Nonaqueous Deacidification of Paper with Methyl Magnesium

advertisement

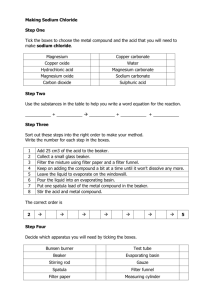

Nonaqueous Deacidification of Paper with Methyl Magnesium Carbonate by L. R. GREEN & M. LEESE INTRODUCTION Paper often becomes acidic with time. This is caused by several factors, including the oxidation of lignin, cellulose and other carbohydrate constituents of the paper to give carboxylic acids, absorption of sulphur dioxide and nitrogen oxides and the presence of alum. These acidic substances can hydro-lyse the cellulose chain and weaken the paper. Therefore, deacidification must be carried out to stabilize the paper. In many cases, an aqueous solution can be used for deacidification but. where water-fugitive media are present, a nonaqueous solution may need to be used. At present, the Western Pictorial Art Section of the Department of Conservation at the British Museum use a solution of barium hydroxide (Ba(OH)2, 2% w/v in methanol) for the nonaqueous deacidification of paper. After application to paper, and exposure to air, the Ba(OH)2 is converted to BaCO3. Both of these barium compounds are harmful to humans (Appendix 1). If the correct handling procedures are followed during treatment the conservator should not be exposed to the harmful materials. However, there is also concern that curators and students who subsequently handle the treated paper may be exposed to the health hazard. Although BaCO3, is only slightly soluble in water (approximately 0.5 mg/m3), there is a risk of absorption through the skin when one touches the treated papers. Treatment of paper with Ba(OH)2 produces an initially high pH within the paper, which could cause hydrolysis, and hence damage to the cellulose chains of the paper. On exposure to air this high pH slowly decreases, as the hydroxide is converted to the carbonate. Methyl magnesium carbonate (MeMgCO3) has been cited as an alternative nonaqueous deacidifying agent (1). Decomposition to magnesium carbonate, MgCO3. occurs rapidly when MeMgCO3 is exposed to the atmosphere, and hence treated paper would not be subjected to an initial high pH period, as is the case for paper treated with barium hydroxide. Magnesium compounds in general are less alkaline than barium compounds. Furthermore, neither of the magnesium compounds pose health and safety problems. As the MeMgCO3 treatments have several apparent advantages over Ba (OH}2, the effects of these treatments on the tensile strength and pH of filter paper and printed book paper were examined. Both treatments were compared as solutions in methanol. Although methanol is toxic to humans, it was used to ensure a direct comparison between the two treatments, as the strength and pH of paper can be affected by soaking in different solvents.3 Methanol is present during treatment only, as it evaporates from the paper soon after treatment. Provided that the correct safety procedures are obeyed during treatment, there should not be any significant exposure to the methanol. The relative effects of aqueous and nonaqueous deacification agents were also of interest. Therefore, the aqueous deacification treatment, calcium hydroxide (Ca(OH)2) was included in the comparison. The effects of all treatments on filter paper and 100-year-old printed book paper were assessed using tensile strength and pH measurements. MeMgCO3 decomposes on contact with the air or moisture. Hence, partially used containers of MeMgCO3 may be unusable within a few days, becoming milky in appearance. The manufacturer claims that a sealed container of PHizz* (MeMgCO3) should have an infinite shelf life, and be useful for approximately one year after opening, although repeated exposure of the solution during use reduces its lifetime substantially. Because commercially available MeMgCO3 has a limited shelf life, the feasibility of on-site laboratory production of MeMgCO3 was also assessed. The shelf life of the laboratory-produced material was unknown. The aim of this evaluation was to determine whether the Western Pictorial Art Section of the Department of Conservation of the British Museum could use MeMgCO3, whether from a commercial supplier or manufactured on-site in the British Museum, as an alternative nonaqueous deaciclification agent to the currently used barium hydroxide solution. Additionally, the relative effect of aqueous deacidification treatments were of interest. MATERIALS The following treatments and controls were compared: A. PHizz commercially produced MeMgCO3 2% w/v), supplied as a solution in a mixture of methanol (MeOH) and trichlorofluoroethane (CC13CH2F); B. MeMgCO3 (1.3% w/v) in methanol produced in the laboratory (see procedure below); *Supplier: Atlantis