Mohd Shahril Bin Mustafa @ Sulaiman

advertisement

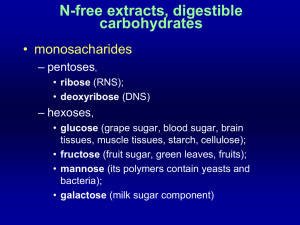

i OPTIMIZATION OF SUGAR PRODUCTION FROM CASSAVA RESIDUE USING RESPONSE SURFACE METHODOLOGY MOHD SHAHRIL BIN MUSTAFA @ SULAIMAN Universiti Malaysia Pahang ii UNIVERSITI MALAYSIA PAHANG BORANG PENGESAHAN STATUS TESIS JUDUL : OPTIMIZATION OF SUGAR PRODUCTION FROM CASSAVA RESIDUE USING RESPONSE SURFACE METHODOLOGY SESI PENGAJIAN 2009/2010 : MOHD SHAHRIL BIN MUSTAFA @ SULAIMAN Saya (HURUF BESAR) mengaku membenarkan tesis (PSM/Sarjana/Doktor Falsafah)* ini disimpan di Perpustakaan Universiti Malaysia Pahang dengan syarat-syarat kegunaan seperti berikut : 1. 2. 3. 4. Tesis adalah hakmilik Universiti Malaysia Pahang Perpustakaan Universiti Malaysia Pahang dibenarkan membuat salinan untuk tujuan pengajian sahaja. Perpustakaan dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi. **Sila tandakan ( √ ) SULIT (Mengandungi maklumat yang berdarjah keselamatan atau kepentingan Malaysia seperti yang termaktub di dalam AKTA RAHSIA RASMI 1972) TERHAD √ (Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan) TIDAK TERHAD Disahkan oleh (TANDATANGAN PENULIS) Alamat Tetap: No 1366 Blok B3, Felda Adela, 81900 Kota Tinggi, Johor Tarikh : 30 April 2010 CATATAN : * ** (TANDATANGAN PENYELIA) PUAN ROHAIDA CHE MAN Nama Penyelia Tarikh: 30 April 2010 Potong yang tidak berkenaan. Jika tesis ini SULIT atau TERHAD, sila lampirkan surat daripada pihak berkuasa/organisasiberkenaan dengan menyatakan sekali sebab dan tempoh tesis ini perlu dikelaskan sebagai SULIT atau TERHAD. Tesis dimaksudkan sebagai tesis bagi Ijazah Doktor Falsafah dan Sarjana secara penyelidikan, atau disertasi bagi pengajian secara kerja kursus dan penyelidikan, atau Lapuran Projek Sarjana Muda (PSM). iii “I hereby declare that I have read this thesis and in my opinion this thesis is sufficient in terms of scope and quality for the award of the degree of Bachelor of Chemical Engineering (Biotechnology)” Signature : …………………………….. Supervisor : Puan Rohaida Binti Che Man Date : 30 April 2010 iv OPTMIZATION OF SUGAR PRODUCTION FROM CASSAVA RESIDUE USING RESPONSE SURFACE METHODOLOGY MOHD SHAHRIL BIN MUSTAFA @ SULAIMAN A thesis submitted in fulfillment of the requirements for the award of the degree of Bachelor of Chemical Engineering (Biotechnology) Faculty of Chemical Engineering and Natural Resource Universiti Malaysia Pahang MAY 2010 ii I declare that this thesis entitled “Optimization of Sugar Production From Cassava Residue using Response Surface Methodology” is the result of my own research except as cited in references. The thesis has not been accepted for any degree and not concurrently submitted in candidature of any other degree Signature : ………………………………………... Supervisor : Mohd Shahril Bin Mustafa @ Sulaiman Date : 30 April 2010 iii This thesis is dedicated to all my love ones, especially to Mak & Abah. Thank You for the endless love & support. iv ACKNOWLEDGEMENT Alhamdulillah, to Allah S.W.T I thank the most on His utmost love and blessings for giving me the guidance in accomplishing this study. The most courteous thank againt Him who made all thing achievable. First and foremost, I would like to acknowledge and extend my heartfelt gratitude to my supervisor, Puan Rohaida Bt Che man, for her guidance, criticisms and inspiration she extended. Thank you so much for her vital encouragement and support. I wish to express my deepest thankfulness to Encik Zaki who had been helping, supporting and motivating me throughout this study. Thank you to the faculty of Chemical & Natural Resources Engineering, UMP for its permission to carry out this study. Exclusive thanks from me to the people that I love especially Abah, Mak, Shafiq, Abanglong, Ahmad Termizi, Elyanes Maslisa, Raja Norazean, Hanifan Abd Jalil, Kamarul Izhan and to all who made this project done. Thank you so much for the everlasting love, upright companionship, honourable supports and exquisite inspirations through out this period. v ABSTRACT Cassava residue, starch processing waste from cassava starch plant, was used as a raw material in sugar production. This is study aims to optimize the production of sugar from cassava residue using response surface methodology. The effect of parameters such as incubation time and enzyme concentration is used to study the concentration of glucose produced. Three different enzymes are used to produce glucose namely cellulase, glucoamylase and α-amylase. Cellulase was the best enzyme that yielded the most glucose. The optimization of the production of sugar is carried out by using response surface methodology (RSM) based on the central composite design (CCD).The optimal set parameters for enzyme concentration are 1.32 g/mL and 4.47 hours of incubation time. Glucose concentration of 1.059 g/L was achieved by using these optimal parameters. vi ABSTRAK Sisa ubi kayu adalah sisa pemprosesan kanji daripada pokok ubi kayu, digunakan sebagai bahan mentah dalam penghasilan gula.. Tujuan kajian ini dilakukan adalah untuk mengoptimumkan penghasilan gula daripada ubi kayu menggunakan kaedah gerak balas permukaan (RSM). Pengaruh parameter seperti masa inkubasi dan kepekatan enzim digunakan untuk mengkaji kepekatan glukosa yang dihasilkan. Tiga jenis enzim digunakan dalam menghasilkan glukosa iaitu cellulase, glucoamylase and α-amylase. Enzim terbaik yang menghasilkan gula yang paling tinggi adalah cellulase. Penghasilan gula dioptimumkan menggunakan kaedah gerak balas permukaaan berdasarkan reka bentuk komposit pusat (CCD). Parameter yang optimum adalah dengan menggunakan 1.32 g/mL kepekatan enzim pada 4.47 jam masa inkubasi. Kepekatan glukosa yang dihasilkan adalah 1.059 g/mL dengan menggunakan parameter yang optimum ini. vii TABLE OF CONTENT CHAPTER TITLE DECLARATION DEDICATION ACKNOWLEDGEMENT ABSTRACT ABSTRAK TABLE OF CONTENT LIST OF TABLES LIST OF FIGURES LIST OF SYMBOLS/ABBREVIATIONS LIST OF APPENDICES 1 ii iii iv v vi viii x xi xii xiii INTRODUCTION 1.1 Introduction 1 1.2 Problem Statement 2 1.3 Objective of Research 1.4 2 PAGE 2 Scopes of Research LITERATURE REVIEW 2.1 Cassava Residue 4 2.2 Structure of Cassava Residue Biomass 5 2.2.1 Cellulose 5 2.2.2 Hemicelluloses 6 2.2.3 Starch 7 2.3 Enzymatic Hydrolysis 2.3.1 Overview of Enzymatic Hydrolysis 8 9 2.4 Optimization of time and enzyme concentration on Production of sugar by Using Response Surface Methodology (RSM) 2.5 Production of Sugar 2.5.1 10 13 Production of xylose from Palm Oil Empty Fruit Bunch (POEFB) using enzymatic hydrolysis process 13 viii 2.5.2 Production of sugar from from pineapple cannery waste using continuous fermentation 2.5.3 Production of sugar from from pineapple cannery waste using continuous fermentation 3 14 METHODOLOGY 3.1 Overview of Research Methodology 15 Enzymatic hydrolysis 16 3.1 Screening of Enzymes 16 3.2 Effect of Parameters 16 3.3 Effect of Incubation Time 17 3.4 Effect of Enzyme Concentration 17 3.5 Concentration of Glucose 17 3.7.1 Preparation of DNS reagent 17 3.7.2 Concentration of Glucose Analyzed by DNS 17 Response Surface Methodology (RSM) 18 3.8 4 13 RESULT AND DISCUSSION 4.1 Screening of Enzymes 20 4.2 Effect of Parameters on Glucose Concentration 21 4.2.1 Effect of Incubation Time 21 4.2.2 Effect of Enzyme Concentration 23 4.3 Determination of the Optimum of Parameters on Sugar Production