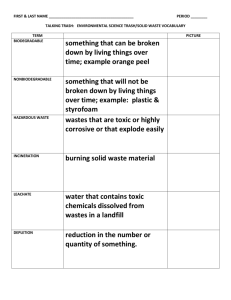

“Clear Thinking, Effective Recycling Solutions” Waste Reduction

advertisement

“Clear Thinking, Effective Recycling Solutions”

Waste Reduction & Recycling Consultants Inc

The Recycling Evolution Continues!

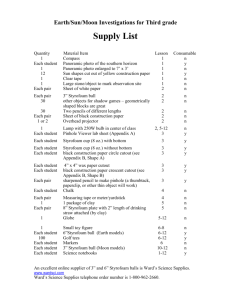

~ STYROFOAM RECYCLING CRITERIA ~

Polystyrene - (PS) & Polypropylene (PP) Styrofoam Recycling Business

Key Considerations to Implementing a Successful Closed Loop Styrofoam Recycling Initiative

~ Proposal to Implement A Sustainable Closed Loop Styrofoam Waste Reduction Program ~

Electro-Thermal Styrofoam Densifier Recycling Equipment & In-House Support Services Now Available!

Purchasers Information Package Equipment & Our In-house Services

WRRC & EPS Molders philosophy is to create and maintain cost effective, environmentally sound “Closed Loop (EPS)

Polystyrene - (PS) & EPP & Polypropylene (PP) Styrofoam” recycling solution for North Americans through the use of our

Electro-Thermal Densifier equipment and in-house administrative support services.

The once non-recyclable Styrofoam materials are sourced, collected and delivered to one of our established material

recovery facilities, the Styrofoam waste materials are processed and recycled into a REUSABLE melt, and then reground and

extruded into re-manufactured new plastic materials. The recyclable Styrofoam materials are sourced from the waste

generators ranging from and including governmental, building construction, manufacturing, retail, commercial, institutional

and residential sectors.

Closed Loop Styrofoam Recycling Industry Emerges Across North America

As the Waste Diversion Recycling industry expands its recoverable and recyclable materials practises, we as leaders in the

development of both the Styrofoam Manufacturing and Recycling industry are clearly seeing the Canadian acceptance from

coast to coast from those with vested Environmental interests in implementing legitimate Closed Styrofoam recycling

practices. *Based on our prospective Styrofoam equipment buyers, all indications are; we have the ultimate legitimate Closed

Loop Styrofoam Recycling System – Complete with the Technological Equipment & In-house Support Services, reportedly

the first complete Closed Loop Styrofoam recycling service of its kind in North America.

The (2nd) Second generation Electro-thermal Densifier Model is available for Purchase & or Lease; this unit was built as both

a Stationary and a mobile Styrofoam recycling processing unit.

Comparisons & Keys to Creating and Maintaining a Successful Closed Loop Styrofoam Recycling Initiative

Our - Electro-Thermal Densifier: Multi-processes Both Types of Polystyrene (PS) & Polypropylene (PP) Styrofoam

Our - Long Term Commodity Return Program – Highest return program available in North America

Our - Support Services - Complete Turn-key In-house support and management services

Our - Environmentally Sound - Legitimate Closed Loop Recycling – From Manufacturing to Re-Manufacturing

Consider purchasing our State-of-art patented Electro-Thermal Densifier unit(s) and acquire our In-house support services to

complete your entry into our Turn-key Closed Loop Styrofoam recycling industry!

EPS Molders Styrofoam Electro-Thermal Densifier Equipment Purchasing & Recycling Services

This unique patented technological equipment and process allows the recycling facilitator to recover and recycle Styrofoam

materials in an Environmentally Sound, Cost Effective viable manner through the use of the Electro-thermal Densifier unit.

Our Polystyrene - (PS) & Polypropylene (PP) Styrofoam Electro-Thermal Densifier machinery is specially designed to

process, both - (PS) #: 6. & Polypropylene (PP) #: 5. Styrofoam into a condensed Melt Ingot format; a compact storage able

Ingot | Plank. The densification ratio is generally 50:1; becoming very easy to handle, store, ready for cost effective transport

and of a Commodity monetary value return to the facilitator! An average Plank is produced every six minutes and is 31/2

inches’ high by 10 inches’ wide and 40 in long = weighing an average of 14 | 16. Ib.

~ Material Recovery Facility 12112 - 67th Street, Edmonton AB T5B 1M7 CANADA ~

“Clear Thinking, Effective Recycling Solutions”

Waste Reduction & Recycling Consultants Inc

“Our Knowledge Provides the Service … You Deserve to Succeed”.

