Gas Turbine Power Plants

advertisement

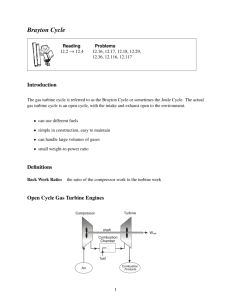

Gas Turbine Power Plants Gas Turbine Power Plants are lighter and more compact than vapor power plants. The favorable power-output-toweight ratio for gas turbines make them suitable for transportation. Air-standard Brayton Cycle 188 Q CV WCV 0 (hin hout ) m m For steady-state: 12 23 34 41 Win Adiabatic compression (h2 h1 ) m Q in Heat addition (h3 h2 ) m W out Adiabatic expansion (h3 h4 ) m Q out Heat removal (h4 h1 ) m Cycle Thermal Efficiency: Brayton cycle Q out m h h 1 1 4 1 Q in m h3 h2 Back work ratio: Win m h h bwr 2 1 W out m h3 h4 189 Ideal Air-standard Brayton Cycle (processes are reversible) 12 23 34 41 Isentropic compression Constant pressure heat addition Isentropic expansion Constant pressure heat removal Qin Qout For the isentropic process 1 2 P Pr 2 Pr 1 2 P1 For the isentropic process 3 4 P Pr 4 Pr 3 4 P3 190 Ideal Cold Air-standard Brayton Cycle For isentropic processes 1 2 and 3 4 k 1 k T2 P2 T1 P1 Since and k k 1 T P2 P3 thus 2 P1 P4 T1 k 1 k T4 P4 T3 P3 k k 1 T 3 T4 T2 T3 T1 T4 Thermal Efficiency Brayton 1 constk h4 h1 c T T T T / T 1 1 P 4 1 1 1 4 1 h3 h2 c P T3 T2 T2 T3 / T2 1 T2 T3 T4 T3 recall T1 T4 T1 T2 Brayton 1 constk T1 1 T2 1 k 1 P2 P1 k 191 Efficiency increases with increased pressure ratio across the compressor Back work ratio Win m W comp m c P (T2 T1 ) T2 T1 bwr Wout m Wturb m c P T3 T4 T3 T4 Typical BWR for the Brayton cycle is 40 - 80% compared to < 5% for the Rankine cycle. Recall, reversible compressor work is given by 12 vdP Since gas has a much larger specific volume than liquid much more power is required to compress the gas from P1 to P2 in the Brayton cycle compared to the Rankine cycle for which liquid is compressed. The turbine inlet temperature is limited by metallurgical factors, e.g., Tmax = 1700K 192 Gas Turbine Irreversibilities In the ideal Brayton cycle all 4 processes are assumed reversible, thus processes 2-3 and 4-1 are constant pressure and processes1-2 and 3-4 are isentropic. The constant pressure assumption does not normally incur any great errors but the compressor and turbine processes are far from isentropic Ideal (reversible) processes: 1 - 2s and 3 - 4s Actual (irreversible) processes: 1 - 2 and 3 - 4 These irreversiblities are taken into account by: turb Wt m h3 h4 h3 h4 s Wt m s comp W c m s h2 s h1 h2 h1 Wc m 193 Efficiency versus Power Consider two Brayton cycles A and B with a similar turbine inlet temperatures T3 P P Since 2 2 A B P1 A P1 B Since (enclosed area 1-2-3-4)B > (enclosed area 1-2-3-4)A W cycle W cycle W cycle , A m A m m m B W cycle , B B A In order for cycle A to produce the same amount of net power as cycle B, i.e., W cycle , A W cycle , B , need m A m B . Higher mass flow rate requires larger (heavier) equipment which is a concern in transportation applications 194 Increasing Cycle Power The net cycle power is: W cycle Wt W c The cycle power can be increased by either increasing the turbine output power or decreasing the compressor input power. Gas Turbine with Reheat The turbine work can be increased by using reheat, as was shown in the Rankine cycle 2 3 a b Compressor 1 4 The turbine is split into two stages and a second combustor is added where additional heat can be added 195 Recall: T2 T3 so, isobars on T-s diagram diverge T1 T4' Q in , 2 3 Q in,1 T b Note: hb - h4 > ha - h4’ a 2 4 4’ 1 s The total turbine work output without reheat is: Wbasic h3 ha ha h4' m The total turbine work output with reheat is: Wturbine Wt ,1 Wt , 2 h3 ha hb h4 m w / reheat Wturbine Wbasic Since hb - h4 > ha - h4’ w / reheat Since the compressor work h2 - h1 is unaffected by reheat Wcycle w / reheat Wcycle basic The reheat cycle efficiency is not necessarily higher since additional heat Q in , 2 is added between states a and b 196 Compression with Intercooling The compressor power can be reduced by compressing in stages with