The Remote Control System - Unesco Virtual Laboratory Toolkit

advertisement

A Remotely Controlled Experiment System

Wei-Ming Ni, Zhu Liu, Jing Li, Song-You Wang, Xiao-Song Zhu, Yun-Sheng Ma, Jian Miao,

and Liang-Yao Chen

School of Information Science and Engineering, Fudan university

Shanghai Research Center for the Applied Physics

Ying-Wen Cai

School of Material Science, Shanghai Jiao-Tong University

Abstract

A method is proposed to provide a remote experiment system environment. The main task is

to develop the framework software that can be used to remotely control the experiment system.

The method has been applied to an advanced infrared spectroscopic ellipsometer to test the

principle. The system includes the local server and remote client, in a test connection. In

communication with the local operator as needed, the remote experimenter can adjust the

experiment parameters, in this case the photon energy range and the incident angle, to run the

system. When the experiment is over, the remote experimenter can immediately obtain the result.

Also, a visual monitoring system is set up to enable the remote user to watch the experiment when

the system is running. An improved methodology, based on a Web interface for more user friendly

and flexible use, is proposed for future development.

Keywords : Person-to-equipment; remote control; infrared ellipsometer.

I.

Introduction

The fast development of the modern information technology has deeply changed the life of

societies and people. One of the significant areas of progress worldwide is the wide use of modern

computer technology in broadband networks, resulting in a rapid growth of Internet applications.

This provides a major opportunity for future research and education and will substantially reduce

the distance limitation in traditional education. Scientists can realize research cooperation by

sharing experimental resources and systems through the Internet.

New methods and tools for this purpose provide an easier way for scientists to do research,

even in different countries, and will save experimental costs, especially for the scientists working

in developing countries. The remotely controlled experiment system also can be applied to the

education and distance learning process.

For the present study, an advanced infrared ellipsometer was used in the remotely

controlled system. We will discuss the method and software used to run the system with success.

The method was tested and realized in a real situation to remotely control the experiment through

an advanced optical network.

In the remotely controlled infrared ellipsometer experiment system, the client, i.e. the remote

operator, can adjust the experiment parameters, in this case the range of wave numbers or the

range of incident angles. During the experiment, the connection to other clients is blocked. For

security considerations, in order to protect the expensive experiment, protective methods such

one-to-one connection and password-setting were used. Moreover, the local operation running on

the server machine has an independent protection.

There are two functions in a remotely controlled system. One is called P-to-E (person to

equipment) function which is the principal subject of this paper while the other is P-to-P (person

to person) function. The P-to-E function provides shared tools to allow the remote client run the

equipment through the Internet. The P-to-P function involves another kind of shared tools to

enable the remote client to communicate personally with the local operator through the Internet.

The remote client, therefore, can be informed about the experimental process, and will understand

what is happening in the experiment.

II. Infrared ellipsometer system

The infrared spectroscopic ellipsometer is useful for many research projects for example in

physics, materials science, biology, medicine, and atmospheric science. From the infrared

spectrum data of the materials, the optical properties of the materials and other structure can be

obtained. This is a non-destructive optical measurement method with greatest advantages in

biological sample testing and photonic device studies. The instrument will also be used as a

powerful tool in the infrared beam line that will be established in the Shanghai Synchrotron

Radiation center in the near future.

The double-Fourier transform infrared spectroscopic ellipsometer was constructed in the

authors’ laboratory. The experiment system is controlled by a computer. The user can input two

parameters in the experiment, i.e., the wave number range from 2100 to 10,000 cm-1 and the

incident angle scanned from 30 to 90 degrees. The software was written by using the Microsoft

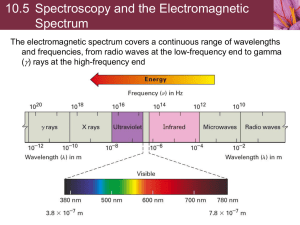

Visual Basic 3.0. The experiment scheme is shown in Fig.1.

1.Polarizer 2. Analyzer 3. Step-Motor 4. Detector Rotaing Table 5. Sample

Rotating Table 6. Sample Support 7. Plane Mirror

Fig.1 The optical and control system scheme of the Double-Fourier Transform

Infrared Spectroscopic Ellipsometer

III. The remotely controlled system

The remotely controlled system includes two components as shown in Fig. 2: one is the

remote client, the other is the local server. The two components have different functions. At the

remote client, the operator can set the experiment parameters and remotely watch and control the

experimental process, through an on-site video camera, and at the same time obtain the

Server

Internet

Client

Experiment

System

Control

Plane

Decoder

Image Capture

Video

Camera

Fig. 2 The remote control system scheme

Fig.3. The structure scheme of the remotely controlled system

experimental data. For the local server system, there are three main parts: 1. the infrared

ellipsometer experiment sub-system; 2. the server with control programs; 3. the video monitoring

camera system.

