ESREDA WG - Example Conceptual Firefighting document

advertisement

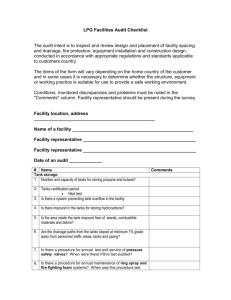

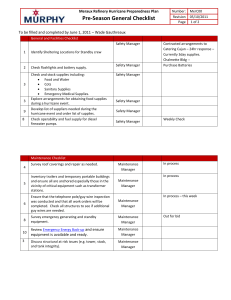

Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: PROJECT CONCEPTUAL PROCESS DESIGN OF FIREWATER FACILITES Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: TABLE OF CONTENTS 1.0 INTRODUCTION 2.0 OBJECTIVE 3.0 REFERENCE STANDARDS 4.0 FIREWATER DISTRIBUTION SYSTEM 4.1 Design Basis 4.2 System Description 4.2.1 Piping Layout 4.2.2 Hydrants Location and Spacing 4.2.3 Monitors Type and Location 5.0 FIRE SCENARIOS 6.0 DRAWINGS Client Project Refinery 1.0 FWI Contract N.: 1-BDRev.: Issue date: INTRODUCTION The present document defines the conceptual design of the fixed firewater facilities for the Project. It includes information about the firewater piping distribution system and associated fixed discharge devices such as hydrants, monitors and hose reels. Fire scenarios are also included for the evaluation of firewater demand. Firewater tank and pumps, firewater distribution to the area are outside the scope of this conceptual design document. Pag 1 of 13 Client Project Refinery 2.0 FWI Contract N.: 1-BDRev.: Issue date: OBJECTIVE This conceptual design provides the basic requirements and design criteria to be utilised for the development of the detailed engineering design of fire fighting facilities for the Project area. The scope of this package is limited to the conceptual design of the following fixed firefighting facilities within the new grass roots area: Fire water piping distribution Hydrants location and spacing Monitors location Hose reels location Mobile and portable fire-fighting facilities like hose nozzles, hoses, extinguishers, portable firewater monitors, foam trucks, etc. are not covered by the present document and shall be advised/provided by the Owner in accordance with local regulation and Refinery standards. Model and type of fire-fighting equipment such as hydrant, valves and connections, fixed monitors, portable monitors, dry chemical extinguishers, etc. shall be specified/confirmed by the Owner. Pag 2 of 13 Client Project Refinery 3.0 FWI Contract N.: 1-BDRev.: Issue date: REFERENCE STANDARDS Firewater system design is based on the following practices/standards: The following drawing is taken as reference: Pag 3 of 13 Client Project Refinery 4.0 FWI Contract N.: 1-BDRev.: Issue date: FIRE WATER DISTRIBUTION SYSTEM Firewater is supplied to the area by extending the existing firewater distribution headers to provide a looped system. The firewater headers will supply hydrants, firewater monitors and hose reels as well as mobile and portable fire fighting equipment such as fire fighting equipment trucks, trailer mounted monitors, hose nozzles, etc. The following paragraphs provide the bases on which the firewater system has been developed and a description of the firewater facilities 4.1 Design Basis The fire protection facilities presented in this document are based on the assumption that only one major fire might occur at any one time in the area. Hence, the governing fire water rate for the Project has been determined by splitting the area in subdivisions for which the maximum extent of any single fire has been established. Each subdivision is separated from all others by a minimum of 15m clear space. Based on the application of Project minimum equipment distances, the pipe rack is considered to ensure a sufficient clear space to be regarded as a fire break between the north and the south side of the unit, while the clear space (> 6 m) under the pipe rack itself is considered as a means of firefighting access. Fire water demand has been calculated based on the fire scenarios included under section 5.0. Scenarios are based on the identification of the following equipment with a high fire potential: (1) (2) (3) (4) (5) P-502 A/B Feed Pumps (2) P-504 A/B Product Pumps (2) P-506 A/B Stripper Reflux/Distillate Pumps (1) D-503 Hot Separator (4) E-502 A/B/C Feed/Effluent Exchanger (4) E-503 Hot separator Overheads/Treat Gas Exchanger R-501 A/B Hydrofining Reactors (4,5) C-501 Recycle Gas Compressor (3) C-502 A/B Make-up Gas Compressor (3) C-701 PSA Tail Gas Compressor (3) Pumps with a rated capacity over 150 gpm (34 m3/h) handling light ends. Pumps with a rated capacity over 200 gpm (45 m3/h) handling combustible liquids when handled at temperatures above or within 15F (8C) of their closed cup flash point. Gas compressors over 200 hp (150 kW) handling flammable materials. Vessels, heat exchangers and other equipment containing flammable liquids at or above 600F (316C), or