PHENOLIC FOAM THERMAL INSULATION BOARD

PHENOLIC FOAM THERMAL INSULATION BOARD

FOB Price:

Port: Ningbo

Minimum Order

3000 Square Meters

Quantity:

Supply Ability: 6000000 Square Meters per Year

Zhejiang Luzhuo Science And Technology Co,.ltd

ADD:Lishan Town,Fuyang,Zhejiang, China (Mainland)

Tel:0086-571-63158096 13868197988

Zhejiang Luzhuo Science and Technology Co,Ltd specializes in producing light, fireproof, thermal insulation and sound insulating building materials, and also selling raw materials and production equipment. We have established ourselves as an innovative leader by pioneering the combination of the research, production and sale.

Heat Insulation

Materials

Place of Origin:

Zhejiang China

(Mainland)

Brand Name: Luzhuo

Model Number: phenolic color: pink/creamy foam board

Smoke density: Very

Harm to the people: non low (14.3Dm)

Recycling: yes

Water absorbing capacity: 0.02kg/m3

Material: Phenolic Resin Apparent Density: 55±5

Highest Working

Temperature: 180

Heat Conductivity:

0.020~0.035

Specifications

HEAT THERMAL INSULATION ABILITY

FIREPROOF

LESS SMOKE,LESS HARMFUL GAS

ENVIRONMENTAL PROTECTION

CHEMICAL RESISTANCE

PF thermal board

Ideal for: The Interlayer of external wall insulation system, The Padding core material of fireproof door, The Heat insulating core material of refrigerator truck and freezer/chill store and etc.

Speciality

1.Difficult to bur

In all of organic insulating materials, phenolic foam has the best fire resistance ability. Oxygen index is 42, belong in level B1 hard burning material. It wont get burned and no melting drops even placed in an over 3000 flaming environment..as soon as the material touchs flame, the flame will not diffuse but extinguish instead. there will be a graphite foam layer created on the surface to protect the material from further carbonization after carbonizing,

2.great thermal insulation ability

Phenolic foams thermal insulating ability can be matched with polyurthanes thermal insulating ability. The heat transfer coefficient of phenolic foam is

0.026, polyurthane foams heat transfer coefficient is 0.023, XPS Foam

Extrusion Planks heat transfer coefficient is above 0.035.for achieving the same insulating effect ,the thickness of PF needs to be 32mm , Pu needs to be

30mm, polystyrene needs to be 40mm and the normal brick need to be over

800mm.

3. Less smoke Less harmful gas.

Polyurthane and polystyrene can create the smother and virulent gas to cause peopls death,increasing the difficulty of putting out the fire. Even after the special treatment they will still decompose and release the hydrogen cyanide and carbon monoxide.

Phenolic foam doesn’t create and release any smokes ,even can not smell any scent while its under a long last burning by the high temperature flame.

4.light weight

Pfs apparent density is 50kg/stere or around. Easy to fix and process in project, also can effectively reduce the deadweight of construction especially when its used on tall building .

5. environmental protection

Non-hamful to huma, wont bring the environm ent permanent pollution, doesn’t contain chlorofluorocarbon, flotsam and used product can be recycled.

6. heat-resistant Chemical resistance

Available temperature scale - to 180, Excellent in anti-corrosion. Especially for acidity and alkalescence. Shape and size is stable and fixed under high temperature working environment.

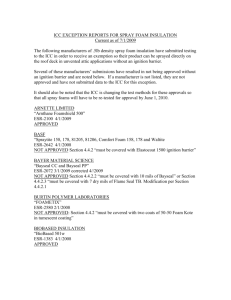

Performance Comparison Table of Phenolic foam Polyurethane rigid foam PVC and Polystyrene

Item / Name

Max Temp.()

Performance in limiting condition

PF

180

210

Color change

PU

120

100

Shrink

PVC

120

140

Intenerate

PS

60

80

Shrink

Thermal conductivity(w/m.k)

Loss of weight()

Degradation testing

Resistance against chemicals

Rate of water

0.016~0.036 0.022~0.036 0.029~0.035 0.033~0.045

37

Best

Good

0.02

100

Bad

Good

0.03

95

Good

Good

0.03

94

Bad

Bad

0.2

absorptionkg/m 3

Crush resistance(kpa) 216

Burning sec.sec

Flame heightmm

Oxygen index

15

42

Difficult to burn

Melt condition NO

Smoke densityDm

Burn produce poisonous gas or not

9

NO

Products types and sizes

127

30

100

25

(Easy to burn)

Drip with flame

51

YES

Product Name

Apparent densitykg/m 3

33

30

250

25~27

(Easy to burn)

YES

68

YES

107

30

250

18~21

(Easy to burn)

Drip with flame

66

YES

Length

(mm)

Width Thickness

(mm) (mm)

PF thermal insulation board

55±5 Unlimited 1200 ≤100

PRODUCTS phenolic thermal insulation panel

Phenolic Foam Insulation Slab

phenolic core board thermal-insulation and decorative (one body) panel

Phenolic foam PU Pre-insulated Ducting Panel prefabricated house polyurethane and phenolic foam Panel For Cold Room