Using Response Surface Methodology (RSM) 4.4 Optimization of sugar production using Response Surface Methodology (RSM) 5 25 29 CONCLUSION ANR RECOMMENDATIONS 5.1 Conclusion 30 5.2 Recommendations 31 ix REFERENCES APPENDIX A - B 32 39-44 x LIST OF TABLES TABLE NO. TITLE PAGE 1.1 Chemical composition in cassava residue 5 1.2 Low level and high level of cultural condition 25 1.3 Experiments designed by Design Expert Software 26 1.4 ANOVA for response surface quadratic model for the production sugar 1.5 27 Summaries of the optimized cultural conditions for sugar production 29 xi LIST OF FIGURES FIGURE NO. TITLE 1.1 Cassava Starch Plant 1.2 Basics compound of cellulose is cellubiose, disaccharides PAGE 1 of two β-1-4 bonded glucoses 6 1.3 Structure of xylan and enzymes cleavage sites 7 1.4 Structure of starch 7 1.5 Schematic for basic process of enzymatic hydrolysis 9 1.6 Research design for the production of sugar 15 1.7 Screening of different enzyme 21 1.8 Effects of incubation time 22 1.9 Effect of enzyme concentration 23 1.10 Response surface plot of sugar production: Incubation time vs. enzyme concentration. 28 xii LIST OF SYMBOL/ABBREVIATIONS ANNOVA - Analysis if variance CCD - Central composite design g - Gram mL - Milliliter DNS - Dinitrosaliccyclic Acid HPLC - High performance liquid chromatography Hr - Hour L - Liter g/mL - Gram per milliliter g/L - Gram per liter min - Minute M - Molar Nm - Nanometer OD - Optical density OFAT - One factor at a time RSM - Response Surface Methodology w/v - Weight per volume °C - Degree celcius % - Percentage xiii LIST OF APPENDICES APPENDIX A1 TITLE PAGE Preparation mixture of 0.1 M Sodium Hydroxide (NaOH), (2000 mL) and 0.1 M Citric Acid (1000 mL) as Buffer 35 A2 Preparation of DNS Reagent (1 L) 36 A3.1 Preparation of 1 mg/mL of Glucose Standard Solution (10 mL) 37 A3.2 Standard Curve of Glucose 37 A4 Enzyme Dilution 38 B1 ANNOVA Results for Optimization of Parameters 39 1 CHAPTER 1 INTRODUCTION 1.1 Introduction Cassava is a shrubby, tropical, perennial plant that is not well known in the temperate zone. For the most people, cassava is most commonly associated with tapioca. The plant grows tall, sometimes reaching fifteen feet, with leaves varying in shape and size. The edible parts are the tuberous root and leaves. The tuber (root) is somewhat dark brown in color and grows up to two feet long. Ironically, any processed raw materials will end up producing waste. Due to the mass production of which originated from cassava starch plant, encourage a mass production of its waste, cassava residue which also called as biomass. Recently, utilization of biomass resources has been the subject of the various studies. Cassava residues is one of the biomass materials, which is the by product from the cassava starch plant industry. Cassava residue has the potential to be utilized to produce sugar due to its containing cellulose, hemi-cellulose and starch at levels of 24.99, 6.67 and 61% (w/w), respectively. Starch components in cassava residue were converting to reducing sugar with different kind of enzymes (Teerapatr et al., 2006). Figure 1.1 shows the cassava starch plant. Figure 1.1: Cassava starch plan 2 1.2 Problem Statement Annually, there is approximately many ton of cassava residues produced from the starch factories in Malaysia. The cassava residue left over from the production processes are abundant and still contain a high amount of starch content. Use of cassava residue as raw material in sugar production not only reduces waste material created from the cassava starch industry, but also lowers the cost of sugar production (La-aied et al., 2006). In addition by using the cassava residue as raw material to sugar production is to prevent from the environmental issues. Fortunately, the main component of cassava residue consists of cellulose 24.99 % (w/w), hemi-cellulose 6.67 % (w/w) and starch 61 % (w/w) (Teerapatr et al., 2006). Therefore, it can be consumed to produce sugar which has a major field of applications in industries and can very useful to the environment and society at large. 1.3 Objective of Research The main objective of this research is to optimize the production of sugar from cassava residue using response surface methodology. 1.4 Scopes of Research In order to achieve the objective, scope of study was divided into three as the following: i) To determine the best enzyme that can produce the most yield of glucose using enzymatic hydrolysis by feeding three types of commercial enzymes into the treated cassava residue, which are: (a) Cellulase, (b) Glucoamylase and (c) α-amylase. ii) To study the effect of parameters of the best chosen from (i) such as incubation time and enzyme concentration on glucose concentration. 3 iii) To optimize the parameters of the enzyme chosen by using response surface methodology (RSM) on sugar production. 4 CHAPTER 2 LITERATURE REVIEW 2.1 Cassava Residue Cassava residue, which is the starch-processing waste from cassava starch plant, was used as a raw material in sugar production (Cholada et al., 2004). The cassava residue left over from these production processes are abundant and still contain a high amount of starch content. Most cassava residue can be used as animal feed due to its high content of protein and other nutrients which are necessary for animal growth. In addition, cassava residue can be used to produce sugar. By using the cassava residue as raw material in sugar production not only reduces waste material created from the cassava starch industry, but also lowers the cost of sugar production (Lerdluk et al., 2006). The main component of most cassava residue containing cellulose at level 24.99%, hemicelluloses at level 6.67% and starch at level 68.34% ( Suthkamol et al., 2006).Annually there is approximately one million of cassava residues produced from the starch factories. The application of using these cassava residues especially for the sugar production would be advantage for the country economy (Bongotrat et al., 2004). Table 2.1 shows the chemical composition in cassava residue. 5 Table 2.1: The chemical composition in cassava residue Composition Cassava residue (Sample 1) 78.16 1.82 0.09 1.61 10.61 69.90 Moisture protein Fat Ash Fiber Starch 2.2 Cassava residue (Sample 2) 79.50 2.03 0.20 2.38 14.35 61.84 Cassava residue (Sample 3) 82.74 2.31 0.16 2.05 14.56 64.36 Structure of Cassava Residue Biomass Main components of most cassava residue are cellulose, hemi-cellulose and starch. Each of this part plays a role in protecting each other and strengthens the plant structure (La-aied et al., 2006). 2.2.1 Cellulose Cellulose consists of linear macromolecular chains of glucose, linked by β-1,4glucosidic bonds between the number one and number four carbon atoms of the adjacent glucose units. Native crystalline cellulose is insoluble and occurs as fibers of densely packed, hydrogen-bonded and anhydroglucose chains of 15 to 10, 000 glucose units (Howard et al., 2003). Theoretically, complete hydrolysis of cellulose into glucose require three main enzymes namely endo-β-glucanase, exo-β-glucanase and β-glucosidase. Endo-βglucanase randomly hydrolyses the cellulose polymers yielding shorter oligosaccharides and also a few cellubiose molecules meanwhile, exo-β-glucanase acts at the end of cellulose chains. β-glucosidase primarily hydrolyses cellubiose into glucose. Figure 1.2 shows the basic compound of cellulose. 