M n

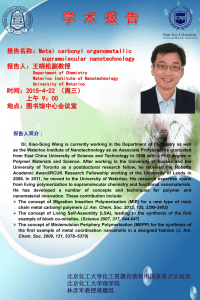

advertisement

Rapid Carbanionic and Oxyanionic Polymerizations Transferred to Continuous Microfluidic Systems: Recent Results and Perspectives Holger Frey Adrian Natalello, Jan Morsbach, Andreas Friedel, Christoph Tonhauser, Daniel Wilms University of Mainz Institute of Organic and Macromolecular Chemistry Duesbergweg 10-14 55099 Mainz, Germany December 4, 2014, Paris Polymerization „Reactors“ Hessel, V.; Serra, C.; Löwe, H.; Hadziioannou, G. Chem. Ing. Tech. 2005, 77, 1693. 2 Review Articles D. Wilms, J. Klos, H. Frey, Macromol. Chem. Phys. 2008, 209(4), 343-356. C. Tonhauser, A. Natalello, H. Löwe, H. Frey, Macromolecules 2012, 45, 9551-9570. 3 Outline Carbanionic / Oxyanionic Polymerization in Continuous Flow • Living Carbanionic Polymerization: Introduction • Use of Micromixing Devices for Carbanionic Polymerization • End-Functional Polymers • Synthesis of Block Copolymers by Carbanionic Polymerization • Controlled Polydispersity via Microfluidic Strategies • Oxyanionic Polymerization in Microfluidic Devices • Conclusion and Perspectives 4 Living Carbanionic Polymerization Characteristics: • Precise Control over Molecular Weight (via M/I), Low Polydispersity • Mostly Rapid Polymerization, even at Low Temperatures • Living Character Various Macromolecular Architectures • Inherently Sensitive to Impurities • Commonly Highly Exothermic Micromixer: Problems: Mixing, Fast Mixing, Heat Dissipation, Excellent Heat Sensitivity, Dissipation, Reaction Continuous Times ? SIMM-V2 HP-IMM Living Anions “on Tap“ 5 Polymerization in Continuous Flow • Effective mixing • High surface-tovolume ratio • Small internal volume • High chemical and mechanical resistance Tonhauser, C.; Natalello, A.; Löwe, H.; Frey, H. Macromolecules. 2012, 45 (25), 9551–9570. Jähnisch, K.; Hessel, V.; Löwe, H.; Baerns, M. Angew. Chem. Int. Ed. 2004, 43, 406-446. Wilms, D.; Klos, J.; Frey, H. Macromol. Chem. Phys. 2008, 209, 343-356. Wurm, F.; Wilms, D.; Klos, J.; Löwe, H.; Frey, H. Macromol. Chem. Phys. 2008, 209, 1106-1114. 6 Slit Interdigital Micromixers: Laminar Mixing Multilamination Mixing Device Parameter SIMM-V2 Mixing principles Multi-lamination Size (L x B x H) / mm 30 x 40 x 30 Temperature / °C -40 – 220 Pressure stability / bar 100 Inner volume / µL 8 7 Living Anionic Polymerization of Styrene High Rate Constants (Dependent on Solvent, Temperature, Concentration) 1 .Solvent: Cyclohexane Non-Polar Reaction Medium Wurm, F.; Wilms, D.; Klos, J.; Löwe, H.; Frey, H. Macromol. Chem. Phys. 2008, 209, 1106 8 Carbanionic Polymerization in Non-Polar Medium • Narrow Molecular Weight Distribution • Convenient Adjustment of Molecular Weight at Varying Flow Rate Ratios Sample Mn (theor.) Mn (SEC) Mw/Mn (SEC) PS-1 500 570 1.25 PS-2 2,000 3,000 1.09 PS-3 3,000 3,300 1.10 PS-4 6,000 8,000 1.08 PS-5 20,000 24,000 1.11 PS-6 30,000 32,000 1.21 Flow Rates: SEC (THF) RI Detection 1 – 3.5 mL/min Residence Times: 40 – 120 s 9 Carbanionic Polymerization in Non-Polar Medium • Full Conversion (NMR spectroscopy) • Quantitative Functionalization (MALDI-ToF-MS) Sample Mn (theor.) Mn (SEC) Mw/Mn (SEC) PS-1 500 570 1.25 PS-2 2,000 3,000 1.09 PS-3 3,000 3,300 1.10 PS-4 6,000 8,000 1.08 PS-5 20,000 24,000 1.11 PS-6 30,000 32,000 1.21 MALDI-ToF MS 1H-NMR (CDCl3) 10 Carbanionic Polymerization in Polar Medium Solvent: THF Polar Reaction Medium • Extremely Fast Kinetics; Control in