The communication system includes a computer that connects the remote client through the

Internet and the local server computer linking to the Internet, video camera, A/D decoder and

multi-dimensional rotating table.

P-to-E means person to equipment, which implies communication between two agents: the

person who will run the system, and the equipment. For the "person part", the operator will have

individual experiment requirements. Taking the equipment into consideration, there will be two

key software choices. One is the operating system, such as the Windows or UNIX systems that are

popular today. In the study, we have used the Windows operating system to test the system. The

other choice concerns the design of the software to control the equipment which was written in

Visual Basic, Visual C++, and Turbo C.

The ISA control software was written in the Microsoft Visual C6.0++ language. It

communicates with the experiment program by the method of translating and transferring the

Windows message. Therefore, the remote client should have the Microsoft Spy++ Tool, which can

capture the Windows message and transfer the information into the control program.

The real control system and operation menu are shown in Figs. 5-8. In 2001, the method was

tested with success in a real situation to remotely control the infrared spectroscopic ellipsometer

through an advanced optical-network across the city of Shanghai.

Fig. 5. Remotely controlled infrared spectroscopic ellipsometer

Fig. 6. Remote experiment system monitor

Fig. 7. Remote operation menu and monitor window viewing the experiment situation

Fig. 8. Remote operation menu and monitor window viewing the sample-mounting situation

IV. The HTTP server extension approach

In order to make the remote control environment process more flexible and user friendly, we

propose a framework software approach for future development. In this approach, the construction

of the remote experiment system is based on the HTTP communication protocol. All experiment

commands (including the setting of parameters and the execution of operations) are sent as HTTP

requests. After the HTTP server receives the request signal, the operation information is extracted

from the request string and then transferred to the experiment control process by IPC (InterProcess

Communication). The HTTP server software (Internet Information Server, Apache, etc.) must be

selected: here the IIS (Internet Information Server) has been chosen. The operational principle is

presented in the diagram in Fig. 4.

Use of the Web presents several advantages. First, Internet Explorer is a well-developed

interface tool for the client computer which is convenient and easily operated. Moreover, this

method faciliates the realization of a generally applicable remotely-controlled experiment system.

Our HTTP-based Server program links to the client by requesting, translating and transferring

command strings.

With respect to the experimental equipment, the sequence of operations is different. For the

proper action of the experiment system, the commands and experimental parameter settings

should be predefined in a data structure such as the following:

Type def struct {

LPSTR Name, Value, Description;

BOOL Required;

BOOL Valid;

} FormField;

where, Name is the name denoting a command and associated parameter set of the experiment;

Value is the value of the parameter set; Description is the description of the command and

parameters; Required=TRUE indicates that parameters of the experiment should be set, otherwise

they are ignored. Valid indicates the validity of the parameters of the experiment; if the

HTTP-based Server finds the setting of the experimental parameters by the remote client to be

invalid, it will send a error message to the client by calling an error information program.

Conveniently, to use the different experimental devices, users need only modify the

corresponding content of the command form and need not change the overall Server program for

the application. Following is the example to explain the process.

To take account of the variety of situations and instruments which can be used in an

experiment, the communication between the server and experiment program may differ. For

example, Windows Message Queue, Winsocket, Windows DDE (Dynamic Data Exchange), or

Named Pipe may be used to provide the interface port for IPC (InterProcess Communication) for

the Server program. One can select the IPC method by modifying an "*.ini" file. For example, for

the Windows Message method, the first parameter in the ini file would be specified as "Windows

Message", followed by the information to control the experiment, such as the title of control

program window or ID button of the control software, and the experimental parameters and

equipment commands. When one runs the HTTP server extension program, the program will read

the ini file first and then execute the operation. Therefore, the HTTP server extension program

functions as an intermediary which communicates between the client by and the experiment

control program, performing double translations between the communication protocol (HTTP) and

the "non-communication" protocol of the instrument. By careful design of a Web page, one can

use the same remote control interface to run several experimental devices.

The remote control process works as follows (please refer to Fig. 4):

1. According to the input requirements for experiment control presented in Web pages, the

"get" or "post" method is used to send to the server the parameters to be set in the experiment.

2. The ISA (International Server Associate) acts as a middleware. It extracts the client request

message first and then communicates with the experiment control process by IPC (InterProcess

Communication). Different methods can be used as IPC as explained above (the functional part of

this process is enclosed in red dashed rectangle in Fig. 4).

