Patella Final Report 120814

advertisement

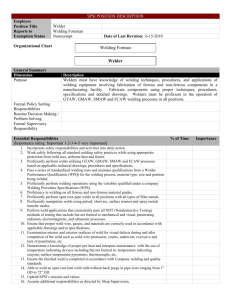

A REVIEW OF WELDING PROCESSES, MECHANICAL PROPERTIES, AND WELDABILITY OF HY-80 CASTINGS by Gregory A. Patella An Engineering Project Submitted to the Graduate Faculty of Rensselaer Polytechnic Institute in Partial Fulfillment of the Requirements for the degree of MASTER OF ENGINEERING Major Subject: Mechanical Engineering Approved: _________________________________________ Ernesto Gutierrez-Miravete, Project Adviser Rensselaer Polytechnic Institute Hartford, CT December 2014 CONTENTS A REVIEW OF WELDING PROCESSES, MECHANICAL PROPERTIES, AND WELDABILITY OF HY-80 CASTINGS .................................................................... i LIST OF TABLES ............................................................................................................ iv LIST OF FIGURES ........................................................................................................... v ACKNOWLEDGMENT .................................................................................................. vi ABSTRACT .................................................................................................................... vii 1. Introduction / Purpose.................................................................................................. 1 2. Theory / Methodology ................................................................................................. 2 2.1 HY-80 Casting ................................................................................................... 2 2.1.1 History .................................................................................................... 2 2.1.2 Material Structure................................................................................... 2 2.1.3 Mechanical Properties of HY-80 Casting .............................................. 4 2.2 HSLA 80 ............................................................................................................ 6 2.3 Review of Destructive Testing ........................................................................... 7 2.4 2.5 2.3.1 Tension Testing ASTM E8 [8]............................................................... 7 2.3.2 Hardness Levels in HAZ E92-82 [9] ..................................................... 7 2.3.3 Charpy V-notch Impact Toughness ASTM E-23 [11] ........................... 8 2.3.4 Explosion Bulge Testing MIL-STD-2149 [10] ...................................... 9 Review of Non Destructive Testing ................................................................. 11 2.4.1 Visual Inspection Testing..................................................................... 11 2.4.2 Penetrant Dye Inspection Testing ........................................................ 11 2.4.3 Magnetic Particle Inspection ................................................................ 11 2.4.4 Radiographic Inspection....................................................................... 12 2.4.5 Ultrasonic Inspection ........................................................................... 12 Weldability ....................................................................................................... 12 2.5.1 Welding Preheat ................................................................................... 13 ii 2.5.2 Welding Interpass Temperature ........................................................... 14 2.5.3 Review of Welding Techniques ........................................................... 14 2.5.4 Weld Metal Hydrogen Cold Cracking ................................................. 16 2.5.5 Controlling Factors of Hydrogen Induced Cracking ............................ 18 2.5.6 Tekken Testing [21] ............................................................................. 20 3. Studies of High Strength Castings Possessing Improved Weldability ...................... 21 4. Results and Discussion .............................................................................................. 25 5. Conclusion ................................................................................................................. 27 6. References.................................................................................................................. 28 iii LIST OF TABLES Table 2.1 Casting Composition [7] .................................................................................... 2 Table 2.2 Grade HY-80 Mechanical Properties [7] ........................................................... 5 Table 2.3 Grade HY-80 Minimum Impact Test Results [7] .............................................. 5 Table 2.4 Chemical Composition of HSLA 80 [20] .......................................................... 6 Table 3.1 Chemical Composition of Phase 1 Castings [4] .............................................. 22 Table 3.2 Chemical Composition of Phase 2 Castings [4] .............................................. 22 Table 3.3 Heat Treatment of Phase 2 Castings [4] .......................................................... 23 Table 3.4 Chemical Composition of alloys E and E-A [3] .............................................. 24 iv LIST OF FIGURES Figure 2-1 Iron-Carbon Phase Diagram [12] ..................................................................... 3 Figure 2-2 Micrographs of Heat Treated Samples: (a) As Quenched; (b) Tempered at 200 ºC; (c) Tempered at 400 ºC; (d) Tempered at 600 ºC [15] ........................................ 4 Figure 2-3 HSLA Microstructure [17] ............................................................................... 7 Figure 2-4 Vickers Hardness Test [12] .............................................................................. 8 Figure 2-5 Charpy Testing [14] ......................................................................................... 9 Figure 2-6 Explosion Bulge Test Equipment [16] ........................................................... 