obleo_aquifer_exampl..

advertisement

Example #2 MODFLOW

This example is the simple "OBLEO" aquifer problem. Figure 1 is a plan view map of the

hydrologic setting of the OBLEO aquifer. The aquifer is an unconfined aquifer with a single well

P-1. The aquifer is bounded to the North and South by mountains, and the East and West by two

large lakes. The water elevation in each lake is 0.0 meters above some datum, while the ground

elevation at the well is 100.0 meters above the same datum.

Zenith Foothills

Lake

Alpha

(z=0.0m)

P-1 (z=100.m)

Lake

Omega

(z=0.0m)

1100 km

Nadir Mountains

Figure 1. Obleo Aquifer Setting

Rainfall records indicate that recharge to the subsurface is approximately 250 mm/yr. The

aquifer is homogeneous and isotropic with a hydraulic conductivity of K=100m/day, and a

specific yield S = 0.25. The example constructs a computer model to help determine the safe

yield of the aquifer - assume minimum permissible saturated thickness is 500 m and that the

aquifer is 1000 m thick.

The OBLEO water board would like to exploit the aquifer, they would like to know (for a 30 year

planning period):

a) What is the maximum rate P-1 that can be used so that the saturated thickness is never less

than 500m?

b) How much of the pumped water is induced recharge from the two lakes? (Why would this

question be of interest?)

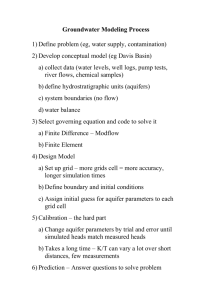

A model is one tool that can help answer these questions. Typically one uses some semblance of

the following steps:

Conceptual model - Translate the real system into a simplified system that can be represented in

a computer (or analog) model.

Mathematical model – Convert the conceptual model to a set of governing equations,

boundary and initial conditions.

Numerical model – Computer program implementing some numerical methods to obtain

solutions to the mathematical model, or good approximations.

The steps of mathematical and numerical modeling are “implicit” if the tool is

MODFLOW. One will be using a diffusion equation with spatially varying material

properties (transmissivity, storativity), with a prescribed set of initial conditions and

boundary conditions. MODFLOW “solves” the mathematical model using a blockcentered finite-difference approximation to the governing equation and various different

linear equation solvers. The time-difference model used is either fully-implicit or

alternating-direction implicit.

Data encoding - This step is where the analyst translates the conceptual model into data streams

(input files) for the computer program to process. Generally the analyst must supply geometry,

material properties, forcing terms (wells, recharge, etc.), and boundary conditions. The program

will generate approximations at different times of heads in the aquifer layers, and cell-to-cell

flow terms (using Darcy’s law).

Solution - Typically the input files need several iterations of manipulation until one is asking the

correct questions (of the model) and the output makes sense. Expect initial program runs to fail

from input that is incorrect, inconsistent, or just plain wrong. Generally the “solution” will be an

array of heads in each model layer, and possibly fluxes at specific locations. Usually a graphical

tool is used to render the arrays into something straightforward to understand.

Interpretation - This step is where the model results are interpreted as answers to the questions

that we built the model for in the first place. This is where we would include “What-if …?”

scenarios and their results. The engineer also uses this step to make recommendations or design

decisions.

Conceptual Model

The obleo aquifer is a single unconfined, homogeneous, isotropic aquifer with hydraulic

conductivity K= 36,500m/yr and a specific yield of S = 0.25. The aquifer is rectangular with

dimensions 1100km x 1100km in the horizontal direction and 0.1km in the vertical. Flow is

assumed to be essentially horizontal so that the Dupuit assumptions can be used.

The Zenith Foothills to the North are conceptualized as a no-flow boundary as are the Nadir

Mountains to the South. Lake Alpha to the east and Lake Omega to the West are conceptualized

as constant head boundaries. A single well, P-1 is planned for the Obleo Aquifer. P-1 is located

at the geographic center of the aquifer, equidistant from all four boundaries.

