The 5 Essentials to Running a Perfect Bead

advertisement

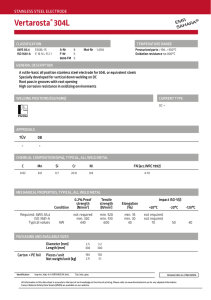

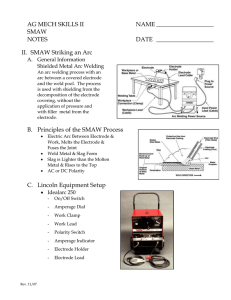

La Mirada High Welding Creating a spark for the future! The 5 Essentials to Running a Perfect Bead Number 1 This is the most important of the 5! Number 2 This is the distance from the end of the rod to the metal. This should be about 1/8th of an inch. Arc Length Number 3 This is how fast your are moving while welding. This also helps control weld size and penetration. Travel Speed Number 4 This is the angle of your rod while welding. The proper angle should be half of your weld angle. Electrode Angles Number 5 This is the amount of heat given out during the welding process. Your heat may vary depending on metal thickness and type of rod being used. Approximate Amperage Settings Approximate Electrode Amperage Settings Fast Freeze E6010 - E6011 Fill Freeze E6013 - E7014 Fast Fill E7024 - E7028 Low Hydrogen E7018 Diameter of Current Setting Electrode Inches(Millimeters) Amperes Current Setting Current Setting Current Setting Amperes Amperes Amperes 75 - 105 100 - 165 135 - 225 185 - 280 235 - 340 260 - 425 85 - 155 100 - 175 160 - 270 220 - 330 270 - 410 315 - 520 70 - 140 90 - 185 140 - 230 210 - 300 230 - 380 290 - 440 3/32 in 1/8 in 5/32 in 3/16 in 7/32 in 1/4 in (2.4 mm) (3.2 mm) (4.0 mm) (4.8 mm) (5.6 mm) (6.4 mm) 40 - 90 75 - 130 80 - 160 110 - 225 200 - 260 220 - 325 All five of the previous steps if done properly will give you a perfect welding bead. Now Your Ready!