ENERGY-SAVING TECHNOLOGY OF

FLUE GASES AND WASTE WATER CLEANING

ABSTRACT

The Energy-Saving Technology (EST) helps both to reduce emission of environmental contaminants

including heat pollution and to raise the Fuel Utilization Efficiency (FUE). The application of

condensation method provides the highest degree of catching the most hazardous highly dispersed

aerosols and dust particles with the size of several micrometers or less. The following description of this

technology includes the various technological systems for energy conservation, the methods of HeatMass Transfer (HMT) evaluation under Adiabatic Evaporation (AE) and Vapor-Gas Mixture (VGM)

condensation, as well as the heat-exchanger designing and the results obtained during the field trial

programs for the pilot plants.

INTRODUCTION

Industries that are the main sources of air pollution (ferrous and non-ferrous metallurgy, production of

construction materials, fossil fuel burning power plants, chemical industry, foundries, transport

engineering, automobile vehicles, etc.) do emit both the greenhouse gasses and the dusts containing

large proportion of highly dispersed fractions. The aerosol particles with the size of several micrometers

are the most hazardous for human health. Furthermore, they influence on the atmospheric processes and

the climate change. To avoid such emission, a big amount of energy is presently consumed in various

purifiers such as Venturi washers, electric filters and the like. Conventional dust collecting apparatuses

(cyclones, scrubbers, etc.) are ineffective in the case of aerosols.

At the same time, a liquid heating is a major consumer of energy. Consumption of hot water for

technological needs, heating and ventilation constitute a major part of the heat load of industrial

enterprises (from 35 to 85 % of their heat balances). The typical low temperature uses of hot water

include pre-heating of boiler feed water or process fluids, space and domestic water heating, swimming

pools, greenhouses, heavy oil and combustion air heating. The utilization of secondary heat resources,

such as waste gases heat, may conserve energy (fuel), thus will decrease heat pollution and diminish a

global warming and climate change as well.

Very often the steam is used as a heating medium for low temperature heating. Its elimination can

enhance the overall efficiency because, in the sense of thermodynamics, to spend the potential of energy

carrier (vapor), which is able to produce mechanical work or/and electricity, is meaningless. At present,

about 75 % of electric energy is generated by heat Power Engineering Stations (PESs) that burn organic

fuel (gas, oil, coal and shale) with Fuel Utilization Efficiency (FUE) of 30-35 %.

The EST was proposed to increase the degree of heat use in various systems with polluted waste gases,

containing COx, SO2, NOx, etc., Komkov [1975, 1976a]. Being a result of long-standing researches

and developments, this technology allows to construct a highly efficient and environmentally clean PES

of any capacity, including small ones based on secondary power resources in various industrial sectors,

such as chemical industry, metallurgy, building and construction materials production, etc. It can

contribute to weaken the menace of global warming, both through conserving energy and reduction of

the environmental pollution, Komkov, 1977a, 1977b, 1977c, 1992, and be useful in ecological revival

of radioactively contaminated areas, Beskrovny and Komkov, 1992. The proposed technological

methods include the use of both traditional standard equipment and not very usual one, such as Heat

Recovery Scrubber (HRS), that utilize heat during a purifying process, Komkov etc., 1988. Here, the

process is organized in a way so that all extra-heat of polluted gases/waters is converted into water vapor

under the condition of AE. Then the saturated VGM enters the surface condenser. Such a transformation

of wet gas cleaning system allows saving waste heat instead of its losing during gas purification as it

was before in the conventional systems. Usually, due to several reasons, the temperature of washing

water in the process of wet cleaning is maintained on the lowest level, mostly equal to the one of the

environment (in summer ≈ 15º C / 68º F). In the new technology, the process temperature has been

recommended to be maintained on the level of AE. Thus, the washing water temperature is equal or

close to the Wet Bulb Temperature (WBT) – tb. The tb depends on initial gas characteristics –

temperature and moisture content. Under the atmospheric pressure the maximum level of WBT is about

tb = 85º C / 185 º F.

When pre-purified VGM is condensed in a surface condenser a final dust cleaning is taking place too. In

the practice of the accustomed installations, using condensation method of gas cleaning, process of

condensation takes place under the direct contact with cooling water, which becomes dirty. Presented in

the new technology, the new element – surface heat-exchanger – is also unusual for a traditional wet gas

purifying systems. It brings new technological opportunities both for cleaning and for waste heat

utilization.

