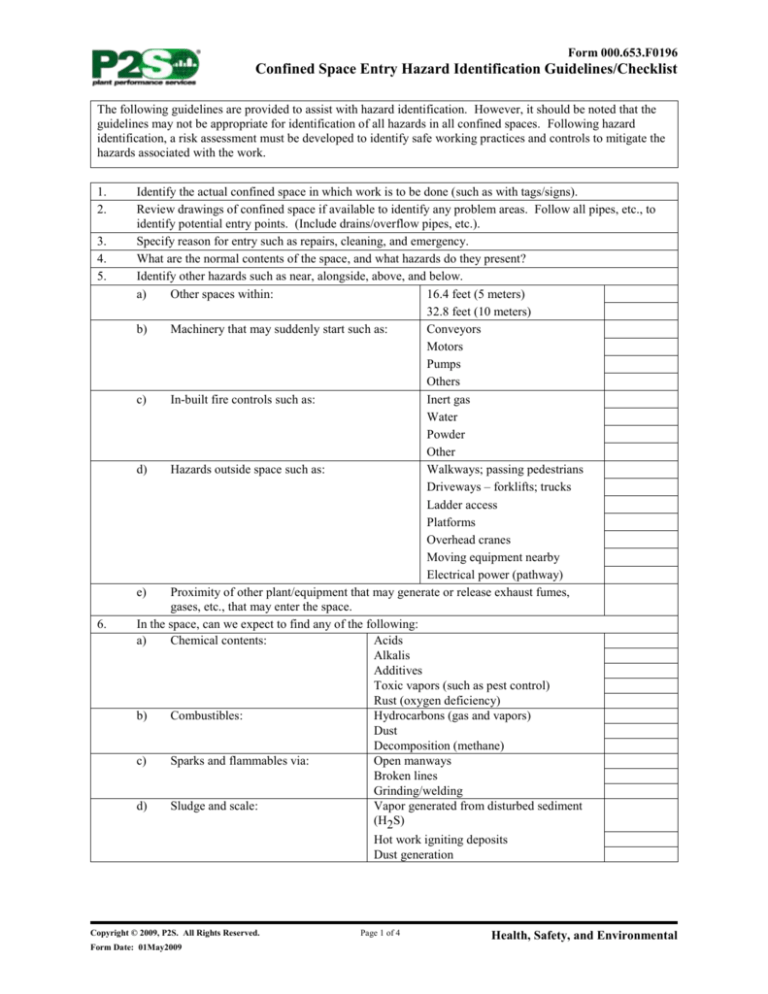

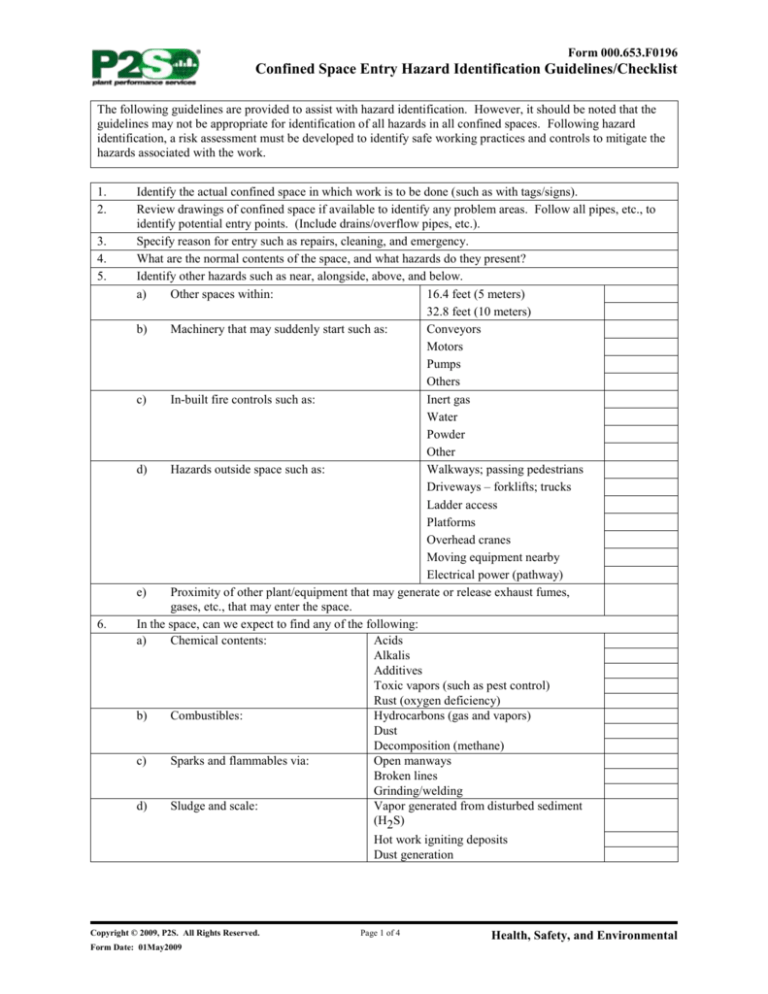

Form 000.653.F0196

Confined Space Entry Hazard Identification Guidelines/Checklist

The following guidelines are provided to assist with hazard identification. However, it should be noted that the

guidelines may not be appropriate for identification of all hazards in all confined spaces. Following hazard

identification, a risk assessment must be developed to identify safe working practices and controls to mitigate the

hazards associated with the work.

