SECTION 1: Demolition, Excavation ,Backfilling and Stone Works

advertisement

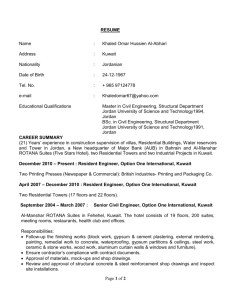

United Nations Development Programme Programme of Assistance to the Palestinian People-PAPP Construction and Rehabilitation of wadi Gaza Bridges PAL10-00054031 Funded by Government of Brazil BILL OF QUANTITIES 2007 UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges A- Construction & Rehabilitation of Al Sikka Bridge UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SECTION 1: Demolition, Excavation and Backfilling Works ITEM DESCRIPTION UNIT QTY. Lump Sum 1 Introduction: the contractor shall visit the site and make all investigations deemed necessary to ascertain the nature of the existing conditions of the structures to be demolished or to receive any alteration, and satisfy him as to the form and nature of works to be carried out, and the existing site conditions. It shall be understood that all salvaged materials and fittings are the UNDP property and stored as instructed by the UNDP. 1.1 Cutting & Removal of the existing demolished bridge elements (2 fallen slabs, 3 damaged piers to the base level, ground slab as min needed for work, hand rails, existing steel bridge two side wire mesh and whatsoever obstructing the works to be executed, according to the design drawings ), and transporting of surplus material to approved places. The price includes careful demolishing of existing temporary steel bridge and support and transports all elements to the ministry of public works stores. The price includes also all safety precautions that any deemed necessary for executing the works including of supplying and erecting support scaffolding system to support the bridge slab before demolishing the damage' slab and piers and during the construction phase according to approved shop drawings and engineer's instructions. The contractor has to submit a work-plan regarding this item for approval of the Engineer. (Demolished bridge length is about 21m and average width =5.2m) UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 1.2 Excavation in any kind of soil/concrete from natural levels to upper levels of the existing foundations according to drawings, and Engineer’s instruction including: UNIT QTY. M3 120 M3 75 UNIT RATE ($) -Cutting the existing Wadi Gaza lining slab should be by using mechanical saw. -Dewatering the surface the ground water during the excavation works. Note: Payment to the contractor according to engineering measurement 1.3 Backfilling from the excavated level to the bottom level of the ground slab using granular fill (Kurkar) compacted to 98% of maximum dry density in layers not exceeding 25cm thick. Note: Payment to the contractor according to engineering measurement TOTAL SECTION 1 5 TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SECTION 2: Concrete Works ITEM DESCRIPTION UNIT QTY. M3 24 M3 32 M3 58 The following items include: Using new plywood 18mm thick for concrete fair face works Polythene sheet for concrete elements exposed to the soil Supply and cast plain concrete B20010cm thick as shown in drawings Supply and fix concrete shuttering using tie-rods “patent rods”, after removal of tie caps it will be filled with non shrinkage cement grout. Supply reinforcement steel bars, bend, shape and fix to specified locations, Supply and cast ready-mixed concrete using mechanical vibrators, curing, and testing, required admixtures for concrete. Two coats of water-proof hot bitumen for all elements under the ground level (foundation, col. Neck, col. To the level of the ground slab) Rubbing and cleaning of existing steel reinf. The price includes using a suitable system to pump way any kind of ground and surface water out of the suit during the work in underground elements till concrete hardening. 2.1 2.2 2.3 Supply and cast reinforced concrete (B350) for Foundations, including all requirements to complete the works as per drawings and engineer’s instructions. Supply and cast reinforced F.F concrete (B400) for Col and Col neck, as per drawings and engineer’s instructions. Supply and cast reinforced F.F concrete (B400-fair face) for Tie Beam, Upper Caps, including support beam, as per drawings and engineer’s instructions. UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM 2.4 2.5 2.6 DESCRIPTION UNIT Supply and cast reinforced concrete (B- M3 350 fair face) for Bridge solid slab, (Fair Face finished), (thickness=30cm) including drop beams, inverted beams and all other required works according to drawings. Including treatment of the expansion joint as detailed in drawings, and according to engineer's instructions Supply and cast reinforced concrete (B- M2 300) for the concrete lining ground slab 15cm thick including polythene sheet(0.15mm thick) under slab price includes compaction of soil under ground slab including expansion joint between old and new slab and around the columns. As per drawings and engineer’s instructions. Ditto, but for the damaged elements M3 everywhere along the existing bridge. The price includes removing