8950176_187006_SEAN MCCABE

advertisement

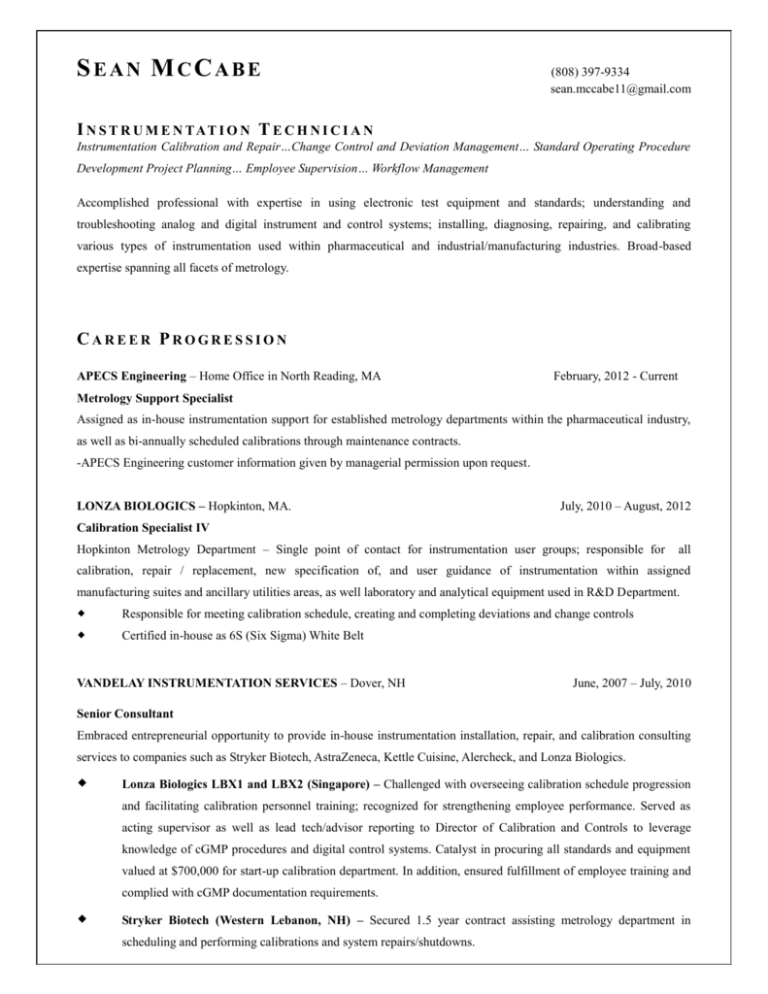

SEAN MCCABE (808) 397-9334 sean.mccabe11@gmail.com I N S T R U M E N TAT I O N T E C H N I C I A N Instrumentation Calibration and Repair…Change Control and Deviation Management… Standard Operating Procedure Development Project Planning… Employee Supervision… Workflow Management Accomplished professional with expertise in using electronic test equipment and standards; understanding and troubleshooting analog and digital instrument and control systems; installing, diagnosing, repairing, and calibrating various types of instrumentation used within pharmaceutical and industrial/manufacturing industries. Broad-based expertise spanning all facets of metrology. CAREER PROGRESSION APECS Engineering – Home Office in North Reading, MA February, 2012 - Current Metrology Support Specialist Assigned as in-house instrumentation support for established metrology departments within the pharmaceutical industry, as well as bi-annually scheduled calibrations through maintenance contracts. -APECS Engineering customer information given by managerial permission upon request. LONZA BIOLOGICS – Hopkinton, MA. July, 2010 – August, 2012 Calibration Specialist IV Hopkinton Metrology Department – Single point of contact for instrumentation user groups; responsible for all calibration, repair / replacement, new specification of, and user guidance of instrumentation within assigned manufacturing suites and ancillary utilities areas, as well laboratory and analytical equipment used in R&D Department. Responsible for meeting calibration schedule, creating and completing deviations and change controls Certified in-house as 6S (Six Sigma) White Belt VANDELAY INSTRUMENTATION SERVICES – Dover, NH June, 2007 – July, 2010 Senior Consultant Embraced entrepreneurial opportunity to provide in-house instrumentation installation, repair, and calibration consulting services to companies such as Stryker Biotech, AstraZeneca, Kettle Cuisine, Alercheck, and Lonza Biologics. Lonza Biologics LBX1 and LBX2 (Singapore) – Challenged with overseeing calibration schedule progression and facilitating calibration personnel training; recognized for strengthening employee performance. Served as acting supervisor as well as lead tech/advisor reporting to Director of Calibration and Controls to leverage knowledge of cGMP procedures and digital control systems. Catalyst in procuring all standards and equipment valued at $700,000 for start-up calibration department. In addition, ensured fulfillment of employee training and complied with cGMP documentation requirements. Stryker Biotech (Western Lebanon, NH) – Secured 1.5 year contract assisting metrology department in scheduling and performing calibrations and system repairs/shutdowns. AstraZeneca (Boston, MA) – Tapped by APECS Engineering to calibrate specific instrumentation for