Conventional Set-Up Only Possible at Low Temperature • Fast Mixing and Excellent Heat Transfer in the Microstructured Reaction Device Permit Continuous Synthesis of Well-Defined Polystyrenes at 25°C 11 Polar Medium (THF): Room Temperature (!) Flow Rates: 0.8 – 2.6 mL/min Residence Times: 1.6 – 5.0 s Sample Mn (theor.) Mn (SEC) Mw/Mn (SEC) PS-7 2,000 1,700 1.28 PS-8 3,000 2,300 1.14 PS-9 4,000 3,600 1.11 PS-10 5,000 6,400 1.10 PS-11 6,000 6,900 1.09 PS-12 10,000 10,500 1.14 PS-13 12,000 11,300 1.09 PS-14 15,000 17,000 1.10 PS-15 40,000 42,200 1.24 PS-16 60,000 71,000 1.25 SEC (THF) RI Detection 12 Conventional Approach vs. Micromixing Living Carbanionic Polymerization of Styrenic Monomers: Batch Reactor vs. Microstructured Reactor Molecular Weights Broad Range Broad Range Polydispersity ≤ 1.05 Mostly ≤ 1.15 Temperature ≤ - 60°C in Polar Solvents ≥ 25 °C Hours Seconds One Sample/Experiment Several Samples/Experiment Reaction Times Versatility 13 Versatile Synthesis of End-Functional Polymers O O O EEGE EEGE (Ethoxy Ethyl Glycidyl Ether) • Conventional Access to End-Functional Polymers via Carbanionic Polymerization • Termination Agents: Chlorosilane, Diphenylethlene (DPE) and Epoxides • Epoxide Derivatives Quantitative Functionalization (Quirk et al.) Quirk, R. et al. Macromol. Symp. 2000, 161, 37-44. Quirk, P. R.; Gomochak, D. L. Rubber Chem. Technol. 2003, 76, 812. 14 Synthesis of End-Functional Polystyrene End-Functionalization of Polystyrene in THF (Polar Medium) • Termination in Supplementary T-Junction • Continuous Flow Process: Polymerisation-Termination Sequence • Rapid and Quantitative Functionalization 15 Synthesis of End-Functional Polystyrene Flow Rates: 0.5 – 1.5 mL/min Residence Times: 5 – 15 s Sample Mn (theor.) Mn (SEC) Mw/Mn (SEC) PS-17 1,900 1,900 1.15 PS-18 2,900 3,000 1.14 PS-19 4,300 3,900 1.14 PS-20 4,500 6,400 1.18 PS-21 7,500 17,000 1.35 SEC (THF) RI Detection 16 Synthesis of End-Functional Polystyrene Flow Rates: 0.5 – 1.5 mL/min Residence Times: 5 – 15 s Sample Mn (theor.) Mn (SEC) Mw/Mn (SEC) PS-17 1,900 1,900 1.15 PS-18 2,900 3,000 1.14 PS-19 4,300 3,900 1.14 PS-20 4,500 6,400 1.18 PS-21 7,500 17,000 1.35 MALDI-ToF MS 17 Functional Termination C. Tonhauser, D. Wilms, F. Wurm, E. Berger-Nicoletti, M. Maskos, H. Löwe, H. Frey, Macromolecules 2010, 43, 5582-5588 Synthesis of End-Functional Polystyrene • Release of Hydroxyl Groups by Acidic Hydrolysis • Semi-Continuous Approach to Hydroxy Functional Polymers Facile Access to Precursors for Complex Macromolecular Architectures (Blockcopolymers, Miktoarm Star Polymers) 19 Synthesis of Block Copolymers Sample S:t-BuOS Mn (theor.) Mn (SEC) Mn (MALLS) Mw/Mn (MALLS) PS-17 0:20 3,600 3,700 4,200 1.21 PS-18 5:5 1,400 1,300 1,500 1.18 PS-19 10:5 1,900 1,900 2,100 1.22 PS-20 22:12 4,400 4,800 4,700 1.17 PS-21 80:30 13,600 13,100 13,600 1.15 PS-22 200:25 25,300 24,700 25,600 1.14 20 Change Mixing Pattern: Turbulent Mixing 4-Way Jet Mixing Device Monomer Initiator 21 Polymerization in Continuous Flow Styrene in THF sec-BuLi in hexane Sample 2-Vinyl pyridine in THF sec-BuLi in benzene Total Flow / Mn (GPC) / mL/min g∙mol-1 PDI Sample Total Flow / Mn (GPC) / mL/min g∙mol-1 PDI PS-7 8 2 200 1.09 P2VP-8 10 1 800 1.16 PS-8 9 4 700 1.08 P2VP-10 8 3 500 1.17 PS-10 7 32 200 1.08 P2VP-11 7 6 400 1.19 PS-11 8 42 500 1.08 P2VP-12 10 14 300 1.15 PS-14 10 74 200 1.05 P2VP-13 11 18 700 1.17 PS-15 11 104 200 1.04 P2VP-14 