cooling between stages. T2 T3 so, isobars on T-s diagram diverge T1 T4' Recall: 2’ 2’ h2’ – hc > h2 – hd d 197 The compressor power input without intercooling is: Wbasic h2' hc hc h1 m The total compressor power input with intercooling is: Wcomp Wc,1 Wc, 2 hc h1 h2 hd m w / reheat Since h2’ – hc > h2 – hd Wcomp Wbasic w / reheat Since the turbine work h3 – h4 is unaffected by intercooling Wcycle w / reheat Wcycle basic 198 Different approach: The reversible work per unit mass for a steady flow device is vdP , so 2’ 2 c 2 W c vdP vdP vdP Without intercooling : m basic 1 1 c area b-1-c-2' -a ' 2 c 2 W c vdP vdP vdP With intercooling : m w/ int 1 1 d area b-1-c-d-2-a Since area(b-1-c-2’-a) > area(b-1-c-d-2-a) W c W c m basic m w / int 199 Aircraft Gas Turbines Gas turbine engines are widely used to power aircraft because of their high power-to-weight ratio Turbojet engines used on most large commercial and military aircraft Ideal air-standard jet propulsion cycle: Diffuser a 1 2 3 Nozzle 4 5 200 Normally compression through the diffuser (a-1), and expansion through the nozzle (4-5) are taken as isentropic Q in Q out In the ideal jet propulsion engine the gas is not expanded to ambient pressure Pa. Instead the gas expands to an intermediate pressure P4 such that the power produced is just sufficient to drive the compressor, no net cycle power produced (W cycle 0 ), thus W c Wt m m h2 h1 h3 h4 After the turbine the gas expands to ambient pressure P5 which is the same as Pa. 201 Apply the steady-state conservation of energy equation to the Diffuser and Nozzle 2 Q CV WCV Vin2 Vout hout 0 hin m m 2 2 Diffuser slows the flow to a zero velocity relative to the engine: Va2 V12 h1 ha 2 2 Va2 h1 ha Diffuser (a 1) 2 Va2 T1 Ta for constant k 2c P Nozzle accelerates the gas leaving the turbine (turbine exit velocity negligible compared to nozzle exit velocity): Nozzle (4 5) V52 V42 h4 h5 2 2 V5 2h4 h5 V5 2c P T4 T5 for constant k 202 The gas velocity leaving the nozzle is much higher than the velocity of the gas entering the diffuser, this change in momentum produces a propulsive force, or thrust Ft Ft m V5 Va Where V is flow velocity relative to engine For aircraft under cruise conditions the thrust just overcomes the drag force on the aircraft fly at high altitude where the air is thinner and thus less drag To accelerate the aircraft increase thrust by increasing V5 In military aircraft afterburners are used to get very large thrust for short take-offs on aircraft carriers An afterburner is simply a reheat device! 203 Other Propulsion Systems Turboprop Turbofan Subsonic ramjet In turbofan bypass flow produces additional thrust for take-off. During cruise thrust comes from turbojet In a ramjet engine there is no compressor or turbine, compression is achieved gasdynamically. Ramjet engines produce no thrust when stationary thus must be coupled with a turbojet engine to get off the ground 204 Supersonic Ramjet Engine The flow is decelerated to subsonic velocity before the burner via a series of shock waves. Combustion occurs at constant pressure Supersonic exhaust flow Supersonic free stream flow choked flow Turbojet-ramjet combination: 205 Supersonic Combustion Ramjet (SCRAMJET) Engine At very high Mach numbers the air temperature gets extremely hot after deceleration through the diffuser Va2 T1 Ta 2c P For Mach 6 flight speed, the air temperature just before the burner reaches about 1550K. At this temperature the air dissociates resulting in a drop in enthalpy At flight speeds greater than Mach 6 (hypersonic) better to burn fuel- in supersonic air stream 206 US National Aero Space Plane (X-30) Was to use 5 scramjet engines to achieve a Mach 12 flight speed To be used for travel to space and also as an airliner, a flight between any two points on earth would take less than 2 hours Canceled in 1993! Several countries have similar planes on the drawing board, Canada is not one of them! 207