Spec Testing Sp Contractometer correction paper

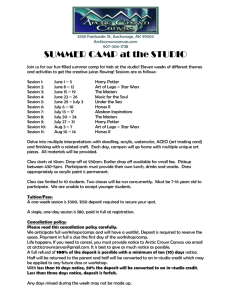

advertisement

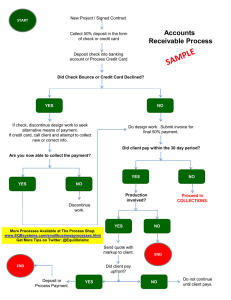

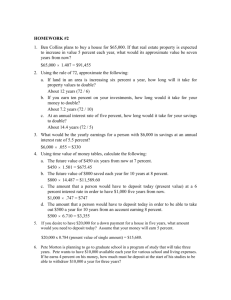

SPECIALTY TESTING SPIRAL CONTRACTOMER TEST PROCEDURE The new design for spiral contractometers corrects problems that are common with earlier models. The basic improvement is the addition of an interior 3/4th inch diameter shaft over which the helix is attached. The shaft serves as a shield to significantly reduce the quantity of the applied deposit on the interior surface of the helix during the plating test, producing results that are usually within a 4 -7% error margin when using helices that are void of a mask material on the inside diameter. Helices having an interior coating of Teflon are only necessary for critical and certifiable applications. Helices recommended for use with the new design contractometer are fully plated externally tip to tip so the deposit surface area remains the same for each, avoiding an estimated guess. The calculations are non-metric. Each helix is 0.010 in thick, has a surface area of 13.57 in2 and has a hole near each end through which a screw is used to fasten the helix firmly to the shaft so helix slippage during the test period is not possible. Also, stripping of threads is prevented by the use of stainless steel inserts. The recommended average test deposit thickness for 0.010 in thick helices is 5x10-4 in (1.27x10-3cm) for hard deposits such as nickel. Deposit thickness values as great as 1x10-3 in (2.5x10-3cm) may become necessary for soft metallic deposits. 1 NEW DESIGN FOR SPIRAL CONTRACTOMETERS The new geometry solves problems related to an exposed interior that allows deposition of the applied deposit to occur on the inside surface. Interior deposits reverse the type of stress and reduce calculated results by as much as 30%, so interior masking is critical. The new design contains an interior geometric shield that reduces the interior plating to the degree that for process control helixes without an interior mask can be used. However, for applications that require certification, an interior mask is necessary. It is a real time saver that offers more accurate results! 2 HELIX ON AN OLDER MODEL SPIRAL CONTRACTOMETER Normally, the helix is attached at the top and bottom with a polycarbonate ring and screw. Note how the interior surface without a masked coating is totally exposed and receives approximately 23% of the deposit. Since an interior deposit reverses the type of the stress being applied to the outer surface, the calculated result is very erroneous. The error is so great that helices cannot be used in this manner for process control. 3 THE SPECIALTY TESTING HELIX ST&DC helices are constructed from 0.010 inch thick stainless steel and have a precise surface area of 13.57 in². Helices mount on the contractometer in a way that the entire spiral plates from end to end and deposition of metal on the inside of helices is minimal even if they are void of a masking material. The average test deposit thickness is 500 microinches. 4 Equipment for Determination of Internal Stress in Nickel Deposits with the Spiral Contractometer ` Spiral contractometer with calibration weights, Spiral contractometer support stand, Container 4ʺ dia. x 10 high for nickel strike anode basket and bath (2,750 ml) only if a nickel strike is required for adhesion of the applied deposit, Titanium mesh anode basket 3.5ʺ outside and 2.25ʺ inside diameter, 8ʺ high for Wood’s nickel strike if desired, Titanium mesh anode basket 5ʺ outside and 4ʺ inside diameter with support tabs for the plating bath, Nickel anode buttons to fill the anode baskets, Pyrex 4,000 ml beaker for the nickel plating bath, Magnetic stirrer hot plate, Temperature controller prewired with probe, Minutes and seconds timer, and Power supply 0-10 amp constant amperage & voltage output. 5 CONTRACTOMETER PLATING SET-UP 6 M Values to Determine Deposit Stress for Various Deposits Stock Material Cu-Fe Fe-Ni Pure Nickel E* 120,690 144,830 206,900 Stock Thickness, in 0.0020 0.0015 0.0008 Metal M** Values for M*** Cadmium 31,720 0.263 0.219 0.153 Chromium 248,280 2.06 1.71 1.20 Cobalt 206,897 1.72 1.43 1.00 Copper 117,240 0.971 0.810 0.567 Gold 74,480 0.617 0.514 0.360 Nickel 206,900 1.71 1.42 1.00 Platinum 146,900 1.22 1.02 0.710 Rhodium 289,650 2.400 2.000 1.400 Silver 75,860 0.629 0.524 0.367 Zinc 82,760 0.686 0.571 0.400 E*, modulus of elasticity of the substrate material. M**, modulus of elasticity of the deposit. M***, modulus of elasticity of the deposit ÷ modulus of elasticity of the substrate in the modified Deposit Stress Analyzer and Stoney Formulas. 