Construction Overview

advertisement

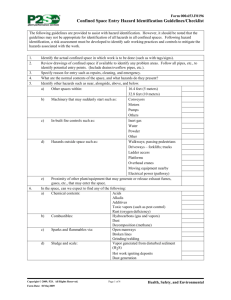

CONSTRUCTION OVERVIEW What is your best source of information? Internet Others Standards 29 CFR 1926 Construction Standard 29 CFR 1910: – 1910.119 PSM CFR Part 68 112(r), “Clean Air Act” – 1910.119 PSM Can a site fall under both the General Industry and Construction standards a the same time? Discuss Most Frequently Cited Handouts Fatality Information Handout HAZCOM “Right to Know” hazards of chemicals in workplace. Chemical hazards communicated. Material Safety Data Sheet. One for all chemicals. Labels Identify chemical. Indicate hazard. All containers labeled. Manufacturer Labels Material Hazard: – HEALTH – FIRE – REACTIVITY Contact Number Do not remove Chemical Exposure First Aid Remove contaminated clothing Safety shower 15 minutes Seek medical attention. Personal Protective Equipment Personal Protective Equipment Foot - ANSI Z41.1 Head - ANSI Z89.2 Hearing Eye & face - Z87.1 Respiratory - NIOSH Harness, lifelines & lanyards Working over or near water Other PPE Job specific: - hearing - respirator - welding hood/cutting goggles - leather gloves - protective clothing - acid suit Fall Protection > 6 feet – guardrail system – safety nets – personal arrest Harness & lanyard Always in manlifts Ladders held & tied Leading Edge Work Definition of leading Edge Exception: – creates greater hazard Holes Fall Protection - Safety Nets Safety nets and safety net installations must be drop-tested at the jobsite: • After initial installation and before being used. • Whenever relocated. • After major repair. • At 6-month intervals if left in one place. Safety Nets Working > 25 ft above surface Where use other safety devices are impractical No work until inspected & tested Extend 8 ft beyond edge Fall Protection - Safety Nets Vertical distance from working level to horizontal plane of net Minimum required horizontal distance of outer edge of net from the edge of the working surface Up to 5 feet 8 feet 5 to 10 feet 10 feet More than 10 feet 13 feet Working Over/Near Water Life jacket Inspected before and after each use for buoyancy Ring buoys provided Lifesaving skiff Fall Protection Harness & lanyard Tied off above Always in manlifts Fall Protection - Guardrails Top rail – 39-45” Midrail / Toeboard Intermediate <19” 200 pounds force Fall Protection – Fall Arrest < 1800lbs arresting force <6ft free fall Inspected before each use Barricades Purpose: – To warn others – Indicate danger – Keep people out Types: – Tape (Red or Yellow) – Wood – Fence Falling Objects Protection from impalement Ladders Inspect before use Firm support 3 rungs above work level 3 point climb Never carry materials Scaffolding 1926.451 Footing - sound & rigid Erection, moving, dismantled or altered under direction of Competent person Guardrail & toeboard > 10 ft Handrail & midrail 12 inch overlap of planking Accident Prevention Signs Visible at all times Danger: – immediate hazard – red Caution: – warn of potential hazards – unsafe practices – yellow Accident Prevention Signs Exit Safety Instruction Traffic Accident prevention tags – – – – temporary tools equipment etc Permits Confined Space Entry Safe Work Hot Work Work which produces fire or spark. Welding, torch cutting, grinding. Electric tools in hazardous locations. Hot Work Permit Fire watch each level. 30 minute check. Expires after 15 minutes if unattended Confined Space - Definition Large enough for entry . Limited or restricted entry. Not designed for continuous occupancy Permit Required Hazardous atmosphere . Engulfment hazard. Inwardly converging walls. Other recognized hazard Confined Space Labels Excavations - 1926.651 Barricading Shoring Sloped walls Confined Space? Egress Ladder Ground Fault (GFCI) Keep dry Handout Excavations - 1926.651 Examine for utilities Means of egress – > 4 ft deep – < 25 ft of travel Barricading Hazardous atmospheres Protection from loose soil Ground Fault (GFCI) Daily inspection - competent person Inspect for what? Cracks - spoils 2’ back Water Cave-in Ladder Shoring/sloping/box Excavation Protection Sloping Shoring Trench box Spoils 2’ back Excavations - 1926.652 Exceptions to shoring: – entirely in rock – < 5 ft & ground examined by competent person showing no indication of potential cave-in Shoring & Slopes Stable rock Type A Type B Type C Handouts 90 deg 3/4:1 1:1 1 1/2: 1 Steel Erection Standard Handout Lockout, Tagout, Test Isolate all energy sources: – – – – – electrical mechanical pneumatic chemical any other Lockout Tagout Test to verify isolation Electrical Safety GFCI Ground All Fault Circuit Interrupters electric tools Connect at source Grounding & Bonding Handout Grounding – equipment – system to earth – grounding electrode to earth Bonding: – between 2 conductive objects Tools and Machines Electrical cords not taped Use the right tools for the job Be aware of sub contractors Protect others from flying particles GFCI electric tools Injuries Seek proper medical attention. Report all Immediately. EMS if necessary. Clean up blood appropriately. Recordkeeping OSHA 300 log Bloodborne Pathogens Diseases carried by blood or body fluids. Examples: – HIV – Hepatitis B & C. Exposure by contact. Bloodborne Pathogens How to handle: – Assume all body fluids are infected. – Wear rubber gloves. Bleach & water solution for cleanup. Red Bio-hazard bag for disposal. Crane Safety Barricade hazard areas and post signs Inspect before each use Hand signals must conform to ANSI standard Signs must be posted at job site Rigging - Types Alloy steel chains Wire rope Natural & synthetic fiber Synthetic webbing Shackles & Hooks Hooks: – safety factor of 5 – safety clasp – rated capacity Shackles Wire Rope - “U” Bolts Never saddle a dead horse? “U” in contact with dead end Handout Rigging - Slings Inspect daily before use Inspect: – wear – broken or worn stitches – red thread – burns Other Rigging Does angle change capacity of sling? Handout & discussion Inspection & Testing Daily before use Periodic Operation of Equipment Forklifts Cranes Etc Emergency Plans In writing Designated actions Fire & other emergencies Elements Escape procedures & route assignments Procedures for those who remain Accounting procedures Rescue & medical duties Means to report Who to contact for further information Training Exceptions Written plan not required if: – less than 10 employees – plan communicated orally Industrial Hygiene Asbestos Lead Silica Welding Fumes Other Chemicals PSM & RMP Requirements Employer Responsibilities Contractor Responsibilities Employer’s Responsibilities Evaluate contractor’s safety performance and programs Inform of know potential fire, explosion, or toxic release hazards Applicable provisions of emergency action plan Employer’s Responsibilities Development of safe work practices; – LOTO – Confined Space Entry – opening process equipment – control over site entrance Employer’s Responsibilities Periodically evaluate contractor performance Maintain contractor injury and illness log Contractor’s Responsibilities Ensure each is trained in work practices necessary to safety perform work Instructed in known potential fire, explosion or toxic release hazards Applicable provisions of emergency action plan Contractor’s Responsibilities Document that each employee has received and understood training. Ensure employees follow safety rules of facility Advise employer of any unique hazards Test