10 Figure 2-7 Fracture of Elliptical Bulge [16] .................................................................... 10 Figure 2-8 Welding Techniques [18] ............................................................................... 15 Figure 2-9 Hydrogen Cracks in the HAZ and Weld Metal [19] ...................................... 17 Figure 2-10 Crack Along the Coarse Grain Structure in the HAZ [19] .......................... 19 v ACKNOWLEDGMENT I would like Ernesto Gutierrez-Miravete for the guidance and leadership for accomplishing this maters project. Brian Whitney for the help, knowledge, and motivation throughout all of my graduate degree. All my friends and coworkers who have listened to my thoughts and ideas and motivated me to finish this project. My mother and father for their everlasting love, guidance, and support. vi ABSTRACT This project reviews the development of HY-80 steel castings which may allow shipbuilders to weld without preheat while maintaining the same required strength and durability of HY-80 structural steel plates. The mechanical properties of HY-80 castings and welding procedures are researched in this paper to gain a better understanding of the shortcomings experienced when welding is performed without the use of preheat. An in depth review is performed of hydrogen assisted cracking which is the critical side effect of welding HY-80 castings without establishing preheat in the base material. Hydrogen cracking is caused by the diffusion of entrapped hydrogen in the base and weld metal after welding. The amount of hydrogen cracking is dependent on material microstructure, hydrogen content and weld residual stresses and can be alleviated by preheat to increases diffusion before solidification. In an attempt to achieve the desired mechanical properties and welding characteristics without hydrogen assisted cracking, castings can be manipulated in both their chemical composition and heat treatment. Research of several organizations producing modified HY-80 castings did not find any successful casting capable of reproducing the current HY-80 plate mechanical properties and can be cold welded without hydrogen assisted cracking. vii 1. Introduction / Purpose Today’s U.S. Navy is in a constant tug of war between the constraints of congressional funding and mission capable vessels to defend the nation. With the increased demand for naval ships made from high strength steel in the past decade the department of defense has been seeking out ways to drive down the cost of manufacturing and fabricating such material. Specifically HY-80 steel which is used extensively in shipbuilding requires preheat for welding to remove its susceptibility to hydrogen assisted cracking in the heat affect zone of welds. Development of high strength low alloy (HSLA) 80 steel allows shipbuilders to weld plates together without preheat while maintaining the same required strength and durability of HY-80 structural steel plates. Without the energy needed to heat the steel and the time required to provide the heat soak significant costs are saved in the manufacturing and repair process of HSLA-80 when compared to HY-80. The same principle is being applied to HY-80 castings. A steel casting alloy of the same yield strength and toughness of HY-80 which does not require preheat prior to installation or repair welding to alleviate hydrogen assisted cracking would be both technically and economically advantageous. This paper researches the principles behind weldability of high strength castings. The purpose is to have a better understanding of the shortcomings and restrictions of welding high strength castings. Finally a summary of the experiments and studies performed in development of a replacement for HY-80 casting which exhibits the same mechanical properties without the need of preheating. 1 2. Theory / Methodology 2.1 HY-80 Casting 2.1.1 History After World War II, significant effort was made to develop steel that would better serve the needs of the US Navy and allow for the development of higher performance platforms [1]. The end result was a steel when compared to high tensile steel (HTS) was twice the yield strength, improved toughness, and increased weldability. Castings are advantageous when compared to other steel manufacturing methods. Machining from solid metal, fabrication from welding, and hot forging fabrication are not as efficient or cost effective as the casting process to form large, irregular shapes. The casting process is highly monitored and carefully performed with heat treatment following the initial pour to achieve the mechanical properties of MIL-S-23008 for HY80 castings. 2.1.2 Material Structure The low carbon content, less than 0.03%, is similar to HTS, but other elements were limited in HY-80 (See Table 2.1). The decrease in carbon content helps achieve better weldability and toughness properties. Other elements are added to the alloy to assist in grain refinement and precipitation hardening which produce ideal mechanical properties. Table 2.1 Casting Composition [7] 2 Castings are initially austenized, heating steel to a temperature at which the material changes its crystalline structure from ferrite to austenite (Figure 1), and quenched to form a nearly 100% martensitic microstructure. Martensite is a very hard form steel crystalline structure of body centered tetragonal (BCT) compared to austenite of facecentered cubic (FCC) structure. Figure 2-1 Iron-Carbon Phase Diagram [12] The martensitic microstructure is very hard and strong, but also extremely brittle after quenching. To obtain acceptable ductility and toughness, the part is tempered. Tempering temperature is to be no less than 1190F for HY-80, which is below the intercritical, two phase (ferrite + austenite) region for the Fe-C system [1]. Tempering hold time is dependent on the thickness of the casting. Holding at the tempering temperature causes the carbon in the supersaturated martensite to react with the iron to form very fine, numerous, and evenly distributed carbide particles within the martensite phase (See