HVAC, animal laboratory environment control, and gas monitoring systems. Alercheck (Portland, ME) – Provided company’s owner with guidance regarding FDA guidelines, wrote all standard operating procedures (SOP), performed all initial and subsequent calibrations and repairs, and designed and implemented validation protocol for aged autoclave. Lonza Biologics (Portsmouth, NH) – Calibrated all instruments pertinent to HVAC system upgrade. LONZA BIOLOGICS – Portsmouth, NH September, 1999 – June, 2007 Validation Specialist Level II (2006 – 2007) Awarded challenging opportunity within $2.7 billion international contract manufacturer of pharmaceuticals to write and execute installations, steer operational activities, assist with Clean In Place (CIP) and Sterilize In Place (SIP) qualifications, and deliver performance protocols for environmentally controlled rooms and chamber temperature mapping, BSC smoke testing, and sterility hold studies. Calibration Specialist – Levels 1 through 4 (1999 – 2006) Independently managed all facets of instrumentation for all assigned areas of manufacturing plant and utilities. When assigned night shift, functioned as sole repair technician for entire manufacturing/utilities plant. Challenged with providing subject matter expertise support to instrumentation installation contractors for $240 million expansion, creating resolutions for issues relative to plant-wide instrumentation (instrumentation calibrated per schedule), and delivering actual installations, calibrations, troubleshooting, and repair to instrumentation (analog, Delta V, Profibus, and PLC devices). Facilitated contractor training and wrote new test methods, change controls, and other cGMP documentation. Leveraged Blue Mountain, Word, Excel, and SAP proficiencies to execute against goals. Recognized by senior leadership team as employee of the months based on team building acumen. E D U C AT I O N EDUCATION AND ADDITIONAL HIGHLIGHTS Certificate of Completion, in Repair of Over the Road Trucks Ohio Diesel Technical Institute – Cleveland, OH Liberal Arts Degree Program with prevalent coursework in Mathematics and Physics New Hampshire Community and Technical College – Stratham, NH PROFESSIONAL DEVELOPMENT Fisher / Rosemount: Delta V Fieldbus Systems and Devices Fisher / Rosemount: Delta V Operate and Implement Fisher / Rosemount: 3051 Smart Pressure Transmitter and Model 275 Communicator Interface Training ISA Training Institute: Troubleshooting Instrument and Control Systems ISA Training Institute: Installing, Calibrating, and Maintaining Electronic Instruments MILITARY SERVICE United States Army, 25th Infantry Division Honorably Discharged AWARDS Employee of the Month; Lonza Biologics Distinguished Service Award - Tutoring; New Hampshire Community and Technical College COMPUTER SKILLS Blue Mountain… SAP… EDMS Doc. Control Software… Microsoft Office: Word, Excel, Access