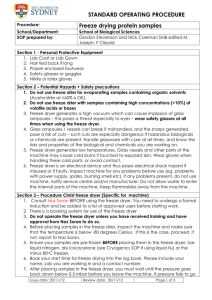

Using the Freeze Dryer, Labconco Freeze Dry System model 77530

advertisement

Flinders University School of Medicine Safe Work Method Statement For Freeze Dryer Doc # 15.07.13 HAZARDS Electrical Fault Burn from Liquid Nitrogen Explosion Freeze Dryer, Labconco Freeze Dry System model 77530 Level 6, room 6E408 Prepared by Phil Michelsen, Dept. Medical Biotechnology and Angela Binns Support Services, Reviewed: 15.07.13 References: 1. Instruction Manual for Labconco FreeZone® 6 Liter Freeze Dry System Models 77530, 77535 2. A Guide To Freeze Drying for the Laboratory, Labconco Safety Issues 1. Using Liquid Nitrogen: if freezing liquid nitrogen , be sure to follow good laboratory practice and use appropriate safety equipment (gloves, face mask/safety glasses) 2. Placing Sample Under Vacuum. Check sample containers for faults – particularly glassware (round bottom and pear shaped flasks) – discard if cracked. When connecting samples to freeze dryer and placing them under vacuum, always wear safety glasses. Prior to Using the Freeze Dryer: 1. Ensure that the waterbath has been electrically tested. 2. Examine the electrical cable. If damaged in any way, immediately notify Biomedical Engineering (Level 3 extn 65042)) to be repaired and place a “DO NOT USE” sign on the equipment Background: Freeze Drying Freeze drying or lyophilization is the process of drying a material that has been frozen, without going through the liquid phase. When a solid material evaporates (becomes a gas) without first becoming a liquid, this is called sublimation. An example of sublimation is dry ice which converts from a solid to a gas (sublimes) at atmospheric pressure at temperatures above the freezing point of carbon dioxide. Frozen water sublimes when under vacuum below 6.11mbar ie ice converts to a gas at temperatures of less than 0oC while at atmospheric pressure, liquid water boils (becomes a gas) at 100 oC. Why Freeze Dry a Sample? to preserve it – dried material (eg food) won’t decay and doesn’t need refrigeration dried spores of many microorganisms will stay viable almost indefinitely if stored correctly to avoid damage from heating – used in other methods of drying Process of Freeze Drying Note: the Labconco 77530 is only suitable for freeze drying aqueous samples. Samples containing acids or organic solvents will damage the machine. 1. Freeze the sample. This can be done in a freezer or using liquid nitrogen or dry ice. When using liquid nitrogen or dry ice, be sure to use safety equipment (gloves, facemask). Slower is better If possible, freeze the sample slowly eg at -20oC first, then at -80 oC. The slower the freezing, the larger the ice crystals in the ice matrix. During drying, water changes from solid to vapour and the vapour must escape through pores or channels in the ice matrix. Pores in the matrix are larger where freezing was slow so drying will be quicker. If rapid freezing is the only option eg for shell freezing (see below) then drying may take longer. 1.1 Liquid Samples: Shell Freezing When freezing liquids, the thinner the layer is, the faster the drying will occur. Liquids can be frozen as a thin layer in a round bottom or pear shaped flask by placing the flask into liquid nitrogen, slightly on its side, and rotating the flask so that the liquid contacts the sides and freezes as the flask is rotated. 1.2 Small Samples Freeze small samples in small containers eg cryophials, preferably at -20oC first, then at -80 oC. 2. Place frozen sample under vacuum. 2.1 Manifold Freeze Drying Larger volumes of sample can be freeze dried in round bottom or pear shaped flasks Attach the flask to the port on the freeze dryer manifold and slowly turn the tap to place the flask under vacuum. The pressure should drop on the pressure gauge then slowly increase again. 2.2 Chamber Freeze Drying Small samples in small containers eg cryophials Put a foil lid on and prick a few holes in foil. Place containers in vacuum chamber inside a larger container eg a beaker , place lid on chamber, ensure the chamber is attached to the manifold and slowly turn tap to place chamber under vacuum. The pressure should drop on the pressure gauge then slowly increase again. 3. Time Taken Time taken to dry sample will depend on the amount of material – may take from several hours to a day or more. Samples in a round bottom or pear shaped flask are dry when they no longer feel cold and the sample is powdery. 4. Write Your name on the User Record Sheet Be sure to write your name, nature of sample and contact number on the User record sheet. 5. Removing sample Slowly close valve to remove the vacuum this will let air into the flask or chamber to bring it back up to atmospheric pressure. If this is done too quickly, it may cause a rush of air to enter the flask which may blow your sample around. 6. Immediately report any faults to Biomedical Engineering 64052, and place a sign on the freeze dryer documenting the problem.