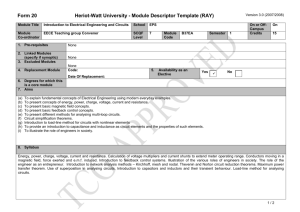

Unit content

advertisement