above their auto-ignition temperature, whichever is less. Reactors that operate at or above 500 psig (3450 kPa) pressure or are capable of producing exothermic reactions. Pag 4 of 13 Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: It is highlighted that as a deviation to the Project standards: EQUIPMENT STACKING, item 2.c; Table 1, ITEM E, point 3; it has been foreseen, within structure “B”, the location of equipment in stacked position over the following equipment containing flammable materials above 316°C or their autoignition temperature: E-502 B/C Feed/Effluent Exchanger (below 316°C, above AIT) E-502 A Feed/Effluent Exchanger (above 316°C, above AIT) D-503 Hot Separator (below 316°C, above AIT) E-503 Hot separator Overheads/Treat Gas Exchanger (below 316°C, above AIT) The following passive/active firefighting provisions have been foreseen in order to mitigate the risk of a fire propagation in the structure: Fireproofing of structural steel; Solid deck between the levels in the structure fireproofed; Provision of fire monitors; Snuffing steam rings on shell girth flanges of E-502 A/B/C. In addition to the above provisions, other features are included in the design to minimize any risk of leaks (e.g. use of camprofile gaskets and Rotabolts on main exchanger flanges, manually operated unit emergency depressuring facilities). Fire fighting facilities (i.e. hydrants, monitors, hose reels) have been located and spaced in accordance with Project standards The possibility to reuse the existing hydrants (either relocated or in the same position) has been taken into account in this document, as specifically indicated in the next paragraphs: the actual position of the existing firefighting facilities shall be checked in field and the feasibility to reuse them for the new installation (either relocated or in the same position) shall be confirmed by the Refinery. For a complete description of required facilities, reference can be made to paragraph 4.2 System Description. 4.2 System Description The system description under this paragraph includes both existing and new or relocated facilities. The possibility of relocating existing firefighting facilities or accepting their present position shall be evaluated and confirmed with the Refinery. Hydrants and monitors location shall be reviewed and confirmed during detailed engineering phase based on final equipment layout. Reference is made to the FIRE FIGHTING SYSTEM drawing attached under section 6.0 Pag 5 of 13 1 Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: 4.2.1 Piping Layout Firewater is supplied to the process area by means of distribution piping tied from the existing underground firewater headers. The new fire water piping, except for branches to hose reels and to elevated monitors (if any) shall be underground and buried 300 mm minimum below the frost line (0.6 m below grade). Fire water connections to monitors, hose reels, etc. shall be designed to prevent water from freezing in the connections and incorporate winterisation features by design. Fire water main will follow the roadway layout. Material of construction of the new firewater lines shall comply with Refinery specifications. Two new 10” lines have been foreseen north and south sides of the unit in order to form a closed loop around the area with the existing fire water line running east and west sides. The loop is fed by multiple connections to the fire main. An additional 8“ firewater branch, running underground along the unit pipe rack, has been foreseen feeding the hose reels located inside the process area (see para. 4.2.4) and the two monitors placed east side of the unit. It has been considered to relocate the portion of the existing fire main running along the west side of the unit to avoid interference with the new facilities and to allow placement of hydrants and monitors at the opposite side of the road (18 straat) with respect to Project ISBL area. Block valves have been located on the new headers, close to the tie-in points with the existing fire main, so that not more than one side of the ring can be lost for maintenance or repair. Piping and valves selection will be as per Refinery standard. 