the brittle part, drilling and fixing new steel bars with approved epoxy and applying bonding agent to the existing concrete, as per drawings and engineer's instruction. TOTAL SECTION 2 QTY. 77 48 3 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SECTION 3: Road Works ITEM DESCRIPTION UNIT QTY. 3.1 Remove the rubble, garbage and clean out the Wadi sides to reach the concrete lining surface. And storm water channel including transporting of surplus material to approved places. Ton 500 3.2 Supply and cast reinforced concrete (B300) for retaining wall, shuttering work shall be using Tie-Rode ''patent rods'', after removal of tie caps it shall be filled with non shrinkage cement grout. The item includes excavation backfilling compaction beneath the foundation painting the buried parts with two coats of hot bitumen over primer coat and all requirements to complete the works as per drawings and engineer's instruction. M2 20 3.3 Supply and cast reinforced concrete M3 (B250) for Retaining beam 20cm*50cm. The item includes excavation, backfilling, compaction beneath the beam, painting the buried parts with two coats of hot bitumen over primer coat and all requirements to complete the works as per drawings and engineer's instruction Supply and cast reinforced concrete M3 (B250) for concrete storm water gutter and chutes, The item includes excavation, backfilling, compaction the subgrade, painting the buried parts with two coats of hot bitumen over primer coat and all requirements to complete the works as per drawings and engineer's instruction Supply and lay and level approved M2 granular sand (Kurkar) with CBR≥30,20cm thick in one layer for sub base with watering and compaction up to 97% of maximum dry density MDD. 3.4 3.5 40 15 1300 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 3.6 Supply, lay and level base course material with CBR ≥ 80 for the carriage way, 25cm thick in two layers with watering and compaction up to 100% of maximum dry density machine. Supply, lay and level base course material with CBR ≥ 80 for the old bridge, 30cm thick in two layers to reach the design level of wearing surface with watering and compaction up to 100% of maximum dry density machine. The item will include removal of existing rubble to approved place Supply, lay and level base course material with CBR > 80 for the shoulders, 12.5cm thick in one layer with watering and compaction up to 100% of maximum dry density machine. The item will include removal of existing rubble to approved place Supply, lay and level base course material with CBR > 80 for underneath the retaining wall, 20cm thick in two layers with watering and compaction up to 100% of maximum dry density MDB. Supply and lay compacted asphalt binder course (3/4'' nominal aggregate size) 6 cm average thickness, compacted to at least 98%, including spraying the concrete slab with RC2 binder coat or MCO to the base course at the rate of I.2kg/m2 and all required test. All in according with the specifications, drawings, and engineer's instructions. 3.7 3.8 3.9 3.10 TOTAL SECTION 3 UNIT QTY. M2 1300 M2 250 M2 400 M2 40 M2 1550 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 4.1 Supply and install handrail of the bridge comprising of F4” & F3”galvanized steel pipes with required welding. The work includes fixing and painting as per the drawings and engineer’s instructions. The painting should be done by using a primer polyzinc layer and two layers of colored paint according the drawings and Engineer’s instructions. Price also includes painting of curbstone according to engineer's instructions. Supply and fix signboard showing allowed vehicles to pass over the bridge as per drawings. The work shall include galvanized steel posts, concrete foundations, Timber or ply backboards and all other required works. Supply and fix from one side a galvanized steel plate 300*10mm to the cover the old expansion joints. Fixation shall use expandable bolts. Supply and fix cast iron rainwater drainage grit 90x40cm including galv. Steel plate tray and galv. Steel pipe 6” and all necessary fittings and pieces as indicated in drawings and according to the engineer's instructions. 4.2 4.3 4.4 4.5 UNIT Linear Meter 200 NO 2 Linear Meter 40 No 4 Supply and lay UPVC pipe 6'', SN8 Linear including concrete encasement Meter 30cm*30cm, elbow, Tee AND all fittings to complete the work as per drawings and the engineer's instructions. TOTAL SECTION 4 QTY. 100 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SUMMARY Section No. Section Description 1 Demolition, Excavation, Backfilling and Stone Works. 