6 Figure 1.2: The basics compound of cellulose is cellubiose, disaccharides of two β1-4 bonded glucoses 2.2.2 Hemicelluloses Hemicelluloses are heterogeneous polymers of pentoses (xylose, arabinose), hexoses (mannose, glucose, galactose) and sugar acids. In hardwood hemicelluloses mostly contains xylan, whereas softwood hemicelluloses contains mostly glucomannans. Xylan of many plant materials are heteropolysaccharides with homopolymeric backbone chains of 1,4-linked β-D-xylopyranose units. The monosaccharides released upon hemicellulose hydrolysis include a large fraction of pentoses (Gunda et al., 1970). In several plants the majority of hemicelluloses is xylan which can be hydrolyzed into xylose. Particularly the hemicellulose of hardwood is rich in xylan. Consequently it is possible to obtain xylan and xylose as by-products from cellulose industry using hardwood (Gunda et al., 1970). Figure 1.3 shows the structure of xylan and enzymes cleavage site. The complex structure of xylan needs different enzymes to complete its hydrolysis. The main enzyme that randomly hydrolysis the main chain of xylan to produce mixture xylooligosaccharides named as endoxylanase and β-xylosidase will liberate xylose from short oligosaccharides. Moreover, the sides groups presents in xylan are liberated 7 by α-L-arabinofuranosidase, α-D-glucuronidase and acetyl xylan esterase. Figure 2 shows the structure of xylan. Figure 1.3: Structure of xylan and enzymes cleavage sites 2.2.3 Starch Starch is a polymer composed of glucose units primarily linked by a (1-4) glucosidic bonds, with some additional a (1-6) linkages. Figure 1.4 shows the structure of starch. Figure 1.4: The structure of starch It consists of a mixture of two types of polymers: amylose and amylopectin. The mass fraction of amylose normally lies around 20-30 % for amylose. Starch varieties with deviating compositions also exist (nearly 100 % pure amylopectin potato 8 and maize starch). Amylopectin is a branched polymer. Linear chains a (1-4)-linked D-glucose residues are connected by (1-6)-D-glucosidic linkages. Amylose is a much more linear polymer since the frequency of a (1-6) linkages (0.2 - 0.7 %) is much smaller than in amylopectin (4 - 5 %) (Richard et al., 2004). The enzymes that break down or hydrolyze starch into the constituent sugars are known as amylases. Alpha-amylases are found in plants and in animals. Human saliva is rich in amylase, and the pancreas also secretes the enzyme. Individuals from populations with a high-starch diet tend to have more amylase genes than those with low-starch diets; chimpanzees have very few amylase genes. It is possible that turning to a high-starch diet was a significant event in human evolution (Steve, 2004). Beta-amylase cuts starch in maltose units. This process is important for the digestion of starch and also used in brewing, where the amylase from the skin of the seed grains is responsible for converting starch to maltose. 2.3 Enzymatic Hydrolysis There are two main approaches to convert cellulose, hemicelluloses and starch into simple sugars such as glucose and xylose are acid hydrolysis and enzymatic hydrolysis (Teerapatr et.al., 2004). Acid hydrolysis is relatively inexpensive and simple but there are several major drawbacks associated with this process including: degradation of sugars due to the high temperature, formation of fermentation inhibitors, such as furfural, and expensive construction materials in equipment to handle the acids. The enzymatic hydrolysis of cellulose, hemicelluloses and starch can be more attractive because of its specificity and absence of competitive degradation, which results in higher yields of sugars. However, enzyme costs can be prohibitively high and it is important to reduce the costs of enzyme production and/or to reduce the amount of enzyme used. Figure 1.5 shows schematic for basic process of enzymatic hydrolysis. 9 Substrate Glucose Hydrolysis Cellulase Hemicelluloses Starch Different Enzymes Mixture α-amylase, Glucoamylase, Cellulase Figure 1.5: Schematic for basic process of enzymatic hydrolysis 2.3.1 Overview Process of Enzymatic Hydrolysis There is a process that simultaneously hydrolyzes cellulose, hemicelluloses and starch to sugars by addition of enzymes. Cellulose, hemicelluloses and starch is degraded by different enzymes that are able to hydrolyse to the sugar glucose. The cellulose molecules are composed of long chains of sugar molecules. One major process to Cellulose hydrolysis (cellulolysis) is an enzymatic reaction. In the hydrolysis process, these chains are broken down to free the sugar, before it is fermented for alcohol production. Hemicelluloses are xylan which can be hydrolyzed into xylose. The complex structure of xylan needs different enzymes to complete its hydrolysis. The main enzyme that randomly hydrolysis the main chain of xylan to produce mixture of xylooligosaccharides named as endoxylanase and β-xylosidase will liberate xylose from short oligosaccharides. Moreover, the sides groups presents in xylan are liberated by α-L-arabinofuranosidase, α-D-glucuronidase and acetyl xylan esterase (Badal, 2003). 10 2.4 Optimization of Time and Enzyme Concentration on Production of Sugar by Using Response Surface Methodology (RSM) During the preliminary investigations into this research it was realized that the classical, “one-time-a-time” factorial design experiments, where a single factor is varied while others are kept constant, are often expensive and time consuming and do not take into account the possible interaction of various independent factors that would skew the results. For these reasons, statistical methods have been developed to reduce the cost and duration of experiments that also allow for the observation of any interacting factors in the final process response. One such highly successful method is “Response Surface Methodology” (RSM), which is defined as a statistical method that uses quantitative data from appropriate experimental designs to determine and simultaneously solve multivariate equations that specify the optimum product for a specified set of factors through mathematical models. It involves four important steps: (1) identification of critical factors for the product or process, (2) determination of the range of factors levels, (3) selection of specific test samples by the experimental design, (4) analysis of the data by RSM and data interpretation (Mutanda et al., 2008). Basically, Response Surface Methodology (RSM) is a systematic approach that can be obtained by using an inverse process of first, specifying the criteria and then computing the ‘best’ design according to a formulation. Response Surface Methodology (RSM) is a collection of statistical and mathematical techniques useful for developing, improving and optimizing the design process. RSM encompasses a point selection method (also referred to as Design of Experiments, Approximations methods and Design Optimization) to determine optimal settings of the design dimensions. It has important applications in the design, development and formulation of new products as well as in the improvement of existing product designs. RSM which includes factorial design and regression analysis can build