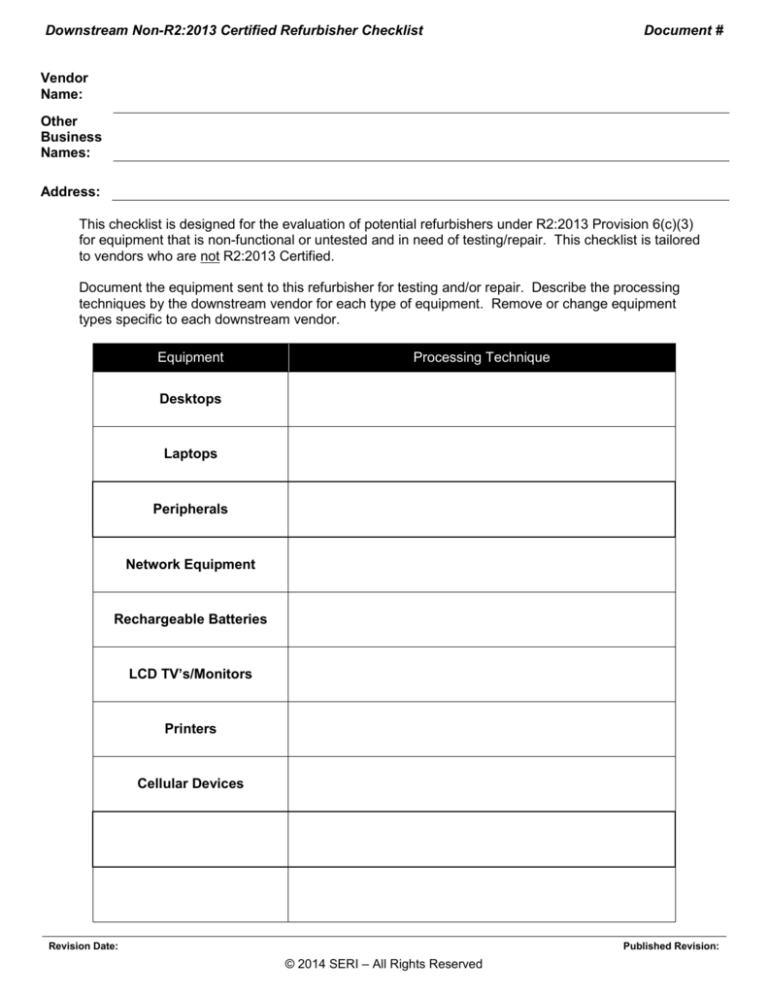

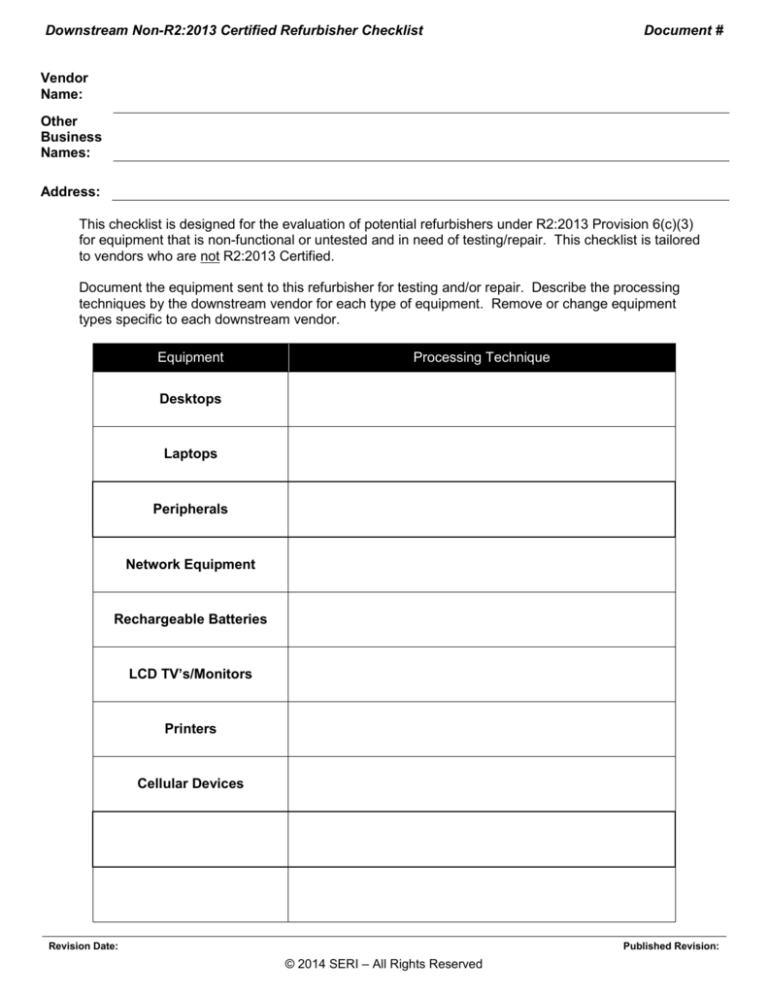

Downstream Non-R2:2013 Certified Refurbisher Checklist

Document #

Vendor

Name:

Other

Business

Names:

Address:

This checklist is designed for the evaluation of potential refurbishers under R2:2013 Provision 6(c)(3)

for equipment that is non-functional or untested and in need of testing/repair. This checklist is tailored

to vendors who are not R2:2013 Certified.

Document the equipment sent to this refurbisher for testing and/or repair. Describe the processing

techniques by the downstream vendor for each type of equipment. Remove or change equipment

types specific to each downstream vendor.

Equipment

Processing Technique

Desktops

Laptops

Peripherals

Network Equipment

Rechargeable Batteries

LCD TV’s/Monitors

Printers

Cellular Devices

Revision Date:

Published Revision:

© 2014 SERI – All Rights Reserved

Downstream Non-R2:2013 Certified Refurbisher Checklist

Document #

Requirements for non-R2:2013 certified Refurbishers

These requirements are documented in R2:2013 Provision 6(c)(3). The cross-referenced provisions are

extracted here for all the requirements incorporated in 6(c)(3). Downstream refurbishers are required to meet

the requirements of Provision 6 in order to qualify as a downstream refurbisher under Provision 6(c)(3). Any

outsourcing to a downstream refurbisher is therefore expected to meet the same requirements as imposed on

the R2:2013 certified recycler.

Prov.

Requirement

6(c)(3)(B)(ii) Verify that downstream

refurbisher does not resell

equipment in untested or nonfunctioning condition?

6(b)(1)

Does the refurbisher label and

sort each shipment downstream

to track throughput?

6(b)(2)

Does the refurbisher sanitize all

data on reusable equipment

before it is shipped downstream?

6(b)(3)

Does the refurbisher handle and

package shipments for reuse to

prevent damage of the equipment

during transit?

6(b)(3)

Does the refurbisher package

shipments for reuse in light of the

risks posed during shipment?

For example, refurbished

batteries packaged according to

transport regulations to prevent

fires or spills.

6(c)

Are shipments by the refurbisher

for reuse identified prior to

shipment as:

Verification

(1) Tested for Full Functions,

R2/Ready for Reuse;

-or(2) Tested for Key Functions,

R2/Ready for Resale

If downstream refurbisher produces fully functional equipment ready for reuse, verify these

requirements.

Tested and Full Functions,

6(c)(1)(A)

R2/Ready for Reuse – Are all

equipment functions tested,

working properly and ready for

reuse as if it were new?

6(c)(1)(A)

Is R2/Ready for Reuse

equipment loaded with legally

licensed software, drivers, and

configured?

Revision Date:

Published Revision:

© 2014 SERI – All Rights Reserved

Downstream Non-R2:2013 Certified Refurbisher Checklist

Prov.

6(c)(1)(B)

6(c)(1)(B)

6(c)(1)(B)

6(c)(1)(B)

6(c)(1)(B)

6(c)(1)(C)

6(c)(1)(C)

6(c)(1)(C)

6(c)(1)(C)

6(c)(1)(C)

6(c)(1)(D)

6(c)(1)(E)

Requirement

Is the refurbisher currently

certified to RIOS or ISO 9001 for

refurbishment activities?

If not certified to RIOS or ISO

9001, has the refurbisher

documented a Quality Assurance

Policy?

If not certified to RIOS or ISO

9001, has the refurbisher

documented a Quality Assurance

Plan?

Does the Quality Assurance Plan

include steps to verify the

accuracy of test methods

(monitoring) and test equipment

(calibration)?

Does the Quality Assurance Plan

include procedures to maintain

records of verification and results

of testing?

Does the refurbisher have a

written Product Return Policy

which includes specific policies

for R2/Ready for Reuse

equipment?

Does the refurbisher have a

written Product Return Plan that

includes plans for R2/Ready for

Reuse equipment sold?

Is the Product Return Policy and

Plan appropriate for the final

destination of R2 Ready for

Reuse equipment

Is the Product Return Policy and

Plan appropriate for the type of

equipment sold to an end user as

R2 Ready for Reuse?