7 PLATING CONDITIONS FOR SPIRAL CONTRACTOMETER TESTS Helix Material Stainless Steel Helix Surface Area, in² 13.57 Square Feet 0.0942 Amps per sq. foot 30 Amps 2.90 Stock Thickness, inches 0.010 Avg. Deposit Thickness, µʺ 500 Plating Time 20m 40s Solution Temperature 140º±1ºF 8 Current Density, Amperage and Plating Time at 95% Cathode Efficiency Amps/ Ft² Amps Time 10 15 25 40 50 100 150 180 200 1.04 1.72 2.60 4.16 5.19 10.39 17.18 18.75 20.84 57M 38M 22M 14M 15S 11M 24S 5M 42S 3M 48S 3M 10S 2M 52S 9 CONDITIONS FOR NICKEL PLATING HELICES Current Density, Amperage and Plating Time at 95% Cathode Efficiency Amps/ Ft² 10 15 25 30 40 50 100 150 180 200 Amps 1.04 1.72 2.60 3.12 4.16 5.19 10.39 17.18 18.75 20.84 10 Time 57M 38M 22M 19M 14M 15S 11M 24S 5M 42S 3M 48S 3M 10S 2M 52S CALCULATING NICKEL DEPOSIT STRESS A. Calculate the Deposit Stress in PSI. Note the formula first used. This one fails to include the influence of the helix material thickness and it produces for instance about 5% error for nickel deposits. Stress = 13.02 (D) (M) ÷ w x d = PSI Where D = Degrees caused by the deposit, M = Modulus of Elasticity of the deposit ÷ Modulus of the substrate Elasticity = 30,000,050 PSI ÷ 28,600,000 PSI = 1.04895 for nickel deposits over Specialty Testing helices 0.010 inch thick, w = degrees Kt from helix calibration if the stress is tensile or degrees Kc if the stress is compressive, d = Deposit thickness in inches, and t = Helix material thickness in inches. The improved formula is as follows: S = 13.02(D) ÷ w (d) x 1 + ED (d) ÷ ES (t) B. Calculation Examples. First Used Formula: S = 13.02 (26) (1.04897) ÷ 33 (0.000536) = 20,073 Second Used Formula: S = 13.02 (26) x 1 + ED (d) = PSI w (d ) S= PSI Es (t ) 338.52 x 1 + 30,000,050 PSI (0.000536) 33 (0.000536) 28,600,000 PSI (0.010) S = 19,138 ( 1 + 16,080 ÷ 286,000) = 20,209 PSI S = 19,138 ( 1.056224 ) = 20,214 11 PSI Recording Data for Spiral Contractometer Tests Deposit weight in grams: Kc degrees: Kt degrees: Degrees deflection caused by the deposit: Spiral weight in grams: Deposit weight in grams by subtraction: Deposit thickness in inches: 12 OPERATION OF THE SPIRAL CONTRACTOMETER It is important that when the spiral is attached to the contractometer, a space of about 1/4 inch should be allowed between the bottom of the contractometer center shaft and the top of the free end to which the spiral is attached. This space prevents binding as the spiral turns during the test plating period. The spiral is calibrated while it is on the contractometer and immersed in the plating solution at the plating bath temperature. Loosen the screw at the top of the contractometer and adjust the zero of the dial to line up with the arrow point. Use a blunt instrument in a tapping motion and make adjustments as necessary to get a reading at the zero mark. Next, calibrate the spiral by using the counterweights. Fasten the loop of a counterweight string over the pin on the right side of the pulley wheel and take the string around the pulley in a clockwise direction. Place it over the Teflon grooved pin of the contractometer near the Kcompressive stress label. Use tapping to get a stabilized degree of stress from the zero point. Record this value as the calibration degrees for compressive stress. Remove the counterweights and strings. If the dial zero doesn't match the arrow with tapping, repeat this procedure. To determine the tensile calibration value, fasten the loop of a counter weight string over the pulley pin on the left side of the pulley wheel. Wrap it in a counterclockwise direction and place the string and counterweight over the Teflon pin near the Ktensile stress label. Use tapping to get a stabilized degree of stress from the zero point. Record this value as the calibration degrees for tensile stress. Remove the calibration weights and strings. Confirm that the desired plating conditions are correct, then begin the plating test procedure. After the plating is completed, tap the top of the contractometer until an equilibrium is reached and 13 record the internal deposit stress value as the compressive or tensile degrees caused by the deposit. Remove the contractometer from the plating cell and rinse in water and isopropyl alcohol. Remove the plated spiral and rinse it again. Note that the spiral can be dried in a short time by rolling up a paper towel and pulling it through the interior of the spiral. When it is completely dry, weigh it and calculate the weight of the applied deposit in grams. Since all of the Specialty Testing spirals have the same surface area and all of the external surface area is plated, the average deposit thickness can be calculated in inches by dividing the deposit weight by 1,979. In the stress formula, d = the deposit weight. For the deposit stress nonmetric calculation formula, see Item 4 in our Spiral Contractometer brochure. Note that compressive stress is indicated by use of a negative sign. Note also that is very important to loosen the screw at the top of the contractometer and lift off the dial and remove the center rod. Do this step over a sink and force water through the hole to remove solution that could over time form a salt that could bind the rod and prevent turning of the lower piece that must remain free to turn as the deposit stress is applied. 14 15