models to evaluate the effective factors and study their interaction and select the optimum conditions in limited number of experiments (Chauhan and Gupta, 2004). A successive response surface method is an iterative method which consists of a scheme to assure the convergence of an optimization process. The scheme determines the location and size of each successive region of interest in the Design 11 Space, builds a response surface in this region, conducts an design optimization and will check the tolerances on the response and design variables for termination. This RSM method has been widely used to evaluate and understand the interaction between different physiological and nutritional parameters (Ambati and Ayyanna, 2001; Hounjg et al., 1989). There have been a few reports on optimization lipase production by Pseudomonas sp. whereas Liu et., al (2006) have reported 5-fold increase in lipase yield after optimization. Production of an alkaline lipase from Burkholderia multivorans increased by 12-fold by a combination of Response Surface Methodology (RSM) and scale-up attempt using 14 L bioreactor (Gupta et al., 2008). Thus the level of lipase production by the strain is significantly high and can be cost effective for its applications. Optimization of ethanol production from hot-water extracts of sugar maple chips was conduct by Jian et al., 2009. Hot-water extracts from sugar maple chips prior to papermaking was employed in this study to produce ethanol by Pichia stipitis 58784. The effects of several factors such as seed culture age, fermentation time, inoculum quantity, agitation rate, percent extract, concentration of inorganic nitrogen source (NH4)2SO4 and pH value on ethanol production were investigated by orthogonal experiments. Orthogonal analysis shows that the optimal fermentation was obtained in the condition of 48 hour seed culture, 120 hour fermentation, 16% inoculum, 180 rpm, containing 30 % extracts, 8 % ammonium sulphate supplement and pH 5. This optimal condition was verified at 800 mL level in a 1.3 L fermentor. The ethanol yield reached 82.27 % of the theoretical (20.57 g/L) after 120 hour (Jian Xu and Shijie Liu, 2009). Optimization of temperature, sugar concentration and inoculum size to maximize ethanol production without significant decrease in yeast cell viability was done by Cecilia et al., 2009. Aiming to obtain rapid fermentations with high ethanol yields and retention of high final viabilities (responses), a 23 full-factorial central composite design combined with response surface methodology was employed using inoculum size, sucrose concentration and temperature as independent variables. From this statistical treatment, two well-fitted regression equations having coefficients 12 significant at the 5 % level were obtained to predict the viability and ethanol production responses. Three dimensional response surfaces showed that increasing temperatures had greater negative effects on viability than on ethanol production. Increasing sucrose concentrations improved both ethanol production and viability (Karen et al., 2009). The interactions between the inoculum size and the sucrose concentrations had no significant effect on viability (Meline et al., 2009). Thus, the lowering of the process temperature is recommended in order to minimize cell mortality and maintain high levels of ethanol production when the temperature is on the increase in the industrial reactor. Optimized conditions (200 g/L initial sucrose, 40 g/L of dry cell mass, 30 °C) were experimentally confirmed and the optimal responses are 80.8±2.0 g/L of maximal ethanol plus a viability retention of 99.0±3.0% for a 4 hour fermentation period. During consecutive fermentations with cell reuse, the yeast cell viability has to be kept at a high level in order to prevent the collapse of the process. Optimization study for sorbitol production by Zymomonas mobilis in sugar cane molasses was conducted by Cazetta et al., 2005. Sorbitol production by Zymomonas mobilis in sugar cane molasses was investigated by batch fermentation. The effects of the mean sugar concentration, temperature, agitation and culture time were studied simultaneously by factorial analysis. Maximum sorbitol production was determined using a second-order central composite design and analyzed by the superficial response method. Response surface methodology analysis showed that the best conditions for sorbitol production were 300 g/L total reducing sugars (TRS) in the culture medium, 36 hour at 35 °C fermentation time (Silva et al., 2004). 13 2.5 Production of Sugar Many types of plant biomass can produce the sugar using some method. For example palm oil empty fruit bunch (POEFB) by using enzymatic hydrolysis process (Choudhury et al., 2007), production of sugar from maize starch by using enzymatic hydrolysis process (Singh et al., 1999). 2.5.1 Production of Xylose From Palm Oil Empty Fruit Bunch (POEFB) Using Enzymatic Hydrolysis Process Xylose is found in the embryos of most edible plants. Xylan, the hemicelluloses used as raw material in xylose production. Xylanase, the enzyme that is used to hydrolysed the structure of xylan to produce xylose. This study aims to improve the production of xylose from palm oil empty fruit bunch (POEFB) using enzymatic hydrolysis process. The effect of cultural conditions such as enzyme concentration and incubation time is used to study the production of xylose. Three different xylanases enzyme are used to produce xylose namely Multifect Xylanase, Multifect CX 12L and optimase CX 72L. Multifect CX 12L was the best enzyme that yielded the most xylose. The optimization of the production of xylose is carried out by using response surface methodology (RSM) based on the central composite design (CCD). The optimal set cultural conditions for enzyme concentration are 50 U/g and 35.5 hours of incubation. Xylose production of 23.15 mg/mL was achieved by using these optimal conditions (Rahman et al., 2007). 2.5.2 Production of Sugar From Maize Starch Using Enzymatic Hydrolysis Process Crude amylases were prepared from Bacillus subtilis ATCC 23350 and Thermomyces lanuginosus ATCC 58160 under solid state fermentation. The effect of various process variables was studied for maximum conversion efficiency of maize starch to glucose using crude amylase preparations. Doses of pre-cooking α-amylase, post-cooking α-amylase, glucoamylase and saccharification temperature were found to 14 produce maximum conversion efficiency and were these selected for optimization. Full factorial composite experimental design and response surface methodology were used in the design of experiments and analysis of results. The optimum values for the tested variables for the maximum conversion efficiency were: pre-cooking α-amylase dose 2.243 U/mg solids, post-cooking α-amylase dose 3.383 U/mg solids, glucoamylase dose 0.073 U/mg solids at a saccharification temperature of 55.1 °C. The maximum conversion efficiency of 96.25 % was achieved. This method was efficient; only 28 experiments were necessary to assess these conditions, and model adequacy was very satisfactory, as coefficient of determination was 0.9558 (Adinarayana et al., 2005). 