Paper Co., 2 St-Andrew΄s Way, Bow, London E3 3PA, UK C. D. E. F. G. Ba(OH)2 (2% w/v in mcthanol: calcium hydroxide (Ca(OH)2 0.2% w/v) saturated solution in water; distilled water; methanol: and untreated control. MeMgCO3 was prepared using the method described by North.4 First, magnesium turnings were reacted with methanol to produce magnesium methoxi-dc. Carbon dioxide was then bubbled through the solution to form MeMgCO3. This was diluted with methano) to form a 1.3% w/v solution. The reaction between the magnesium turnings and the methanol was vigorous and had to be controlled by cooling. The initial attempt to produce MeMgCO3 was successful. However, when the attempt was repeated several months later, the reaction could not be initiated. This was thought to be caused by the accumulation of an oxide layer on the magnesium turnings. Even when the turnings were abraded to expose a fresh metal surface, or iodine was added to catalyse the reaction, it was not always successful, and much time was taken trying to repeat the initial reaction. (The presence of iodine in the deacidifying solution is undesirable, because of the risk of discoloration when applied to paper.) In the light of these difficulties and the cost of on-site production of MeMgCO3 relative to the purchase of PHizz (Appendix 2), it was deemed more efficient to purchase PHizz as and when required. However, as sufficient McMgCO3 had been produced on-site. it was used in the following evaluation. Had it proved to be a better treatment, time could then have been spent investigating improvements in production. EXPERIMENTAL DESIGN The effects of the 3 nonaqueous and one aqueous dcacidification treatments were compared using two papers: • Whatman No. 2 filter paper (a pure cellulose paper), . 103 g/m2; and • printed book paper (nineteenth-century), 54 g/m . Statistical principles were used to design an appropriate experimental regimen. The aim was to average out random variation as far as possible and to estimate realistic errors that would incorporate any remaining unavoidable variability caused by natural mhomogeneity in paper and differences in application of the treatments and in experimental technique. Book paper was chosen to reflect the degree of variation often observed in acidic paper requiring deacidification treatment. Choice of filter paper was less critical, since it was present in the experiment as a comparison for the book paper rather than being of interest per se. Previous work has shown that the tensile strength of filter paper does not change on aging. It was therefore useful to investigate whether there was a change in tensile strength on aging after treatment with a deacidifying solution. Altogether, three book pages and three sheets of filter paper were chosen. Each set of three was further divided into seven subpieces, one or each of the treatments A-G. The treatments were randomly assigned to the subpieces, one from each of the three pages or sheets as appropriate. Each subpiece was further split into two: one to be artificially aged, and one to be left imaged. In statistical terminology, the book pages or paper sheets are known as blocks, their purpose being to enable natural inhomogeneity to be averaged out. The subpieces to which the treatments are randomly applied are known as plots: hence, the name for this standard experimental design is the split-plot randomized block Fig. 1). METHOD Treatment Deacidification treatments may be applied to paper by spraying, brushing through tissue or by immersion. The first two methods are not easily controlled Fig. 1. Experimental design used for tensile strength and initial pH measurements. The diagram shows the full method for aged book paper only. and depend on the user, whereas conditions can be precisely controlled during immersion. Immersion was therefore chosen as the technique for treatment of the experimental papers. The papers were immersed in the solutions for 2 min, which is an average time for treatment in a real situation. In this time the solutions appeared to have penetrated into the papers. The treated paper pieces were allowed to dry, lightly sandwiched between sheets of blotting paper, in a fume cupboard. Some of the printed book paper became brighter during treatment because of the cleaning effects of the solvents, with water producing a brighter paper than the methanol. Consequently, the deacidification solutions became yellow after treatment of the book paper. None of the treatments had a visibly affected the appearance of the filter paper, as this was clean and white prior to treatment. Heat aging Pieces of treated and untreated filter paper and printed book paper were aged in an oven at 60°C