Figure Figure 2-2). These particles result in a largely improved toughness with an acceptable loss in strength. This quench and temper process creates a tempered martensitic structure. The microstructure gives 3 HY-80 high yield strength while maintaining good toughness and ductility [1]. After tempering the casting is removed from the heat source and rapidly cooled by a water quench. Figure 2-2 Micrographs of Heat Treated Samples: (a) As Quenched; (b) Tempered at 200 ºC; (c) Tempered at 400 ºC; (d) Tempered at 600 ºC [15] 2.1.3 Mechanical Properties of HY-80 Casting MIL-S-23008 [7] in the specification that covers grade HY-80 steel casting intended for critical structural application where a weldable, notch-tough, high-strength material is required. The chemical composition heat analysis shall be in accordance with Table 2.1. After all heat treatments including stress relief, the casting shall meet the mechanical properties of Table 2.2 and Table 2.3. 4 Table 2.2 Grade HY-80 Mechanical Properties [7] Table 2.3 Grade HY-80 Minimum Impact Test Results [7] As required by Ref [7], the casting shall be heat treated by quench and temper. Quenching should be preceded by a homogeneous annealing treatment. The exact heat treatment procedure is at the discretion of the manufacturer with only minor restrictions. This allows for various practices to achieve the minimum required mechanical properties. Restrictions are listed in Ref [7] Section 3.5. Quality assurance testing includes chemical analysis, tensile tests, Charpy impact test, dynamic tear test, and explosion bulge tests. Testing is done on a series of test blocks which are of the same heat, having the same heat treatment, and heat treated at the same time as the castings [7]. The test block sizes are specified in Ref [7] Table IV. The desired ductile to brittle transition temperature for HY-80 is 0oF. This is well below the transition temperature for HTS and represents added fracture safety in that the brittle transition of properly processed HY-80 occurs far below operating temperature. 5 2.2 HSLA 80 To achieve superior weldability without requiring pre heat, HSLA 80 differs from HY-80 in chemical composition (see Table 2.4) and procurement that does not rely on conventional quenched and tempered technology. HSLA 80 has a ferritic microstructure and achieves its strength through precipitation hardening rather than martensitic transformation (see Figure 2-3). This allows the material to be produced with a much lower carbon content which reduces the tendency for hydrogen assisted cracking. By use of micro alloying to produce fine grain size good toughness can also be obtained in HSLA 80, in spite of its non-martensitic microstructure. Table 2.4 Chemical Composition of HSLA 80 [20] 6 Figure 2-3 HSLA Microstructure [17] 2.3 Review of Destructive Testing Destructive testing usually bends, twists, notches, or breaks the specimen tested and destroys its usefulness for service. Destructive test utilize material from the same melts that the casting is produced at predefined depths and sizes as defined by the appropriate standards. 2.3.1 Tension Testing ASTM E8 [8] Tension tests, standardize in Ref [8], provide information on the strength and ductility of materials under uniaxial tensile stresses. Test methods cover metallic material at room temperature for determining yield strength, yield point, elongation, tensile strength, elongation, reduction of area. Specimens are typically secured in grips which strain the material at a defined rate for a set amount of time. Tensile strength is determined by dividing the maximum force carried by the specimen during the tension test by the original cross section area of the specimen. 2.3.2 Hardness Levels in HAZ E92-82 [9] The Vickers hardness test, standardized in Ref [9], is an indentation hardness using calibrated machines to force a square based pyramidal diamond indenter having specified face angles, under a predetermined force, into the surface of the material under test and to measure the diagonals of the resulting impression after removal of the force 7 (Figure 2-4). The Vickers hardness test is adaptable to a wide variety of test specimens ranging from large bars and rolled section to minute pieces in metallographic mounts. Based on the length of the diagonal a corresponding hardness is defined in Table 2 of ASTM E 92-82. Equipment for the Vickers hardness test usually consists of a testing machine which supports the specimen and permits the indenter and the specimen to be brought into contact gradually and smoothly under a predetermined force, which is applied for a fixed amount time. A measuring microscope is usually mounted on the machine in such a manner that the impression in the specimen may be readily located in the optical field. Based on the setup the measurement of hardness can be cumbersome for larger sized castings. Figure 2-4 Vickers Hardness Test [12] 2.3.3 Charpy V-notch Impact Toughness ASTM E-23 [11] The significance of the Charpy V-notch Impact toughness test (see Figure 2-5) relate specifically to the behavior of metal when subjected to a single application of a force resulting in multi-axial stresses associated with a notch, coupled with high rates of loading and in some cases with high or low temperatures. For some materials and temperatures with results of impact tests on notched specimens, when correlated with service experience, have been found to predict the likelihood of brittle fracture accurately. 