Supplementary Notes - Word file (3.2 MB )

advertisement

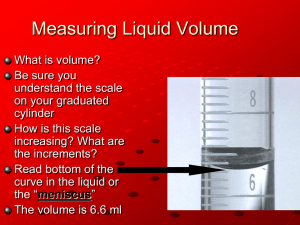

Manuscript number: 2005-12-14787 1 Supplementary Information for Smart Microlenses Using Pinned Liquid-Liquid Interfaces Liang Dong, Abhishek K Agarwal, David J Beebe, and Hongrui Jiang Microlens properties The water is stored inside the hydrogel ring. The oil prevents evaporation of the water. The reflective index (n) of the mineral oil (noil = 1.48) is greater than that of water (nwater = 1.33), so the convex menisci (bulging upward) form divergent microlenses, while the concave (bowing downward) menisci form convergent microlenses. Pressure difference across water-oil interface We calculated the pressure difference across water-oil interfaces Im at θ = θα and IIm at θ = -(90 o-θβ) (Fig. 1a) by using Young-Laplace equation P = γ(1/R1+1/R2), where P, γ, R1,2 are the pressure difference across the meniscus interface, the liquid surface free energy, and the radii of the meniscus curvature, respectively. For a circular aperture, R1 = R2 = R = r/sinθ, where r is the radius of the aperture. The water contact angles on the surfaces ‘ts’ and ‘ca’ (Fig. 1a) obtained by the surface chemistry treatment (see Methods) are θα = 117.5 o and θβ = 28.7 o, respectively. For an aperture diameter of 1.0 mm, the pressure differences across the interface Im and IIm are 208 and -265 N/m2, respectively. The negative pressure difference represents that the pressure at the water side is less than the oil side. Temperature-sensitive liquid microlens in Fig. 2 Polymer jacket The polymer jacket made of poly(IBA) in Fig. 2a prevents leakage between the NIPAAm hydrogel and glass substrate. Potentially, this jacket can be eliminated by improving the adhesion of the hydrogel to the substrate. Transition of focal length from a negative to a positive value in Fig. 2d The microlens starts as divergent at a low temperature (23 C) by intentionally making the liquid meniscus protrude upward. The increase of temperature causes the liquid meniscus to bow downward until the temperature reaches 47 C (convergent microlens). The focal length changes from a negative (divergent microlens) to a positive (convergent microlens) value at 33 C. Here, a 670 nm-wavelength 2 mm-diameter round laser beam strikes the microlens. The output is shown on a screen. The equation 1/u + 1/v = 1/f is used to calculate the focal length, where u and v represent the object and image distance, respectively. Manuscript number: 2005-12-14787 2 pH-sensitive liquid microlens in Fig. 3 Delivery of buffer solution to device To simulate a change in local environmental pH, a syringe pump is used to deliver buffer solution to the device through the input channels. The pumping rate is kept at 0.4 mL/min to avoid the effect of pumping pressure on the shape of meniscus. Focal length of microlens In Fig. 3d, the focal length is calculated by treating the microlens as a spherical lens1. To observe and measure the geometry of the meniscus through a goniometer, the meniscus is kept protruding above the aperture slip (Fig. 1). Therefore, the microlens is divergent (focal length tuning range, -2.6 mm ~ -6.6 mm) throughout the range of the pH during the experiment. Initially the liquid microlens has a low protruding height at low pH (pH = 2.0) and higher pH buffer solutions make it bulge upward. The initial amount of water-based lens liquid can be properly set to achieve a microlens that initially starts as a convergent lens (meniscus lower than the aperture slip) and transits to a divergent one when the meniscus bulges above the aperture slip. Liquid microlens array in Fig. 4 Both liquid microlenses have the same structure, except utilizing opposite pH-responsive hydrogels (AA and DMAEMA hydrogels). They are situated in one microchannel and exposed to the same pH buffer solution at all times during the experiments. Reference 1. Meyer-Arendt J. R. Introduction to classical and modern optics (Prentice-Hall, Englewood Cliffs, NJ. 1984). Manuscript number: 2005-12-14787 3 Supplementary Figure S1: The volume of the liquid meniscus of the temperature-sensitive liquid microlens (Fig. 2a) as a function of temperature. To visualize the water-oil interface through a goniometer, the liquid meniscus initially has a starting volume of 0.8 μL with a low protruding height at a high temperature (47 C). As the temperature decreases to 23 C, the meniscus keeps bulging upward. The reverse temperature cycle from 23 C to 47 C causes the meniscus to retreat to the starting point. The observed maximum percentage of volume change of the NIPAAm hydrogel-water system is approximately 18.6 % (the absolute volume change determined from the liquid meniscus volume, and total volume of the hydrogel-water system are 1.75 μL and 9.42 μL, respectively) over a temperature range of 23 – 47 C. The thermal expansion of water and other materials (i.e., oil, glass, and non-responsive polymer) of the device has little impact on the volume change in the liquid meniscus and can be ignored due to their low volume thermal coefficients on the order of 10-6 – 10-4/ C. Error bars are s.d. Supplementary Figure S2: The volume of the liquid meniscus of the pH-sensitive liquid microlens (Fig. 3a) as a function of pH. The liquid meniscus initially has a starting volume of 0.07 μL with a low protruding height at a low pH environment (pH = 2.0). High pH buffer solutions cause the liquid meniscus to bulge upward. The volume of the liquid meniscus at varying pH is determined by the net volume change between the hydrogel in the inside periphery and the water-based lens liquid enclosed by the ring, though the volumetric change also occurs in the outside periphery of the hydrogel ring. Error bars are s.d. Manuscript number: 2005-12-14787 4 Supplementary Figure S3: Smart cylindrical liquid microlens using NIPAAm hydrogel. A rectangular window is photopatterned to form the aperture. Supplementary Figure S4: 3-dimensional 2×4 microlens array distributed on a flexible substrate. Two polycarbonate cartridges are adhered together to form a 375 μm-thick cavity. One cartridge acts as the substrate (170 μm-thick), the other as the aperture where 2×4 holes are punched. An oxygen plasma treatment before adhering the two cartridges renders one side of the aperture hydrophilic; polycarbonate possesses excellent hydrophobicity without any surface chemistry treatment. The hydrogel rings are patterned using the fabrication process described in the Methods section.