2.5.3 Production of Sugar From Sorghum Straw Using Acid Hydrolysis Process. Xylose is a hemicellulosic sugar that can be used as a carbon and energy source for the growth of microorganisms. The main use of xylose is its bioconversion to xylitol. Sorghum straw is a raw material for xylose production that has not yet been studied. The objective of this work was to study xylose production by hydrolysis of sorghum straw at 122 °C, using three concentrations of sulphuric acid (2 %, 4 % and 6 %). Kinetic parameters of mathematical models for predicting the concentration of xylose, glucose, acetic acid and furfural were found and optimal conditions selected. These were 2 % H2SO4 at 122 °C for 71 minutes, which yielded a solution with 18.17 g xylose/L, 6.73 g glucose/L, 0.9 g furfural/L and 1.51 g acetic acid/L (Ramirez et al., 2001). 15 CHAPTER 3 MATERIAL AND METHODS 3.1 Overview of Research Methodology Basically, there are three steps to be accomplished in producing the highest yield of sugar. The first step is to performing an enzymatic hydrolysis method on the cassava residue by (i) screening the best enzyme (ii) studying the effects of parameters; incubation time and enzyme concentration. Finally, optimize the parameters to maximize the production of sugar by using response surface methodology (RSM). Details on this research design are shown in Figure 1.6. 1. Screening of Enzymes: Enzymatic hydrolysis Cellulase Glucoamylase α-amylase 2. Effect of parameters on the best enzyme Incubation time Enzyme concentration 3. Optimization by RSM Figure 1.6: Research design for the production of sugar 16 3.2 Enzymatic Hydrolysis Experiment was carried out with constant pretreated substrate 1 g (dried weight) in shake flask (250 mL volume) with enzyme. The substrate was suspended to mixture are Sodium Hydroxide (NaOH) and Citric acid (C6H8O7) as buffer. The pH of buffer was measured by pH meter. The enzymatic hydrolysis was performed by incubating the mixture in an oven. Supernatant was collected through filter paper. Reaction was stopped by boiling the mixture at 100 °C for 3 minutes. 3.3 Screening of Enzymes Different types of enzyme were used to determine the best enzyme that can produce the most yield of sugar by feeding three types of commercial enzymes into the treated cassava residue: (1) Cellulase, (2) Glucoamylase, (3) α-amylase. On cellulase treatment, cassava residue was hydrolyzed with cellulase at PH 4.8, 40 °C, α-amylase at pH 5.5, 100 °C and glucoamylase at pH 4.5, 60 °C. Time to hydrolyze is 7 hour and concentration of each enzymes is 1 g/mL. 3.4 Effect of Parameters In the production of sugar, the yield of the product depends on its cultural parameters in executing the experiments. There are various parameters that affect the yield of sugar such as enzyme concentration, incubation time, reaction time, reaction temperature, agitation rate, pH of buffer used and also the concentration of substrate. However, this research is to study about the effect of incubation time and enzyme concentration. It is believe that these two parameters give a big impact on sugar yield. 17 3.5 Effect of Incubation Time The best enzyme chosen from above is used in this step but with a range of time of 2, 4, 6, 8, 10 and 12 hours. 3.6 Effect of Enzyme Concentration The best time will then used for further study on cultural conditions but with a range of concentration of 0.5, 1.0, 1.5, 2.0 and 2.5 g/mL. 3.7 Concentration of Glucose This concentration of glucose analysis is to determine how many reducing glucose yield from the hydrolyzed samples all along this research experiments. 3.7.1 Preparation of DNS reagent An amount of 10.6 g of 3,5 - dinitrosalicylic acid crystals was dissolved with 19.8 g of NaOH in 1,416 of distilled water. 306 g of sodium-potassium tartrate (Rocchelle salts) was added into the mixture. A phenol crystal was melt at 50 °C using a water bath. Then 7.6 mL of the dissolved phenol was added to the mixture. Next, 8.3 g of sodium meta-bisulfate (Na2sS2O4) was added and finally, NaOH was added to adjust the pH to 12.6, if required (Fisher and Stein, 1961). 3.7.2 Concentration of Glucose Analyzed by DNS Total glucose produced was measured by DNS method (Sanjeev et al., 2002). The reaction was done by boiled 2 mL of diluted samples in test tubes for 3 minutes in water at 100 °C. At the end of boiled period, 2 mL of the sample is then mixed with 2 mL of DNS reagent to stop the reaction followed by boiled for 5 minutes to generate 18 the colour. A colour change was measured at wavelength 540 nm by using Uv-vis Spectrophotometer. Blank lacking of distilled water was analyzed simultaneously with each batch of samples. Standard curve of glucose was prepared by replacing the sample with various concentration of glucose. Concentration glucose was calculated from the absorbance (A540nm) of the sample using the calibration curve. 3.8 Response Surface Methodology (RSM) Design Expert Software (State-Ease Inc, Statistic Made Easy, Minneapolis, MN, USA, (Version 6.0.4) was applied to execute the response surface methodology. The central composite design (CCD) was chosen in the optimization process due to its ability in providing factorial analysis in 2 levels of the factors involves (enzyme concentration & incubation time), which will be from the centre point to the star point. The relation between the coded values and actual values is described in Equation 3.1: Xi = (Ai – Ao) / ∆A (Equation 3.1) Where; Xi = Coded value of the variable Ai=Actual value Ao= Actual value of Ai at the centre point The quadratic model to predict the optimal point is coded in Equation 3.2: Y=βo+∑βiXi+∑βiiXi2+∑βijXiXj Where; Y= Predict response variable βo= Offset term βi= Linear effect βii= Interaction effect (Equation 3.2) 19 X= Coded levels of the independent variables The regression equation above was optimized for the optimal values using Design Expert Software. An experiment was conducted in a randomized order to stay away from systematic bias. Next, the ANOVA test was used to analyzed the experimental data obtained. P-value was determined to identify the significance of the quadratic model. A P-value ≤0.05 are considered to be significant. 20 CHAPTER 4 RESULT AND DISCUSSION 4.1 Screening of Enzymes Three types of enzymes were screened to determine which one of them is the best enzyme that can hydrolyze the cassava residue producing the most glucose. These enzymes were used as catalysts to produce glucose that contain in cassava residue. Figure 1.7 shows the difference between these three enzymes in concentration of glucose. The experiments were conducted in the same cultural conditions which are incubated at 7 hours in an oven with 1 g/mL of each enzyme concentration. Cellulase shows the highest yield of concentration of glucose in Figure 1.7. An amount of 1.018 g/L, 0.6813 g/L and 0.9664 g/L of concentration were detected from cellulase, glucoamylase and α–amylase respectively. Based on report Mark et al., (2007), hydrolyses with cellulase had higher yields of glucose, galactose and xylose than hydrolyses without cellulase. Moreover, Krishnamurthy et al., (2010) reported that, by using cellulose pretreatment for the any production, higher yield will be obtained. Therefore, cellulase enzyme was used for the next study on the effect of cultural conditions on glucose concentration. 21 Concentration glucose (g/L) 1.2 1 0.8 0.6 0.4 0.2 0 Glucoamylase Cellulase Types of enzyme α-amylase Figure 1.7: Screening of different enzyme. 