The designing of the condenser includes a process evaluation both on the surface and in the volume

especially on condensation centers such as dust particles. This is accompanied by drops growth, their

enlargement and interception through various mechanisms (coagulation, diffusion, phoresis, turbulence,

etc.). Sometimes a fog formation takes place as well. The phenomenon alters heat and mass transfer

rates from vapor-gas mixture to wall, and hence the performance of the heat-exchanger, but at the same

time it may help drop growth and thus increase cleaning effect of condensation.

Although the wet method is one of the oldest, it continues to be universal one comparatively with other

modern dry methods: it is possible to catch the contaminants of all sorts – solid, liquid and gaseous.

Some of “dry” methods use water to transport caught dust, thus creating a dirty water cycle.

In the new technology, the washing water re-cycling allows cleaning other waste water and combining

both processes in the one unit. The method may also be used in automotive vehicles both to reduce

greenhouse gases emission and to increase the fuel utilization efficiency of engine.

The trials at the pilot plants discovered the possibility of using ordinary carbon steel heat-exchangers as

surface condensers. In long-term experiments under VGM condensation there have been installed

standard finned heat-exchangers usually applied for clean air heating in ventilation systems. The

corrosion rate was not faster than under atmospheric conditions. The explanation of the phenomenon

needs special corrosion experiments.

THE TECHNOLOGICAL SYSTEMS

Industrial Energy Sector

The technology has been used in the operations loops of fuel-burning apparatuses employed in various

industrial branches (chemical industry, metallurgy, building materials production, etc.). The several

