Aggregation behaviors of pH- and thermo

advertisement

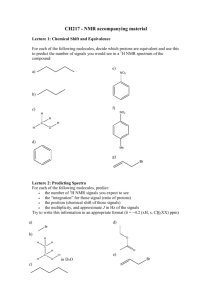

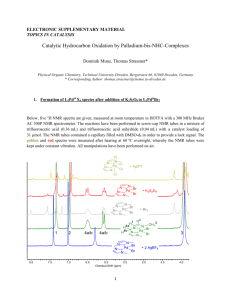

Supporting Information for: Aggregation behaviors of pH- and thermo-responsiveblock copolymer Protected Gold Nanoparticles Junbo Li · Wenlan Wu· Chen Han · Shijie Zhang · Huiyun Zhou · Jinwu Guo S1. Materials. Tert-butyl methacrylate (t-BMA) was purchased from Fluka and distilled under vacuum prior to use. 2, 2-Azobis (isobutyronitrile) (AIBN) was purchased from J&K Chemical and recrystallized before as an initiator. N-isopropylacryl-amide (NIPAM) was purchased from Aldrich and recrystallized twice from benzene. Dioxane, tetrahydrofuran, N, N-Dimethylformamide were purchased from National Pharmaceutical Group Chemical Reagent and distilled before use. HAuCl4·4H2O, sodium citrate, Trifluoroacetic acid were purchased from National Pharmaceutical Group Chemical Reagent and used as received. The RAFT agent, 2-(2-cyanopropyl) dithiobenzoate (CPDB) was systhesized according to the literature procedure [1]. All other reagents were used as received. S2. Synthesis of the PNIPAM-CTA. The RAFT agent CPDB (0.1470 g, 0.6670 mmol), AIBN (0.0273 g, 0.1662 mmol), NIPAM (10.0002 g, 0.0883 mol), and dry Dioxane (10 mL) added to a sealed dry ampule with a magnetic stirring bar. After the solution was degassed using three freeze-pump-thaw cycles, the polymerization was conducted at 70oC over 24 h. The final polymer was purified using a two-step precipitation in diethyl ether and isolated by filtration to give PNIPAM-CTA. _____________________ J. Li* ·. W. Wen · C. Han · S. Zhang · H. Zhou · J. Guo College of Chemical Engineering & Pharmaceutics, Henan University of Science & Technology, Luo Yang 471023, Henan, China E-mail: Lijunbo@haust.edu.cn S3. Synthesis of the SH-PNIPAM-b-PMAA. The PNIPAM-CTA (0.2344 g, 0.0494 mmol), AIBN (0.0020 g, 0.0123 mmol), tBMA (1.9001 g, 0.0134 mol), and dry DMF (1.0 mL) were placed in a sealed dry ampule. After the solution was degassed using three freeze-evacuate-thaw cycles, the polymerization was conducted at 70oC over 48 h. The reaction mixture was obtained using a two-step precipitation from DMF in methanol and water mixxed sloution(v:v=4:1) and isolated by filtration to give PNIPAM-b-PtBMA. SH-PNIPAM-b-PMAA was prepared by hydrolyzing the PNIPAM-b-PtBMA in a 1.5ml trifluoroacetic acid and 25 ml dioxane solution. The reaction mixture was stirred at room tempreture for 24 h. Then, the solution was concentrated and precipitated in diethyl ether and isolated by filtration to give a white powder of SH-PNIPAM-b-PMAA. S4. Preparation of PNIPAM-b-PMAA-SH. The PNIPAM-b-PMAA-SH was prepared by the hydrolysis of Pt-BMA-b-PNIPAM. Pt-BMA-b-PNIPAM was synthesized by two-step RAFT polymerization using CPDB as initial chain trasfer agent via different order of feed. S5. Characterization of SH-PNIPAM-b-PMAA and PNIPAM-b-PMAA-SH. RAFT polymerization became a widely method of the preparation of block copolymers due to the mild condition of the reaction and the widely use of the monomer. In this paper, PNIPAM-b-PtBMA is synthesized by the RAFT polymerization of tBMA with PNIPAM-CTA as chain transit agent. The 1H NMR spectrum of PNIPAM-CAT, PNIPAM-b-PtBMA and SH-PNIPAM-b-PMAA is displayed in Fig. 1. From Fig. 1a, besides the presence of signals characteristic of PNIPAM at δ:=5.8-7.1 (for NH), 4.0 (for CH connected to NH), and 1.1 ppm (for CH3), the 1H NMR spectrum of PNIPAM-CAT in CDCl3 also reveals the signals at δ=7.9, 7.6, and 7.4 ppm ascribing to the dithiobenzoyl groups located at the PNIPAM chain end. The degrees of polymerization (DP) of the PNIPAM homopolymer were determined by 1H NMR to be 40 and the molecular weight was calculated to be 4740. The peak of methyl hydrogens of the tert -butyl ester at 1.5 ppm was appeared in the 1 H NMR spectrum of PNIPAM-b-PtBMA. So, the molecular weight of PNIPAM-b-PtBMA was 12580 calculated by 1 HNMR. Therefore, the block copolymer was denoted PNIPAM40-b-PtBMA60, where the subscript indicates the number of the repeating units. After hydrolysis of PNIPAM40-b-PtBMA64, the SH-PNIPAM40-b-PMAA64 was obtained conformed by the disappearance of tert-butyl resonance at δ=1.5 ppm, and the emerging of carboxyl at δ=12.3 ppm. In the meantime, the disappearance signals at δ=7.9, 7.6, and 7.4 ppm indicated the dithiobenzoyl end is also hydrolyzed. The molecular weight distribution of PNIPAM-CTA and PNIPAM-b-PtBMA was characterized by GPC in THF using polystyrene as calibration. The polydispersity indexes of PNIPAM-CAT (a) and PNIPAM-b-PtBMA (b) 1.17 and 1.34, respectively. Fig. 1S. 1HNMR spectrum of PNIPAm-CAT (a) and PNIPAM-b-PtBMA (b) in CDCl3, SH -PNIPAM-b-PMAA in DMSO(c) Fig. 2S. GPC traces of PNIPAm-CAT (a) and PNIPAM-b- PtBMA (b) in THF at room temperature The process and characterization of PMAA35-b-PNIPAM64 was similar to PNIPAM40-b-PMAA60. Finally, Molecular weight and polydispersity of all polymers are listed in the Table S1. Table S1. Molecular weight and polydispersity of all polymers measured by 1H NMR and GPC method. 1 H NMR GPC Samples PtBMA-CAT PNIPAM-CAT PtBMA-b- PNIPAM PNIPAM-b- PtBMA SH-PMAA64-b- PNIPAM35 SH-PNIPAM40-b- PMAA60 Mn(g/mol) Mn(g/mol) Mw/Mn 5300 4740 12000 12580 9560 9220 4970 5120 13120 13740 1.12 1.17 1.38 1.24 References 1. Zhao, D., X. Chen, Y. Liu, C. Wu, R. Ma, Y. An, and L. Shi (2009) Thermosensitive and pH-sensitive Au–Pd bimetallic nanocomposites. Journal of Colloid and Interface Science 331: 104-112.