8 The Charpy test procedure includes thermally conditioning the test specimen and positioned on supports against the anvils (See 11). A pendulum is released without vibration, and the specimen is impacted by the striker. Information is obtained from the machine and from the broken specimen. The information obtained from the impact test in the absorbed energy in the striking member at the instant of impact with the specimen and the nervy remaining after breaking the specimen. This value is determined by the machine’s scale reading which has been corrected for windage and friction losses. Figure 2-5 Charpy Testing [14] 2.3.4 Explosion Bulge Testing MIL-STD-2149 [10] The explosion bulge test (see Figure 2-6), standardized in Ref [10], is an explosion test principally used to qualify prospective contractors products wherein a flat test plate specimen or weldment is explosively loaded into a circular test die. When bulge testing castings, the contractor shall provide sufficient cast plate to produce a minimum of two 50 inch by 30 inch explosion/mechanical prolongation weldments and four 2 by 30 by 30 inch explosion weldments (see Figure 2-7) [10]. 9 Figure 2-6 Explosion Bulge Test Equipment [16] Figure 2-7 Fracture of Elliptical Bulge [16] The explosion bulge test consists of two crack starter shots, two bulge tests, and a minimum four additional shots. The first crack starter shot shall crack the bead and no through thickness cracks shall be present. The second shot may produce through thickness cracks. After each shot the percent reduction in thickness shall be obtained. The first and second bulge shot shall crack the bead and no through thickness cracks shall be present. After each shot the percent reduction in thickness shall be obtained and a three percent reduction per shot is expected. Additional shots shall continue until a minimum of four shots and a minimum of 10 percent reduction in thickness is obtained on one or both sides. Shots shall be discontinued when cracks go into the hold-down 10 area, a through-thickness crack occurs, or if the reduction in thickness and minimum number of shots is met. 2.4 Review of Non Destructive Testing Nondestructive testing determines the quality of a test specimen without altering its physical qualities or usefulness. The nondestructive test can be used on the final application and provide quality assurance the material is satisfactory for end use. 2.4.1 Visual Inspection Testing Visual Inspection is the simplest, quickest, and least expensive way to determine deficiencies in the weld. An assortment of measurement tools are used to verify the weld has been completed, met size requirements, and weld discontinuities such as cracks, slag, porosity, and splatter are not present. 2.4.2 Penetrant Dye Inspection Testing Penetrant dye inspection testing inspection uses a dye penetrant to detect only surface defects on any nonporous or nonabsorbent material. The material does not have to be magnetic and therefore can be used on welds, metal, glass, ceramics, castings, forgings, and machined parts. Penetrant testing works when a liquid with high surface wetting characteristics is applied to the surface of the part and allowed time to seep into breaking defects. The excess liquid is removed and a developer (powder) is applied to pull the trapped penetrant out of the defect and spread it on the surface where it can be seen. The penetrant is often loaded with a fluorescent dye and the inspection is done under UV light where it is visually inspected. 2.4.3 Magnetic Particle Inspection Magnetic particle inspection is a simple, fast, and reliable test for slightly sub- surface indications in the weld. The magnetic particle test cannot be used on nonmagnetic materials, locate deep subsurface discontinuities, or small rounded discontinuities (porosity). Equipment used includes a power supply, contacts, and magnetic particles most likely iron powder. 11 Magnetic particle testing works when the part is magnetized and finely milled iron particles coated with a dye pigment are then applied to the specimen. The particles attract to magnetic flux leakage fields and will cluster to form an indication directly over the discontinuity which can be visually detected by the inspector. After test the magnetic particles are to be cleaned up. 2.4.4 Radiographic Inspection Radiographic inspection consists of an X-ray tube or isotope Gamma ray source to produce pictorial results of volumetric defects. RT can be used on any material for welds, shapes, plates, forgings, castings, and piping systems. Unfortunately RT has a high risk of radiation exposure, requires highly trained technicians, costly, and timely. Radiographic inspection works by having the weld in between the film and the radiation source. The part will absorb some of the radiation therefore thicker and more dense material will require a more intense radiation source. The RT is applicable to materials up to 16 inches thick. 2.4.5 Ultrasonic Inspection Ultrasonic inspection uses a cathode ray tube, pulser, and receiver amplification circuit to take volumetric inspections. Ultrasonic testing can be used on most metals and hard nonmetallic materials, welds, braze joints, shapes, plates, castings, forgings, piping systems, and composites. Ultrasonic testing is an easily performed inspection with immediate results. Possible disadvantages of ultrasonic testing are results are subject to proper calibration and interpretation, sensitivity is dependent on orientation of defects, and the equipment is expensive and delicate. The ultrasonic testing principle consists of introducing high frequency sound waves into a material. The waves are reflected back from either the back surface or the internal flaws. The reflected energy is displayed on a screen showing signal amplitude versus time (or distance). Any defects would show an irregular echo on the receiver. 