4.2 Effect of Parameters on Glucose Concentration Studies on the parameters that affect the concentration of glucose were carried out by using the conventional method. The method studies one factor at a time (OFAT) while keeping the others at a certain level. This study was done to determine the optimum range of parameters for further optimization process. Principally, the low and high levels of every parameter were obtained before and after peak values respectively in the appropriate experiments. The parameters involved were incubation time and enzyme concentration. 4.2.1 Effect of Incubation Time The best time was determined by conducting an enzymatic hydrolysis, where the samples were incubated in an oven at 40° C by using 1 g/mL enzyme concentrations, whereas the incubation time is varied in a range from 2 – 12 hours. The effects of incubation time on the concentration of glucose are shown in Figure 1.8. 22 Concentration gluose (g/L) 1.2 1 0.8 0.6 0.4 0.2 0 0 2 4 6 8 10 12 14 Time (hour) Figure 1.8: Effects of incubation time Based on the result in Figure 1.8, initially the concentration of glucose produced increased exponentially at the time of 2 – 6 hour. Based on report by Hao et al., (2010), as substrate loading increased, the end-product inhibition caused by cellobiose and glucose increased. It is because, the enzyme produces product at an initial rate that is approximately linear for a short period after the start of the reaction. When there were higher of time, the more the interaction between enzymes and substrates. However, as the reaction proceeds and substrate is consumed, the rate continuously slows. Based on the Figure 1.8, at the time of 8 – 12 hour the concentration of glucose started to decreased. Based on report Cinar, (2005), the higher enzyme loadings resulted in faster total hydrolysis and probably end-product inhibition occurred. Moreover, Kristense, (1972) reported that a digestibility trials undertaken on redclaw gastric juice here showed that reducing sugars could be produced in relatively short time frames suggesting that cellulose digestion by redclaw occurs rapidly. As redclaw have very short, simple digestive tracts effectively a straight tube. Digestive enzymes need to act rapidly as digestive times are relatively rapid. 23 The best time to be used in order to obtain the maximum yield of glucose is 6 hours. This condition will then used for the effect of enzyme concentration. 4.2.2 Effect of Enzyme Concentration Based on the result from the effect of enzyme concentration, the best time was used to study the effect on enzyme concentration. All of the samples were incubated for 6 hours, in an oven at 40 °C by using a various concentration of enzyme in a range of 0.2 – 2.5 g/mL. The effects of enzyme concentration on the concentration of glucose are shown in Figure 1.9. Concentration glucose (g/L) 1.06 1.04 1.02 1 0.98 0.96 0.94 0.92 0.9 0.88 0.86 0 0.5 1 1.5 2 2.5 3 Concentration enzyme (g/mL) Figure 1.9: Effect of enzyme concentration Based on the result in Figure 1.9, initially the concentration of glucose produced increased exponentially at the concentration of 0.5 – 1.5 g/mL. However, at the concentration of 2.0 – 2.5 g/mL the concentration of glucose started to decreased. When there were higher concentration of enzyme, the more the interaction between enzymes and substrates so, the concentration of glucose increased initially. Based on report by Rajesh et al., (2009), higher enzyme loading rate decreased the 24 migration time of cellulases on the cellulose surface and increased the liberation of reducing sugars till the complete surface coverage of the substrate. Moreover, Sarkar et al., (1998) reported that increase in enzyme concentration saturated the active sites of the enzyme with substrate leading to lower activity. Nevertheless, when there are excessive of enzymes, there are higher probabilities of inhibitors to inhibit these enzymes that caused by proteins interaction. This may deduce the results that less glucose concentration as it is been proved by the above Figure 1.9 at the concentration of 2.0 - 2.5 g/mL of enzyme. Based on a report by Nathalie et al., (2006), the understanding of proteins interactions is important for plant protection. The protections could be required to enhance plant resistance. The role of plant cell wall polysaccharides in disease resistance has been reviewed recently. To penetrate and use plant cell walls nutritionally, pathogens secrete a remarkable array of polysaccharides degrading enzymes including exopolygalacturonases, endopolygalacturonases, pectin methylesterases, pectin lyases and pectate iyases, acetyl esterases xylanases and a variety of endogluconases that cleave cellulose, plants resists hydrolytic attack by deploying inhibitor proteins of Cell Wall Degrading Enzymes (CWDE). As a result, the best enzyme concentration was at the 1.5 g/mL. Clearly, these two parameters; incubation time and enzyme concentration are very important in concentration of glucose. Thus, these factors are used for further study in the optimization to obtain higher yield of glucose concentration. 25 4.3 Determination of the Optimum of Parameters Sugar Production Using Response Surface Methodology (RSM) Optimization on the parameters in glucose productions are performed using response surface methodology (RSM). The parameters involved are incubation time and enzyme concentration. The low level and high level of the parameters are determined from the previous result. Table 2.2 shows the low level and high level of each parameter. Table 2.2: Low level and high level of parameters Parameters Incubation Time (hr) Enzyme Concentration (g/mL) Low Level High Level 4 8 1.0 2.0 By using central composite design (CCD), the experiments with different combination of enzyme concentration and reaction time were performed. Experiments arranged by Design Expert Software and the producing of concentration of glucose are listed Table 2.3 Run 4 gave the highest concentration of glucose which produced 1.063 g/L of concentration. The parameters of Run 4 are: 1.50 g/mL of enzyme concentration and 6 hours of incubation time. Conversely, Run 3 gave the lowest concentration of glucose which produced only 0.8122 g/L of concentration. The parameters of Run 3 are: 1.00 g/mL of enzyme concentration and 8 hours of incubation time. This is because, according to Marimuthu et al., (2005), less prolonged reaction time, the better sugar yields. Moreover, Sun and Cheng, (2002) reported that a increasing the dosage of cellulases in the process, to a certain extent, can enhance hydrolysis yields. 26 Table 2.3: Experiments designed by design expert software Run Factor 1 A: Time (hr) Factor 2 A: Enzyme Concentration (g/mL) 1 2 3 4 5 6 7 8 9 10 11 3.17 6.00 8.00 6.00 6.00 4.00 8.00 8.83 4.00 6.00 6.00 1.50 0.79 1.00 1.50 1.50 2.00 2.00 1.50 1.00 2.21 1.00 Response: Reducing Sugar (g/L) 1 0.9898 0.8122 1.063 1.022 1.04 0.8832 0.7921 1.053 0.9932 1.042 Table 2.4 shows the ANOVA and regression analysis for the concentration of glucose. The precision of a model can be checked by determination coefficient (R2) and correlation confession (R). As a rule, a regression model having an R2 value higher than 0.9 is considered to have a very high correlation (Haaland, 1989). The value of R indicates better correlation between the experimental and predicted values. In Table 2.4, the P-value obtained for regression model 0.0006 compared to a desired significant level of 0.05. This signified that the regression model is precise in predicting the pattern of significance to the concentration of glucose. 