3. The experiment control software receives the message to control the system and translates

the message to the appropriate data format for the equipment, or just simply executes the

corresponding process in the software to control the instrument.

ISAPI Filter

www client

WWW

IIS

Experiment

IPC

ISA

Control

Figure 4. The Principle of HTTP Server Extension

An example of a Web based user interface in such a scheme is shown below:

Save File Name:

Rotate(2-10):

Incident Angle(0-90):

Wave Number Range (2100-10000)cm

-1

Setting

DataProcess

Html page source code:

<HTML>

<BODY>

<H1><B>Remote Experiment Sample</B></H1>

<FORM

id=FORMSETTING

title="Experiment

Parameter

Setting:"

name=FORM1

action

=

/scripts/Samples/RemoteCtrl_ISA.dll method="get" style="BACKGROUND-COLOR: gray">

<P>&nbsp;&nbsp;Save

File

Name:<INPUT

id=TextSaveFName

style="LEFT:

53px;

TOP:

54px"

name=FName></P>

<P>&nbsp;&nbsp;Rotate(2-10):<INPUT id=TextRotate style="LEFT: 52px; TOP: 97px" name=Rotate></P>

<P>&nbsp;&nbsp;Incident Angle(0-90):<INPUT id=TextAngle name=Angle></P>

<P>&nbsp;&nbsp;Wave Number Range (2100-10000)cm<SUP>-1</SUP> </P>

<P>&nbsp;&nbsp;&nbsp;&nbsp;<INPUT

id=SubmitSetting

type=submit

value=Setting

name=SubmitSetting title="" style="LEFT: 10px; TOP: 289px"></P>

</FORM>

<FORM

id=EXEC

title="Experiment

process:"

name=FORM2

action=/scripts/RemoteExec_ISA.dll

method="get">

<P>&nbsp;&nbsp;&nbsp;&nbsp;<INPUT

id=SubmitExec

title="DataProcess"

type=submit

value=DataProcess name=Ctrl_Proc></P>

</FORM>

</BODY>

</HTML>

In the above HTML code, the words in blue are the HTML language expressions.

When enters the experimental parameters (only the rotation angle and incident angle fields

are active on this sample page; in the actual interface, the user will also be able to choose the wave

number range) and save file name, and then clicks on the "Setting" button, the requested

parameters are sent by HTTP to the IIS Server program. called RemoteCtrl_ISA.dl to deal with the

request. This is done by sending a request string such as the following to the local server:

Get /scripts/samples/RemoteCtrl_ISA.dll ? FName=D:\\Data & Rotate=%2 & Angle=%70…

The ISA process "RemoteCtrl_ISA.dll" will then extract the data from the request string, and save

them to the array data base with the data structure described above. Clicking on the "DataProcess"

button will send the extracted message to the experiment control software through the

RemoteExec_ISA.dll program on the server.

At the local server end, one of the following systems are required:

Windows NT Workstation, version 3.51 or higher, with Peer Web Server

or

Windows NT Server version 3.51 or higher, with IIS (Internet Information Service)

Acknowledgement

This work was supported by the UNESCO and the Ministry of Education of China.

References

[1]. J. Wagstaff, G. McKay, A. Reid, G. Reid,"Remote operation of a Camera SX100 scanning

electron microprobe", Computer & Geosciences, 25 (1999), 523-529

[2] F. Ferrieu, "Infrared spectroscopic ellipsometry using a Fourier transform infrared

spectrometer: Some applications in thin-film characterization", Rev. Sci. Instrum. 60 (10),

3212-3216, 1989

[3] R. Ossikovski and B. Drevillon, "Infrared-ellipsometry evidence of disorder-induced vibration

frequency shifts in hydrogenated-amorphous-silicon thin films",

Phys. Rev. B,

54

(15),10530-10542,1996

[4] A. Canillas, E. Pascual, and B. Drevillon, "Phase-modulated ellipsometer using a Fourier

transform infared spectrometer for real time applications", Rev. Sci. Instrum, 64 (8),

2153-2159 ,1993

[5] Guo-Qiang Xia et al. "New design of the variable angle infrared spectroscopic ellipsometer

using double Fourier transforms." Rev. Sci. Instrum., 71, July 7,2000.

[6]. R. W. Younglove, "IP security: what makes it work?" Computing & Control Engineering

Journal, 2 (2001),44-46

[7]. Z. Liu, X. S. Zhu, W. M. Ni, Y. S. Ma, J. Miao, L. Y. Chen, "Application of remote control

system to infrared spectroscopic ellipsometer", J. Infrared Millim. Wave, 21 (2002),129