Resume` of Joe Smith

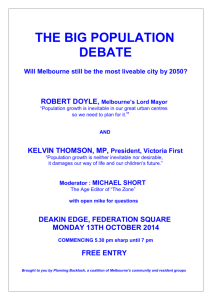

advertisement

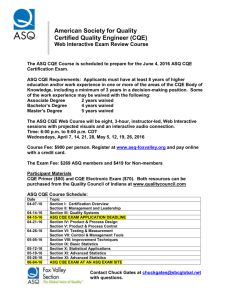

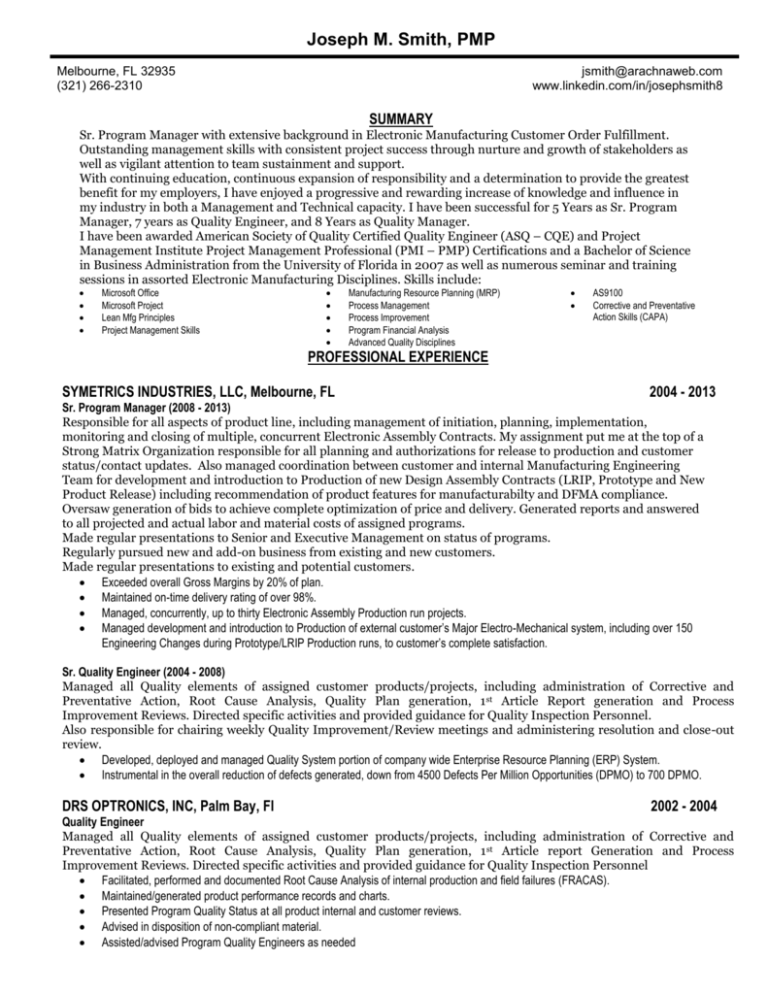

Joseph M. Smith, PMP Melbourne, FL 32935 (321) 266-2310 jsmith@arachnaweb.com www.linkedin.com/in/josephsmith8 SUMMARY Sr. Program Manager with extensive background in Electronic Manufacturing Customer Order Fulfillment. Outstanding management skills with consistent project success through nurture and growth of stakeholders as well as vigilant attention to team sustainment and support. With continuing education, continuous expansion of responsibility and a determination to provide the greatest benefit for my employers, I have enjoyed a progressive and rewarding increase of knowledge and influence in my industry in both a Management and Technical capacity. I have been successful for 5 Years as Sr. Program Manager, 7 years as Quality Engineer, and 8 Years as Quality Manager. I have been awarded American Society of Quality Certified Quality Engineer (ASQ – CQE) and Project Management Institute Project Management Professional (PMI – PMP) Certifications and a Bachelor of Science in Business Administration from the University of Florida in 2007 as well as numerous seminar and training sessions in assorted Electronic Manufacturing Disciplines. Skills include: Microsoft Office Microsoft Project Lean Mfg Principles Project Management Skills Manufacturing Resource Planning (MRP) Process Management Process Improvement Program Financial Analysis Advanced Quality Disciplines AS9100 Corrective and Preventative Action Skills (CAPA) PROFESSIONAL EXPERIENCE SYMETRICS INDUSTRIES, LLC, Melbourne, FL 2004 - 2013 Sr. Program Manager (2008 - 2013) Responsible for all aspects of product line, including management of initiation, planning, implementation, monitoring and closing of multiple, concurrent Electronic Assembly Contracts. My assignment put me at the top of a Strong Matrix Organization responsible for all planning and authorizations for release to production and customer status/contact updates. Also managed coordination between customer and internal Manufacturing Engineering Team for development and introduction to Production of new Design Assembly Contracts (LRIP, Prototype and New Product Release) including recommendation of product features for manufacturabilty and DFMA compliance. Oversaw generation of bids to achieve complete optimization of price and delivery. Generated reports and answered to all projected and actual labor and material costs of assigned programs. Made regular presentations to Senior and Executive Management on status of programs. Regularly pursued new and add-on business from existing and new customers. Made regular presentations to existing and potential customers. Exceeded overall Gross Margins by 20% of plan. Maintained on-time delivery rating of over 98%. Managed, concurrently, up to thirty Electronic Assembly Production run projects. Managed development and introduction to Production of external customer’s Major Electro-Mechanical system, including over 150 Engineering Changes during