ME453_W12_lab1_introduction - Classes

advertisement

OREGON STATE UNIVERSITY

ME 453 – STRUCTURE AND MECHANICS LABORATORY

Lab 1 Introduction – Winter 2012

Mechanics Phenomenon: Shear Stress in Beams

Shear stresses/strains develop in beams when bending moment varies in the axial direction. This is

a useful topic of study as it is unintuitive, and it requires the measurement of shear strains (not as

simple as measurement of normal strains.)

Objective of the Experiment: Verify the standard beam shear formula:

VQ

It

Eq. 1

where is the shear stress, V is the internal resultant shear force, Q is a geometric descriptor of the

beam cross-section

above the level of analysis/measurement, I is the second moment of the beam

cross-section about the centroidal axis, and t is the width of the cross-section at the level of

analysis/measurement.

(Note 1: The difficult part of applying this formula is the calculation of Q. Review a mechanics of

materials text and develop a description of the calculation of Q.)

(Note 2: Stress cannot be measured; strain is the measureable quantity. Describe the conversion of

stress to strain using generalized Hooke’s Law.)

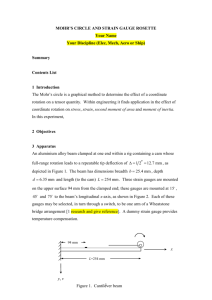

Experimental Set-up: In the lab you have a polycarbonate beam with a rosette strain gauge

bonded to the side at the level of the neutral axis. The fixture holding the beam allows for cantilever

bending with the rosette near the fixed-end. The following illustration (Figure 1) shows a coordinate

system for the beam, and the orientation of the rosette. Please use this coordinate system for all of

your measurements and calculations.

y

a

b

c

x

z

Figure 1. Coordinate system and rosette strain gauge orientation and labeling.

1

Objective 1: Strain components from rosette gauge readings

A strain gauge rosette is simply a collection of three individual strain gauges all monitoring normal

strain at various angles. The normal strain values reported by the individual gauges is useful

information, but what we really want is the full strain tensor (all of the individual components,

including shear) for a given coordinate system. It will not be obvious at this point (we will cover this

in lecture), but the conversion of rosette strain gauge readings into strain tensor components is

given by the following:

xx 1 1 1 ma

1

0 mb

yy 0

xy 0.5 0 0.5mc

Eq. 2

where {xx, yy, xy) are the strain tensor components, and {ma, mb, mc} are the individual strain

gauge readings. We are primarily interested in the shear component, xy, but as you will discover

the course of the experiment, we need to monitor the full strain state in order to understand

during

and correct for experimental artifacts.

Get started by developing a LabVIEW program that does the following:

1. Collect “continuous” readings from each strain gauge.

2. Filter signals to eliminate high-frequency noise and produce steady output.

3. Allow zeroing (nulling) of all the channels.

4. Provide both graphical and numerical indicators of the strain levels. Clearly label the signals

from each of the individual gauges (ma =, mb =, mc =).

5. From the individual strain gauge readings calculate and display the strain tensor components

with respect to the coordinate system shown above (xx = , yy = , xy = ).

Never forget about the context help system (actually an on-line documentation system) or the

function search button in LabVIEW; these are your main guides to making LabVIEW work.

However, there are a few things that are somewhat obscure. I have listed here a few helpful

functions and suggestions on implementation.

From the Array functions palette:

Build Array

Index Array

Array Constant

From the Linear Algebra functions palette:

AxB

Transpose

Eigenvalues and Eigenvectors

2

Objective 2: Expected results and identifying experimental artifacts

This is the point during an experiment, at the beginning, to calculate your expected results. It is also

the point to identify experimental artifacts. For our purposes, consider experimental artifacts as

unintended experimental conditions that affect your measurements.

(Note 3: Your intention is to load the beam in vertical-plane bending. Consider what happens to the

strain gauge readings if there is lateral bending and/or torsion applied to the beam.)

(Note 4: We treat a strain gauge as a point-measurement device at an exact location within our

experimental system. In reality it averages response over a finite area, and is never perfectly

positioned. Consider how this will affect your strain gauge readings.)

3