CVC 601 DC Sputterer, Metals

advertisement

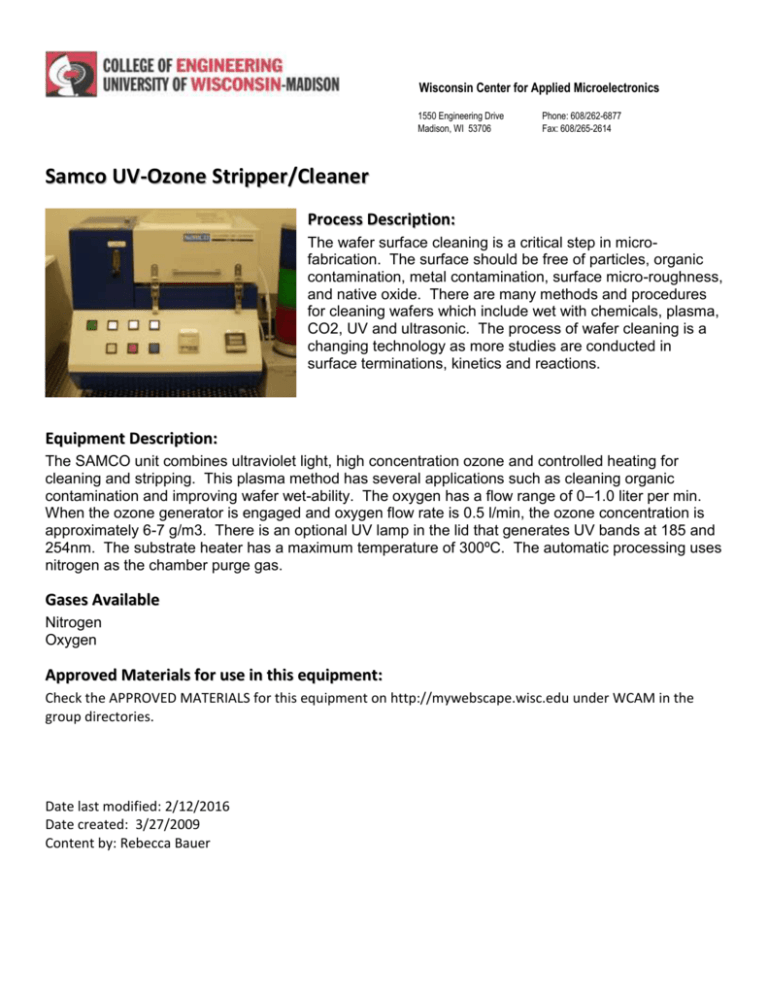

Wisconsin Center for Applied Microelectronics 1550 Engineering Drive Madison, WI 53706 Phone: 608/262-6877 Fax: 608/265-2614 Samco UV-Ozone Stripper/Cleaner Process Description: The wafer surface cleaning is a critical step in microfabrication. The surface should be free of particles, organic contamination, metal contamination, surface micro-roughness, and native oxide. There are many methods and procedures for cleaning wafers which include wet with chemicals, plasma, CO2, UV and ultrasonic. The process of wafer cleaning is a changing technology as more studies are conducted in surface terminations, kinetics and reactions. Equipment Description: The SAMCO unit combines ultraviolet light, high concentration ozone and controlled heating for cleaning and stripping. This plasma method has several applications such as cleaning organic contamination and improving wafer wet-ability. The oxygen has a flow range of 0–1.0 liter per min. When the ozone generator is engaged and oxygen flow rate is 0.5 l/min, the ozone concentration is approximately 6-7 g/m3. There is an optional UV lamp in the lid that generates UV bands at 185 and 254nm. The substrate heater has a maximum temperature of 300ºC. The automatic processing uses nitrogen as the chamber purge gas. Gases Available Nitrogen Oxygen Approved Materials for use in this equipment: Check the APPROVED MATERIALS for this equipment on http://mywebscape.wisc.edu under WCAM in the group directories. Date last modified: 2/12/2016 Date created: 3/27/2009 Content by: Rebecca Bauer