2.5 Weldability A good weld is one which is of proper size, free from defects, and completely fuses the adjoining pieces. A good weld is not only a function of welder efficiency, it is 12 also dependent on exclusion of oxygen, proper amperage (which controls heat), proper rate of travel to ensure good fusion without overheating or burning through, proper preheat and post weld heat treatment, cleanliness and dryness of joint and filler material, proper fit up and weld joint dimensions, proper weld material type and size, and proper base material. Welding procedures consist of manual, semiautomatic, mechanized, and automatic. Manual welding is performed all by hand while in semiautomic the arc welding machine controls the filler wire feed. Mechanized welding uses equipment which controls the filler wire speed, travel speed, and a mechanical control of the touch position and angles. Automatic welding is mechanized welding but also utilizes a feedback system. Weldability of HY-80 steel presents complex construction difficulties due to its more critical applications and it is less forgiving to normal construction variation. In the case of HY-80 steel with minimum yield strength of 80ksi, despite its higher strength and weight ratio compared to conventional steel, the heat input of welding process significantly affects the heat affected zone (HAZ) mechanical properties which are critically for the application widely used by the U.S. Navy. 2.5.1 Welding Preheat Preheat is the process of heating the base material prior to welding. The base material can be heated in its entirety or just a local region surrounding the weld joint. Heating can be accomplished by use of heating torches, electrical strip heater, or induction or radiant heaters. Best practice is to heat the back side of the material if not a full penetration weld to ensure the required temperature has been met throughout the welding member. Preheating is used primarily on HY-80 and greater tensile strength steels. The use of preheat slows the cooling rate of weld and increases the amount of time hydrogen diffuse from the weld metal. The trapped hydrogen in the weld metal decreases the resistance to cracking. The temperature range between the weld metal and joining members are decreased therefore lowering the shrinkage stresses. 13 Also the higher temperature of the base metals raises it above the temperature at which brittle fracture would occur in fabrication. Welding with preheat that is too low negatively affects the strength, toughness, and ductility of welds. Low preheat can create welds that are very high in strength and therefore very hard. This elevated hardness makes the weld more susceptible to cracking. Also low preheat can cause low toughness in welds which means the welds cannot withstand impact or shock loading as well. Finally low preheat can possibly reduce ductility due to hydrogen damage. If a material is more ductile, it will yield or stretch under load before breaking. A material that is not ductile is brittle. Brittle material will not yield under load and will break with little or no warning. 2.5.2 Welding Interpass Temperature Interpass temperature is the temperature at the base metal at the weld joint before each pass (except the first which is preheat) of a multiple pass weld. For HY strength steels a range of minimum and interpass temperatures are defined based on base material thickness. A minimum interpass temperature will help prevent cracking while a maximum interpass temperature preserves the yield and tensile properties of the weld and base metal. Interpass temperature can be affected by the time between passes, base metal thickness, ambient conditions, heat transfer characteristics, and heat input from welding. Similarly to low preheat temperatures, welds with low interpass temperatures are highly susceptible to high strength, low toughness, and low ductility. 2.5.3 Review of Welding Techniques Common welding techniques used with HY-80 steel include the shielded metal arc welding, gas metal arc welding, gas tungsten arc welding, and submerged arc welding. The sections below give an overview of each technique and a pictorial representation can be seen in Figure 2-8. 14 Figure 2-8 Welding Techniques [18] 2.5.3.1 Shielded Metal Arc Welding (SMAW) Stick Electrode SMAW is advantageous since it uses small electrode holder that has flexibility and be used in all positions for many types of metals. The welding equipment is simple and easy to use and the quick set up can be performed in many different environment conditions. Welding electrodes are not automatically fed therefore continuous stops are required. Production rate is rather slow and post-weld cleaning to remove slag and spatter is necessary. 2.5.3.2 Gas Metal Arc Welding (GMAW) GMAW is highly productive compared to SMAW since the weld wire is constantly fed through the welding gun. The weld beads are cleaner resulting in less time cleaning weld beads of splatter and slag. With the added convenience of semiautomic welding the welding gun is larger, less accessible to tight spaces, and the equipment is more complex, less mobile. GMAW is less environmentally friendly as winds and drafts can blow away shielding gases. 15 2.5.3.3 Gas Tungsten Arc Welding (GTAW) (TIG) GTAW is a two hand task which has a tungsten electrode gun in one hand and the other feeding the filler rod into the arc. The GTAW process produces high quality welds in many metals requiring little post weld work at numerous positions. The welder can view the arc and weld puddle as welding is performed. 2.5.3.4 Submerged Arc Weld (SAW) SAW is very efficient weld process that deposits weld wire between 10 to 30 pounds per hours. The welds are of the highest quality radiographic welds because the arc is protected by the flex covering. Welds do not produce smoke or spatter and can be performed despite windy or drafty environmental conditions. However the process is limited to flat and horizontal grooves groove tees, and fillets. The welder cannot see the weld puddle and arc and post weld work includes removing the slag. 2.5.3.5 Effects of Welding Process on Mechanical Properties of HY 80 Steel Welding methods have significant effects on the fracture resistance and hardness of the HAZ. With regard to tension tests the rupture occurred in the main material and not the weld metal when the weld metal is of equal strength or greater to the HY-80 steel. The Charpy V-notch impact tests reveal that due to the higher heat input, the SAW and SMAW specimens have better HAZ toughness than the GMAW process. The hardness tests results show the SMAW and SAW welding methods have given slightly higher hardness profile across weld metals and HAZ than the GMAW welding method. In general, the maximum hardness reached in the HAZ is 425 HV for all methods but for the weld metal the hardness varies for each method but at its maximum only reaches a maximum of 275 HV. The hardness profile through the thickness weld metal has a lower hardness at the roots than the upper surface due to the tempering effects of the filler passes in multipass welds. 