Has the Product Return Policy

and Plan been communicated to

buyers and sales persons as one

step in the implementation?

Is the refurbishers R2/Ready for

Reuse equipment and

components clean and free of

major cosmetic defects?

Does the refurbisher ensure that

R2/Ready for Reuse equipment

or components meet the

requirements of the recipient?

Revision Date:

Document #

Verification

Published Revision:

© 2014 SERI – All Rights Reserved

Downstream Non-R2:2013 Certified Refurbisher Checklist

Document #

If downstream refurbisher produces equipment tested for key functions and ready for resale, verify

these requirements.

Tested for Key Functions,

6(c)(2)(A)

R2/Ready for Resale – Does the

refurbisher use effective test

methods and testing equipment

to confirm that the Key Functions

of the equipment or components

are working properly? For

example, are “key functions”

defined for each type of

equipment and processes written

to specify expected results for

“working”?

6(c)(2)(B)

Is the refurbisher currently

certified to RIOS or ISO 9001 for

refurbishment activities?

6(c)(2)(B)

If not certified to RIOS or ISO

9001, has the refurbisher

documented a Quality Assurance

Policy?

6(c)(2)(B)

If not certified to RIOS or ISO

9001, has the refurbisher

documented a Quality Assurance

Plan?

6(c)(2)(B)

Does the Quality Assurance Plan

include steps to verify the

accuracy of test methods

(monitoring) and test equipment

(calibration)?

6(c)(2)(B)

Does the Quality Assurance Plan

include procedures to maintain

records of verification and results

of testing?

6(c)(2)(D)

Does the refurbisher have a

written Product Return Policy

which includes specific policies

for R2/Ready for Resale

equipment?

6(c)(2)(D)

Does the refurbisher have a

written Product Return Plan that

includes plans for R2/Ready for

Resale equipment sold?

6(c)(2)(D)

Is the Product Return Policy and

Plan appropriate for the final

destination of R2 Ready for

Resale equipment?

6(c)(2)(D)

Is the Product Return Policy and

Plan appropriate for the type of

equipment sold?

6(c)(2)(D)

Has the Product Return Policy

and Plan been communicated to

buyers and sales persons as one

step in the implementation?

Revision Date:

Published Revision:

© 2014 SERI – All Rights Reserved

Downstream Non-R2:2013 Certified Refurbisher Checklist

6(c)(2)(C)

6(c)(2)(C)

6(c)(2)(E)

Document #

Does the refurbisher disclose to

buyers in writing any functions

that are not working properly with

R2/Ready for Resale shipments?

Does the refurbisher provide a

description of cosmetic defects

and missing components in

writing with R2/Ready for Resale

shipments?

Does the refurbisher ensure that

the equipment or components

meet the specifications of the

recipient vendor or the end user?

Data Destruction Requirements

If equipment is not sanitized of data prior to shipment from the R2:2013 recycler, then the downstream

refurbisher must meet the requirements of Provision 8 for Data Destruction. Use the Downstream Data

Destruction Vendor Checklist to qualify the refurbisher for Data Destruction requirements under R2:2013

Provision 6(b)(2).

5-Downstream Data Destruction Vendor Checklist.docx

Recycling of Residual equipment containing FMs

Downstream refurbishers who are not certified to R2:2013 must also meet the downstream requirements for

recycling residual components containing Focus Materials from the refurbishment process. This includes any

components removed during repair that contain FMs. It also includes any equipment that could not be resold

or could not be repaired to a working status and therefore must be recycled. Use the Downstream NonR2:2013 Certified Recycler Checklist to qualify the refurbisher to the Provision 3 and Provision 5 requirements

for recycling of these residuals.

Downstream Non-R2:2013 Certified Recycler Checklist.docx

The above information applies to the minimum requirements of R2:2013 Provision 6 for downstream due

diligence of refurbishers not certified to R2:2013. Additional evaluation is recommended. Onsite audits are

encouraged.

Revision Date:

Published Revision:

© 2014 SERI – All Rights Reserved

Downstream Non-R2:2013 Certified Refurbisher Checklist

Document #

Year 1

Evaluator:

Attached

Evidence:

Comments:

Status:

☐ Approved

☐ Suspended

Date

Completed:

Year 2

Evaluator:

Attached

Evidence:

Comments:

Status:

☐ Approved

☐ Suspended

Date

Completed:

Year 3

Evaluator:

Attached

Evidence:

Comments:

Status:

☐ Approved

☐ Suspended

Date

Completed:

Revision Date:

Published Revision:

© 2014 SERI – All Rights Reserved