Mathematical Model

The solution domain can be expressed as:

D = { (x,y) | 0 <x<1300m,

The boundaries can be expressed as:

0<y<1100m

}

G1 = { (x,y) | x=0;

G2 = { (x,y) | 0<x,1300m;

G3 = { (x,y) | x=1300m;

G4 = { (x,y) | 0<x<1300m;

0<y<1100m

y=1100m

0<y<1100m

y=0

}

}

}

}

The head in the aquifer is governed by the following diffusion equation:

∂h

div (Kh grad(h) ) = S ∂t + q - r

q- pumping; r- recharge

subject to the following boundary conditions:

h(x,y,t) = H(left) on G1

∂h

-K∂y (x,y,t) = 0 on G2

h(x,y,t) = H(right) on G3

∂h

-K∂y (x,y,t) = 0 on G4

h(x,y,0) = f(x,y)

on D

(Fixed head)

(No-Flow)

(Fixed head)

(No-Flow)

(Initial condition)

Numerical Model

The solution to the mathematical model will be obtained using the Finite-Difference Method.

The numerical implementation will be using the USGS-MODFLOW code.

Row

1

-1

1

1

1

1

1

1

1

1

1

1

1

-1

2

-1

1

1

1

1

1

1

1

1

1

1

1

-1

3

-1

1

1

1

1

1

1

1

1

1

1

1

-1

4

-1

1

1

1

1

1

1

1

1

1

1

1

-1

-1

1

1

1

1

1

1

1

1

1

1

1

-1

-1

1

1

1

1

1

1

1

1

1

1

1

-1

-1

1

1

1

1

1

1

1

1

1

1

1

-1

-1

1

1

1

1

1

1

1

1

1

1

1

-1

-1

1

1

1

1

1

1

1

1

1

1

1

-1

10

-1

1

1

1

1

1

1

1

1

1

1

1

-1

11

-1

1

1

1

1

1

1

1

1

1

1

1

-1

1

2

Column

3

12

13

Figure 2. Boundary-array diagram

The Obleo aquifer is modeled using the Dupuit assumptions as a single aquifer layer. The

horizontal resolution is 1km x 1km; the vertical resolution is 0.1 km. Flow is assumed to be

essentially horizontal. Figure 2 is a plan-view diagram of the aquifer with the constant head (-1),

no-flow (0), and computational cells (1) indicated. This diagram is the boundary array that will

be required by the program. Each cell is 1000 meters x 1000 meters.

Figure 3 depicts the vertical resolution of the model. The “aquifer” is 1 km thick. Boundary

heads at the two lakes are 900 meters above the bottom of the aquifer, but the lake is the datum,

thus the bottom is located 900 meters below the lake.

z=+100 m

z=0.0 m

z=-900m

Figure 3. Vertical conceptual model and datum

The MODFLOW packages that are used include:

BASIC + BLOCK CENTERED FLOW (always)

RECHARGE + WELLS

SIP (or SSOR ...)

The data stream will be located in the following set of DATA FILES, that correspond to the

different packages.

FOR001 <--- BASIC

FOR011 <--- BCF

FOR012 <--- WELLS

FOR018 <--- RECHARGE

FOR019 <--- SIP

The version of MODFLOW used assumes FORMATTED data sets.

Initial conditions - Because we really don't know the initial conditions, we will run the model

once without any pumping to obtain an equilibrium solution. This solution will represent our

initial condition for the "what-if" modeling. An alternative is to run the model “steady state”

first and save the output for subsequent modeling. Either method should result in identical

output, but the transient to equilibrium is sometimes easier.

Figure 4 illustrates the concept. We simulate for 30 years “pre-development” then for 30 more

years to evaluate the pumping impact. We select different pumping rates until we can satisfy the

draw down requirement then report this simulation as the “design” case.

Figure 4. Concept of transient to equilibrium ,then apply stress.

Data files are built using a text editor - examples are shown below:

Data Encoding

FOR001 <--- BASIC

CE6361 OBLEO AQUIFER EXAMPLE PROBLEM

<= first two lines are notes to ourselves!

1 LAYER, 11 ROWS, 13 COLUMNS, UNCONFINED

1

11

13

2

5 <= layers, row, column, periods, time unit.

11 12 0 0 0 0 0 18 19 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 <= modules

0

0

<= memory handling

1

1(20i3)

3

IBOUND- 1

<=boundary array

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

-1 1 1 1 1 1 1 1 1 1 1 1 -1

100.

<= head at no flow cells, use unusual number.

1

1.(10f10.0)

3

SHEAD- 1

<=initial head array

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

0.

30.

30.

0.