Prototype/LRIP Production runs, to customer’s complete satisfaction. Sr. Quality Engineer (2004 - 2008) Managed all Quality elements of assigned customer products/projects, including administration of Corrective and Preventative Action, Root Cause Analysis, Quality Plan generation, 1 st Article Report generation and Process Improvement Reviews. Directed specific activities and provided guidance for Quality Inspection Personnel. Also responsible for chairing weekly Quality Improvement/Review meetings and administering resolution and close-out review. Developed, deployed and managed Quality System portion of company wide Enterprise Resource Planning (ERP) System. Instrumental in the overall reduction of defects generated, down from 4500 Defects Per Million Opportunities (DPMO) to 700 DPMO. DRS OPTRONICS, INC, Palm Bay, Fl 2002 - 2004 Quality Engineer Managed all Quality elements of assigned customer products/projects, including administration of Corrective and Preventative Action, Root Cause Analysis, Quality Plan generation, 1 st Article report Generation and Process Improvement Reviews. Directed specific activities and provided guidance for Quality Inspection Personnel Facilitated, performed and documented Root Cause Analysis of internal production and field failures (FRACAS). Maintained/generated product performance records and charts. Presented Program Quality Status at all product internal and customer reviews. Advised in disposition of non-compliant material. Assisted/advised Program Quality Engineers as needed Joseph M. Smith, PMP (321) 266-2310 MACK TECHNOLOGIES, INC, Melbourne, FL Page 2 1995 - 2001 Quality Systems Manager, Document Control/Configuration Manager Managed company-wide Quality, Quality Engineering and Product Configuration/Documentation Control Operations. Reviewed and approved Customer Orders for all Quality requirements and capabilities. Oversaw all Vendor Quality Control elements. 12 Quality Inspector Direct Reports. 4 Quality Engineering Direct Reports.. Developed and deployed employee empowered, closed-loop, real-time corrective action system, thereby reducing production downtime by quick-turn process/product defect resolution. Developed and Maintained ISO 9001 based Quality Systems. Reduced defect rates from 1400 DPMO to 450 DPMO in 12 months and subsequently maintained. EDUCATION / CERTIFICATIONS B.S. in Business Administration, December, 2007, University of Florida, Gainesville, Florida Project Management Professional (PMP) Certification, August 2013 Certified Quality Engineer (CQE) Certification, June 2014, American Society of Quality (ASQ) Technical Electronics Degree (2 year), Board of Cooperative Educational Services (BOCES), Bellmore, New York PROFESSIONAL AFFILIATIONS Current member Space Coast Project Management Institute (PMI) Current member American Society for Quality (ASQ) – Greater Melbourne Chapter Current member and Former Board Member of Space Coast Area Mensa Current member Jaycee International - Senator #58197 Current member and former President of Eau Gallie Civic Association 2002-2004 President of Palm Bay Jaycees 1993-1994