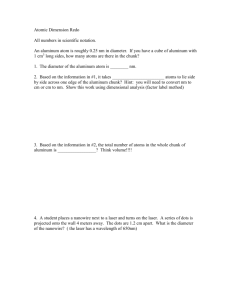

- American Chemical Society

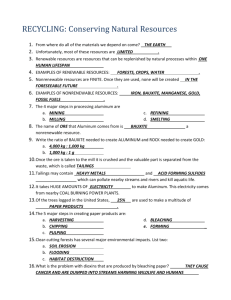

advertisement