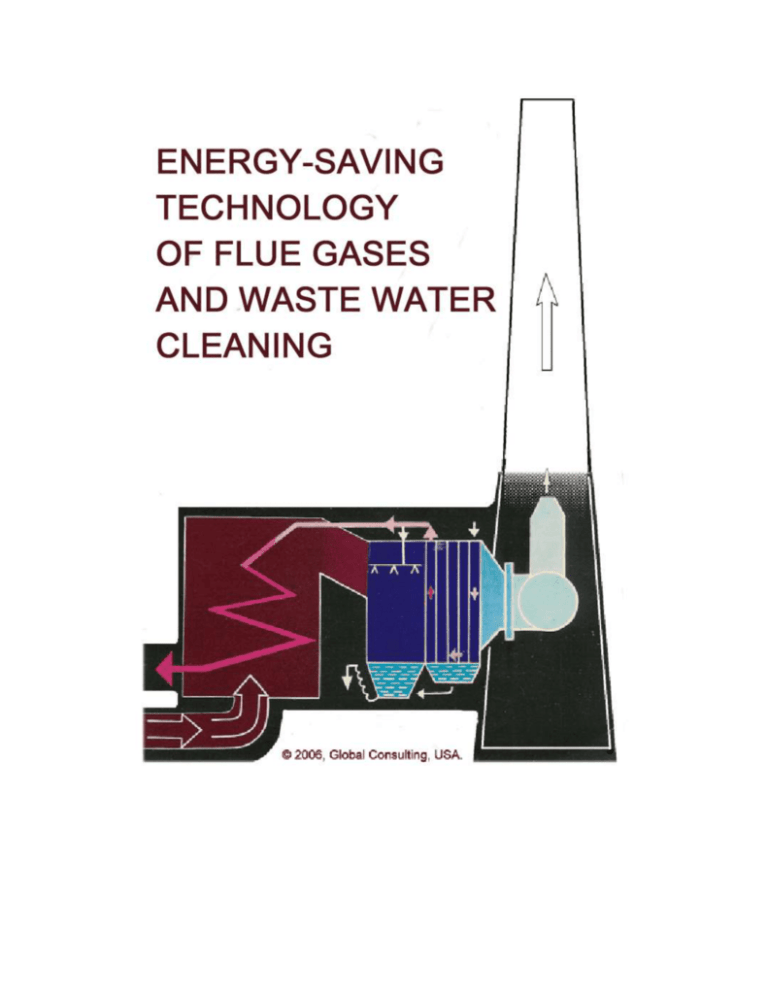

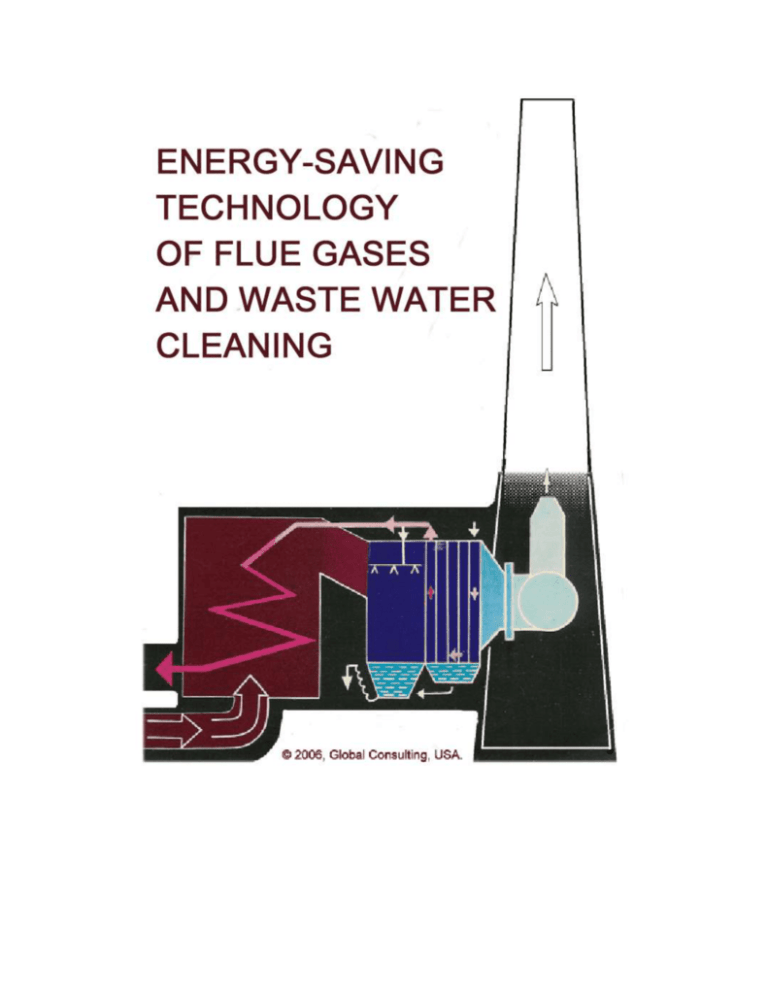

examples of the technology realization in using secondary power resources are given on the Figs. 1 - 4.

Fig. 1 is a view of a principal scheme of the installation for heat utilization and the flue gases cleaning

that was put into operational practice after the rock wool-lined furnace in Vilnius, Lithuania, during

1983 – 86, Komkov etc, 1988. The flue gases contained dust, SO2, NOx. The acids were neutralized

with burnt lime. The heated water was used in the ventilation system. There were two options for the

heating of cooling water:

a) in condenser (4) till the temperature

tw = tb – (7 …12)º C

or tw = tb – (44.6 … 53.6) º F

At the pilot plant in Vilnius tw was about 50 … 55º C (323 … 328º K) or 122 …131 º F;

b) in waste heat boiler (economizer) (2) after condenser (4) till thw = 90 ºC (363º K), or 194 º F, and

more. The upper value is limited by flue furnace gas temperature. The economizer surface was exposed

to dust drift.

Fig. 2 is a view of a principal scheme of the further developed installation, Komkov, 1990. The

installation contains scrubber-absorber (1), connected with flushing water tank (2), condenser (3) with a

tray, connected with blast air spray chamber (6). There are evaporating tank (11), additional condenser

(14) and other auxiliary equipment for treatment of waste water till dry remainder.

Those energy-saving industrial installations for cleaning of contaminated flue gases were successfully

tested and put into industrial use at the pilot plants in Ukraine, the foundry of the industrial enterprise

“Veda”, and in Belarus, research foundry of the Belarus Polytechnic Institute, Minsk.

Heat and Electric Power Engineering

Fig. 3 is a view of the principal scheme of the boiler with utilization of waste heat, both gaseous and

liquid, Komkov, 1989. The combination of the shown boiler with other systems, illustrated on Figs. 1,

2, give them the corresponding advantages.

There exists a special opportunity to raise FUE on Power Engineering Stations as it is exposed on Fig. 4,

Komkov, 1976c. The ultimate efficiency makes unnecessary the attainment of high temperature for

transfer mediums heating. Combustion process may be run at the lowest of possible temperatures a big

air excess that is to prevent NOx and CO generation, Komkov, 1993.