The Proposal Evaluation Process

The following information may be used evaluate the purchase of our EPS Molders Electro-Thermal Styrofoam Densifier

machinery or obtain the usage of our specialized In-house Commodity Brokerage program and support services

The EPS Electro-Thermal Densifier RE - E502 X Unit:

Densifies Both => {Polystyrene - (PS) #: 6. & Polypropylene (PP) #: 5. Styrofoam}

EPS Machine Specifications:

- EPS Thermal High Melter Densifier (RE-E502)

- Machine processing capacity is 80 kg/hr | Equalling 640 kg/day | Equalling 13.5 metric tonnes | 21 Workday per month

- Established and proven world renowned Japanese technology

Machine Investment Pricing:

- $ 69,750 per unit, single order of 1 unit

- $ 67,750 per unit, single order of 2 units

- $ 65,750 per unit, single order of 3 units

- $ 63,750 per unit, single order of 4 units

Payment and order Terms:

- Minimum 50% of full purchase price provided at time of order

- Minimum 30% of full purchase price provided at Canadian Port Arrival

- Balance of 20% due at proven machine operation or no later than 60 days from port arrival

- GST charged in addition to indicated machine pricing as applicable

- A discount of 1.5% of full purchase price will be provided for 90% payment at time of order

- Delivery 60 to 90 days from order, timing confirmed with time of order invoicing and documentation

Purchase Includes:

- Complete EPS Molders Electro-Thermal Styrofoam Densifier machine, landed at Edmonton Alberta or anywhere in Canada

- Self contained pre-grind feeder hopper

- Installation, EPS technical setup, training

- Maintenance machine parts, manuals, and reference materials

- In-house purchase agreement on the Commodity Brokerage Management of our Thermal Melt produced by our equipment

- Marketing program agreement to be determined c/o WRRCI

Not Included:

- Site commissioning must be prepared by others; foundation, power etc.

- Transport from Edmonton to customer site

- Preparation of recycle site for machine (i.e. electrical, area preparation)

- Silo or feed bins if desired | required at EPS recycle site

- Freight for produced melt from site to shipping point if applicable

Economics: Capacity and Commodity Value Comparisons

- Savings per eliminated 40 cu. yd Roll-off bin delivery, haulage, tipping Landfill disposal fees of $475.00 or more

- Typical 40 yard bin with “Bagged” EPS | EPP capacity is approximately 200 kg

- Current estimated Commodity Market value pricing of EPS | EPP Melt (non-FR) $400 | per Metric tonne

- Estimated Commodity Market value | pricing of EPS-FR Melt $300 | Metric tonne (FR = Fire Retardant)

Mid to High Volume EPS Situations – Machine Installation

The following information may be used to evaluate larger volume EPS situations for the possible supply and operation of the

EPS Molders recycling machine directly at the EPS Molders material recovery and recycling facility. Prospective purchasers

are invited to contact us directly for more details on the suitability of our recycling facility and the purchase of the EPS

Electro-Thermal Styrofoam Densifier machinery.

~ Material Recovery Facility 12112 - 67th Street, Edmonton AB T5B 1M7 CANADA ~

“Clear Thinking, Effective Recycling Solutions”

Waste Reduction & Recycling Consultants Inc

We look forward to partnering with you to help build the Closed Loop Canadian Styrofoam Recycling industry!

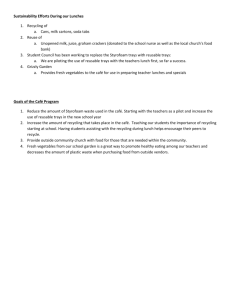

*Return on Investment Cross Reference Table

Purchasers Criteria Informational Table + Commodity Value

600

1200

2400

4800

7200

10000

15000

20000

50%

50%

45%

35%

25%

20%

15%

13%

7.50

15.00

30.00

60.00

90.00

125.00

187.50

250.00

1.07

2.14

4.29

8.57

12.86

17.86

26.79

35.71

Melt Gross Revenue

Per M/Tonne

$240

$480

$960

$1,920

$2,880

$4,000

$6,000

$8,000

EPS Molders Broker

Fee $ Per M/Tonne

$(120)

$(240)

$(432)

$(672)

$(720)

$(800)

$(900)

$(1,000)

Eqpt Operational

Staff Hours Cost $

$(105)

$(210)

$(420)

$(840)

$(1,260)

$(1,750)

$(2,625)

$(3,500)

$30

$108

$408

$900

$1,450

$2,475

$3,500

Monthly KG

of Melt Produced

Commodity Value

Broker Fee Rate

Operational Machine

(Hours)

Equivalent

7 Hr Days

Net Revenue $

$15

For additional info

Please contact myself directly and I will address any and all inquiries.

Purchasers Info

Notes:

- Electro-Thermal Styrofoam Densifier machine operational production capacity is 80kgs per hour ref; 8 hrs = 1 metric tonne

- Gross Revenue is based on the $400 per metric tonne Commodity Value; EPS melt resin Commodity market Nov 2010

- Average Commodity over the past five years, averaged $330.00 per metric tonne - based on the Global Oil & Gas industry

- Average part time staff hour costs are based on $14/hour basic labour wage rate

- The average Ingot | Plank produced is 14 | 16 Ibs ea. Processing in an average of every (6) six minutes 81/2 WX31/2HX40”

- Broker fees may be contracted for other rates based on specific customer situations and commitments

- Table does not show significant recovered revenue from eliminating landfill disposal and haulage costs

Market Value

Market research, the following information may be used for producers of EPS Styrofoam waste to evaluate their current

landfill disposal costs, in order to justify either the purchase of our EPS Molders recycling machinery, and or Commodity

Brokerage services.

