Turbocharger matching

advertisement

Turbocharger matching

• While the operating engineer will not

normally be involved in turbo-charger

matching, a familiarity with the procedure

will lead to a better understanding of the

interdependent relationship between

engines and their turbochargers, and of

the effects, in service, of operation off the

design point.

1.

2.

Inlet conditions of the

compressor P1 (after

pressure drop across air

suction filter) and T1 are

selected.

An estimate is made of the

power of the engine at a

particular engine RPM.

Also, an estimate is made

of amount of air, ma, the

engine would require at

above conditions.

ma = Vsw x a x vol x N (for

two stroke diesel engine).

The pressure in the air

manifold and temperature

are estimated to get the a.

3.

4.

A drop across air cooler is

assumed and added to air

manifold pressure to get

the compressor discharge

pressure P2. The

compressor pressure ratio

P2/P1 can now be

calculated.

The compressor frame size

and its diffuser can now be

selected by entering the

family of compressor maps

with the values of P2/P1 and

Va or (maT0/P0). The

operating point must have

adequate margin from

surge limit i.e. it must be

10% to 20% to the right of

the surge limit at the value

of P2/P1.

5. From the performance

map of the selected

compressor and

diffuser, the

compressor efficiency

(c) and turbocharger

RPM are read at the

operating point.

6. The required power to

drive the compressor

is given by

Wc=maCpaT1[(P2/P1)(-1)/ -1]/ c

The required turbine

power Wt = Wc / mech

where mech is the known

characteristic of the

bearings.

7. Again an estimate is made of the gas

conditions at the turbine inlet i.e. P3 and T3

from basic principles and empirical data

including previous performance.

8. The turbine outlet pressure P4 is also

estimated by adding an amount to

atmospheric pressure to allow for typical

losses through exhaust gas economiser.

Then expansion ratio P3/P4 is calculated.

9. The mass flow rate of gas, mg, is calculated

by adding mass flow rate of fuel, mf, to

mass flow rate of air, ma, which was

estimated previously.

10. In general, the selection of a

compressor wheel diameter

predetermines turbine

characteristics, which

includes wheel diameter and

blade length. With values of

P3/P4 and Vg, a turbine blade

and nozzle angle selection

curve, can be entered for the

frame size under

consideration, to select nozzle

opening and blade angle.

11. The following are calculated:

Mean tangential velocity of blade,

Um = x Dm x RPM

where Dm = mean diameter of

turbine wheel

Ideal gas speed at nozzle exit

Cg = [2Cpg T3 {1- (P4/P3)-1/]

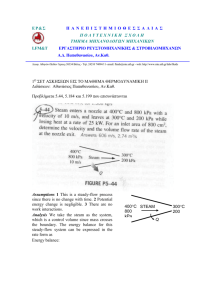

12. The turbine efficiency t

can then be obtained from

figure.

13. The available power of the

turbine

Wt = mgCpgT3 [1–(P4/P3)(-1)/] t

14. A comparison is made

between the turbine power

available and turbine

power required. If available

power is greater than

required power, then the

estimate of air manifold

pressure, made in step 2,

can be raised and the

procedure is repeated with

this new assumption. If the

available power is lower, a

lower value of air manifold

pressure is assumed.

• This iterative process is continued till the

required turbine output matches the

achieved value within a percent or two,

with the final matching to be done by

actually running the turbocharger and

engine on a test-bed and making final

adjustments by changing compressor

diffuser vanes and turbine nozzle rings.