1

1

0.

1.

1.

<= st. period length, time step multiplier, time step length

FOR011 <--- BCF

0

1

11

0

<= some flags

<= simulation type (transient)

1.00

(10G10.3)

0

TRPY-

0

0

DELR1.00

0

1.00

1.00

1.00

1.00

DELC1.00

0

1.00

1.00

1.00

1.00

1.00

11

1.E3

1.00

1.00

1.E3

1.00

(10G10.3)

1.00

1.00

(10g10.3)

1.00

1.00

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

11 1.E3

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

11 1.00

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

(10G10.3)

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

(10G10.3)

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

(10G10.3)

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

1.00

1.00

11

1.00

1.00

11

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

1.00

1.00

1.00

1.00

0.250

0.250

SF1- 1

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

3.65

3.65

HYDCON3.65

1

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

3.65

-900.

-900.

BOT- 1

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

0

3

3

3

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

-900.

FOR012 <--- WELLS

1

1

1

1

1

0

6

7 0.000

6

7 -1.E9

FOR018 <--- RECHARGE

1

0

18

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

1.00

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

18 1.00

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0

0

(10G10.3)

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

(10G10.3)

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

3

RECH- 0

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

RECH- 0

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

0.250

3

FOR019 <--- SIP

50

1.

5

1.E-07

MXITER NPARM

0

.001

1

ACCL,ERR,IPCALC,WSEED

These “files” are not expected to work the first attempt. Essentially we build the model to be

sure the program reads the files correctly (even if the data are incorrect), then iteratively correct

the input data until we are modeling the situation of interest. The biggest issues will be

adjustments to the FOR019 file to get convergence with reasonable accuracy, changing the predevelopment period length, and move the output from pre-development into the starting head

array. The analyst keeps tracks of these changes in a simulation log and it is best to change only

one thing at a time.

A log of the changes to the model is illustrated below:

Simulation Number

run1

run2

run3

run 4

run 5

Remarks

files read OK, but supplied

template is missing two

columns.

geometry OK, model fails to

converge.

solution converges, but not

sure if year 0 is equilibrium.

Year 0 and Year 30 heads are

same; run3 changes verified.

Year 0 and Year 30 heads are

different (no pumping)

run 6

Year 0 and Year 30 heads are

same.

run 7

Set P1 = 3,650 cu.m./year

(about 2,000 gpm)

Set P1 = 36,500 cu.m./year

(about 20,000 gpm)

Set P1 = 365,000 cu.m./year

(about 200,000 gpm)

Set P1 = 3,650,000 cu.m./year

(about 2,000,000 gpm)

run 8

run 9

run 10

run 11

Set P1 = 36,500,000

cu.m./year (about 20,000,000

gpm)

run 12

Set P1 = 43,100,000

Suggested Changes

Add data in

FOR001,FOR011,FOR018 to

get model into 11X13

Adjust FOR019 – increase

MAXITER to 200.

Set P1=0 in second stress

period (no pumping). Set

FOR018 recharge to small

value. Set Starting heads to

900, year 0 and year 30

solution should match.

Set FOR018 recharge to

specified value.

Year 0 is not an equilibrium

solution. Use Year 30 heads

as start heads, and start

simulation at –240 years.

Model is ready for pump

evaluation. Year 0 solution is

an equlibrium state. Save this

output file as Case0 – it will

be part of appendix.

Drawdown is undetectable.

Drawdown is about 1 meter in

well cell.

Drawdown is about 5 meters

in well cell.

Drawdown is about 44 meters

in well cell. Head is 980

meters (> 500 meters).

Drawdown is about 412

meters in well cell. Head is

588 meters (> 500 meters);

we are close to our “safeyield” criterion.

Head in well cell is 509 meters

cu.m./year

(>500 meters). Save this

output file as Case 1.

COMPUTER OUTPUT: (after graphical post-processing)

Running the program produces pages of output. In the absence of a contouring tool one can take

the output, superimpose a grid and manually contour the output or use graphical post-processing.

Modern versions of MODFLOW handle a lot of this for the analyst.

Figure 5 is an example of hand-drawn contour maps using the output displayed in Figure 6.

Figure 7 is the same array in Figure 6 rendered using a graphics tool (in this case EXCEL).

Figure 5. Hand-drawn contour map using MODFLOW output (circa 1991).