2.5.4 Weld Metal Hydrogen Cold Cracking Arc welding leads to the entrapment of hydrogen gas in the solidifying weld metal which can diffuse into various segment of the weldment as it cools down. Due to 16 metals microstructure, hydrogen content, and weld residual stresses, the risk of hydrogen induced cold cracking in steel can arise when the weld cools down to below 150oC. Hydrogen cracking generally occurs several days after welding has been completed. These cracks of hydrogen can occur both in the weld metal itself or in the surrounding heat affected zone (HAZ) as seen in Figure 2-9. Figure 2-9 Hydrogen Cracks in the HAZ and Weld Metal [19] The widespread solution to hydrogen cracking is to use preheating which consists of heating up a great volume of the weld area of a structural member prior to welding or in the case of multipass welding to apply elevated interpass temperature through the welding operation. Although preheating is successful is alleviating hydrogen cracking the process is expensive and labor intensive. Large amounts of energy are required to heat up and maintaining large volume steel castings. The time involved in heating the castings is lengthy. Also when performing repairs the use of heat may require the removal of paints, solvents, or other heat sensitive materials which can be burdensome and costly. Weld hydrogen cracking is attributed to three main factors: microstructure, hydrogen content, and residual stresses. The risk of cracking becomes apparent and rises as strength of parent steel and/or weld metal increases and welding thick plate section that often employ multipass welding techniques [5]. The cracks which form can be the size of few thousands of an inch to an inch and can be critical to the structural integrity of the members at the smallest range of cracking. 17 2.5.4.1 Hydrogen Cracking in the HAZ [5] The heat affected zone (HAZ) cracking is generally caused by hydrogen diffusion in the form of root crack, toe crack, and underbead crack. Underbead cracks are associated with shorter delay times and higher hydrogen levels in the parent material than toe and root cracks with all other factors constant. Therefore an alloy with lower hydrogen content effectively prevents underbead cracks. The main problem in both single and multipass welding is usually root and/or underbead cracking. HAZ underbead and root cracks formation is mainly dependent on the transverse stress across the weld and against the transverse shrinkage during cooling. These factors are determined by the weld metal strength and structural restraint of the joined members. This is why thicker steel is more susceptible to hydrogen cracking in the HAZ. Structural rigidity in thin plates is far too low to cause structural restraint and transverse stresses high enough to promote cracking therefore as the strength of steel increases the critical thickness for hydrogen cracking in the HAZ decreases. 2.5.5 Controlling Factors of Hydrogen Induced Cracking 2.5.5.1 Hydrogen While the weld cools, the hydrogen absorbed by the weld pool escapes from the solidified bead by diffusion since the hydrogen molecule is smaller size than the metal atoms. Part of the hydrogen in the weld metal loses its ability to move by diffusion and is classified as residual hydrogen. The counterpart, diffusible hydrogen, is the primary cause of cold cracking in welding [5]. The cracking risk is greatly dependent on the amount of diffusible hydrogen at cold cracking temperatures after cooling and not the initial hydrogen content [5]. This is why preheating is such an effective method at reducing the hydrogen content. The extended period of time at elevated temperatures allows for increased hydrogen diffusion out of the metal. Multipass welds have a bit more complex diffusion process than the single pass welds. Due to a number of repetitive thermal cycles of successive passes, part of the already solidified weld metal becomes re-melted, as welding proceeds. The re-melting of weld metal, along with the thermal effect elevating the temperature of those parts of the weld metal remaining in the solid state, cause part of the hydrogen present in the 18 previous passes to become mobile again [5]. Residual hydrogen formed in the previous passes becomes active and transform to diffusible hydrogen in already formed beads. Studies have found that the crack density increases with the hydrogen concentration and towards the filling layers, as well as that most transverse hydrogen cracks tend to locate predominantly beneath the welds surface under the 2nd or 3rd last bead layer [2]. 2.5.5.2 Microstructure With regards to hydrogen cracking in the HAZ in general the harder the microstructure the more susceptible the material is to cracking. Microstructure hardness is determined by the steels carbon composition and weld cooling time. With regards to the weld metal the cracking is also dependent on the strength of weld metal. Weld metal strength increase puts the weld metal at higher risk of hydrogen cracking. Harder microstructures are the result of less ductile grain boundary ferrite (GBF) where plastic strain accumulates. At these boundaries hydrogen diffuses into these regions and cracks initiate [5] as shown in Figure 2-10. Studies support a positive correlation between the volume percentages of GBF and weld mental hydrogen cracking [5]. Figure 2-10 Crack Along the Coarse Grain Structure in the HAZ [19] 2.5.5.3 Stresses Stresses as a direct result of the welding process are either residual welding stresses due to internal restraint or reaction stresses caused by internal restraint. Residual stresses, more commonly associated with hydrogen cracking, are located close 19 to the weld metal and can be prevented by an even temperature distribution throughout the base material and HAZ [5]. Residual stresses are a result of the clamping effect which is when other non-joining members are used to prevent thermal shrinkage. The distance at which the two members need to be restrained, root gap, can be shortened to alleviate the residual stress since less weld metal is required to form the weldment. Stress concentrations can arise due to geometric discontinuities in the weld metal and therefore extra attention shall be spent in weld bevel preparation. 