27 Table 2.4: ANOVA for response surface quadratic model for the concentration of glucose. Sources Sum of Square 0.092 Model Degree of Freedom 5 Mean Square FValue P-Value R2 (Prob>F) 35.83 0.0006 116.89 0.0001 0.96 0.3713 57.72 0.0006 6.67 0.0492 1.36 0.4500 0.9728 Significant 0.018 A-Enzyme concentration B-Incubation Time 1 0.060 0.060 1 4.931E004 4.931E004 1 A2 0.030 0.030 1 B2 3.413E003 3.413E003 5 Residual 2.558E003 5.115E004 3 Lack of Fit 1.717E003 5.723E004 2 Pure Error 8.407E004 Correlation Total Not Significant 4.203E004 10 0.094 To investigate the effects of the two parameter on the concentration of glucose, the response surface methodology was used and the three-dimensional plot was drawn. Figure 1.10 shows the response surface plot for the parameters studied; incubation time and enzyme concentration. Incubation time and enzyme concentration gave the significant effect to the concentration of glucose (Figure 1.10). Higher enzyme concentration and shorter incubation time increase the concentration of glucose, whereas lower enzyme concentration and longer incubation time decrease the concentration of glucose. The maximal concentration of 1.063 g/L glucose was obtained when using 1.5 g/mL of enzyme concentration and 6 hours of incubation time. 28 Based on report by Marimuthu et al., (2005), less prolonged reaction time, the better sugar yields. Moreover, Sun and Cheng, (2002) reported that a increasing the dosage of cellulases in the process, to a certain extent, can enhance hydrolysis yields. The production of total and individual soluble glucose reached the maximal level after five hours of reaction. Extending the reaction beyond five hours enhanced the yields of glucose, but did not result significant increase in the concentration of total soluble glucose from cassava residue. Figure 1.10: Response surface plot of glucose concentration: Incubation time vs. enzyme concentration. 29 4.4 Optimization of Sugar Production Using Response Surface Methodology (RSM) Based on the Table 2.5, the concentration of glucose was successfully optimized after the optimization process was carried out. The Incubation time and enzyme concentration used was reduced after optimization. Table 2.5 shows summary of the optimized parameters for concentration of glucose. Table 2.5: Summary of the optimized parameters for sugar production Parameters Before Optimization Value Concentration After Optimization Value Concentration Glucose (g/L) Glucose (g/L) Incubation Time (hr) 8.83 Enzyme concentration (g/mL) Experimental 1.066 1.059 4.47 0.7921 1.50 Predict 1.32 30 CHAPTER 5 CONCLUSION AND RECOMMENDATIONS 5.1 Conclusion The concentration of glucose was successfully obtained by hydrolyzing the cassava residue by using hydrolyses enzymes. Three types of enzymes which are cellulase, glucoamylase and α-amylase have been employed to hydrolyze the substrate; cassava residue to produce glucose. The best enzyme that yields the most glucose is cellulose, followed by α-amylase and glucoamylase. Therefore, cellulose is used for further parameters studied by (i) incubation time at 4 – 8 hours and (ii) enzyme concentration in the range of 0.5 – 2.5 g/mL. Based on the result before optimization, the response surface methodology shows that the conditions in concentration of glucose by using 1.50 g/mL of enzyme concentration at 8.83 of incubation time producing only 0.7921 g/L of reducing glucose. However after optimization occurred, the concentration of glucose was successfully increased until 1.059 g/L using the optimum condition of 1.32 of enzyme concentration at 4.47 of incubation time. This research demonstrated that this agricultural waste of cassava residue which had no economical value could be converted by enzymatic hydrolysis to a more valuable product. As a result, with optimum use of cassava residue, it will not only solve the environmental pollution problems but also will give back a high economic value product to the cassava starch plant industry above all. 31 5.2 Recommendations In order to improve this research method and results to a better concentration of glucose, it can be carried out in various modifications on these parameters. The concentration of glucose using the method of enzymatic hydrolysis can also be done using the method of acid hydrolysis which is cheaper in terms of the cost of raw material. Besides using only single enzyme, the concentration of glucose can be increased by mixing the three commercialized enzymes (cellulose, glucoamylase and α-amylase). There are also differences when using immobilize enzyme and free enzyme in concentration of glucose which can be studied to compare the concentration between the two types of enzymes. The concentration of glucose was analyzing using DNS reagent. But for future studies, analyzing the samples using High Performance Liquid Chromatography (HPLC) can gives more accurate concentration of glucose. In this study, the substrate used is cassava residue. In future, to study the concentration of substrate will give the significant in concentration of glucose. Moreover, there are more substrate other than cassava residue that are also capable of producing sugar such as Cotton Stalk, Corn Stover, Wheat Straw, Tobacco Stalk and Palm Oil Empty Fruit Bunch. This research can also be done by varying the agitation rate and the reaction temperature while incubating. The pH of the buffer may give effect on the productions. Therefore, this can also be study by varying the pH of buffer. In addition, other kind of buffer can also be used such as Potassium Phosphate and Ampso. 32 REFERENCES Adinarayana, K. and Suren, S. (2005). Response Surface Optimization of Enzymatic Hydrolysis of Maize Starch for Higher Glucose Production. Biochemical Engineering. 27: 179-190 Ammbati, P. and Ayyanna, C. (2001). Optimization of Medium Constituents and Fermentation Condition for Citric Acid Production from Palmyra Jaggery using Response Surface Methodology. World Journal of Microbiology and Biotechnology. 17: 331-335 Badal, C. S. (2004). Production, purification and properties of endoglucanase from a newly isolated strain of Mucor circinelloides. Process Biochemistry. 39: 871-1876 Cecilia, L. Joao, O. T. Karen, F. O. Crisla, S. S. and Meline, R. M. (2009). Optimization of temperature, sugar concentration, and inoculum size to maximize ethanol production without significant decrease in yeast cell viability. Biotechnological Products and Process Engineering. 83: 627-637 Chauhan, B. and Gupta, R. (2004). Application of Statistical Experimental Design for Optimization of Alkaline Protease Production from Bacillus sp. RGR-14. Biochemistry Process. 39: 2115-2122 Gaur, R. and Gupta, A. (2008). Lipase from Solvent Tolerant Pseudomonas aeruginosa strain: Production Optimization by Response Surface Methodology and Application. Bioresource Technology. 99: 4796-4802 Gunda, K.P.B. and Walteir, L. (1970). Enzymatic Degradation of Cellulose, Cellulose Derivatives and Hemicelluloses In Relation to the Fungal Decay of Wood 1. Wood Science and Technology. 