for 28 d and any colour changes were assessed visually. No discoloration of the filter paper samples was observed on aging. However, the printed book papers yellowed slightly on heat aging, although those that had been deacidified (treatments A-D) showed less colour change on aging than the control. Microscopic examination Samples of paper from each treatment were examined in reflected light at x 120 magnification using a stereo microscope. No change was visible with the untreated paper samples. Slight precipitation was visible at a magnification of x 120 on the papers treated with barium hydroxide and calcium hydroxide. This could be damaging, as the precipitated material could cause abrasion of the fibres within the paper when handled. Tensile strength Ten consecutive strips (l00 x 10 mm) were cut from each piece (aged and unaged) leaving a small area that was retained in case it was necessary to repeat analysis. Prior to tensile strength measurements, the papers were humidified overnight up to 55 + 5% relative humidity (RH). The thickness of a typical strip was measured using a micrometer by measuring the total Tensile strength measurements were made using a JJ Lloyd tensile tester type T5003) fitted with a 50 N load cell. The tensile strength of each strip of paper was calculated using the formula: - See Table 1 and Fig. 2 for results. As the ten strips in a given set were contiguous, it was initially assumed that they would be similar to one another in strength. In that case, most of the variation observed would be caused by the measurement procedure itself, and the data for a given set could be regarded as repeated measures and hence summarized by a single value. However, it became apparent that variations between strips in a given piece of book paper were not entirely caused by measurement error, or even to slight inhomogeneities in the paper. In some instances, these appeared to be caused by the presence or absence of printing. This showed itself in the occasionally much stronger strip, usually at one end of the block, where it just clipped a non-printed area. Because this was not obvious until most measurements were completed, and because of the impracticality of individually reviewing the 340 tensile strength measurements, a statistically robust measure was sought that would reflect the strength of the main part of the paper, which in this case was the weakest, printed area, thus excluding the influence of unusually strong strips that contaminate the statistical sample. A number of options were considered for such a robust measure, but some (such as trimmed or "Winsorized" means) require an estimate of the number of statistical contaminants: assuming' too few can produce erroneous results. The mode does not have this problem but requires a larger number of measurements than was available. However, the median is easy to compute and is acceptable whatever the number of contaminants, so long as their number represents less than 50% of the sample (5). The median, since it is close to the mean of each basic group, even in the presence of contaminants, was therefore chosen as the indicator of tensile strength. This resulted in a total of 42 values for book paper and 42 for filter paper. RESULTS The means of the tensile strength values from each of three pieces of filter paper and printed book paper alter treatments A-G, before and after aging, are shown in Table 1 and illustrated in Fig. Table 1. The mean tensile strength of filter paper and book paper after treatments A-G, before and after ageing The means are based on three values from different pieces of paper, each of which is the median of ten repeat measurements. The estimate of the standard error on tabulated means is ± 0.5 for both book and filter paper, based on analysis of variance of 42 values in each case. Since the tensile strength values from the three pieces of filter paper were more reproducible than those from the book paper, it was decided to analyse the results for book paper and filter paper separately. In each ease, analysis of variance was performed to summarize the effect of each treatment, and the effect of aging. and to estimate the experimental errors. The analysis used the methods appropriate to the split-plot design (6). These take account of the differing precision attaching to different combinations of experimental units. For example, an overall aged vs imaged comparison would not have the same error as a between-treatment comparison. The relevant comparison in this context is that between different treatments (considering aged or imaged only . In this ease, the analysis of variance indicated that any such dilferences greater than 1.2 x 106 N m-2 are