SI Cycle

advertisement

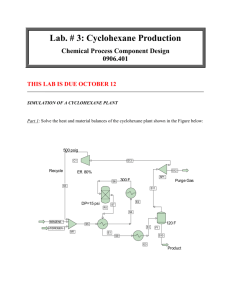

The Sulphur-Iodine Cycle The sulphur-iodine (SI) cycle is characterised by the following three basic reactions: xI 2(l ) SO2( g ) 2 H 2 O(l ) 2 HI x ( aq) H 2 SO4( aq) (1) H 2 SO4( g ) H 2 O( g ) SO2( g ) 1 O2( g ) 2 2 HI x ( g ) H 2 ( g ) I 2 ( g ) (2) (3) where x in the reactions represents the average of several polyiodides that are formed. Equation (1) is the Bunsen reaction. It is an exothermic reaction that is spontaneous in the range 20oC<T<100oC. At certain reactant concentrations, involving an excess of iodine, a phase separation occurs between the two acid products leading to a H2SO4 phase principally devoid of HI and vice versa. Equation (2) is the sulphuric acid decomposition step. This is an endothermic 2-stage reaction: H 2 SO4 H 2O SO3 (4) 2SO3 2SO2 O2 (5) The first stage, as seen in equation (4), occurs at a temperature of 400-500oC, whereas the second stage, given by equation (5), occurs at 800oC in the presence of a solid catalyst. Equation (3) is the hydriodic acid decomposition reaction. This is a slightly endothermic reaction and can be conducted in the liquid or gas phase. Figure 1 shows a flowsheet of the SI process. The only input is water and the only products are hydrogen and oxygen. The HI processing stage is very important. The simple option would be to distill the HIx (HI-H2O-I2) solution, followed by the gas phase thermal decomposition of HI. However, due to the presence of the azeotropic composition in HI-H2O (which occurs at a molar ratio of 1:5), this distillation requires a large amount of thermal energy. Also, the low equilibrium decomposition ratio of HI of about 20% imposes a large HI circulation which leads to an increased thermal requirement and therefore a decreased thermal efficiency. Much research and effort have been directed at improving the efficiency of the HI decomposition section. In the late 1990's GA restarted investigating thermochemical cycles. They screened 115 cycles and as the SI cycle had the highest predicted efficiency and the greatest potential for further improvement they selected it for further research. The helium gas cooled reactor was chosen as the most suitable for coupling to the cycle as it has high temperature potential and is sufficiently developed for nuclear hydrogen production to be possible with essentially no further development. An intermediate helium loop between the reactor coolant loop and the hydrogen production system is used to ensure that any leakage from the reactor will not contaminate the hydrogen. Using an assumed peak process temperature of 827oC (i.e. a reactor temperature of 850oC) the process efficiency was estimated to be 42%. If the maximum process temperature and reactor temperature are increased to 900oC and 950oC respectively, an efficiency of 52% can be achieved.