Yeast fermentation

advertisement

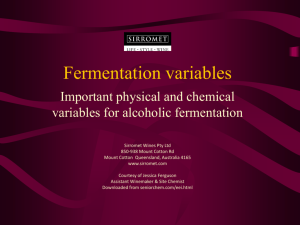

Powering the Future: Biofuels Activity: Yeast fermentation • Describe the production of ethanol from renewable sources • Describe the process of fermentation • Carry out fermentation to produce ethanol • Analyse the rate of fermentation of different sugars • Evaluate the use and economic advantages of producing liquid biofuels (gasohol) from sugar Facts and Figures • To help combat climate change the UK has a target to reduce carbon emissions by 80% by 2050. • 30% of the UK renewable energy could come from biomass heat and electricity by 2020. • To meet the European Renewable Energy Directive, the UK is aiming for 10% of transport energy to be from renewable sources by 2020. • 18% of the sustainable renewable road transport fuel used in the UK between April 2012 and April 2013 came from UK feedstocks. © Rothamsted Research Bioenergy is the energy derived from harvesting biomass such as crops, trees or agricultural waste and using it to generate heat, electricity or transport fuels. © Thinkstock® Sugar cane: Currently sugar cane (27%) is a significant source of sugar for bioethanol production using current methods. Sugar cane is produced on a large scale in Brazil and sugar beet is cultivated in the UK. © National Collection of Yeast Cultures Scanning Electron Microscope image of yeast: Researchers are developing novel yeast strains and fermentation processes that optimise bioethanol production. Bioethanol is produced by fermentation of simple monosaccharide and disaccharide sugars by yeast such as Saccharomyces cerevisiae. © University of Nottingham To harness the potential of lignocellulosic (plant cell wall) materials, we need to optimise the release of sugars from agricultural and wood-industry wastes to produce a fermentable feedstock that microorganisms can use to produce fuels. Developing robust microbial strains that can use these feedstocks will enable sustainable production of bioethanol. Professor Katherine Smart BSBEC LACE Programme School of Biosciences University of Nottingham © National Collection of Yeast Cultures Scanning Electron Microscope image of Yeast:The yeast Saccharomyces cerevisiae produces ethanol by fermentation of sucrose or glucose but is unable to ferment pentose (C5) sugars. © National Collection of Yeast Cultures Scanning Electron Microscope image of Yeast: Sugars from sugar cane can be fermented by Saccharomyces cerevisiae without prior treatment as they are already disaccharides, but starch polymers from maize or wheat need conversion to di- or monosaccharide sugars, by a hydrolysis reaction prior to fermentation. © Institute of Food Research Food Waste: Scientists at the Institute of Food Research are investigating how our waste problem can be turned into an energy solution. © University of Dundee at SCRI Plant Cell Walls: Woody plants, such as miscanthus and willow, convert much of the carbon that they capture into lignocellulosic polymers, which are not a readily fermentable form of carbohydrate. © University of Dundee at SCRI Plant Cell Walls: Feedstocks rich in lignocellulose require treatment with acids, alkalis or steam explosion methods to hydrolyse hemicellulose and break down lignin, enabling access to the cellulose by enzymes. © Institute of Food Research Steam explosion unit: We need to optimise the release of sugars from agricultural and woodindustry wastes to produce a fermentable feedstock that microorganisms can use to produce fuels. Pretreatment of feedstocks with steam opens up the structures in plant cell walls to enable access by cellulase enzymes. Activity: Yeast fermentation • Describe the production of ethanol from renewable sources • Describe the process of fermentation • Carry out fermentation to produce ethanol • Analyse the rate of fermentation of different sugars • Evaluate the use and economic advantages of producing liquid biofuels (gasohol) from sugar Contributors