2.5.5.4 Welding Process In general hydrogen cracking is independent of the welding procedure for single pass welds. For multipass welds when all other variables are consistent (material thickness, weld filler) the submerged arc weld metals are at greater risk of hydrogen cracking than shielded metal arc welding. The reason being is the difference in bead shapes and sizes which are dependent on the welding process. SAW beads are narrow weld beads with high depth to width ratio which affect the hydrogen diffusion distances and hydrogen concentration. 2.5.6 Tekken Testing [21] The Tekken test is used to assess the cold cracking susceptibility of steel. A test weld of a single weld bead is welded into a prepared single V butt joint of which the root gap is kept constant by previous produced anchor welds. Under the giving welding conditions a crack maybe observed. 20 3. Studies of High Strength Castings Possessing Improved Weldability Improved weldability would consist of a casting which does require preheat or interpass heat for welding to prevent hydrogen assisted cracking. A successful replacement cast material would need to meet all the mechanical property requirements of MIL-S-23008D [7]. The National Shipbuilding Research Program investigated the possibility of high yield strength cast steel with improved weldability in May 1991 [4]. Based on previous research and tribal knowledge researchers hypothesized that improved weldability of HY-80 was plausible by reducing the carbon content and increasing the nickel content as shown in cast martensitic stainless steels. Nickel acts as an austenite stabilizer to compensate for low carbon levels. Austenite crystal structure after heat treatment is critical to the quality of the casting of the low temperature toughness. Another result of lower carbon content is the formation of ferrite, pearlite, and upper bainite which reduce the hardness of steel. The development of five casting alloy compositions, whose chemical composition is shown in Table 3.1, went through an initial screening which went through a tensile test and ten Charpy V-notch specimens tested at 72oF, 0oF, and -100oF. Based on the results of phase 1, Chemical composition was optimized and a remaining four heats, whose chemical composition and thermal treatment is shown in Table 3.2 and Table 3.3, respectively, in phase two. In phase 2, the same destructive tests were carried out as in phase 1. 21 Table 3.1 Chemical Composition of Phase 1 Castings [4] Table 3.2 Chemical Composition of Phase 2 Castings [4] 22 Table 3.3 Heat Treatment of Phase 2 Castings [4] Phase 3 castings samples were tested for weldability without preheat. Weldability evaluation was done prior to welding using the Tekken test. Welding was performed by GMAW and FCAW welding techniques at a 55 kJ/in heat input on 1 inch thick specimens. After the completion of welding the specimens were held at room temperature for 72 hours prior to examination. Three resections were cut, ground, examine for cracks. Hydrogen content was measured using gas chromatography (AWS B4.3). Studies also looked into the use of HSLA-100 plate as a substitute for HY-80 castings 12 inches thick. The results were unsatisfactory for the toughness at -100oF. Furthermore, macrocracks and hairline cracks were present in the as-cast and heattreated conditions of the alloy. Also plates are limited in thickness and geometry when compared to castings therefore plates cannot always be a plausible substitute. More recent studies by Kannan and Valencia in 2001 [3] further optimize the alloy composition and heat treatment of alloys similar to the previous study. The objective was to modify alloy chemistries and heat treatment which lead to properties similar to current military standard HY-80 castings, while not requiring preheat. The second study compared two castings labeled alloy E and E-A whose chemical composition, is specified in Table 3.4. In contrast to previous castings, alloy E had a higher carbon content and Mn to improve hardenability which could be loss during 23 tempering and still ensuring weldability. Alloy E-A also included rare earth metals not utilized before in heats. The alloy E casting was heat treated using an austenitization, first temper, and second temper. The alloy E-A was treated with a preliminary heat treatment, austenitized, tempered, and second tempered. Table 3.4 Chemical Composition of alloys E and E-A [3] The castings were evaluated using the tensile and CVN impact tests in accordance with ASTM Standard E-8 and E-23, respectively. Weldments are then inspected for signs of HAC in both the HAZ and weld metal. The welding processes used were the SMAW using E-10018M electrode, 1.1 kJ/mm energy input and GMAW using MIL-100S electrode with 1.46 kJ/mm energy input. The key results of the study are discussed in Chapter 4. 