CORROSION FUNDAMENTALS

advertisement

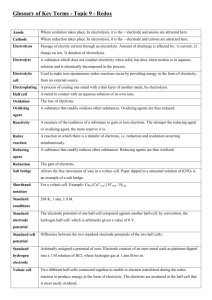

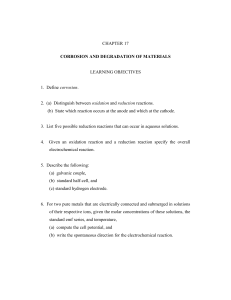

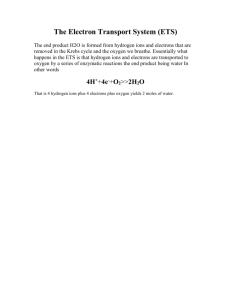

CORROSION FUNDAMENTALS In this section, a detailed description of the electrochemical processes leading to and controlling corrosion will be outlined. The first section deals with the electrochemical basis for corrosion, which is controlled by thermodynamic principles, while the effect of kinetic, or rate control will be introduced later in the section. It is important to understand the role of both thermodynamic and kinetic processes in initiating and controlling corrosion in order to determine corrosion rates, or reduce corrosion by different methods, such as sacrificial anodes or alloy development such as stainless steels. Metal Dissolution In most corrosion processes, with the exception of cathodically controlled processes, metal will dissolve. An understanding of the principles behind how metal dissolves in a solution is a necessary part of understanding corrosion. Consider a piece of pure metal M in a solution which contains its own ions, Mz+. In this case the metal has solubility in the solution in which it is placed. An example would be a piece of pure copper in a solution of copper sulfate. The general equilibrium reaction for a metal electrode in a solution of its own ions is:M = Mz+ + zewhere M represents a metal atom, Mz+ is the metal ion, Z is the possible valences and erepresents an electron. At equilibrium there is no net current flow and the above reaction can be separated into two different reactions. One reaction produces metal ions in solution from metal atoms in the solid with the reaction :M > Mz+ + zeAgain at equilibrium there is no net current, so the electrons produced in the reaction above are consumed in a reaction where all the electrons combine with metal ions in solution to deposit as atoms on the solid metal surface in contact with solution in the reaction :Mz+ + ze- > M These individual reactions are called “half cell” reactions as they another reaction to either consume or produce electrons for them to proceed. These half cell reactions are also oxidation and reduction reactions. Oxidation is a reaction that produces electrons. The ionization of metal atoms to ions is therefore an oxidation half cell reaction. Reduction is a reaction that consumes electrons. De-ionization to form a metal atom is therefore a reduction half cell reaction. M = Mz+ + zeThe above reaction is called a “REDOX” reaction because it contains both an oxidation and a reduction half cell reaction. Both oxidation and reduction are important reactions. The oxidation reaction is the basis of corrosion as metal is dissolved whilst transforming from atoms to ions in a solution. The reduction reaction is also important as it is the basis of electroplating where ions in solution are deposited as atoms on a surface, for example chrome or gold plating. During corrosion, the half cell reactions do not usually involve the same elements and ions in both the oxidation and reduction reactions. The electrons produced in the oxidation 1 reaction are not available for the reverse reduction reaction, which would replace the metal atoms back on the metal surface. Instead, the electrons from the oxidation reaction are consumed by a different reduction reaction resulting in a new reaction product. This leads to a secondary reaction between the products of the oxidation and reduction half cells to form a stable material. These can further react with the environment to form stable compounds such as rust. These are then very difficult reactions to reverse back to the atomic form of the metal which is one of the major reasons why corrosion is an extremely deleterious process. Basic Corrosion Processes. Four necessary processes are required to have corrosion take place. All these processes must be available for corrosion to occur. If any of these are unavailable then corrosion will not occur. This provides the first measures of corrosion protection – by disabling any one of the four necessary processes, then corrosion will be blocked. This very simple approach to corrosion protection is often overlooked but can be an invaluable tool for the engineer to avoid costly corrosion problems. Oxidation Half Cell Reaction. The first process is an oxidation or anodic half cell reaction. The oxidation half cell reaction was described above. The corrosion process is essentially this oxidation reaction as metal atoms are transformed to their ions. Solid metal in a solution is transformed into metal ions in solution, resulting in weight loss or thinning of the solid material. M > Mz+ + zeReduction Half Cell Reaction. The second process of a corrosion cell is a reduction or cathodic reaction. One reduction or cathodic reaction was also described above which is the plating or deposition reaction. Mz+ + ze- > M Other cathodic reactions are described below in terms of their REDOX reactions, although a cathodic reaction would be in the direction from left to right:2. Reduction of hydrogen ions in strong, de-aerated acids: 2H+ + 2e- = H2 For the cathodic half cell reaction hydrogen gas is produced at the same time as the anodic reaction is progressing.. 