4: 273-283 Hao, F. Chen, Z. and Xiang, Y.S. (2010). Optimization of enzymatic hydrolysis of steam-exploded corn stover by two approaches: Response surface methodology or using cellulase from mixed cultures of Trichoderma reesei RUT-C30 and Aspergillus niger NL02. Biosource Technology. 101: 4111-4119 Sowbhagya, H.B. Srinivas, P. and Krishnamurthy, P. (2010). Effect of enzymes on extraction of volatiles from celery seeds. Food Chemistry. 120: 230-234 33 Herrera, S. J. Tellez, L. Ramirez, J. A and Vazquez, M. (2003). Production of Xylose from Sorghum Straw using Hydrochloric Acid. Cereal Science. 37: 267-274 Houjg, J.Y. Chen, K. C. and Hsu, W.H. (1989). Optimization of Cultivation Medium Composition for Isoamylase Production. Journal of Applied Microbiology and Biotechnology. 39: 61-64 Howard, R.L.A. Jansen, E.V.R. and Howard, S. (2003). Lignnocellulose Biotechnology: Issues of Bioconversion and Enzyme Production. African Biotechnology. 2: 602-619 Inci, C. (2005). Effects of cellulase and pectinase concentrations on the colour yield of enzyme extracted plant carotenoids. Process Biochemistry. 40: 945-949 Jian, X. and Shijie, L. (2009). Optimization of Ethanol Production from Hot-water Extracts of Sugar Maple Chips. Renewable Energy. 34: 2353-2356 Jin, Z. Yong, H.W. Ju, C. Ling Z. L. Ying, P. Z. and Si, L. Z. (2010. Optimization of cellulase mixture for efficient hydrolysis of steam-exploded corn stover by statistically designed experiments. Biosource Technology. 101: 4111-4110 Kristensen, J.H (1972). Carbohydrases of Some Marine Invertebrates With Notes on Their Food and on the Natural Occurrence of the Carbohydrates Studied. Biotechnology.14: 130–142. Kyung, H.C, Hee, S.J, Na, K.L. Se, H.P, Na, W.L. and Hyun, D.P. (2009). Optimization of the Enzymatic Production of 20 (S)-Ginsenoside Rg3 from White Ginseng Extract using Response Surface Methodology. New Biotechnology. 26: 3-4 Li, L. Liu, X. Guo, Y and Ma, E (2005). Activity of the enzymes of the antioxidative system in cadmium-treated Oxya chinensis (Orthoptera Acridoidae). Environmental Toxicology and Pharmacology. 20: 412-416 Mark, R. W. Wilbur, W.W. Karel, G. and Randall G.C. (2007). Hydrolysis of grapefruit peel waste with cellulase and pectinase enzymes. Bioresource Technology. 98: 1596–1601 Cazetta, M.L. Celligoi, M.A.P.C. Buzato, J.B. Scarmino, I.S. and Silva, R.S.F. (2005). Optimization Study for Sorbitol Production by Zymomonas Mobilis in Sugar Cane Molasses. Process Biochemistry. 40: 747-751 34 Marimuthu, J. Ye, W.Z. In, W.K and Jung, K. L. (2009). Enhanced Saccharification of Alkali-Treated Rice Straw by Cellulase from Trametes Hirsuta and Statistical Optimization of Hydrolysis Conditions by RSM. Bioresource Technology.100: 5155-516 Mutanda, T. Wilhelmia, B. S. and Whiteley, C. G. (2008). Response Surface Methodology: Synthesis of Inulooligosaccharides with an Endoinulinase from Aspergillus Niger. Enzyme and Microbial Technology. 43: 362-368. Nathalie, J. (2006). Plant Protein Inhibitors of Cell Wall Degrading Enzymes. Trends In Plant Science. 23: 359-367 Rajesh, S. Rajender, K, Kiran, B and Narsi, R.B. (2009). Optimization of Synergistic Parameters for Thermostable Cellulase Activity of Aspergillus Heteromorphus using Response Surface Methodology. Biochemical Engineering. 48: 28-35 Richard F. T. John, K. and Xi, Q. (2004). Starch-Composition, Fine Structure and Architecture. Journal of Cereal Science. 39: 151-165 Rahman, S.H.A. Choudhury, J.P. Ahmad, A.L. and Kamaruddin, A.H. (2007) Optimization Studies on Acid Hydrolysis of Oil Palm Empty Fruit Bunch Fiber for Production of Xylose. Bioresource Technology. 98: 554-559 Sun, Y. and Cheng, J. (2002). Hydrolysis of Lignocellulosic Materials for Ethanol Production: A review. Bioresoure Technolology. 83: 1–11 Steve, J. (2004). Improving starch for food and industrial applications. Current Opinion in Plant Biology. 7: 210-218 Suthkamol. S. Ancharida, B. F. and Teerapatr, S. (2006). Conversion of Cassava Waste into Sugar Using Aspergillus Niger and Trichoderma reesei for Ethanol Production. Biotechnology. 54: 234-240 Teerapatr. S, Cholada, S. Bangatrat, P. Wichien, K. and Sirintip, C. (2004). Utilization of Waste from Cassava Starch Plant for Ethanol Production. Sustainable Energy and Environment (SEE). December 1-3. Hua Hin, Thailand, 360 – 365 Teerapatr, S. Lerdluk, K and La, S. (2006). Approach of Cassava Waste Pretreatments for Fuel Ethanol Production in Thailand. Biotechnology. 31: 241-246 Xiao, M.X. Alys, J.A. Neil, A.R. Alex, J.A. Gang, P.X. and Peter, B.M. (1999). Charac terisation of Cellulase Activity in the Digestive System of the Redclaw Crayfish (Cherax quadricarinatus). Aquaculture. 180: 373-386 35 APPENDIX A MATERIAL AND METHODS Appendix A1 Preparation mixture of Sodium Hydroxide (NaOH), (2000 mL) and Citric Acid (C6H8O7), (1000 mL) as Buffer i) Preparation of Sodium Hydroxide (NaOH), (2000 mL) Molecular weight of Sodium Hydroxide, NaOH = 40 g/mol Prepare volume of 10.8 mL from 0.1 M Sodium Hydroxide (NaOH) solution Then, 10.8 mL Sodium Hydroxide ( NaOH) was diluted with 1000 mL distilled ii) water in volumetric flask. Preparation of Citric Acid (C6H8O7) , (1000 mL) Molecular weight of Sodium Hydroxide, NaOH = 192.14 g/mol Prepare mass of 19.214 g from 0.1 M on Citric Acid (C6H8O7) Therefore, 19.2 g of Citric acid (C6H8O7) was mixed into 1000 mL distilled water. iii) Preparation of buffer Then, add some drop of Sodium Hydroxide, (NaOH) and Citric Acid (C6H8O7) into the mixture to achieve the value of pH needed. 36 Appendix A2 Preparation of DNS Reagent (1 L) Table A – 1: Ingredients of DNS Reagents No. Chemical g/L 1. DNS Acid 10 2. Phenol Crystal 2 3. Sodium Sulfite 0.5 4. Sodium Hydroxide 10 5. Potassium – Sodium Tartarate 182 37 Appendix A3 1. Preparation of 1 mg/mL of Glucose Standard Solution (10 mL) 1 mg/mL = 1 mg of glucose in 1 mL buffer 1 mL = 1 mg 10 mL = 10 mg Hence, 10 mg of glucose is added into 10 mL of buffer (Mixture of 0.1 M Sodium Hydroxide, NaOH with 0.1 M Citric Acid) 2. Standard Curve of Glucose Concentration Glucose (g/L) OD (λ = 540 nm) 0.2 0.424 0.4 1.158 0.6 1.834 0.8 2.276 1.0 2.482 Standard Curve of Glucose 3 2.5 y = 2.617x + 0.0646 R² = 0.9572 A 540 2 1.5 1 0.5 0 0 0.2 0.4 0.6 0.8 Concentration glucose (g/L) Figure A – 1: Standard Curve of Glucose 1 1.2 38 Appendix A 4 Enzyme Dilution (W enzyme / V buffer) % = g/mL Thus, W enzyme = 0.5 g, 1.0 g, 1.5 g, 2.0 g, 2.5 g V buffer = 100 mL Therefore, add each weight of enzyme into 100 mL of buffer buffer (Mixture of 0.1 M Sodium Hydroxide, NaOH with 0.1 M Citric Acid). 39 APPENDIX B OPTIMIZATION PROCESS Appendix B1 ANNOVA Results for Optimization of Cultural Conditions Figure B – 1: Graph of the normal plot of residual of sugar production 40 Figure B-2: Residual versus predicted values of sugar production Figure B-3: Residual values of sugar production for each run experiment 41 Figure B-4: Residuals versus time values of sugar production Figure B-5: Graph of the Outlier T of sugar production 42 Figure B-6: Graph o the Cook’s distance of sugar production Figure B-7: Leverage versus run values of sugar production 43 Figure B-8: Graph of predicted versus actual values of sugar production Figure B-9: Plot of the Box-Cox for power transforms