20(Chemistry)

advertisement

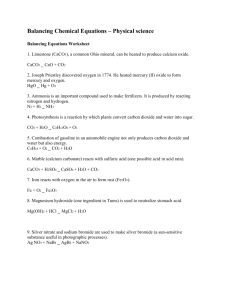

Limestone Engineering Consultants Ltd. To: Methanol Project Team From: Carolyn Wong, Chief Chemist Chemistry of Syngas Reaction The feed to the system is basically a 2:1 H2:methane mixture (molar ratio). It also contains inert gases (mostly nitrogen, but with other components such as argon) to the extent of 2.5% of the methane. It is suggested that the all the inerts be modeled as nitrogen. The feed is heated to 880 ºC in a furnace and fed to the reactor where the reaction CH4 + H2O => CO + 3H2 takes place. This is an endothermic reaction (that is why it requires a high temperature) and additional heat must be added to maintain the 880ºC temperature. Methane conversion is 95%. Because of the presence of water in the system, some CO will be converted to CO2 by the water gas reaction CO + H2O => CO2 + H2. However the catalyst does not promote this reaction, and the amount of CO converted in the initial reaction will be small. Recent developments by the client allow for an optional second reaction system that carries out this water gas shift reaction. Chemistry of Methanol Reaction Methanol can be made from CO and/or CO2 plus hydrogen. From CO2 the reaction is: CO2 + 3H2<=> CH3OH + H2O. [1] Much of the earlier literature talks about CO and hydrogen reacting to form methanol via the reaction CO + 2H2< => CH3OH. [2] The latest thinking is that the CO2 to methanol reaction does not occur at any measurable rate, and the reaction actually takes place in two steps. First, CO is converted to CO2 by a water gas reaction CO + H2O <=> CO2 + H2 (note that this requires water). [3] Then the CO2 reacts as shown in reaction [1]. 533567707 - 2 The water required in [3] is regenerated in [1]. Therefore, the process only requires a trace of water to operate. Since the syngas process which produces CO is awash in water, this is never going to be a problem. Since the reaction is exothermic, the equilibrium is more favorable at low temperatures. Unfortunately, the reaction rates are low at low temperatures. The overall process from methane to methanol has a serious problem. The overall reaction is CH4 + H2O => CH3OH + H2 [4] This means that for every molecule of methanol that is made, a molecule of hydrogen must be removed from the process (either in the syngas part or the methanol part). If an attempt is made to remove the hydrogen from the syngas process, it would be necessary to separate hydrogen from CO/CO2 . This is not a trivial task. Because of the unfavorable equilibrium in the methanol process it is necessary to run a low conversion per pass through the reaction system, and use a high recycle rate. A huge purge would have to be taken to remove the hydrogen. Unless we are prepared to separate the CO/CO2 from the hydrogen and recycle it, the losses through a purge would be ruinous. Either way, we are faced with separating a H2/CO/CO2 mixture. There is a better way. If we add more CO2 to the syngas as it enters the methanol plant we can build a stoichiometric mixture of CO, CO2 and hydrogen that will consume all of the hydrogen in the feed if all of the CO/CO2 is reacted. In this situation, the purge need only deal with nonreacting non-condensible materials in the feed (e.g. nitrogen, methane). A significant amount of useful material will still be lost through the purge, but much less. This stream will used as fuel in the syngas process to heat the feed. Let us investigate how this can be done. The syngas process generates three moles of H2 for each CO. Two of these hydrogens will react with the CO to produce methanol, leaving one to react with added CO2. This requires 1/3 mole of CO2. This makes it much easier to handle a low conversion per pass system with recycle. The two products can easily be condensed from the stream leaving the reactor, and the gases recycled. - 3 - The next question is “where do we get the CO2 from?”