SMAW characteristics and definition

advertisement

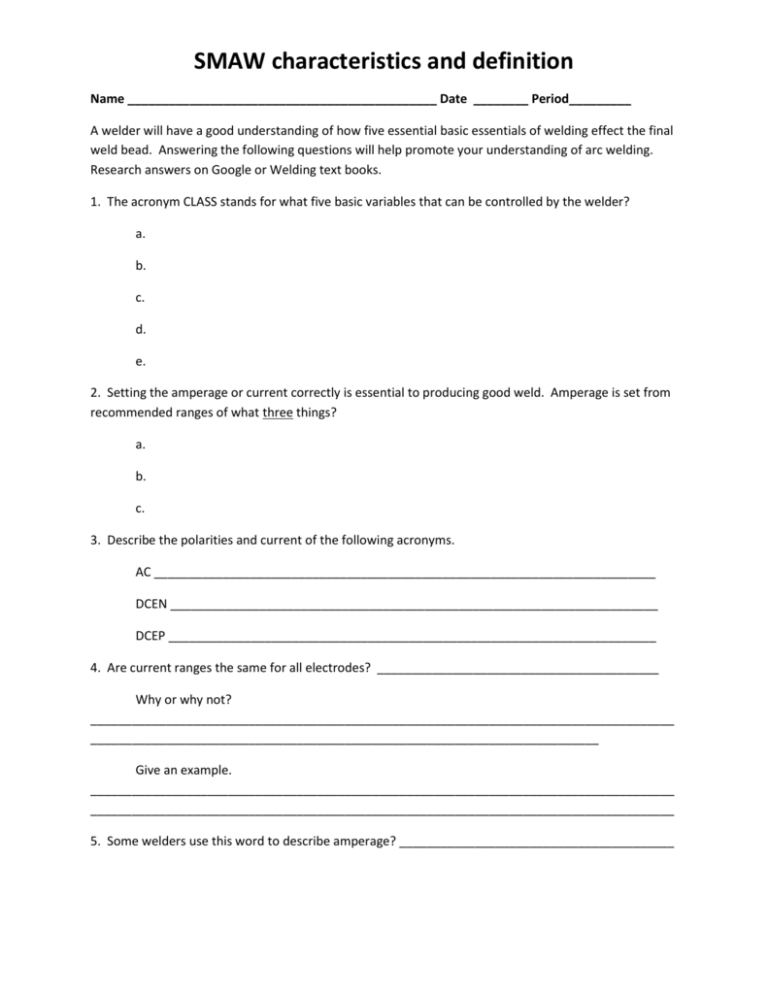

SMAW characteristics and definition Name _____________________________________________ Date ________ Period_________ A welder will have a good understanding of how five essential basic essentials of welding effect the final weld bead. Answering the following questions will help promote your understanding of arc welding. Research answers on Google or Welding text books. 1. The acronym CLASS stands for what five basic variables that can be controlled by the welder? a. b. c. d. e. 2. Setting the amperage or current correctly is essential to producing good weld. Amperage is set from recommended ranges of what three things? a. b. c. 3. Describe the polarities and current of the following acronyms. AC _________________________________________________________________________ DCEN _______________________________________________________________________ DCEP _______________________________________________________________________ 4. Are current ranges the same for all electrodes? _________________________________________ Why or why not? _____________________________________________________________________________________ __________________________________________________________________________ Give an example. _____________________________________________________________________________________ _____________________________________________________________________________________ 5. Some welders use this word to describe amperage? ________________________________________ SMAW characteristics and definition 6. What steps might a welder do before welding on the actual work piece? _____________________________________________________________________________________ _____________________________________________________________________________________ _____________________________________________________________________________________ 7. Describe the meaning of the word arc gap? _____________________________________________________________________________________ 8. What eventually happens if the arc gap gets to wide? _____________________________________________________________________________________ 9. When using a constant current welding machine, what increases to maintain current flow set on the machine? ____________________________________________________________________________ 10. There are two basic angles to position the electrode relative to the work being welded. Name them and describe them? a. ____________________________________________________________________________ b. ____________________________________________________________________________ 11. How might the angle of the electrode affect the final weld bead appearance? ____________________________________________________________________________________ 12. Rate of travel is important in welding. What determines how fast or slow the electrode should travel across the base metal when welding. ____________________________________________________________________________________ 13. List the variables to consider when selecting electrodes and describe the meaning of each variable. _____________________________________________________________________________________ 14. Electrodes have a number identification. Describe what the numbers mean on an E6010 rod. _____________________________________________________________________________________ 15. Which electrodes would be a good choice for each of the following weld conditions? a. Name the electrode that is the same as E6010 but runs on AC current. __________________ b. Name the electrode that would be a good choice for welding thinner metals or poor fit up conditions. __________________ SMAW characteristics and definition c. These electrodes should be stored in a heated oven to drive off moisture and contain extra iron powder in the coating. __________________________________________________ 16. Describe the possible reasons given for the following weld discontinuities. a. Excessive Convexity ______________________________________________________________ b. Undercut _______________________________________________________________________ c. Poor Fusion _____________________________________________________________________ d. Porosity ________________________________________________________________________ e. Slag inclusions ___________________________________________________________________ f. Excessive Spatter __________________________________________________________________