significant at the 10% level, and hence are unlikely to have arisen by chance. Another finding of the analysis of variance was a significant statistical interaction between treatment and aging for book paper, suggesting that treatment effects appear in change differentially on artificial aging. This was not the ease for the filter paper, and differences between each treatment were clearer and more significant for the filter paper results than the printed book paper. A decrease in tensile strength of between 34- 53% was measured after the filter paper was treated with solutions A-F (Table 1). The decrease in tensile strength of paper after immersion in solvents has been reported, where similar Fig. 2. Tne tensile strength of filter paper and printed book paper after treatments A-G. before and after aging values were observed.5 Kilter paper suffered a greater loss in strength for the aqueous treatments (D and E) than for the nonaqueous treatments (A, B, C and F) . The MeMgCO3 treatments caused the least loss in tensile strength in the filter paper but aging is important. An apparent increase in the strength of the filter paper after aging is illustrated by Fig. 2. Although unexpected, this increase is statistically significant. As aging was undertaken in dry conditions, the paper may have lost water from between us fibres, which may not have been completely replaced by standing in 55 ± 5% RH. This water may act as a lubricant during tensile strength measurements, allowing the fibres to slide over each other more easily. Hence, reduction of the amount of water in the paper may cause an increase in the force necessary to pull the fibres apart, i.e., to break the strip of paper, and hence the tensile strength of the paper may appear greater, though a different measure of strength, such as folding endurance, possibly would not show this apparent increase on aging. pH measurements Using the same experimental design as for the tensile strength measurements, the pH of three strips for each treatment was measured before and after aging, using a Chemlab HI8417 pH meter fitted with a surface electrode (H1413B). A surface electrode was used, as this is the method used in the real situation with works of art. The means from three repeat measurements were used as raw data for analysis of variance. The means of the pH values from three different samples of paper after treatments A-F. and untreated, were calculated. The mean values of filter Table 2. The mean pH of filter paper and book paper after treatments A-G before and after aging The means are based on three values from different pieces of paper; each mean is itself the mean of three repeat measurements. The estimate of the standard error on the tabulated means is ±0.2. for both hook and filter paper, based on an analysis of variance of 42 values in each case. paper and printed hook paper before and after aging for each treatment arc shown in Table 2 and illustrated in Fig. 3. The analysis of variance showed that differences between means greater than approximately 0.5 arc significant at the 10% level. All the deacidified papers had a pH greater than 7. The highest pH values were achieved in filter paper treated with methyl magnesium carbonate. The printed book paper did not acquire a high alkaline pH after treatment, as this was acidic - pH 4.1) prior to deacidification. The pH of the filter paper and printed book paper decreased on aging, though the effect was statistically significant only for the filter paper, perhaps because of a greater influence of random variation on the book paper results. The pH of the filter paper that was non-aqueously deacidified did not change significantly. A small drop in pH, from pH 8.9 to pH 7.7, was recorded after the filter paper treated with calcium hydroxide was aged. The water- and methanol-treated papers showed the greatest drop in pH after aging, from pH 6.1 to pH 5.0 (water) and pH 6.0 to pH 4.5 (methanol). In the initial study, filter paper treated with commercial methyl magnesium carbonate had, in some cases, a pH greater than 10. However, initially acidic book paper had a lower, more acceptable pH of around 7. The residual pH of three older papers was therefore investigated after treatment with Phizz. The laboratory-manufactured product was not investigated further. Three papers were selected: • heavy gauge. laid paper, porous, c. 1800 (150 g/m2); • medium gauge, sized paper, c. 1800 (130 g/m2)and • light gauge, porous paper c. 1770 (120 g/m2). Three pieces of each were subjected randomly to the following treatments (Fig. 4): • no treatment: • imniersion in MeOH; and • immersion in PHizz/ (MeMgCO3). After treatment, each piece of paper was divided into