OREGON STATE UNIVERSITY

advertisement

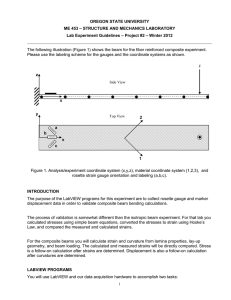

OREGON STATE UNIVERSITY ME 453 – STRUCTURE AND MECHANICS LABORATORY Lab 2 Experiment – Winter 2012 Composite Beam Bending Experiment F z Rosette Gauge Optical Markers x Cantilever Beam Side View Note: You may conduct the rosette measurements and marker measurements as separate experiments with separate LabVIEW programs. Make sure nulling of the gauges and calibration of the optical measurement plane is completed at the start of the experiments. Data Collection: 1. Begin with the beam unloaded. Record the rosette strain gauge readings, and the positions of each of the markers along the beam (at least six markers.) 2. Load the beam with masses of approximately 15, 30, and 50 gm (the “small nut” is about 15 gm, the “big nut” about 50 gm, use actual masses for analysis). Record the rosette gauge readings and beam marker positions for all load levels. 3. Repeat the loading sequence seven times (n=7). Note that seven is recommended as a minimum for reasonable standard deviation calculation. It is important to configure data acquisition codes to make repeat measurements fast and convenient. 4. Use the camera to measure the twist at the end of the beam. Find the drop of one corner with respect to the other corner, and convert to an angle value. Data Processing: 1. Convert strain gauge readings into strain tensor components in the beam geometric coordinate system. Determine principal strain values, max shear, and orientation of the principal coordinate system. Calculate averages and standard deviations of all measurements. 1 2. Convert marker position measurements into displacements in millimeters. Express as displacement versus position along the beam. Calculate averages and standard deviations of the measurements. Analysis: Adapt the Composites Calculator spreadsheet to represent the beams we are testing (lamina properties, stacking sequence). Extend the calculator by establishing a series of columns that represent discrete points along the beam from the fixed-end (x = 0) to the free-end (x = L). Find the internal bending moment (Mx) at each location. Use the abcd partitioned matrix to find reference plane strains and curvatures at each location. Strain and stress at the top surface of the beam can then be found at each location using Equations 1 and 2 from the “Mechanics of Laminated Beams” handout. Converting curvatures into displacements takes a bit more work. For the vertical displacement of points along the beam first express kx as a function of position x (it ought to be linear). Symbolic double integration with respect to x produces w (vertical displacement) as a function of position x (it ought to be cubic). Twist requires double integration of kxy (as a function of position x) with respect to x and y (for our loading kxy is constant in the y direction). 1. Calculate for your sequence of points along the beam: a. strain at the top surface, b. stress at the top surface, c. vertical deflection, d. amount of twist (as an angle, degrees). 2. Find principal strains and stresses, max shears, and orientations of the principal coordinate systems, for the calculated values. 2