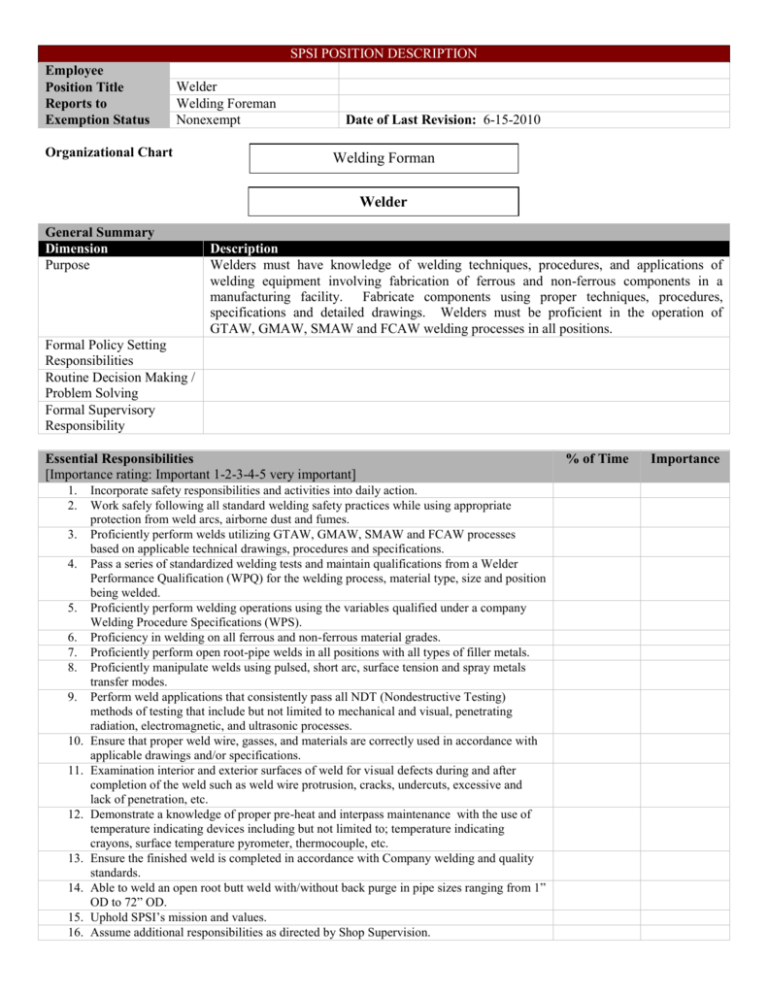

Welder - Scott Process Systems, Inc.

advertisement

SPSI POSITION DESCRIPTION Employee Position Title Reports to Exemption Status Welder Welding Foreman Nonexempt Organizational Chart Date of Last Revision: 6-15-2010 Welding Forman OFFICE PROJECT Welder MANAGER General Summary Dimension Purpose Description Welders must have knowledge of welding techniques, procedures, and applications of welding equipment involving fabrication of ferrous and non-ferrous components in a manufacturing facility. Fabricate components using proper techniques, procedures, specifications and detailed drawings. Welders must be proficient in the operation of GTAW, GMAW, SMAW and FCAW welding processes in all positions. Formal Policy Setting Responsibilities Routine Decision Making / Problem Solving Formal Supervisory Responsibility Essential Responsibilities [Importance rating: Important 1-2-3-4-5 very important] 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Incorporate safety responsibilities and activities into daily action. Work safely following all standard welding safety practices while using appropriate protection from weld arcs, airborne dust and fumes. Proficiently perform welds utilizing GTAW, GMAW, SMAW and FCAW processes based on applicable technical drawings, procedures and specifications. Pass a series of standardized welding tests and maintain qualifications from a Welder Performance Qualification (WPQ) for the welding process, material type, size and position being welded. Proficiently perform welding operations using the variables qualified under a company Welding Procedure Specifications (WPS). Proficiency in welding on all ferrous and non-ferrous material grades. Proficiently perform open root-pipe welds in all positions with all types of filler metals. Proficiently manipulate welds using pulsed, short arc, surface tension and spray metals transfer modes. Perform weld applications that consistently pass all NDT (Nondestructive Testing) methods of testing that include but not limited to mechanical and visual, penetrating radiation, electromagnetic, and ultrasonic processes. Ensure that proper weld wire, gasses, and materials are correctly used in accordance with applicable drawings and/or specifications. Examination interior and exterior surfaces of weld for visual defects during and after completion of the weld such as weld wire protrusion, cracks, undercuts, excessive and lack of penetration, etc. Demonstrate a knowledge of proper pre-heat and interpass maintenance with the use of temperature indicating devices including but not limited to; temperature indicating crayons, surface temperature pyrometer, thermocouple, etc. Ensure the finished weld is completed in accordance with Company welding and quality standards. Able to weld an open root butt weld with/without back purge in pipe sizes ranging from 1” OD to 72” OD. Uphold SPSI’s mission and values. Assume additional responsibilities as directed by Shop Supervision. % of Time Importance Qualifications To perform this job satisfactorily, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill and/or ability, and environmental conditions required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. Dimension Description Required knowledge Must have the ability to create and deposit acceptable welds in accordance with applicable standards and fabrication codes. Knowledge of welding principles including the prevention of welding defects and discontinuities. The welder should possess the skills necessary to make in and out of position welds on piping systems while maintaining a high quality standard. The welder should understand and utilize the proper handling techniques regarding weld cleanliness of all grades of ferrous and non ferrous materials. Required skills or abilities Possess the skills needed to pass the following minimum weld tests: 6G position GTAW Root/GMAW-P fill and cover weld test in P-1 carbon steel 6G position GTAW Root/FCAW fill and cover weld test in P-5B alloy steel 6G position GTAW Root/GMAW fill and cover weld test in P-8 stainless steel Formal education A high school education is preferred. Any equivalent combination of experience and training that provides the required knowledge, skills, and abilities. Experience A minimum of 3 years of welding experience in the field of high pressure pipe welding. Experience operating “Rotoweld” semi automated equipment as well as GMAW FCAW and/or Submerged Arc semi automated welding equipment. Unusual Working Conditions, if any Visual acuity. The ability to see details of objects at a close range (within a few feet of the observer). The ability to see details at a distance. The ability to see objects or movement of objects to one’s side when the eyes are focused forward. Ability to move freely throughout a manufacturing facility. Carrying and moving objects weighing up to 50lbs. Ability to stand for long periods of time and to frequently stoop, crouch, kneel and perform other related physical activities. Able to work safely around welding arc, grinding dust, welding fumes, floor and overhead obstructions, etc.