two equal halves. The pH of one half was measured after 24 h. by cold aqueous extraction (7). The pH of the second hall was measured alter one week by the same method (Table 3). The results are expressed as the mean pH of each of the three pieces of paper, which were subject to identical conditions. On the basis of analysis of Fig. 3. The pH of fitter paper and printed book paper after treatments A-G, before and after aging variance, the standard error on any tabulated mean is approximately 0.07 Any observed difference in means greater than approximately 0.1 7 is significant at the 10% level. Immersion in methanol caused no significant change in pH of any of the paper. However, alter treatment with PHizz, all papers possessed a high residual alkalinity and hence a high pH. Clearly, most papers undergoing Table 3. pH of old papers before and after treatment with methanol or methyl magnesium carbonate, after 24 h and after one week deacidification will be acidic prior to treatment. In these trials, the acidic papers (medium and light gauge) had a lower pH than the paper (heavy gauge) that was neutral prior to treatment. Ideally, paper should not be exposed to a high pH. as alkaline hydrolysis may occur. However, the pH of the initially acidic papers did not rise above pH 10. This is a similar value to that found by Baynes-Cope (8) in his work with barium hydroxide, which has been used to deacidify paper in the British Museum for the past 20 years. The method of application may also affect the pH of the paper after deacidi-fication. It is likely that less solution would be transferred to the paper if a Fig. 4. Experimental designs for further pH measurements on the three older papers deacidification solution is sprayed onto the paper than if the paper is immersed. This may lead to a lower final pH of the paper. The pH of the deacidificd papers did not decrease over a week. This is to be expected, as MeMgCO3 forms MgCO3 immediately on contact with the air, i.e., as the solution is applied to the paper. DISCUSSION This study was designed to test a number of treatments under different experimental conditions, using a standard design, the split-plot randomized block. The rationale has been to minimize the effect of random variation in experimental material and or procedures. Apart from the unforeseen effect of the presence of printing on strength (a point worth bearing in mind when designing future experiments), the approach has been successful in the main, although the results from samples of realistic paper (old book paper) have generally been more informative, as expected. Despite a number of unexpected results, in particular the apparent increase in strength on aging, a number of definite recommendations can be made on the basis of this study. MeMgCO3 poses no health and safety risks, caused the least loss of tensile strength of the filter paper, reduced discoloration of the book paper on aging and did not produce visible precipitation on the paper surface. However, the residual pH of this treatment was high when used on filter paper. The residual pH was not as high when used on printed book paper, as this paper was more acidic prior to deacidification. Alteration of concentration or method of application may reduce this residual pH to a more acceptable level. The effects of MeMgCO3 in methanol or. the tensile strength and prl of treated paper are similar to those caused by Ba(OH)2 in methanol. On-site laboratory production of MeMgCO3 is not feasible because of the cost, not only of raw materials and time, but also because of the unknown shelf life of the product and performance when sprayed or brushed. Therefore, it is recommended that a commercially produced material such as PHizz be used for the nonaqueous deacidification of paper. ACKNOWLEDGEMENTS We would like to thank Mr A. Donnithorne of the Western Pictorial Art section of the Department of Conservation for information and Mrs S. Bradley for advice and encouragement in writing this article. SUMMARIES Nonaqueous Deacidijication of Paper with AJethvl Magnesium Carbonate The use of methyl magnesium carbonate has been examined as an alternative to barium hydroxide for nonaqueous deacidification of paper. Nonaqueous and aqueous deacidification agents were compared by assessing their effects on the tensile strength, pH, colour and aging characteristics of filrer paper and ninetheenth-century printed book paper. Methyl magnesium carbonate was shown to be an effective nonaqueous deacidifying agent. The commercial product, PHizz, has been found to be preferable to methyl magnesium carbonate produced on-site in the laboratory. Desacidification non Aqueuse du Papier aver Carbonate de