Synthesis of Silica-Strengthened Poly(methylmethacrylate) Using

advertisement

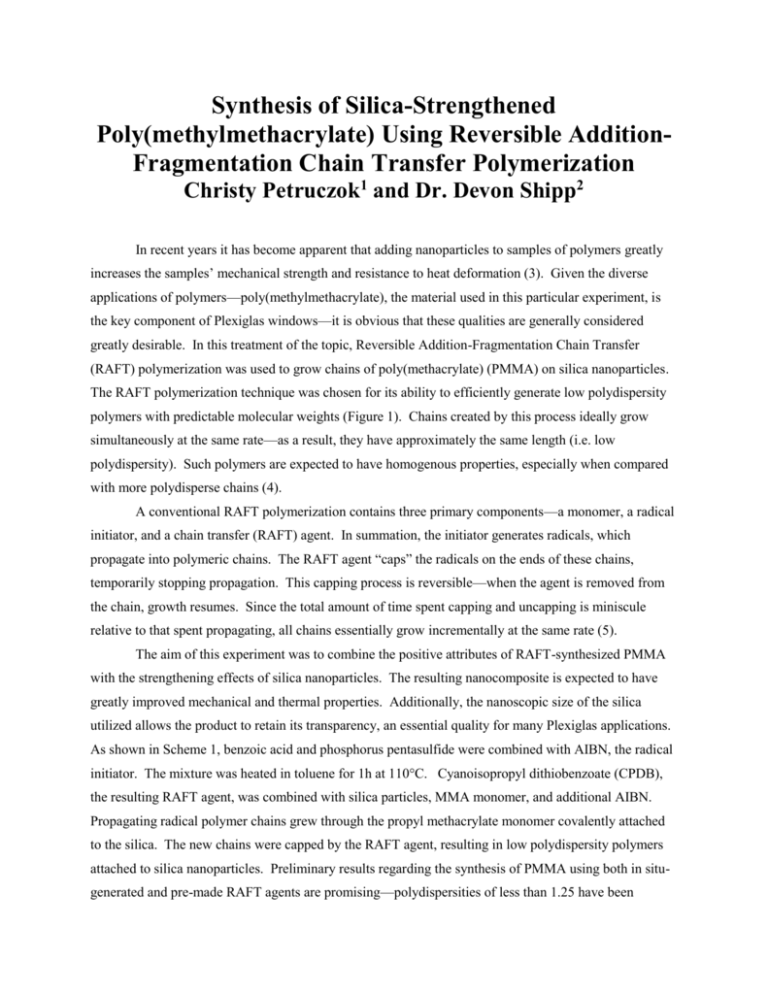

Synthesis of Silica-Strengthened Poly(methylmethacrylate) Using Reversible AdditionFragmentation Chain Transfer Polymerization Christy Petruczok1 and Dr. Devon Shipp2 In recent years it has become apparent that adding nanoparticles to samples of polymers greatly increases the samples’ mechanical strength and resistance to heat deformation (3). Given the diverse applications of polymers—poly(methylmethacrylate), the material used in this particular experiment, is the key component of Plexiglas windows—it is obvious that these qualities are generally considered greatly desirable. In this treatment of the topic, Reversible Addition-Fragmentation Chain Transfer (RAFT) polymerization was used to grow chains of poly(methacrylate) (PMMA) on silica nanoparticles. The RAFT polymerization technique was chosen for its ability to efficiently generate low polydispersity polymers with predictable molecular weights (Figure 1). Chains created by this process ideally grow simultaneously at the same rate—as a result, they have approximately the same length (i.e. low polydispersity). Such polymers are expected to have homogenous properties, especially when compared with more polydisperse chains (4). A conventional RAFT polymerization contains three primary components—a monomer, a radical initiator, and a chain transfer (RAFT) agent. In summation, the initiator generates radicals, which propagate into polymeric chains. The RAFT agent “caps” the radicals on the ends of these chains, temporarily stopping propagation. This capping process is reversible—when the agent is removed from the chain, growth resumes. Since the total amount of time spent capping and uncapping is miniscule relative to that spent propagating, all chains essentially grow incrementally at the same rate (5). The aim of this experiment was to combine the positive attributes of RAFT-synthesized PMMA with the strengthening effects of silica nanoparticles. The resulting nanocomposite is expected to have greatly improved mechanical and thermal properties. Additionally, the nanoscopic size of the silica utilized allows the product to retain its transparency, an essential quality for many Plexiglas applications. As shown in Scheme 1, benzoic acid and phosphorus pentasulfide were combined with AIBN, the radical initiator. The mixture was heated in toluene for 1h at 110°C. Cyanoisopropyl dithiobenzoate (CPDB), the resulting RAFT agent, was combined with silica particles, MMA monomer, and additional AIBN. Propagating radical polymer chains grew through the propyl methacrylate monomer covalently attached to the silica. The new chains were capped by the RAFT agent, resulting in low polydispersity polymers attached to silica nanoparticles. Preliminary results regarding the synthesis of PMMA using both in situgenerated and pre-made RAFT agents are promising—polydispersities of less than 1.25 have been obtained. Further results regarding synthesis of the nanocomposite will be discussed during the presentation. O OH + CN Benzoic Acid + P4S10 N N CN S toluene S 1 hr, 110oC CN AIBN CPDB O MMA O O SiO2 O + AIBN S NC O S O PMMA PMMA bound to SiO2 Figure 1: Characteristics of molecular weight development in RAFT polymerization 1 Scheme 1: Synthesis of PMMA and silica nanocomposites using RAFT polymerization Class of 2008, Department of Chemical Engineering, Clarkson University, Honors Program, Oral Presentation Project Advisor, Department of Chemistry, Clarkson University 3 Ash, B. J.; Siegel, R. W.; Schadler, L. S. Macromolecules 2004, 37, 1358. 4 Chiefari, J.; Chong, Y. K.; Ercole, F.; Krstina, J.; Jeffery, J.; Le, T. P.; Mayadunne, R. T. A.; Meijs, G. F.; Moad, C. L.; Moad, G.; Rizzardo, E.; Thang, S. H. Macromolecules 1998 , 31 , 5559. 5 Shipp, D. A. J. Macromol. Sci., Part C: Polym. Revs. 2005, 45, 171. 2