The current market bears the minimum flat rate and processing fees through the use of the EPS Molders recycling machinery,

recovery, processing and the Closed Loop recycling methods. Note: *Given these conditions, an asset's fair market value

should represent an accurate valuation or assessment of its worth

Low Volume Situations

Use of EPS Molders Materials Recovery Facility & Services (to be provided upon request)

“A Viable Legitimate Closed Loop Styrofoam Recycling Initiative”

~ Material Recovery Facility 12112 - 67th Street, Edmonton AB T5B 1M7 CANADA ~

“Clear Thinking, Effective Recycling Solutions”

Waste Reduction & Recycling Consultants Inc

*(a Typical Market Bearing Service Fee Scenario)

EPS Molders Flat Rate Tipping | Recovery | Recycling | Processing Service Fees (Effective 01.10.10)

All services must be coordinated and approved thru WRRC; proper delivery | scheduling must be adhered to by the supplier.

~ 3x3x7 ~ Typical ~ 2.5 cu. yd.

~ 8x7x14 ~ Typical ~ 28 cu. yd.

~ 40 cu yd ~ Typical ~ 30 | 40 cu. yd.

~ 8x9x24 ~ Typical ~ 64 cu. yd.

~ 8x9x53 ~ Typical ~ 140 cu. yd.

Pick-up Truck Loads

Cube Van

Roll-off Container

Tractor Pup Trailer

Tractor Trailer Hwy Van

$5.00 ~ Flat Per bag charge

$150.00 ~ Flat rate charge

$225.00 ~ Flat rate charge

$250.00 ~ Flat rate charge

$275.00 ~ Flat rate charge

Contamination Surcharge

EPS Molders accepts only properly prepared and identified EPS | EPP Styrofoam waste: Polystyrene - (PS) #: 6. &

Polypropylene (PP) #: 5. Styrofoam and approved related products. At EPS Molders discretion all shipments received and

examined that are determined contaminated by more than 10% volume on a per bag bases, the client | supplier will be

charged back a flat rate of $5.00 per bag for re-handling, re-processing and or additional disposal costs.

Local Recover ~ Recycling Facility Delivery, Terms & Conditions (*24 Hour Minimum Notification)

A minimum of 24 hour notification must adhered to prior to an accepted delivery of goods. Prior to any delivery; all

deliveries must be approved and scheduled by the Manager Shipper | Receiver at EPS Molders, it is prohibited for the waste

generator | recycler | supplier | carrier | transporter or customer to deliver their Styrofoam material to our Recovery Facility

unless they have an approved account and a confirmed delivery date.

*Our Facility Delivery Hours

8:00 am - 03:30 pm - Monday to Friday

Contact: EPS Molders - Manager Shipper | Receiver

Office: (780) 477-7133 - Cellular: (780) 224-2493

Notes:

- All accounts must be approved prior to any and all deliveries. No random drops. Non-bagged materials will not be accepted

- Contact: Jim Donaldson of W.R.R.C. | (jdonaldson@wrrci.ca) | Credit Applications | Tel: 780-801-1648

- All EPS | EPP Styrofoam to be received and processed all Styrofoam must be Dry, Clean, Free of debris and contaminants

- Requested diversionary ratios documentation for CaGBC - LEEDS and efficiency recycling programs will be provided

- Equipment Manuals, Operational Guidelines, Operating Cost Analysis (A refundable security deposit is required)

Together we can set the example for others to follow and faithfully do our part as good stewards of the earth.

Associates, where possible we would like to work with you as a Waste Diversion Styrofoam Recycling associate providing

the In-house Tools to Develop and Maintain a Closed Loop, Environmentally Sound, Commodity Driven Styrofoam

recycling initiative!

Kind Regards,

Jim Donaldson

Waste Diversion | CaGBC – Member (Alberta Chapter)

WRRC Office: (780) 801-1648 ~ Mobile: (780) 239-5445 | jdonaldson@wrrci.ca

Waste Reduction & Recycling Consultants Inc ~ In Partnership with ~ EPS Molders Inc

Canada Green Building Council – (CaGBC)

Leadership in Energy and Environmental Design (LEED)

Our recycling initiatives are based on the Criteria;

Adapted & implemented by The Canada Green Building Council – (CaGBC)

------------------ www.wrrci.ca -----------------REDUCE THE CARBON FOOTPRINT

LEED R4: Rethink

Reduce

Reuse

Recycle - Styrofoam

~ Material Recovery Facility 12112 - 67th Street, Edmonton AB T5B 1M7 CANADA ~