24 4. Results and Discussion The SP-7 [4] study tested five air-melt induction heats (1089, 1090, 1091, 1092, and 1093) and four 2,000 pound AOD heats (1094, 1103, 1118, and 1132) which were heat treated and evaluated for their mechanical properties and weldability for a replacement to HY-80 casting. The air melt heats were all slightly below the tensile requirements of HY-80. The other downfall of the air melt heat was the low temperature toughness was extremely low. The researchers were discouraged by this work and future melts similar because even if the strength were increased through the use of a lower tempering temperature, the toughness would not have been improved and the material would still have been an unacceptable substitute for cast HY-80. Three of the four AOD heats met the strength requirements specified in MIL-STD-23008 Rev D. Also three of the heats (1103, 1118, and 1132) met the toughness values. After welding on the different heats without preheat, two exhibited cracking as a result of the Tekken tests for FCAW. The cracks initiated at the root of the weld and propagated through the weld metal. The FCAW process resulted in greater cracking susceptibility than did the welds deposited by GMAW. At the conclusion of the project the proposed replacement for weldable HY-80 casting without preheats was unsuccessful. A combination of low strength, toughness, or cracking was prevalent in each of the melts. Researches were convinced that with additional funding, a great deal more could be learned regarding different alloy compositions and heat treatment. The later study which further optimized the alloy composition and heat treatment similar to the SP-7 study with alloys E and E-A for improved weldability used some of the lesson learned to the SP-7 study. To increase the toughness properties of the casting a double tempering operation consisting of an intercritical temper followed by a subcritical temper was required to improve low temperature toughness. During the first temper, some of the existing microstructure transforms to austenite while the rest undergoes over tempering (softening). Upon water quenching, the austenite transforms to martensite. In the second tempering, the martensite is tempered, thus leading to overall improved toughness. Therefore alloy E increased the impact properties at both 25 temperatures but the yield strength was reduced to below the requirements of MIL-S23008D. With respect to weldability for alloy E, cracks were not present in the HAZ when the SMAW process with E10018-M weld wire as used. However cracks were evident in the weld metal indicating a need for a more hydrogen free welding consumable. Alloy E-A had a yield strength value short of the HY-80 cast requirements and satisfactory hardenability. The combination of yield strength and hardness could not be achieved. Each experiment proved that the improvement of one mechanical property negatively impacted the other. The authors noted the properties were a general improvement over the SP-7 study. The E-A casting was reasonably sound and free of cracks when compared to HY-80 casting at the same preheat temperature. 26 5. Conclusion Overall, current engineered alloy castings cannot be a direct replacement for the MIL-S-23008D HY-80 casting used in today’s military. The alloys are below standards in mechanical properties specifically, fracture toughness and are still at risk for hydrogen assisted cracking. A very large number of composition variations and thermal process must still be investigated which would take extensive funding to support. The possibility of non-preheated HY-80 cast steel is still out there but at significant cost. The applications are usually the most hostile environments and the biggest budget constraints so the chances to revamp the HY-80 are probably limited. 27 6. References 1. Holthaus, John E., Koul Michelle G., Moran, Angela L. Property and microstructure evaluation as a function of processing parameters: Large HY-80 steel casting for a US Navy submarine. August 26, 2005. 2. Yayla, P., Kaluc, E., Ural, K. Effects of Welding Processes on the Mechanical Properties of HY 80 Steel Weldments. 31 March 2006. 3. Kannan, K., Valencia, J.J., Evaluation of High-Strength Steel Castings Possessing Improved Weldability. 16 April 2001. 4. Churchill, R.K., Devletian, J.H. High Yield Strength Cast Steel with Improved Weldability, Naval Surface Warfare Center CD Code 2230-Design Integration Tools Bldg 192, Room 128 9500 MacArthur Blvd, Bethesda, MD 20817-5700. May 1991. 5. Nevasmaa, P. Predictive Model for the Prevention of Weld Metal Hydrogen Cracking in High-Strength Multipass Welds. 2003. 6. AD 258 306. Armed Services Technical Information Agency. HY-80 Steel Fabrication in Submarine Construction. March 21, 1960 7. MIL-S-23008D. Steel Castings, Alloy, High Yield Strength (HY-80 and HY100). 10 April 1981. 8. ASTM E8/E8M-13a. Standard Test Methods for Tension Testing of Metallic Materials. 1 June 2013. 9. ASTM E92-82. Standard Test Methods for Vickers Hardness of Metallic Materials. 10 January 2003. 10. MIL-STD-2149A(SH). Standard Procedures for Explosion Testing Ferrous and Non-Ferrous Metallic Materials and Weldments. 14 November 1983. 11. ASTM E23-12c. Standard Test Methods for Notched Impact Testing of Metallic Materials. 15 November 2012. 12. Computational Thermodynamics. Calculation of Phase Diagrams using the CALPHAD Method. http://www.calphad.com/iron-carbon.html 13. Vickers Hardness Test. Wikipedia. http://upload.wikimedia.org/wikipedia/commons/4/4e/Vickers-path-2.svg 14. Charpy Testing. www. Twi-global.com 28 15. Hong-ying Li. Effect of Tempering Temperature on Microstructure and Mechanical Properties of AISI 6150 Steel. Journal of Central South University. April 2013 Volume 20. 16. Pelini, W.S. Use and Interpretation of the NRL Explosion Bulge Test. Metal Processing Branch Metallurgy Division. Naval Research Laboratory. September 4, 1952. 17. http://automotive.arcelormittal.com/saturnus/sheets/images/large/HSLA%20340.j pg 18. Arc Welding Pros and Cons. Everlast IGBT Inverter Technology. http://www.everlastgenerators.com/arc-welding-pros-and-cons 19. Defects – Hydrogen Cracks in Steels- Identification. TWI. http://www.twiglobal.com/technical-knowledge/job-knowledge/defects-hydrogen-cracks-insteels-identification-045/ 20. MIL-S-24645A (SH). Steel Plate, Sheet, or Coil, Age-Hardening Alloy, Structural, High Yield Strength (HSLA-80 and HSLA-100). 10 January 1990. 21. Campbell, W.P. Experience with HAZ Cold Cracking Tess on a C-Mn Structural Steel. Welding Research Supplement. May 1976. 29