Figure 6. Std. MODFLOW output file (used to draw Figure 5 and 7).

100

-100

-300

-500

-700

9

1

-900

7

5

3

5

13

11

9

1

Figure 7. Rendering of head array after 30 years of pumping. Note bottom of plot is bottom of aquifer.

The contour plots are useful for answering where (and when) the aquifer fails to meet the

minimum saturated thickness requirement (which in this example will always be at the well cell).

One could also use Darcy’s law and hand calculations to determine the amount of water flowing

into the aquifer from the lakes (how?). Instead of making this calculation by-hand, the model

also computer cell-by-cell flow terms and a water balance summary. Figure 8 is an excerpt from

the standard output file that shows this summary.

Figure 8. Water balance summary.

Typically we would present plots of Case00 (The pre-development condition) and Case01 (the

“management solution”). Figure 9 is a perspective (3D) rendering of the predevelopment

condition. The water table is mounded because of the uniform recharge (this result is easily

predicted with an analytical solution – review course notes for the solution). Figure 10 is the

same array rendered as a contour map (using EXCEL which is not the best contouring tool – the

contour intervals are indicated by different colors/shading).

10500

1060-1100

1060-1100

1020-1060

9500

980-1020

8500

980-1020

940-980

7500

940-980

900-940

6500

860-900

1020-1060

900-940

860-900

820-860

5500

780-820

4500

780-820

740-780

3500

740-780

2500

700-740

700-740

660-700

12500

11500

9500

500-540

10500

8500

7500

6500

5500

540-580

4500

500

3500

580-620

2500

1500

500

620-660

1500

10500

8500

6500

4500

2500

12500

500

8500

10500

4500

6500

500

2500

1100

1060

1020

980

940

900

860

820

780

740

700

660

620

580

540

500

820-860

660-700

620-660

580-620

540-580

500-540

Figure 9. Predevelopment Perspective Plot.

Figure 10. Pre-development contour map.

10500

1060-1100

1060-1100

9500

1020-1060

1020-1060

980-1020

8500

980-1020

940-980

7500

940-980

900-940

6500

860-900

5500

820-860

900-940

860-900

820-860

780-820

4500

780-820

740-780

3500

740-780

2500

700-740

700-740

660-700

1500

Figure 11. Management Solution Perspective Plot

12500

11500

9500

8500

7500

6500

5500

4500

10500

500-540

3500

540-580

2500

580-620

500

620-660

1500

10500

8500

6500

4500

2500

12500

500

8500

10500

4500

1100

1060

1020

980

940

900

860

820

780

740

700

660

620

580

540

500

6500

500

2500

Next we present the renderings for the “management solution” where the result of pumping

produces a water table that nearly hits our management objective (head > 500 meters). Figures

11 and 12 are the 3D plot and the contour map.

500

660-700

620-660

580-620

540-580

500-540

Figure 12. Management Solution contour map

Interpretation

Interpretation of the results is critical to the whole effort (there is really no point to modeling if

there is not going to be interpretation). Figures 11 and 12 actually help answer the second

question without any flux calculations. The contour map suggests that there is a hydraulic

“divide” between the well and the lakes and the lakes actually receive water from the aquifer.

This conclusion is supported by the flux calculations in MODFLOW that are repeated below.

The second column displays the rates and there is no flux into the model from the constant head

(lake) boundaries, but there is an outflow to the lakes amounting to about half of the volume rates

pumped. Thus in this aquifer scenario, the entire pump discharge over the planning period is

supplied entirely by recharge (precipitation).

Figure 13. Volumetric budget calculations from the program.

Thus to answer the two questions we arrive at:

a) What is the maximum rate P-1 that can be used so that the saturated thickness is never less

than 500m? P1 on the order of 43,100,000 cubic meters per year.

b) How much of the pumped water is induced recharge from the two lakes? (Why would this

question be of interest?) None of the pumped water is from the lakes. The aquifer is a net

supplier of water to the lakes.

Exercise:

The files on the server should produce the results used pt produce figures 9-13. So start from

these files and do the following:

1) Run the model and verify that the results are consistent with the figures above.

2) Determine the pumping rate that lowers the water table to 250 meters above bottom of the

aquifer.

3) Plot the water table 3D plot and contour map for this management solution.

4) Does this new management solution draw any water from the lakes?