Méthyle, Magnesium L'utilisation du carbonate de methyle magnesium a ete etudiee en tant qu'alternativc a-celle d'hydroxyde de baryum pour la desacidification non aqueuse du papier. DES agents de desacidification aqueuse et non aqueuse ont ete compares en evaluant leurs effets stir la resistance a la traction, le pH la couleur et le vieillissemeiit d'un papier filtre et d'un papier provenant d'un livre du XIXe siecle. Il a ete montre que le carbonate de methyle magnesium esi un agent de desacidification non aqueuse enu ace. Le produit commercial. PHizz, a eie juge preferable an carbonate de methyle magnesium produit sur place en laboratoire. Nichtwäßriges Neutralisieren von Papier mit Methylmagnesiumcarbonat Es wurde der Einsatz von Methylmagnesiumcarbonat für das nichtwäßrige Neutralisieren von Papier als Alternative zu Bariumhydroxid untersucht. Die Wirkung dieser Mittel auf Bruchlast, pH, Farbänderung vor und nach beschleunigter Alterung wurden bei einem Filtrierpapier und einem Buchdruckpapier des 19. Jh. Im Vergleich zur wäßrigen Neutralisierung gemessen. Es ergab sich, daß Methylmagnesiumcarbonat ein wirkungsvolles Mittel der nichtwäßrigen Neutralisierung ist. Weiterhin erwies sich, daß ein vom Handel angebotenes einschlägiges Produkt mit Namen PHizz dem im eigenen Labor zubereiteten vorzuziehen ist. References 1. Kelly G. B. Jr. Composition for use in deacidification of paper 1976 US patent 3,939,091. 2. Library of Congress publications on Conservation of Library Materials. Conservation Workshop notes on Evaluating Procedures, series 500 No 2 deacidification – methyl magnesium carbonate. Non-aqueous treatment, 1976. 3. Green, L. R. & Bradley, S. M.: A re-evaluation of the use of N-methyl 2 pyrrolidone. Restaurator 9 1988: 82-95. 4. North, N. A.: Non-aqueous deacidification of paper, ECCM Bulletin 5 (1) (1979): 25-40. 5. Barnett, V. & Lewis, T.: Outliers in statistical data. New York: Wiley, 1984. 6. Cochrane, W. G. & Cox, G. M.: Experimental designs. 2nd edn. New York: Wiley, 1957. 7. British Standard Institute, no. 2924. Aqueous extracts of paper, board and pulp. Part 1: Method determination of pH, pub BSI, 1983. 8. Baynes-Cope, A. D.: The non aqueous deacidification of documents. Restaurator 1 (1969): 2-9. 9. Manufacturer´s health and safety data sheet. 10. Sax, I. N.: Dangerous properties of industrial materials. 4th edn. New York: Van Nostrand Reinhold, 1975. APPENDIX 1. HEALTH AND SAFETY DATA9,10 Barium hydroxide OES*: barium compounds (soluble) as Ba 0.5 mg • m-3 FJFects of exposure: • skin: irritation from dust • eyes: irritation from dust • inhalation: nasal irritation from dust • ingestion: toxic; may cause vomiting, stomach ache, bleeding of stomach, intestines and kidneys. First aid: • skin: wash with plenty oi soap and water. • eyes: irrigate with water. • ingestion: give plenty of water and then saline solution to induce vomiting: seek medical advice. Methanol Handling: rubber gloves and goggles. OES: 260 mg•m-3 Effects of exposure: • • • • skin: eczematoid dermatitis. eyes: may cause blindness. inhalation: headache; blurred vision; muscular incoordination; bronchitis. ingestion: toxic, may cause blindness. First aid: • skin: wash thoroughly with soap and water. If very large splashes, patient should be sent to doctor. • eyes: irrigate with water. seek medical advice. • inhalation: move to fresh air. If high exposure: seek medical advice. • ingestion: seek medical advice. *OES is the occupational exposure limit and is the British equivalent of TLV (USA), MAK (Germany) and WME (France). Methyl magnesium carbonate No available data. Decomposes to methane! and magnesium carbonate. Magnesium carbonate OES: no data, but probably low (only hazardous as a dust, which is not encountered during the deacidification of paper). Trichloroflnoroethane OES: no data. Fluorinated hydrocarbons are generally highly irritating and toxic. APPENDIX 2. COST OF LABORATORY PREPARATION OF MeMgCO3 The Western Pictorial Art (WPA) section of the Department of Conservation estimated that their consumption of MeMgCO, would be approximately 0.5 litres per month. The method used for laboratory preparation of the MeMgCO3 assuming a yield of. say. 85%, produces approximately 3.0 litres of solution, after dilution to the desired concentration. This would fulfil the demand for WPA for six months. Cost estimation to prepare approximately 3 litres of MeMgCO3: 1. Production on-site in the laboratory Cost of reactants £ 72.24 Estimated time: 2.75 h (1 h~£ 17.00) £ 46.75 Total £ 118.99 (excl. tax and power) ; 2. Cost of commercially available PHizz £ 25.05 per litre: 3 litres: L. R. Green & M. Leese British Museum London WC1B 3DG United Kingdom £ 72.14 (excl. tax)