2 Concrete Works 3 Road works 3 Miscellaneous Works Value ($) Total VAT ZERO Grand Total Total In Words: ــــــــــــــــــــــــــــــــــ DATE: _____/______/________ Contractor’s Stamp and Signature _________________________________________________________________ UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges B- Construction & Rehabilitation of Wadi Gaza Bridge UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SECTION 1: Demolition, Excavation and Backfilling Works ITEM DESCRIPTION UNIT QTY. Lump Sum 1 M3 1500 Introduction: the contractor shall visit the site and make all investigations deemed necessary to ascertain the nature of the existing conditions of the structures to be demolished or to receive any alteration, and satisfy him as to the form and nature of works to be carried out, and the existing site conditions. It shall be understood that all salvaged materials and fittings are the UNDP property and stored as instructed by the UNDP. 1.1 1.2 Cutting & Removal of the existing demolished bridge elements (damaged foundations, concrete lining, approach slabs, end and retaining beams, piers, walls, deck, upstand beams, ground slab, protection fill, protection lining, retaining beams, hand rails, and whatsoever obstructing the works to be executed according to the design drawings ), and transporting of surplus material to approved places. The price includes all safety precautions that any deemed necessary for executing the works inclusive of supplying and erecting support scaffolding to support the bridge slab if required before demolishing the damaged slab and piers according to approved shop drawings and engineer's instructions. The contractor has to submit a workplan regarding this item for approval of the Engineer. (Demolished bridge length is about 40m and average width =6m) Cleaning the site area of bridge and cutting and removal of existing artificial fill and rubbish to the natural ground level (Wadi bottom level) to flow naturally, In addition to transportation of surplus material to approved places. UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 1.3 Excavation in any kind of soil/concrete from natural levels to bottom levels of caps according to drawings, and Engineer’s instruction. 1.4 1.5 UNIT QTY. Note: Payment to the contractor according to engineering measurement M3 150 Backfilling from the excavated level to the bottom level of the ground slab using granular fill (Kurkar) compacted to 98% of maximum dry density in layers not exceeding 25cm thick. M3 400 Ditto, but embankments. M3 100 for the TOTAL SECTION 1 inclined UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SECTION 2: Concrete Works ITEM DESCRIPTION UNIT QTY. The following items include: Using new plywood 18mm thick for concrete fair face works Polythene sheet for concrete elements exposed to the soil Supply and cast plain concrete B20010cm thick as shown in drawings Supply and fix concrete shuttering using tie-rods “patent rods”, after removal of tie caps it will be filled with non shrinkage cement grout. Supply reinforcement steel bars, bend, shape and fix to specified locations, Supply and cast ready-mixed concrete using mechanical vibrators, curing, and testing, required admixtures for concrete. Two coats of water-proof hot bitumen for all elements under the ground level (piers, walls and pile caps) and the backside of walls, Make openings and sleeves in the walls with the required steel detailing. Clean of existing steel reinf. 2.1 2.2 2.3 Supply and cast reinforced concrete (B350) for Pile Foundations, of depth 10m, and diameter 40cm. The price includes steel pipe casing, the casing to be removed and cutting the top 40cm to the bottom of concrete cap foundation, drilling and all other requirements to complete the works as per drawings and Linear engineer’s instructions. Meter Supply and cast reinforced concrete (B350) for piles caps Type1, as per drawings and engineer’s instructions. M3 Ditto, but for type 2 including drilling and fixing new steel bars with approved epoxy and applying bonding agent to the existing concrete, as per drawings and engineer’s instructions. M3 220 22 3 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 2.4 Supply and cast reinforced concrete (B350-fair face) for piers type 1, (Fair Face finished for sides not exposed to earth including supplying and fixing 2cm kalkal in girder support and 300x200x25mm galvanized steel plates as per drawings and engineer’s instructions. 2.5 2.6 2.7 2.8 2.9 2.10 2.11 Ditto, but for type 2 (including backwalls). Price shall includes 2cm kalkal in the backwalls and drilling and fixing new steel bars with approved epoxy and applying bonding agent to the existing concrete, as per drawings and engineer’s instructions. Supply and cast reinforced concrete (B350 fair face) for Bridge solid slab, Fair Face finished, (thickness=20cm) including drop beams, inverted beams and all other required works according to drawings. Including supplying and fixing 300x200x25mm galvanized steel plates to main girders as detailed in drawings, and according to engineer's instructions. Supply and cast reinforced concrete (B300) for the concrete lining ground slab 15cm thick including expansion joints and polythene sheet (0.15mm thick) under slab, price includes excavation for the ground slab. As per drawings and engineer’s instructions. Ditto, but for the concrete approach slab 15cm including expansion Joint and all requirements as per drawings and engineer’s instructions. Ditto, but for