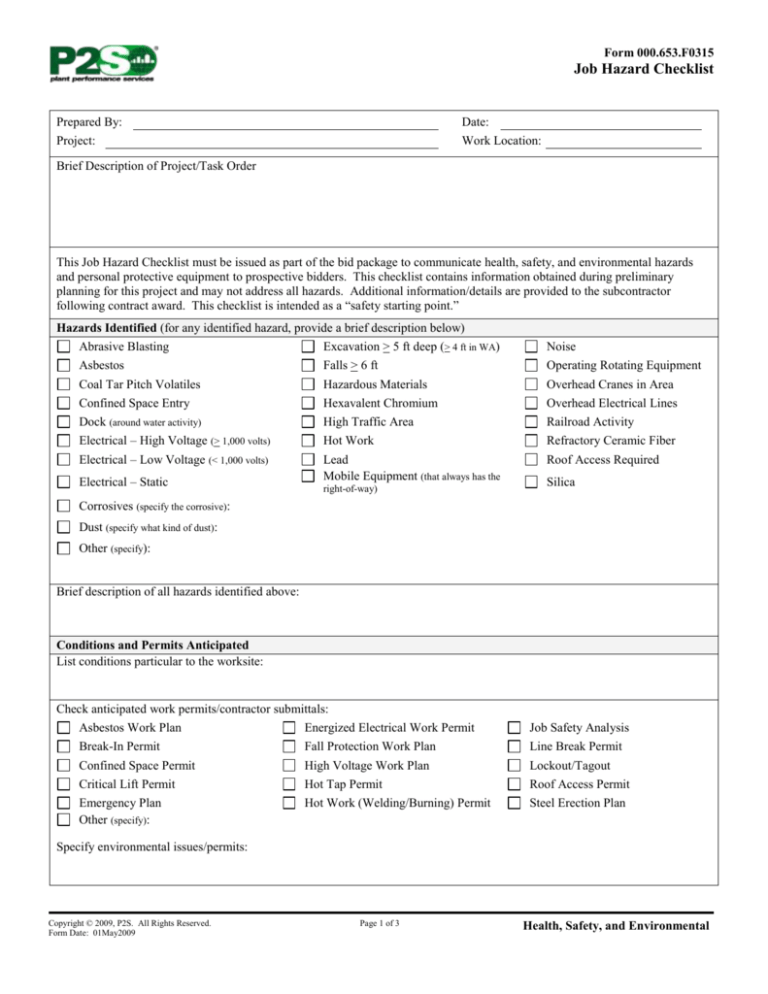

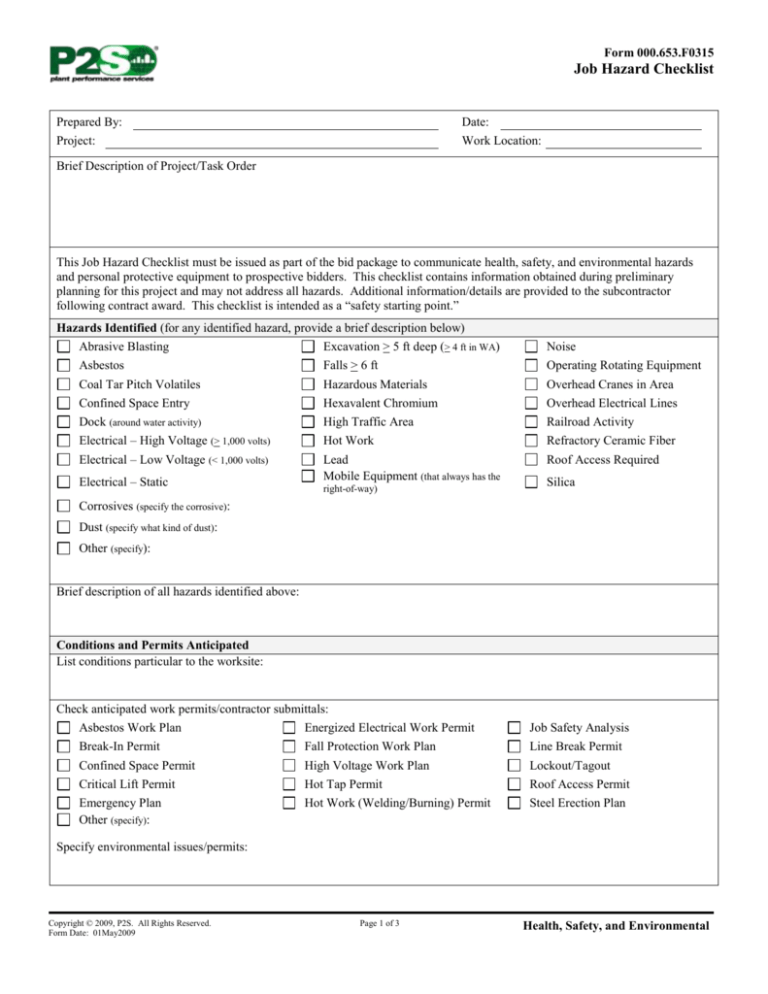

Form 000.653.F0315

Job Hazard Checklist

Prepared By:

Date:

Project:

Work Location:

Brief Description of Project/Task Order

This Job Hazard Checklist must be issued as part of the bid package to communicate health, safety, and environmental hazards

and personal protective equipment to prospective bidders. This checklist contains information obtained during preliminary

planning for this project and may not address all hazards. Additional information/details are provided to the subcontractor

following contract award. This checklist is intended as a “safety starting point.”

Hazards Identified (for any identified hazard, provide a brief description below)

Abrasive Blasting

Excavation > 5 ft deep (> 4 ft in WA)

Noise

Asbestos

Falls > 6 ft

Operating Rotating Equipment

Coal Tar Pitch Volatiles

Hazardous Materials

Overhead Cranes in Area

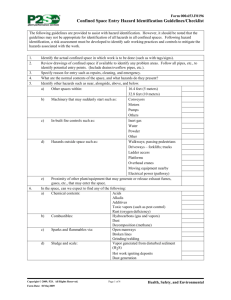

Confined Space Entry

Hexavalent Chromium

Overhead Electrical Lines

Dock (around water activity)

High Traffic Area

Railroad Activity

Electrical – High Voltage (> 1,000 volts)

Hot Work

Refractory Ceramic Fiber

Electrical – Low Voltage (< 1,000 volts)

Lead

Mobile Equipment (that always has the

Roof Access Required

Electrical – Static

right-of-way)

Silica

Corrosives (specify the corrosive):

Dust (specify what kind of dust):

Other (specify):

Brief description of all hazards identified above:

Conditions and Permits Anticipated

List conditions particular to the worksite:

Check anticipated work permits/contractor submittals:

Asbestos Work Plan