. Methanol plants are commonly built on the same site as ammonia plants. Ammonia plants generate CO2 as a waste product at pressures similar to the pressure we will use in the methanol process. We will work up out case on the basis that CO2 is available onsite. At some point we will have to examine the economics of operating at a site without an ammonia plant, but we will leave that to a future study. Note that the feed to the methanol reactor will not be exactly as shown for a number of reasons: because of the water used in the syngas reaction, the feed to the methanol reactor will contain a significant amount of unreacted water some inert gases will be present (nitrogen and argon) because they existed in the natural gas (it is suggested that these be modeled as though it is all nitrogen) some unreacted methane will be present in the syngas (we should assume 95% conversion in the syngas process) in the syngas process a small proportion of the CO will be converted to C02 by the water gas reaction - we will ignore this for two reasons: o it has no effect on the equilibrium state for the methanol reaction, and only a minor effect on the kinetics in the first stage of the reaction (especially with a high reycle rate) o until we see how the syngas process behaves we will not know the extent of this conversion Kinetics Methanol reaction: CO2 + 3H2 <=> CH3OH + H2O Forward rate: rfm = kfm[CO2][H2]3 Reverse rate: rrm = krm[CH3OH][H2O] Equilibrium constant: Km = kfm/krm = [CH3OH][H2O] ------------------[CO2][H2]3 Water gas reaction: CO + H2O <=> CO2 + H2 Forward rate: rfw = kfw[CO][H2O] Reverse rate: rrw = krw[CO2][H2] Equilibrium constant: Kw = kfw/krw = [CO2][H2] -----------[CO][H2O] - 4 The rate constants have been measured in the lab and correlated with the Arrhenius equation: k = A*exp((-E/RT) Reaction Water Gas Forward Water Gas Reverse Methanol Forward Methanol Reverse A (kg-moles, hr, m3) 1.37E24 2.17E26 1.04E22 2.60E28 E (KJ/kg-mole) 178 219 170 220 Impurity Reactions Side reactions will generate small amounts of impurities. The two most important ones are acetone, ethanol and fusel oil (a mixture of higher alcohols and other oxygenated species). We will not attempt to model the individual components of fusel oil – most of them are not known. Previous work suggests that it can be modeled as nheptanol. To confirm the validity of this simplification, K-value measurements (Y/X) were made with solutions of 5% fusel oil in water and methanol. These two values were compared with predictions on waterheptanol and methanol-heptanol systems obtained from the NRTL thermodynamics package. See the results in appendix 1. Although the precise reactions that generate the impurities are not known, the following mechanism gives a reasonable representation of the available data. In much the same way that methanol is produced (CO2 + 3H2 <=> CH3OH + H2O) a second step can produce ethanol: CH3OH + CO2 + 3H2 <=> C2H5OH + 2H2O In a sense this is a polymerization reaction with a monomer consisting of CO2 + 3H2. It can proceed to make a whole range of higher alcohols: propanol, butanol, pentanol etc. For example, the heptanol mentioned above can be thought of as coming from a series of reactions equivalent to: C2H5OH + 5CO2 + 15H2 <=> C7H15OH + 10H2O. We will model the process in this form. Limited data show that all of the above reactions are first order in CO CH3OH and C2H5OH, and third order in H2. It is believed that acetone is produced from ethanol: 2 C2H5OH <=> CH3COCH3 + CH3OH + H2 - 5 and is second order in ethanol. Although these side reactions are reversible, they are much slower than the methanol reaction, and the low concentration of higher alcohols means that the reverse reactions can be ignored. Limestone Engineering Consultants Ltd. Appendix 1 – Representation of Fusel Oil by Heptanol and NRTL Thermodynamics Water - Heptanol System 25 K Values 20 15 Water Heptanol 10 Fusil Oil 5 0 0 0.5 1 Liquid Composition - Mole Fraction Water Methanol - Heptanol System 1.4 K Values 1.2 1 Methanol Heptanol Fusil Oil 0.8 0.6 0.4 0.2 0 0.25 0.45 0.65 0.85 Liquid Concentration - Mole Fraction Methanol 533567707 - 7 -