3. Reduction of oxygen in weak aerated acids to form water. O2 + 4H+ + 4e- = 2H2O 4. Change in ionic state, e.g., Cupric to cuprous ion. Cu2+ + e- = Cu1+ 5. Reduction of oxygen in neutral or basic solutions to form hydroxyl ions. O2 + 2H2O + 4e- = 4(OH-) 2 For many practical service situations the last reaction is the most important. All the necessary constituents for the reaction to proceed are present in normal environmental exposure. The oxygen is present as dissolved oxygen in water. A later section will discuss the reduction of oxygen in water in greater detail. The only component missing are four electrons, which during corrosion will be produced by the oxidation or anodic half cell reaction. Cathode Site. An important feature at this stage is to distinguish the cathodic half cell reaction from the physical cathode. The physical cathode is the location where the cathode half cell reaction occurs. The cathode only provides the electrical conductivity necessary for electron transfer for the cathode half cell reaction. An example can be obtained from the reduction of oxygen in water reaction above, reaction 5. This reaction will occur on a surface which has the capability to conduct electrons. The surface only needs to be a conductor of electricity, it does not need to be metallic, therefore non metallic materials that are electrically conductive can be cathodes. It should also be apparent that the cathode does not dissolve and can be termed as being “cathodically protected”. Another cathode reaction is reduction of hydrogen ions to hydrogen, reaction 2. In this case hydrogen gas will be nucleated on a conducting surface as a corresponding anodic reaction produces the electrons for consumption. This distinction between cathode reaction and the cathode material is important in later stages when localized corrosion forms such as pitting and crevice corrosion are discussed and large amounts of the metal surface exposed to an environment show no signs of corrosion while extensive corrosion is present in local regions on the surface. It is thought that the non–corroded regions are cathodically protected. Ion Transport. The third process is ionic transport for which a conductive medium or electrolyte is required. In many cases of environmental exposure this can be water, seawater, acidic or basic solutions. The greater the ionic flow capability of the solution the greater the corrosion rate which can be supported. Therefore distilled water with a high resistance and low conductivity, usually supports a lower corrosion rate than seawater with a low resistance and high conductivity. Electron Transport. The fourth necessary process is a mechanism for electron transport between the anode and cathode sites. As electrons are produced by the oxidation anodic half cell reactions and consumed by the reduction cathodic reaction, electrons flow from the anode to the cathode. Without flow of electrons between the anode and cathode, these half cell reactions cannot occur. Blocking this electron flow is therefore another method of corrosion protection. The anode therefore has an excess of electrons and is therefore the negative pole. The cathode is the positive pole. The necessary electron flow can be achieved by several mechanisms. One is a wire conductor which connects the anode and cathode. Electrons flow along the wire from the anode to the cathode. A good example of this process is a flashlight. The battery in the flashlight has a cathode and an anode. The zinc casing is the anode and usually the negative pole. The center 3 post of carbon is the positive pole. When the switch is placed in the “on” position a circuit is completer between the positive and negative pole through the light bulb filament which glows white hot due to resistive heating from the electron flow from the anode to the cathode. The electron flow is therefore providing both a voltage and a current. A second and much more important method of electrical connection for an engineer is controlled by the microstructure of the materials. The intimate contact of phases in a metallic alloy can provide the necessary electrical contact to establish anode and cathode regions. It should be remembered that each phase has its own distinct composition so each phase will react differently to the environment. These differences will cause anodes and cathodes to form which are in physical contact. Impurities in metals can also act as anodes or cathodes due to