edge beams 20x100cm. As per drawings and engineer’s instructions. Ditto, but for retaining and end beams 20x50cm. As per drawings and engineer’s instructions. Ditto, but for 10cm thick slab for the protection embankment fill including expansion Joint and all requirements as per drawings and engineer’s instructions. UNIT QTY. M3 15 M3 5 M2 230 M2 500 M2 60 M3 10 M3 7 M2 200 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION UNIT QTY. 2.12 Supply and apply special painting material (FOSROC –Brush Bond or SIKA– Top Seal 107) for any concrete elements above the ground level (piers, walls, beams and slab). M2 710 TOTAL SECTION 2 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SECTION 3: Miscellaneous Works ITEM DESCRIPTION 3.1 Supply, assemble and fix Elastomeric bearing joint, (Bearings TYPE 1) according to German Standards DIN 4141 Part 14, plan size 200x300mm with a total thickness of 30mm (two elastomeric layers 8mm each and three reinforcing steel shims with 3mm each) and with allowable vertical load of 750kn. As detailed in drawings, and according to Engineer’s instructions. 3.2 Supply and lay compacted asphalt binder course (3/4” nominal aggregate size) 7 cm average thickness, compacted to at least 98%, including spraying the slab with RC2 binder coat at the rate of 1.0 kg/m2 and all required tests. All in accordance with the specifications, drawings, and Engineer’s instructions. 3.3 3.4 3.5 Supply and lay approved sub-base material (Kurkar) for the carriageway (under the approach slab) with CBR >30% in layers of 15cm thickness each with watering and compaction up to 98% of maximum dry density MDD. The price includes preparation of subgrade to design levels and compaction up to 95% according to modified Procter test. Ditto but Kurkar, of 10 cm thick in one layer for sidewalks with CBR >30% and compaction to 95 %. Supply and lay pre-cast concrete interlock tiles 6cm thick for the sidewalks on a layer of 5 cm clean sand. Price include compaction and filling joint with sand to required grades, Shape, pattern and color are as advised by the engineer. UNIT QTY. No. 15 M2 350 M3 60 M2 40 M2 40 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 3.6 Supply and install handrail of the bridge comprising of F3” & F1.5”galvanized steel pipes with required welding. The work includes fixing and painting as per the drawings and engineer’s instructions. The painting should be done by using a primer polyzinc layer and two layers of colored paint according the drawings and Engineer’s instructions. Price also includes painting of curbstone according to engineer's instructions. Supply and install double galvanized steel pipes 4” including all fittings and welding and hanging holder. The holder consists of (80x45x6mm) galvanized steel section and fixed to the bottom of bridge slab through galvanized steel Plates and anchored to the slab through 3F20 anchors according to Engineer’s instructions. The item also includes connecting the pipes with the existing manholes at the both ends of the bridge. The contractor shall coordinate with the PALTEL regarding transferring the telephone lines. Supply and fix signboard showing allowed vehicles to pass over the bridge as per drawings. The work shall include galvanized steel posts, concrete foundations, Timber or ply backboards and all other required works. Supply and fix cast iron rainwater drainage grit 90x40cm including galv. Steel plate tray and galv. Steel pipe 6” and all necessary fittings and pieces as indicated in drawings and according to the engineer's instructions. 3.7 3.8 3.9 UNIT QTY. Linear Meter 200 MR 50 No. 2 No 4 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges ITEM DESCRIPTION 3.10 Maintain and clean out the existing gutters and Paltel manholes at the both ends of the bridge to the operational conditions. Price includes supply and installs missing cast iron grills and covers 25 tons capacity and connecting the gullies to the wadi flow using pipes of the same existing size and type of pipes and all requirements according to the engineer’s instructions. TOTAL SECTION 3 UNIT QTY. L.S 1 UNIT RATE ($) TOTAL ($) UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges SUMMARY B Section No. Section Description 1 Demolition, Excavation, Backfilling and Stone Works. 2 Concrete Works 3 Miscellaneous Works Value ($) Total VAT ZERO Grand Total Total In Words: ــــــــــــــــــــــــــــــــــ DATE: _____/______/________ Contractor’s Stamp and Signature _________________________________________________________________ UNDP/PAPP-Construction and Rehabilitation of Wadi Gaza Bridges General Summary A- Al Sikka Bridge ……………………………USD____________ B- Wadi Gaza Bridge …………………………… …USD____________ Total ………………………………. USD____________ VAT ……………………………………..ZERO Grand Total ……………………………… USD_____________ Grand Total in Words …………………………………………. …………………………………………………………………… Contractor ………………………………. Authorized Person to sign ……………………………….. Signature ………………………………… Stamp ………………………………… Date ………………………………… Address ………………….. Tel. ……………………… Fax ………………………