net working capital

(80) (32)

280

312

388

302

557

364

698

368

858 1,024 1,145

370 420 452

86

193

330

488

604

693

Current ratio

.7:1 .9:1 1.3:1 1.5:1 1.9:1 2.3:1 2.4:1 2.5:1

Long-Term Debt/

Equity Ratio

63/37 54/46 47/53 38/62 30/70 23/77 17/83 12/88

9.07

The long-term debt equity ratio improves from the present 65/35

to better than 50/50 by March 1974 and the current ratio improves to 1.5:1

by March 1975. These ratios assume defermentof Rs 85 million debt (see

para. 4.08) and no further increase in long-term funds above the the

financing for Cochin I and Cochin II. After 1974 the company's financial

position improves steadily and its long-termdebt/equity ratio is forecasted

to reach 12/88 by FY79. Net working capitalbecomes positiveby FY74 and

increases each year. Dividends and debt prepaymentswill not be permitted

if they would reduce the current ratio below 1.5 to 1.

X. RECOMMENDATIONS

10.01

During credit negotiations,agreementwas reached between the

Government,FACT and IDA on the followingprincipal points:

(i) GOI will furnish at least Rs 190 million in equity and

the balance (not less than Rs 150 million) in loan for

the project (para. 4.05);

(ii) GOI will provide additionalfunds as necessary to complete