chemical differences. In summary, the four necessary processes for a corrosion cell are anode reaction, cathode reaction, electrolyte and electron transport. Unfortunately for many engineering materials such as steels in water, all these four processes are present and corrosion will occur. For other materials in the same environment, no corrosion will occur. An example would be gold in water. If there is no corrosion, then one of these four processes is not occurring, For gold it so happens that no anode half cell reaction is available which makes it immune to corrosion. Exchange Current Density. The REDOX half cell reactions of oxidation and reduction both involve electrons. The oxidation, anodic reaction produces electrons while the reduction, cathodic reaction consumes them. M = Mz+ + zeAt equilibrium for a REDOX reaction there is no net ionic or electron flow, so there is no corrosion weight lost by the metal or deposition or weight increase of the metal. The weight of the metal M will be the same at the end as at the beginning and the concentration of Mz+ in solution will be the same at the end as the starting concentration. However, for an oxidation reaction, there is a current flow –number of electrons per unit time- as they are produced in the anodic half cell reaction. There is also current flow for the reduction half cell reaction as electrons are consumed. M > Mz+ + zeMz+ + ze- > M At equilibrium the number of electrons produced by the anodic half cell reaction and the number of meal ions transformed from metal atoms is the same as the number of electrons consumed by the cathodic half cell reaction and also the number of ions transformed back to atoms, and so both the half cell reactions proceed at equal rates. The current flows for the anode and cathode half cell reactions are finite and identical, but in opposite directions. But the magnitude of the current flows is identical for both half cell reactions. This magnitude of current is called the Exchange Current Density. The units used are current per unit area of surface exposed, for example A/cm2, The reaction surface and ions involved controls the exchange current density. Some examples are given below for zinc when it is placed in a solution containing zinc ions of the type indicated in the table below:- 4 Ion Perchlorate Sulfate Chloride ECD (A/cm2) 3 x 10-8 3 x 10-5 3 x 10-4 The exchange current density or ECD represents an equilibrium point. The metal in solution of its own ion type can only corrode or have ions deposit when the current density is not at the exchange current density value. Potentials. As described above, REDOX reactions are both anodic and cathodic half cell reactions but balanced under equilibrium conditions. Clearly, some standard has to be set for this equilibrium and so standard conditions are defined as one atmosphere of gas pressure, pure solid present, normal ionic solution strengths at 25oC temperature. Normalcy is the number of equivalents per liter of solution. Normal ionic strength is when one gram equivalent is dissolved per liter of water. For hydrochloric acid, a one normal solution would be the gram molecular weight, or gms per liter of solution. For one normal sulfuric acid, H2SO4, half the gram molecular weight in a liter of water would be required as it has two hydrogen ions present and a normal solution requires only one electron to be available. For basic solutions the number of hydroxyl ions is used instead of hydrogen ions or the number of electrons transferred in the reaction. What is unavailable at this stage is a scale to differentiate between the different REDOX reactions listed for both metals and non metals. A reference scale is required. This is sometimes called the Electro Motive Force (EMF) series or REDOX potential series. To measure potentials (or voltages) for comparison of REDOX reactions, the reference used is a Standard Hydrogen Electrode (SHE). This electrode is a constructed by bubbling gaseous hydrogen at 1 atm. of pressure over a piece of pure platinum in a solution of one normal H+ ions. The redox reaction is therefore:2H+ + 2e- = H2g 5 H 2g Pt foil Permeable membrane 1 N H ions Standard Hydrogen Electrode. The potential for this reaction by definition is 0.0 V. It is a complete REDOX reaction and will maintain a standard, constant voltage unless the conditions change away from the defined standards. The oxidation, anodic reaction and the reduction, cathodic half cell reactions are given below:H2 > 2H+ + 2e2H+ + 2e- > H2 No electron removal is allowed and the hydrogen ion strength must be maintained. By coupling different metals M to the SHE their potentials can be measured in volts on a voltmeter. This gives rise to the data below for EMF or REDOX potentials. Note that is some areas , the scale is opposite with gold for example at –1.48V. Most engineering practices use the scale below, but be careful. Reaction Au = Au3+ + 3eO2 + 4H+ + 4e- = 2H2O Pt = Pt2+ + 2eO2 + 2H2O + 4e- = 4(OH-) 2H+ + 2e- = H2 Fe = Fe2+ + 2eCr = Cr3+ + 3eZn = Zn2+ + 2eAl = Al3+ + 3e- 6 Potential at equilibrium (volts). 