Energized Electrical Work Permit

Job Safety Analysis

Break-In Permit

Fall Protection Work Plan

Line Break Permit

Confined Space Permit

High Voltage Work Plan

Lockout/Tagout

Critical Lift Permit

Hot Tap Permit

Roof Access Permit

Emergency Plan

Other (specify):

Hot Work (Welding/Burning) Permit

Steel Erection Plan

Specify environmental issues/permits:

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 1 of 3

Health, Safety, and Environmental

Form 000.653.F0315

Job Hazard Checklist

Training Anticipated

Subcontractor Training – As required by applicable standards, personnel must be trained, and possibly certified, to do the work

they are contracted to do. Proof of training/fitness to do the work must be provided upon request.

Check anticipated training (includes but is not limited to):

Asbestos

Electrical High Voltage

Lead

Bloodborne Pathogens

Equipment Operation

Lockout/Tagout

Confined Space

Fall Protection

PCBs

Crane Operator

Hazard Communication

Respiratory Protection

Dangerous/Hazardous Waste Handler

Hexavalent Chromium

Scaffolding

Electrical (general)

Ladder Use

Lockout/Tagout

Other (specify):

Mandatory Personal Protection and Safety Equipment Requirements

The following 3 items are required on all projects and for construction-type work in office areas:

Long pants and shirt with minimum 1/2 sleeves

“Substantial” footwear — construction work boots/shoes (canvas shoes of any type are not allowed)

Nonconductive frame safety glasses meeting ANSI Z87.1 (2003) criteria

Hard hats meeting ANSI Z89.1 criteria

Additional Protective Devices/Controls Anticipated

Check all that apply:

