MOHR

advertisement

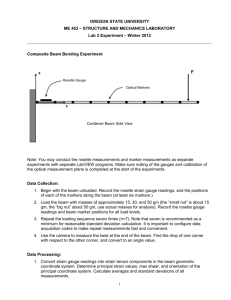

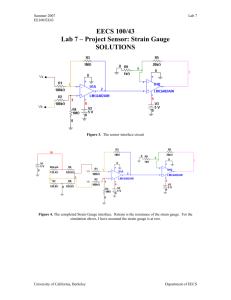

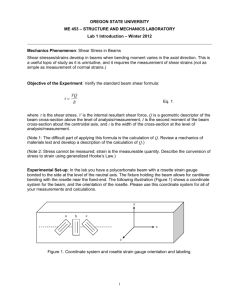

MOHR’S CIRCLE AND STRAIN GAUGE ROSETTE Your Name Your Discipline (Elec, Mech, Aero or Ship) Summary Contents List 1 Introduction The Mohr’s circle is a graphical method to determine the effect of a coordinate rotation on a tensor quantity. Within engineering it finds application in the effect of coordinate rotation on stress, strain, second moment of area and moment of inertia. In this experiment, 2 Objectives 3 Apparatus An aluminium alloy beam clamped at one end within a rig containing a cam whose full-range rotation leads to a repeatable tip deflection of 1 2 12.7 mm , as depicted in Figure 1. The beam has dimensions breadth b 25.4 mm , depth d 6.35 mm and length (to the cam) L 254 mm . Three strain gauges are mounted on the upper surface 94 mm from the clamped end; these gauges are mounted at 15 , 45 and 75 to the beam’s longitudinal x-axis, as shown in Figure 2. Each of these gauges may be selected, in turn through a switch, to be one arm of a Wheatstone bridge arrangement [1 research and give reference]. A dummy strain gauge provides temperature compensation. 94 mm x L=254 mm y, v 1 beam Figure 1. Cantilever 4 Procedure 1. The strain gauge amplifier should be warmed up, and set to the correct gauge factor (G.F.) of 2.1. 2. Select gauge 1 and balance (zero) the bridge with the beam unloaded. Rotate the lever to bend the beam, and take the strain gauge reading. 3. Repeat step 2. for gauges 2 and 3; note that it will be necessary to re-balance the bridge for each gauge whilst unloaded – this is necessary because the cables from each gauge to the switch will have slightly different length and hence slightly different electrical resistance. The measurements should be recorded as Beam condition Gauge 1 Gauge 2 Gauge 3 Unloaded 0 0 0 Loaded where the strain gauge readings are in microstrain. 94 mm 1 2 x 3 z Figure 2. Strain gauges 1, 2 and 3 mounted at 15°, 45 °, and 75 °, respectively, to the x-axis 2 5 Analysis of results On graph paper, construct the Mohr’s circle for strain and determine the principal strains 1 and 2 . For this educational example, the maximum strain 1 should be in the direction of the longitudinal x-axis, that is 1 x . Inevitably there will be experimental errors, so discuss possible reasons why the maximum strain obtained may not be predicted to occur in the x-direction. Determine a value of the Poisson’s ratio, , for the material. Compare your experimental values with those from the theory presented below. 6 Theoretical predictions For the rectangular beam cross-section, the second moment of area is I bd 3 25.4 6.353 542 mm4 542 1012 m 4 . 12 12 The tip deflection of a cantilever beam subject to a force W at the free-end is WL3 3EI [give reference]. Assuming a Young’s modulus for aluminium of E 70 109 Nm2 , then the required force to produce a deflection of 12.7 mm is W 3EI 3 70 109 542 1012 12.7 103 88.21 N . L3 0.2543 W M 94 mm x Q L=160 mm y, v Figure 3. Bending moment at strain gauge location. 3 At the strain gauge location, Figure 3, the bending moment M is M W 0.16 14.11 Nm . Now employ the expression x reference], and on the upper beam surface y x 14.11 3.175 103 542 10 12 My [give I 6.35 mm = 3.175 103 m , to give 2 82.66 106 Nm 2 . There is zero stress in the y- and z-directions, so the Hooke’s law reduces to x Thus x x E , y z x . 82.66 106 1181106 1181 , y z 0.3 1181 354 . 9 70 10 7 Discussion 8 Conclusions References 1. PP Benham, RJ Crawford and CG Armstrong, Mechanics of Engineering Materials, 1996, second edition, Harlow, Addison Wesley Longman. 2. Bibliography Nomenclature In alphabetical order, Greek symbols at end b breadth d depth E Young’s modulus I second moment of area L length M bending moment W load 4 x, y, z Cartesian coordinates direct strain direct stress deflection Appendices If required. Notes 1. Do not use every bit of formatting available on WORD – the report will look like a “dog’s breakfast”! Do not underline, use bold. Use an appropriate numbering system for each section. But the Introduction is numbered 1. 2. Download a free (trial) copy of MATHTYPE – it will revert to a light version after the trial period of one month, but this is perfectly adequate. This will automatically do various things such as a) variables should be italic – otherwise how does one distinguish between “a” and “a”, “I” and “I”. b) There should be no “I”, “me” or “we” within the report. c) It will allow one to use (times) instead of (ex) x, (minus) – instead of (hyphen) -. Unfortunately, it will also make units italic as in x 28 MN / m2 , but this can be corrected to x 28 MN/m 2 by changing the “style” to text. All the usual mathematical symbols and Greek alphabet are available at the touch of a button. The equations in the above were composed using MATHTYPE, and you will need a copy to open or edit them, although this should not be necessary. 3. Common mistakes Inadequate references: Author, Title, Year, Edition, Place of publication, Publisher, for books. See section XX. Author, Title, Name of Journal, Volume, Year, Page numbers, for journal papers. 4. 4. This is meant to be a FORMAL Report – do not use colloquialisms, don’t abbreviate. 5. TENSE – past! Do not over rely on spellchecker. 6. Material highlighted above needs addressing by you, together with your words in various sections. 5