1.498 1.229 1.2 +0.401 0.0 -0.440 -0.744 -0.763 -1.662 In the figure below showing how a SHE is coupled to the REDOX reaction being measured, a high resistance voltmeter is used to measure the voltage for this series to ensure that no current flows from the REOX cells and so no corrosion or deposition is occurring as all the reactions are equal and opposite in rate. The REDOX reaction being measured must also be at standard condition. This series provides the thermodynamic probability that a pure metal under standard conditions will either ionize by an anodic reaction or plate out in a cathodic reaction. V olts H 2g Pt foil M etal 1 N H ions 1 N M ions Permeable membrane Cell for determination of EMF series or Redox potentials. The more negative the potential measured in the EMF or REDOX series, the more likely the material is to oxidize in an anodic half cell reaction. Therefore, gold, Au is termed very noble as it has a high positive EMF value. Zinc is very anodic as it has a low negative value of EMF. Therefore connecting a half cell of gold to a half cell of zinc will induce anodic reaction of the zinc to produce electrons, i.e.:Zn -> Zn2+ + 2eConcurrently, the cathodic half cell reaction will be favored in the half cell with the more positive potential and gold ions will be reduced to gold by:Au3+ + 3e- -> Au. The zinc will have corroded as weight loss will occur. This process is essentially galvanic corrosion. As will be discussed later this is a useful corrosion process as protection techniques sometimes rely on dissolving a cheap, easily replaced metal rather than the expensive structural metals. Two examples of this are galvanizing and sacrificial anodes. 7 Some important features for the SHE and EMF series. The standard hydrogen electrode is a difficult piece of apparatus to use. Hydrogen gas is required along with a reasonably strong acid solution. It is not practical for everyday use. Secondly the EMF series only applies to pure metals in highly specified conditions, which are not often seen, such as one normal ionic solutions. It is a good guide only for these conditions. Thirdly, some elements are very low in the series such as chromium, yet this element is added to iron to make steels "stainless". At this point there is some discrepancy between theory and practice, which is answered by the so far un-described role of kinetics on corrosion. Kinetics involves the rate of a reaction; thermodynamics considers whether a reaction is favorable or not. For a reaction to proceed it must be thermodynamically favorable. So reactions can be thermodynamically favorable, but kinetics determines the rate at which the reaction proceeds. Fortunately in corrosion, the kinetics of a reaction will often aid in reducing the expected rate. Examples would be stainless steels and titanium and its alloys. Reference Electrodes. The Standard Hydrogen reference electrode has already been described in earlier notes. It is an impractical electrode with a strong acid and highly flammable hydrogen gas required. A simpler reference electrode is required for practical measurements and several exist. The most common ones are the Calomel electrode, the copper/copper sulfate electrode and the silver/silver chloride electrode. The requirements of a reference electrode is that are a constant reference against the standard hydrogen electrode over a wide range of conditions. This usually means that a self contained half cell reaction occurs that cannot be change by the environment in which the reference electrode is placed. A good example is the Saturated Calomel Electrode or SCE. A diagram of the electrode is shown below. 8 To Voltmeter Platinum Wire Filling Hole Glass or Plasic Body Saturated KCl Porous Tip Saturated Calomel Reference Electrode. This is a very common electrode. It is based on the mercurous to mercury half cell reaction of:Hg2Cl2 = Hg2++ + 2ClHg2++ + 2e- = 2Hg Overall Reaction:Hg2Cl2 + 2e- = 2Hg + 2ClNernst Equation gives:ECal = Eo - (RT/zF) ln (aCl-)2 = Eo - (2.303RT/F) log aClECal = +0.2677 - 0.059 log aClEcal = +0.242 V against SHE for Hg/Hg2Cl2 in saturated KCL. 9 In the SCE the Calomel paste of mercurous chloride is mixed with mercury and and the filling solution is saturated potassium chloride. The saturated solution has a fixed chloride ion activity and the mercurous chloride is only slightly insoluble in water. A porous tip enables ionic transport to complete the necessary components for measuring voltage along with connection to a high resistance voltmeter.The electrode maintains its chemical conditions and provides a reference potential against