Air Monitor

Gloves

Personal Exposure Monitoring

Barricades/Safety Cones

Goggles

Radiation Clothing

Coveralls

Ground “Spotter” for Lifts/Equipment

Reflective Vests

Disposable Coveralls

High Voltage Escort

Retrieval Tripod

Ear Plugs/Muffs

Lab Coat

Respirator

Face Shield

Lifeline

Safety Shower/Eye Wash

Fall Protection

Local Exhaust

SCBA

Fire Extinguisher

Lockout/Tagout

Silt Fence/Erosion Control

Flame-Retardant (FR) Clothing

MSDSs

Hazardous Waste Clothing:

Level A

Level B

Spats (a cloth or leather “gaiter” covering

Level C

Level D

the instep and ankle)

100% Cotton Shirts (long sleeve) and

100% Cotton Pants

Other (specify):

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 2 of 3

Health, Safety, and Environmental

Form 000.653.F0315

Job Hazard Checklist

General Site Information/Expectations

First Aid, Medical Treatment, and Emergency Medical Response – subcontractor must provide as required by applicable standards; P2S

employees are on site to provide assistance (signing a Hold Harmless clause may be required to use onsite/client-provided services, if available).

Substance Abuse – conformance to onsite/client policy may be required.

Plant-Specific Safety Rules – contained in the HSE Management System.

Project-Specific Safety Rules (when subcontractors are expected to comply with requirements that go beyond the HSE Management System) –

covered in the pre-task meeting.

Environmental Management – covered in the pre-task meeting.

Housekeeping and other basics:

Subcontractors are expected to maintain a clean, safe jobsite, including ongoing and daily cleanup.

Refuse, cords, cables, etc., are kept clear of walking surfaces.

Subcontractor provides receptacles for trash, welding rod, scrap wire, etc.

Passageways and walkways are kept free of debris.

Cords, plugs, ladders, fall protection equipment, and tools are inspected and marked with contractor identifier. A GFCI is required on

all extension cords and power tools.

No riding in the back of pickup trucks.

No live electrical work without a special permit.

The contractor prepares and furnishes a Job Safety Analysis using Form 000.653.F0100 or similar. Depending on the job, other hazard

analyses may be required. The JSA is prepared from the information obtained in this checklist, the site visit, the pre-task meeting, and

contractor’s knowledge and experience.

Pre-construction meeting is conducted by the P2S and may be attended by representatives from Contracts and Procurements, Safety,

Environmental, Security, and other subject-matter areas.

Plant-specific subcontractor employee orientation may be required.

Sanitary washing facilities.

Unless otherwise identified in writing, P2S does not furnish any equipment for use on this contract; the subcontractor furnishes all lifting,

mobile, safety, and other equipment for the job. No work is performed without authorization by a P2S purchase order. Any work

performed without an authorized P2S purchase order is at the subcontractor’s risk and expense.

Selection of Safe Subcontractors – subcontractors are to have the attitude, awareness, and capacity to protect their employees and others

from injury, and can demonstrate the ability to fulfill their obligations under the contract and under the law.

Subcontractor agrees to bring on site only lower-tier contractors that meet P2S HSE requirements including, but not limited to, acceptance

by P2S of the safety prequalification for the potential lower-tier contractor(s).

Monitoring/Auditing/Inspecting – conducted by P2S and contractor personnel.

Event Notification, Investigation, and Reporting – an Incident Investigation Report (Form 000.653.F0198 or similar) is filed with P2S

on any incident* that occurs at the project worksite. The preliminary report must be completed within 24 hours.

*

Note:

Incident that causes:

–

injury (no matter how slight)

–

illness (no matter how slight)

–

fire/explosion

–

property/equipment damage (whether P2S-owned/leased or contractor-owned/leased property/equipment)

–

release of “stored” energy

–

excavation cave-in/collapse

–

unearthing/discovery of any “structure” or human remains

–

spill, airborne, or waterborne release into the environment

–

near miss/near hit with the potential to result in any “incident” listed above

This form is referenced in Practices 000.653.1003 and 000.653.1304.

Copyright © 2009, P2S. All Rights Reserved.

Form Date: 01May2009

Page 3 of 3

Health, Safety, and Environmental