1.

2.

3.

4.

5.

6.

Identify the actual confined space in which work is to be done (such as with tags/signs).

Review drawings of confined space if available to identify any problem areas. Follow all pipes, etc., to

identify potential entry points. (Include drains/overflow pipes, etc.).

Specify reason for entry such as repairs, cleaning, and emergency.

What are the normal contents of the space, and what hazards do they present?

Identify other hazards such as near, alongside, above, and below.

a)

Other spaces within:

16.4 feet (5 meters)

32.8 feet (10 meters)

b)

Machinery that may suddenly start such as:

Conveyors

Motors

Pumps

Others

c)

In-built fire controls such as:

Inert gas

Water

Powder

Other

d)

Hazards outside space such as:

Walkways; passing pedestrians

Driveways – forklifts; trucks

Ladder access

Platforms

Overhead cranes

Moving equipment nearby

Electrical power (pathway)

e)

Proximity of other plant/equipment that may generate or release exhaust fumes,

gases, etc., that may enter the space.

In the space, can we expect to find any of the following:

a)

Chemical contents:

Acids

Alkalis

Additives

Toxic vapors (such as pest control)

Rust (oxygen deficiency)

b)

Combustibles:

Hydrocarbons (gas and vapors)

Dust

Decomposition (methane)

c)

Sparks and flammables via:

Open manways

Broken lines

Grinding/welding

d)

Sludge and scale:

Vapor generated from disturbed sediment

(H2S)

Hot work igniting deposits

Dust generation

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 1 of 4

Health, Safety, and Environmental

Form 000.653.F0196

Confined Space Entry Hazard Identification Guidelines/Checklist

7.

10.

Will other chemicals be introduced to the space for other purposes such as:

a)

Cleaning, painting, stripping, and neutralizing?

b)

Are material safety data sheets available for them?

a)

Atmosphere.

Oxygen deficiency

Oxygen enrichment

Toxic (PPM)

Explosive

Flammable

LEL percent

b)

Continuous monitoring of the

Is required

environment:

Is not required

c)

Ventilation:

Is required

Is not required

Any dead spots

Natural

Forced

Mechanical

Exhaust waste air to

d)

Entry will be safe under the

Natural ventilation

following conditions:

Mechanical ventilation

With supplied air/airline

With self-contained breathing apparatus

Without respiratory protection

Entanglement; moving machinery

Uncontrolled substances.

Steam

Water

Chemicals

Others

Electrical hazards.

11.

Noise.

8.

9.

Generated within the space

From outside the space

12.

Manual handling.

Size of load

Posture

Small spaces

Room to move

13.

Temperature extremes.

Hot

Cold

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 2 of 4

Health, Safety, and Environmental

Form 000.653.F0196

Confined Space Entry Hazard Identification Guidelines/Checklist

14.

Lighting.

Natural

Will be required

Nearest power supply (local/portable)

Emergency

Backup (battery)

Voltage

Earth leakage protection

15.

Communication.

Voice

Radio

Telephone

Line

Visual

16.

Personal protective equipment.

17.

Eye

Hearing

Foot

Head

Body

Hand

a)

Respiratory:

Cartridge

Airline

Self-contained

b)

Fall protection:

Safety harness

Inertia reel

Static line

Safety line

Other

Hot work – any special conditions that may apply such as Hot Work Permit.

18.

Psychological.

19.

Slips, trips, and falls.

20.

Access into and within the space.

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 3 of 4

Health, Safety, and Environmental

Form 000.653.F0196

Confined Space Entry Hazard Identification Guidelines/Checklist

21.

22.

Note:

Isolation.

Identify problem areas such as:

Pipes

Ducts

Vents

Drains

Conveyors

Bleed back

Fire protection equipment

Confirm that isolation can be achieved such as remove valve, insert blank/spade, cap/plug pipe, double

block, and bleed.

Identify deenergization requirements such as:

Springs

Wheels

Hydraulic rams

Pneumatics

Belts

Thermal

Conveyors

Mechanical

Electrical:

Remove fuses

Lockout

Tagout

Will you require?

Sign posting

Barriers

Barricades

Witches hats

This form is referenced in Practice 000.653.3322.

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 4 of 4

Health, Safety, and Environmental