4.2.2 Hydrants Location and Spacing Hydrants have been placed around the process area, located along the roadways, spaced not more than 45m from each other. Fire hose boxes with hose, nozzles, branchpipes and couplings will be installed near each hydrant or at strategic locations as per Refinery practice. Hose boxes and their contents will be supplied and installed by Refinery. The following hydrants have been considered for the protection of the unit; existing hydrants have been also considered either in their original location or reused in a different position as detailed in the following table: Pag 6 of 13 Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: Hydrant N. 643 645 656 655 NEW 813 NEW NEW 657 NEW 814 Location East Side – Left corner East Side – Right corner East Side North Side - Top corner North Side North Side – Lower corn West Side – Left corner West Side – Right corner South Side– Top corner South Side South Side – Lower corner Relocated No No Yes Yes --Yes ----Yes --Yes Relocation of the existing hydrants shall be reviewed and approved by the Refinery. Hydrants selection and installation will be as per Refinery standards. 4.2.3 Monitors Type & Location Fixed water monitors have been located, at grade, in strategic position to protect critical equipment and structures. Monitors are located approximately 15 m (50 ft) from the equipment being protected; where closer spacing were required, the actuating valve shall be located at least 15m from the protected equipment. Monitors have been considered with an effective range of 45m (150 ft) under zero wind conditions. All monitors have been considered Style #649 Station Monitor (Protek) equipped with Style #823 Master stream Nozzle (Protek) having a nominal capacity of 700 gpm (159 m3/h). Monitor/nozzle selection shall be reviewed and approved by the Refinery. Pag 7 of 13 Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: The following new monitors have been foreseen for the protection of the ISBL area: Monitor D5-1 Location East Side D5-2 East Side D5-3 South Side D5-4 South Side D5-5 South Side D5-6 West Side D5-7 West Side D5-8 North Side D5-9 North Side D5-10 East-west access way Notes: Covered Equipment/Structure PSA Unit X-701 Feed Pumps P-502 A/B Product Pumps P-504 A/B (Note 1) Feed Pumps P-502 A/B Product Stripper T-503 Structure “A” Structure “B” Reactors R-501 A/B Reactors R-501 A/B Treat Gas Furnace F-501 Reactors R-501 A/B Treat Gas Furnace F-501 Make-up Compressors C-502 A/B Make-up Compressors C-502 A/B Make-up Gas Compressors C-502 A/B Recycle Gas Compressor C-501 PSA Tail Gas Compressor C-701 Recycle Gas Compressor C-501 PSA Tail Gas Compressor C-701 PSA Unit X-701 Recycle Gas Scrubber and KO Drum T-502/D-510 Stripper Reflux/Distillate Pumps P-506A/B (Note 1) Recycle Gas Scrubber and KO Drum T-502/D-510 1) Due to the limited accessibility to pumps P-504 A/B and P-506 A/B, coverage by the respective monitor shall be reviewed and confirmed at a later stage of plot plan development. The possible adoption of fixed water spray systems shall be evaluated and reviewed with Refinery. 4.2.4 Hose Reels Hose reels (totally three) have been located within the process area, along the main pipe rack with spacing at 60 m centres maximum, in order to cover the entire process area by means of 30 m length hoses. Hose reels take water supply from a firewater header connected to two separate sections of the fire main, with valves at each end where it connects to the main. Pag 8 of 13 1 Client Project Refinery 5.0 FWI Contract N.: 1-BDRev.: Issue date: FIRE SCENARIOS The firewater demand for the ISBL area and fire protection systems presented in this document are based on the following fire scenarios: 1. 2. Fire in the Unit, south side of the piperack: 1.a Fire in Feed Pumps P-502 A/B area 1.b Fire in Structure “B” 1.c Fire in Reactors R-501 A/B Structure “C” Fire in the Unit, north side of the piperack The fire demand is based on the governing scenario. Refinery shall confirm that the existing facilities (firewater pumps, distribution piping, sewer pipes) are adequate for the below given firewater requirements. Scenario 1.a: Fire in the Feed Pumps (P-502 A/B) area In this scenario, fire is in the Feed Pump area, close to Product Stripper tower (T-503), Product Pumps (P-504 A/B) and Structure “A”. The new fire monitor (D5-2) installed at grade, east side of Feed Pumps, will be used to cool the equipment on fire. The new fire monitor (D5-3) installed at grade south side of Feed Pumps will be used to cool Product Stripper tower (T-502) and equipment in Structure “A” area. Additional three 2-1/2 in. hoses (from hydrants) are considered to provide additional surface cooling and to control possible spill fires. Extinguishing of the fire will be carried out with foam solution provided by Refinery fire truck. Firefighting Devices Water Demand per device m3/h (gpm) 159 (700) 57 (250) Number of firefighting devices in use 2 3 Firewater demand m3/h (gpm) 318 (1400) 171 (750) 1 114 (500) Water