The design view of the mid-size industrial Heat Utilizer of Contaminated Gases is presented on Fig. 5.

Here, for the project with the capacity of 10,000 cubic m (35,315 cubic ft) of gases per hour, the

calculated dimensions of the energy saving gas cleaning installation will be 12 ft x 2 ft x 10 ft.

CONCLUSIONS

The Energy-Saving Technology allows to create Power Engineering Stations of various capacities, high

and low, with ultimate efficiency, protect the environment and use the reserves of fuel conservation to

produce heat and electricity with a short pay-off period. The applied methods of Heat-Mass Transfer

evaluation allow designing of the exchangers and the systems of the Energy-Saving Technology.

ABBREVIATIONS

EST – Energy-Saving Technology

tb – Wet Bulb Temperature (WBT), ºC

tw – Warm Water Temperature, ºC

thw – Hot Water Temperature, ºC

AE – Adiabatic Evaporation

WGM – Vapor-Gas Mixture

HTM – Heat-Mass Transfer

HRS – Heat Recovery Scrubber

MTC – Mass Transfer Coefficient

FUE – Fuel Utilization Efficiency

PES – Power Engineering Station

REFERENCES

Komkov, 1975, “The Use of Low Temperature Heat Utilizers for Reduction of Industrial Furnaces

Emission in Atmosphere”, in The Use of Gas in the National Economy (Ispolzovanie Gaza v Narodnom

Khozyaistve), No. 6, pp. 30-33, VNIGasprom Press, Moscow.

Komkov, 1976a, “The Use of Polutted Gases Heat”, in The Industrial Power Engineering

(Promyshlennaya Energetica), No. 2. 1976, pp. 51-52, Moscow.

Komkov, 1976b, “The Investigation of the Steam-Gas Mixture Condensation in Heat Utilizers-Waste

Gas Purifiers”, in The Use of Gas in the National Economy (Ispolzovanie Gaza v Narodnom

Khozyaistve), No. 6, pp. 15-20, VNIGasprom Press, Moscow.

Komkov, 1976c, Patent of Russia No. 785530.

Komkov, 1977a, “The Use of Combined Heat Utilizers / Gas Purifiers (HUGP) for Reducing Emission

of Contaminants and for Fuel Economy” in The Gas Industry and the Environment: Proc. Of

Symposium of the Committee on Gas, ECE, Minsk, Belarus, 1977, published for UN by Pergamon

Press, Oxford, UK, 1978 ISBN 0-08-0224-12-1, pp. 41-44.

Komkov, 1977b, “The Heat Generation Schemes for Use of Secondary Power Resources” in Heat

Supply System Designing: Proc. Of VNIPIENERGOPROM, issue No. 9, pp. 91-93, Moscow, Russia,

1977.

Komkov, 1977c, “The Schemes of Hot Contaminated Gases Use with Application of Condensation

Effect” in The New Achievements in Automobile Industry (Peredovoi opit v avtomobilestroenii), No. 5,

pp. 19-23, 1977, Toljatti, Russia.

Komkov et al, 1988, “The Energy-Resource Saving Technology of Gas Cleaning”, The information

letter of the Ukrainian Academy of Science, published by Reclama Press, 1988, Kiev, Ukraine.

Komkov, 1989, Patent of Russia No. 1621650

Komkov, 1990, Patent of Russia No. 1776907

Komkov, 1992, “The Results of Research, Development and Promoting of the Power-Saving Gas-Water

Cleaning Technology” in The Physical Problems of Ecology, Nature Management and Resources

Conservation: Proc. Of the 1st International Symposium, pp. 97-98, Izhevsk, Russia, 1992.

Beskrovnyi and Komkov, 1992, “ERR Project (Project of Ecological Revival of Regions) Applying

Biomosses and Using Biomass Energetically” ibid, pp. 51-52.

Komkov, 1993, “The Heat Recovery Scrubbers: Results and Perspectives” in Gas Cleaning at High

Temperatures: Proc. of the 2nd International Symp, Guildford, UK, 1993, the Poster Presentation, p.22.

Komkov, 1998, “Experience in Research, Development and Designing, of Heat Exchangers in PowerSaving Technology (PST) of Waste Gas/Water Cleaning” in The Heat Exchangers for Sustainable

Development. Proc. of the International Conf., Lisbon, Portugal, 1998.

© Global Consulting, 2006, USA. All Rights Reserved.