Guidelines and requirements for report number two.

advertisement

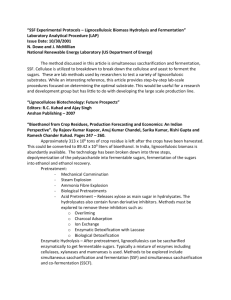

Guidelines and requirements for report number two. Both groups have begun to identify the process steps necessary in their design. The task over the next two weeks is to research all the options for the various steps in the process. This means a comprehensive review of the literature – not just picking one article and going with it. We will be looking for extensive literature references for each process. The following outlines some of the questions that need to be addressed in the design. Requirements for both groups: The red liquor composition and approximate flow rate needs to be well-established. Typical compositions of softwood red liquors produced by a magnesium acid sulfite pulping can be found in the literature. This composition can then be modified -improved -- by comparing the composition of hemlock (species used at Cosmopolis) and the composition of the species in the literature report. Ethanol production group: 1. Fermentation process. For fermentation there are two major questions; what fermentation organism(s) should be used, and what type of fermenter(s) should be used. The answer to the first question depends a lot on the composition of the red liquor. Specifically, how much pentose sugars are in the red liquor. There is A Lot of literature on fermentation organisms and approaches to fermenting five carbon sugars. This literature needs to be reviewed thoroughly and the advantages and disadvantages of the different potential organisms needs to be determined. There is also a lot of literature on fermenters. You have begun to look at some of the design configurations but it is by no means complete. As with the fermentation organisms, you need to thoroughly review the literature on fermenters and determine the advantages and disadvantages of different design configurations. One important consideration is the potential to recycle some of the fermentation organisms back into the reactor; is this a good idea, and if so how much should be recycled and how much should be purged to the recovery system. You also need to begin designing reactor(s) that will be needed to grow the fermentation organisms. Questions such as how much organism do we need to grow and what are the nutrient requirements to grow those organisms will be critical for the design. 2. Ethanol recovery. In a typical biorefinery there are usually three unit operations for ethanol recovery: A beer column that has a ethanol/water mixture going overhead and everything else going to the bottom, a distillation column that has an approximately 95% ethanol/water solution going overhead and a system for getting to 99%+ ethanol. You need to research these unit operations and come up with approximate flows and compositions for each of the process streams. 3. Sludge to ethanol. The process for production of ethanol to sludge needs to be developed. This has been investigated by a few groups around the country so there should be some literature on different approaches; you need to do a thorough literature review. The sludge is mainly made up of cellulose which will need to be hydrolyzed to sugars. Once the hydrolysis is complete the process is pretty similar to the red liquor process. There are lots of hydrolysis options, including combining hydrolysis and fermentation into one step. Another issue for this process will be integration with the red liquor process: do you have two separate processes or do you combine things at some point. If you combine them you need to think about the impact on processes and on the mill since you will be returning the waste stream from the ethanol recovery to the evaporators in the mill. Glycol production group: 1. Separation of lignin from sugars. You correctly identified this as the 1st step in the glycol process and it will require a membrane separation. But there are a lot of options of how this is done and there are even some commercial operations: the now closed Bellingham mill, a Tembec mill, a mill in South Africa, and the Domsjo mill Sweden (there may be others). There is also literature on ultrafiltration of lignin sulfonates that you need to investigate. One issue that is critical here is the purity requirement of the glycol feed stream. That is, can you tolerate some lignin and other impurities going to the glycol process? Furthermore, what will be the fate of the magnesium? We want to recover as much of it as possible to keep our chemical make up cost down. We don’t want to send it to hydrogenation processes where it could mess things up. 2. Production of sugar alcohols. This can be done biologically or catalytically and you need to explore both options. One place to look is the literature (patent and published) on the production sorbitol and xylitol from sugars. These are both well established process that we may be able to adopt here. One BIG difference for us will be the purity of the feed stream; ours is decidedly un-pure. In a catalytic system you need consider about catalyst life, pH, and catalyst poisons. 3. Production of glycols. This will be done catalytically and you need to investigate options for catalyst and catalytic reactors. Generally there are lots of different catalyst/reactor systems you can adopt and it usually comes down to tradeoffs between expensive with high performance and cheaper with moderate performance. We would also like to know how we can change catalyst and reactor operation to get the best product composition. At this point we want to know what all the options are. We will draw conclusions later. 4. Separation of products. The separation of the products will be done by distillation. At this point you need to determine what the feed composition to the distillation train is and what the product purity requirements will be. In addition, there is certainly patent literature (and could be published literature) on separation of glycols. This needs to be thoroughly investigated. We will get into design of the actual columns next quarter. 5. Sources of hydrogen. You process needs hydrogen and you need to consider all the options: How is it typically made? Is there a way to produce it from renewable resources? Is there excess electricity capacity that could be used for production – even if it is done sporadically and the hydrogen saved? Are there processes that have enough excess hydrogen that we could use? For Wednesday 9 February we will want a written and oral report that addresses the issues raised above. We are especially looking for a clear presentation of the different process options, the pros and cons of each, and something about how you are going to make a decision on which to adopt. If you already have made decision on a processing technology you should state that be prepared to defend your choice. The defense needs to be based on sound technical or economic arguments. “This one looked good” is not a good defense. We will also (as we do every with report) updated timeline and milestones. If you have questions please contact me or Dr. McKean.