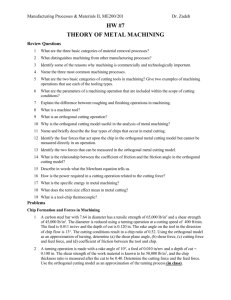

ME 482 - Exam #2

advertisement

ME 482 - Exam #2 Oct. 31, 2005 Name____________________ Problems (40) 1. Consider a turning operation on a part of diameter 6”. The part material has shear strength of 40,000 psi and a tool rake angle of 10 deg. In addition, the cutting conditions are rotational speed = 500 rpm, feed = 0.0075 in/rev, and depth = 0.075 in. The chip thickness after the cut is 0.015 in. Determine the horsepower required in this operation. Solution Power from P (hp) = Fc v/33,000; thus need Fc and v. r = 0.075/0.015 = 0.5 = 2(45°) + – 2 = 2 (45°) + 10° – 2(28.3°) = 43.4° = tan-1 (0.5 cos10°/(1 – 0.5 sin10°)) = 28.3° As = 0.0075(0.075)/sin 28.3° = 0.00119 in2 Fs = 40,000 (0.00119) = 47.5 lb Fc = 47.5 cos(43.4 – 10)/cos(28.3 + 43.4 – 10) = 83.6 lb v = 500 rpm (6 in/rev)/(12 in/ft) = 785 fpm HP = 83.6(785)/33,000 = 1.99 hp Grading: 1. 2. 3. 4. (20) 2. Student determines chip thickness ratio and equations to determine shear plane angle. Student applies Merchant relation to get friction angle. Student determines shearing force and applies force vector equations to determine cutting force. Student determines cutting horsepower. 10 pts 10 pts 10 pts 10 pts Answer the following T/F questions: a. The value of the Merchant Eqn. is that it relates rake angle, shear angle and chip thickness. T__ F_X_ b. In the machining optimization paper, the cost minimized cutting speed is constant over the planning period over any time of day or week. T_X_ F__ c. In the high speed machining of titanium alloys paper, it was shown that at a lower feed rate the tool life can actually be higher at a higher cutting speed. T_X_ F__ d. Flank wear causes a surface crater caused by by the chip sliding against the surface. T__ F_X_ e. WC-Co should not be used for machining steel alloys. T_X_ F__ f. In optimized machining the production rate is improved by decreasing the tool change time. T_X_ F__ g. Titanium is more machinable than copper. T__ F_X_ h. Cast cobalt alloys have a better hardness than high-speed steels at all temperatures. T__ F_X_ i. Taylor’s tool life equation was shown to apply to high speed machining in the text. T__ F_X_ k. Active lubrication of the tool is very effective in high speed machining. T__ F_X_ Grading: 2 pts each correct answer 2 (40) 3. A vertical boring mill is used to bore the inside diameter of a large batch of tube-shaped parts. The diameter = 28 in. and the length of bore = 14 in. Current cutting conditions are speed = 200 fpm, feed = 0.015 in./rev, and depth = 0.125 in. The Taylor equation parameters are n = 0.23 and C = 850. Tool change time = 3 min., and tooling cost = $3.50 per cutting edge. The total time to load and unload the part is 12 min. The cost of machine time on the mill is $42/hr. Management has decreed that the production rate for this job must be increased by 25%. Is this possible? Assume that the feed must remain unchanged to achieve the required surface finish. What are the current production rate and the maximum possible production rate for this job? Solution: At current operating speed v = 200 fpm: From Taylor’s eqn: T = (850/200)1/0.23 = 540 min Machining time = Tm = (28)(14)/[(200)(12)(0.015)] = 34.2 min/pc np = 540/34.2 = 15 pc/tool life Tc = 12 + 34.2 + 3/15 = 46.4 min/pc Production rate = Rc = 60/46.4 = 1.293 pc/hr current production rate Find vmax for optimum production rate: vmax = 850/[(1/0.23 – 1)(3.0)]0.23 = 500 fpm Tmax = (1/0.23 -1)(3.0)) = 10 min Machining time = Tm = (28)(14)/[(500)(12)(0.015)] = 13.7 min/pc np = 10/13.7 = 0.73 pc/tool life Tc = 12 + 13.7 + 3/0.73 = 29.8 min/pc Production rate = Rc = 60/29.8 = 2.01 pc/hr max production rate Since this represents a 56% increase in production rate, a 25% increase is possible. Grading: 1. Student determines machining time and tool life time at current speed. 2. Student determines optimum machining speed and tool life time. 3. Student determines current and maximum production rate (or cycle time) 4. Student notes that 25% increase possible. 10 pts 10 pts 10 pts 10 pts