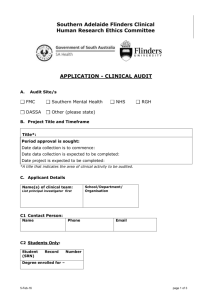

PR-1712 - Level 3 Audit (Engineering Operations)

advertisement