Monitors Hoses (2-1/2 in.) Foam solution by Refinery 114 (500) Truck Scenario 1.a - Total Firewater Flowrate Pag 9 of 13 603 (2650) Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: Scenario 1.b: Fire in Structure “B” The present scenario considers the fire in the Structure “B”, at the location of Hot Separator (D-503) and Feed/Effluent Exchanger (E-502 A/B). The new fire monitor (D5-4) installed at grade south side of Structure “B” will be used to cool the equipment on fire. The new fire monitor (D5-3) installed at grade eastside of Feed Pumps will be used to cool adjacent equipment in Structure “A”. The new fire monitors (D5-5 and D5-6) installed at grade, respectively, south side and northwest side of Reactors structure will be used to cool Reactors (R-501 A/B) in Structure “C”. Extinguishing of the fire will be carried out with foam solution provided by Refinery fire truck. Additional three 2-1/2 in. hoses (from hydrants) are considered to provide additional surface cooling and to control possible spill fires. Firefighting Devices Water Demand per device m3/h (gpm) 159 (700) 57 (250) Number of firefighting devices in use 4 3 Firewater demand m3/h (gpm) 636 (2800) 171 (750) 1 114 (500) Water Monitors Hoses (2-1/2 in.) Foam solution by Refinery 114 (500) truck Scenario 1.b - Total Firewater Flowrate Pag 10 of 13 921 (4050) Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: Scenario 1.c: Fire in Reactors Structure “C” The present scenario considers the fire in the Reactors Structure “C”. Due to the high operating pressure and temperatures above AIT a release in the form of a jetfire can be expected. It is noticed that both reactors are insulated and fireproofed. The new fire monitors D5-4, D5-5, D5-6, located at grade adjacent to the Reactors structure, can be used for cooling of reactor and of surrounding equipment directly impinged by the flame or exposed to heat radiation. Emergency depressurisation of the reaction section is foreseen, which can be activated in order to deplete the leak source. Firefighting Devices Water Demand per device m3/h (gpm) 159 (700) --- Number of firefighting devices in use 3 --- Firewater demand m3/h (gpm) 477 (2100) --- --- --- Water Monitors Hoses (2-1/2 in.) Foam solution by Refinery --truck Scenario 1.c - Total Firewater Flowrate 477 (2100) Scenario 2: Fire in the Unit, north side of the piperack The process area located north side of the pipe rack is almost totally dedicated to equipment processing flammable gases, lighter than air, at relatively low temperature (far below AIT), like: Make-up Gas Compressors, Recycle Gas Compressor, PSA Tail Gas Compressor, PSA Unit, Recycle Gas Scrubber, various K.O. drums. Furthermore, it is noticed that each compressor is provided with emergency suction/discharge isolation valves remotely actuable from control room, which allow a quick intervention for the isolation of the possible source of gas leak. Based on the above considerations, the event of a major fire in the area appears unlikely provided that a quick response to a fire situation is initiated. In order to avoid a potential fire escalation and prevent a prolonged unit downtime, fixed monitors have been foreseen along unit perimeter in order to cover the following critical equipment: Gas Compressors C-501, C-502 A/B, C-701; PSA Unit X-701 (including Adsorbers and Tail Gas Drum); Monitors have been located in order to meet full coverage of the equipment from at least two different directions (refer to monitors D5-6/7/8/9/1 location). Pag 11 of 13 Client Project Refinery FWI Contract N.: 1-BDRev.: Issue date: Stripper Reflux/Distillate Pumps P-506 A/B, which handle a light ends product (wild naphtha) above its flash point, is an additional equipment with a high fire potential located in this area: a liquid spill might evolve into a vapour cloud that could explode if subject to a delayed ignition. A dedicated monitor (D5-10) located at the east-west access way, at the top right corner of PSA Unit, has been foreseen for the protection of pumps P-506 A/B. Considering the absence of significant inventories of flammable liquids in this area and the localized nature of a gas fire, the firewater demand in this area is considered to be not controlling with respect to the fire scenarios identified for the process area placed on the south side of the pipe rack. Based on this consideration, it was deemed not necessary to develop specific fire scenarios in this area. Pag 12 of 13 Client Project Refinery 6.0 FWI Contract N.: 1-BDRev.: Issue date: DRAWINGS Drawing No. Description FIRE FIGHTING SYSTEM Pag 13 of 13