the standard hydrogen electrode of +0.242 V. Other common reference electrodes are the Copper/Cupric Sulfate electrode where a copper bar is placed in a saturated cupric sulfate solution. E Cu/CuSO4 = +0.34 V(SHE) for saturated copper sulfate solution Corrosion Rates , Polarization and Faradays Law So far, much has been examined regarding equilibrium conditions. However, corrosion and deposition do not occur under equilibrium conditions. The measurement of the corrosion rate of material in the environment is vital to the correct selection of a material. One method to place the material in the environment and monitor any weight change. Another is conduct a laboratory study and conduct measurements. The issue is what should be measured. In this section, the parameters which provide information on corrosion rates and which can be measured in a laboratory will be determined. In considering the general REDOX reaction at a metal electrode - M :M = Mz+ + zeAt the Redox potential under standard conditions used to determine the Redox series, there is no net current flow as the anode reaction rate is the same as the cathode reaction rate. This voltage will be called Er for Redox potential. When the potential moves away from this equilibrium value so it no longer equals Er, then the reaction rates becomes unbalanced and one or other of the half cell reaction dominates, either cathodic or anodic. At this new potential either a net flux of electrons will be produced, if the anodic half cell dominates, or electrons will need to be provided to allow the cathodic half cell reaction to proceed. So by controlling the potential the reaction can be either anodic or cathodic. This is also called Polarization, the movement away from the Redox potential value. Polarization of an Electrode. Polarization of an electrode is the movement away from the equilibrium state where the anode reaction rate is equal and opposite to the cathodic rate at standard conditions. A simplified model of the situation will be presented in this section to determine what happens when the conditions are altered away from the standard ones. The particular case will be when some electrons produced by the anodic half cell reaction are removed and not available for use by the cathodic half cell reaction. Consider a pure metal at equilibrium in its own ions. Atoms sit in low energy positions on the surface. An activation energy barrier exists for these atoms to become ions and produce electrons. A schematic diagram of the situation is shown in the first figure below. At equilibrium the ion exchange current density is available of atoms transforming to ions (anode reaction) and at an equal rate the ions from solution are transforming to atoms (cathodic reaction) at the redox potential of Er At equilibrium the activation energy barrier is Ge Ge = BF 10 The energy barier, Ge, is the same independent of the reaction direction, anodic or cathodic. In the second figure below, the energy of the atom in the surface was increased, or it was Anodically Polarised to make it more favorable for the atoms to form ions. Assume BE = FG Let BC/AC = Then AB/AC =1- Ge Atom in Surface Ion in Solution G Ga F D Atom in Surface E C B Ion in Solution A By similar triangles, CD/EB = AC/AB =1/(1-) EB = CD(1-) CD = Change in anodic energy applied by an external voltage CD = zaF where z - number of electrons involved in the half cell reaction, a - overpotential or voltage movement from Er value, F - Faradays constant (96500 coulombs). 11 EB = (1-a)zaF Then the new activation energy barrier for an atom to ion transfer, releasing electrons is:Ga =Ge - CD + FG Ga = Ge -CD + EB Ga = Ge - zaF + (1- )zaF Ga = Ge - zaF Also, as the process is activation controlled it follows an Arhenius rate law of:Rate = Ke(-G/RT) R - Boltzmanns constant of 1.96 cal/oK, T temperature in oK The rate in this case is proportional to the current flowing. Then:i = Ke(-G/RT) ia= Ke(-Ga/RT) ia=Ke(-(Ge-zaF)/RT) At equilibrium io is the Exchange Current Density at Redox potential, Er io=Ke(-Ge/RT) Expanding the equation for anodic dissolution:ia= K exp(-Ge/RT)exp(zaF/RT) ia = ioexp(zaF/RT) Taking logs ln ia = ln io + zaF/RT Rearranging:a = (ln ia - ln io)(RT/zF) For cathodic polarization. c = (ln io - ln ic)((RT/(1-)zF) These are the Tafel equations for polarization of an electrode. They follow the general form of a straight line if is plotted as a function of log i. y= c + mx = a +/- b logi The equation above is the TAFEL equation which relates potential to current density for an electrochemical reaction. The constants for the equation are listed below. The constant "b" is called the Tafel constant. Anodic a = -ln io(RT/zF) b = RT/zF Cathodic a = ln io(RT/(1-)zF) b= -(RT/(1-)zF) Overall ,changing the conditions from the half cell reactions therefore produces polarization resulting in a current. 12