11 49 300 1.12 PS-16 12 148 700 1.04 P2VP-15 10 96 000 1.05 22 Polymerization in Continuous Flow Comparison PS and P2VP Characteristics Batch Multilamination Jet mixing Effort High Middle Low Side reaction Difficult to avoid No No Molecular weights Broad range 70 000 10 000 150 000 100 000 PDI < 1.10 1.09 – 1.28 1.19 – 1.26 1.04 – 1.10 1.05 – 1.19 Temperature ≤ - 78°C RT RT Versatility One sample Several samples Several samples Natalello, A.; Morsbach, J.; Friedel, A.; Alkan, A.; Tonhauser, C.; Müller, A. H.E., Frey, H.; Org. Process Res. Develop., 2014, dx.doi.org/10.1021/op500149t 23 Influence of Mixing on Polydispersity C. Serra et al., LAB ON A CHIP, 2008, 8,1682-1687 DOI: 10.1039/b803885f 24 Control of Polydispersity by Microreactor Influence of PDI on polymer properties • Common mindset: “monodisperse polymers are good; polydisperse are bad”1 • Mainly theoretical investigations but only a few experimental contributions2 • Most experimental studies are based on mixing of several polymer samples3 Key issue: • No controllable parameter to tailor polydispersity is available (1) Lynd N A, Meuler A J, Hillmyer M A. Polydispersity and block copolymer self-assembly. Progress in Polymer Science 2008; 33; 875-893. (2) Leibler L. Theory of microphase seperation in block copolymers. Macromolecules 1980;13:1602-17. (3) Noro A, Cho D, Takano A, Matsushita Y. Effect of molecular weight distribution on microphase seperated structures from block copolymers. Macromolecules 2005;38;4371-6. 25 Carbanionic polymerization Microreactor setup T M Mixer I Pump 3: Termination reagent Pump 1: Monomer/Solvent Flow rate: x • Controlled living carbanionic polymerization Mixing device Well defined polymer architectures Pump 2: Initiator/Solvent Flow Very narrow rate: y mass distributions possible (PDI < 1.10) Linear dependence of the achieved molecular weights DP = [M]/[I] Turbulent mixing device – point of broadening T M Mixer I sample sample Mmax(GPC, g mol-1) PDI flow rate (ml s-1) PS03-01 PS03-01 3403 3403 1,15 1,15 8,0 PS03-02 3586 1,16 8,0 PS03-03 3283 1,22 7,0 PS03-03 PS03-04 3283 3233 1,22 1,22 7,0 6,2 PS03-05 PS03-04 3262 3233 1,22 1,22 5,4 6,2 3 PS03-06 PS03-05 3206 3262 1,26 1,22 4,8 5,4 2.8 PS03-07 3129 1,29 4,2 PS03-08 3162 1,28 3,6 PS03-02 PS03-06 PS03-07 PS03-09 3586 3206 3129 3111 1,16 1,26 1,29 1,34 8,0 8,0 4,8 2.6 4,2 2.4 3,2 1,28 1,33 3,6 2,8 PS03-11 PS03-09 3089 3111 1,45 1,34 2,4 3,2 PS03-12 PS03-10 3197 3453 1,56 1,33 2,0 PS03-13 3176 1,68 1,6 PS03-14 3193 1,75 1,2 2,4 1.4 PS03-12 PS03-15 3197 3387 1,56 1,83 2,0 0,8 1.2 PS03-16 PS03-13 3399 3176 1,95 1,68 0,4 1,6 PS03-17 PS03-14 3484 3193 2,21 1,75 0,3 1,2 PS03-15 3387 1,83 0,8 PS03-16 3399 1,95 0,4 PS03-17 3484 2,21 0,3 3089 1,45 PDI 3162 3453 PS03-11 Flow rate/ ml min-1 2.2 PS03-08 PS03-10 2,8 Pmax = 6600 Pmax = 3400 2 1.8 1.6 1 0 2 1000total 1000 4 flow rate / 6 8 ml 10000 min-1 -1 -1 molecular mass / g mol 10 8.0 8.0 8.0 8.0 7.0 7.0 6.2 6.2 5.4 5.4 4.8 4.8 4.8 4.2 4.2 3.6 3.6 3.2 3.2 2.8 2.8 2.4 2.4 2.4 2.0 2.0 1.6 1.6 1.2 1.2 0.8 0.8 0.8 0.4 0.4 0.3 0.3 Carbanions are still living: -> Quantitative functionalization (MALDI-ToF) T M Mixer I total flow = 0.8 ml/min PDI (MALDI) = 1.10 total flow = 3.0 ml/min PDI (MALDI) = 1.09 total flow = 4.0 ml/min PDI (MALDI) = 1.07 total flow = 6.0 ml/min PDI (MALDI) = 1.06 total flow = 10.0 ml/min PDI (MALDI) = 1.05 + 104 g/mol Jan Morsbach PhD student T M Summary Mixe r I • Systematic influence on the PDI of a polymerization at 8.0 8.0 7.0 6.2 5.4 4.8 4.2 3.6 3.2 2.8 2.4 2.0 1.6 1.2 0.8 0.4 0.3 constant molecular weights achieved 1000 • System can be transferred to other polymer systems • Analysis how the properties are influenced are in progress • Quantitative functionalized polymers enables further investigations of block copolymer behavior 10000 molecular mass / g mol -1 Hyperbranched Polymers & Microreactors 30 Hyperbranched Polyglycerol: Target Mn = 1,000 g/mol SEC analysis (DMF) T = 120°C Continuous flow Mn ~ 750 g/mol Throughput: 1 – 5 ml/min Mw/Mn = 1.6 Reaction time: several minutes D. Wilms, J. Nieberle, J. Klos, H. Löwe, H. Frey, Chem. Eng. Technol. 2007, 30(11), 1519-1524. Hyperbranched Polyglycerol: Target Mn = 1,000 g/mol 1H-NMR analysis Repeat units Hydroxyl groups Initiator core Methanol-d4 O CH2 CH2 O O CH2 CH2 CH3 Mn = 1,100 g/mol 5.0 4.5 4.0 3.5 3.0 2.5 Chemical Shift (ppm) 2.0 1.5 1.0 0.5 DPn= 16 Hyperbranched Polyglycerol: Initiator attachment? Confirmation of initiator core incorporation MALDI-ToF analysis 800 1000 1200 1400 Mass/Charge Complete core incorporation (Independent of flow rates) 14 1600 Hyperbranched Polyglycerol: Variation of Flow Rates Sample Target Mn [g/mol] Flow Rate Monomer [ml/min] Flow Rate Initiator [ml/min] Molar Ratio Initiator:Monomer Mn 1 ( H-NMR) PG-1 1,000 0,87 1 1 : 10,7 1100 PG-2 1,000 1,74 2 1 : 10,7 1300 PG-3 1,000 2,17 2,5 1 : 10,7 1600 SEC analysis (DMF) D. Wilms, J. Nieberle, J. Klos, H. Löwe, H. Frey, Chem. Eng. Technol. 2007, 30(11), 1519-1524. Hyperbranched Polyglycerol: Variation of Flow Rates Sample Target Mn [g/mol] Flow Rate Monomer [ml/min] Flow Rate Initiator [ml/min] Molar Ratio Initiator:Monomer Mn (1H-NMR) PG-4 1,000 0,87 1 1 : 10,7 1100 PG--5 1,020 0,91 1 1 : 12,0 1600 PG-6 1,100 1,97 2 1 : 13,0 1200 PG-7 2,000 1,81 1 1 : 25,0 3200 SEC analysis (DMF) Mn ~ 150,000 g/mol Isolation by Dialysis 16 Mw/Mn ~ 1.1 Standards) (PS Conclusion & Perspectives Polymer Synthesis in Microreactors: Carbanionic and Oxyanionic Techniques • • • • • Efficient Continuous Flow Process for Living Carbanionic Polymerization Facile and Fast Processes Serve to Optimize Reaction Parameters Convenient Molecular Weight Adjustment Tailoring of the Polydispersity of Living Polymer Cabanions Quantitative Implementation of Various End-Groups at Polymers • Facile Extension to Complex Polymer Architectures (Star Polymers, Block Copolymers) 36 Conclusion & Perspectives Pending Questions • Unprecedented Polymer Structures? • Kinetic Control of Polymerization of Metastable Monomers? (Example: Vinyl Alcohol) • Gradients, One-Step Block Copolymer Syntheses, Architectures by versatile multi-microfluidic systems 37 Acknowledgments Prof. Holger Löwe Elena Berger-Nicoletti Michael Maskos Monika Schmelzer Institut für Mikrotechnik Mainz POLYMAT 38 Conclusion & Perspectives Pending Questions • Unprecedented Polymer Structures? • Kinetic Control of Polymerization of Metastable Monomers? (Example: Vinyl Alcohol) • Gradients, One-Step Block Copolymer Syntheses, Architectures by versatile multi-microfluidic systems 39 Multilamination Flow Pattern Micromixer Inlay Mulitlamination Flow Pattern • Hydrodynamic Focusing • Jet Formation in the Slit-Shaped Interdigital Micromixer Method of Operation Hessel, V. et al. AIChE Journal 2003, 49, (3), 566-577. Löb, P. et al. Chemical Engineering Science 2006, 61, (9), 2959-2967. 40